Step changing method for stator segment winding of medium speed magnetic suspension train long stator linear synchronous motor

A magnetic levitation train and linear synchronization technology, applied in the direction of AC motor control, electrical components, control systems, etc., can solve the problems of train loss of traction, complicated wiring, speed loss, etc., to reduce traction loss, high equipment utilization, and equipment cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

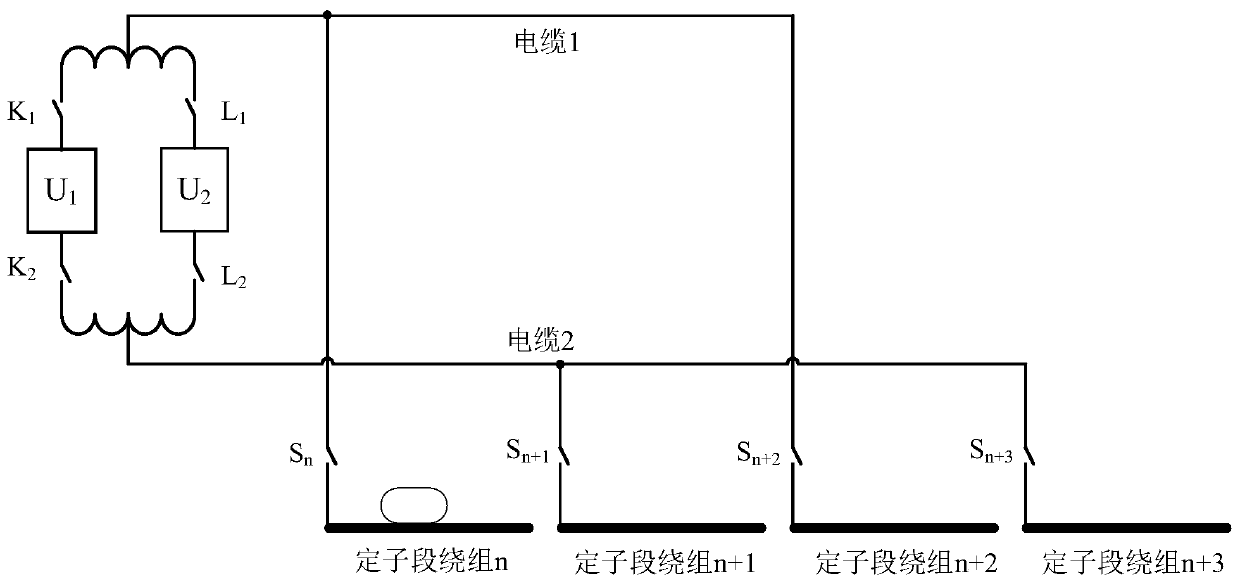

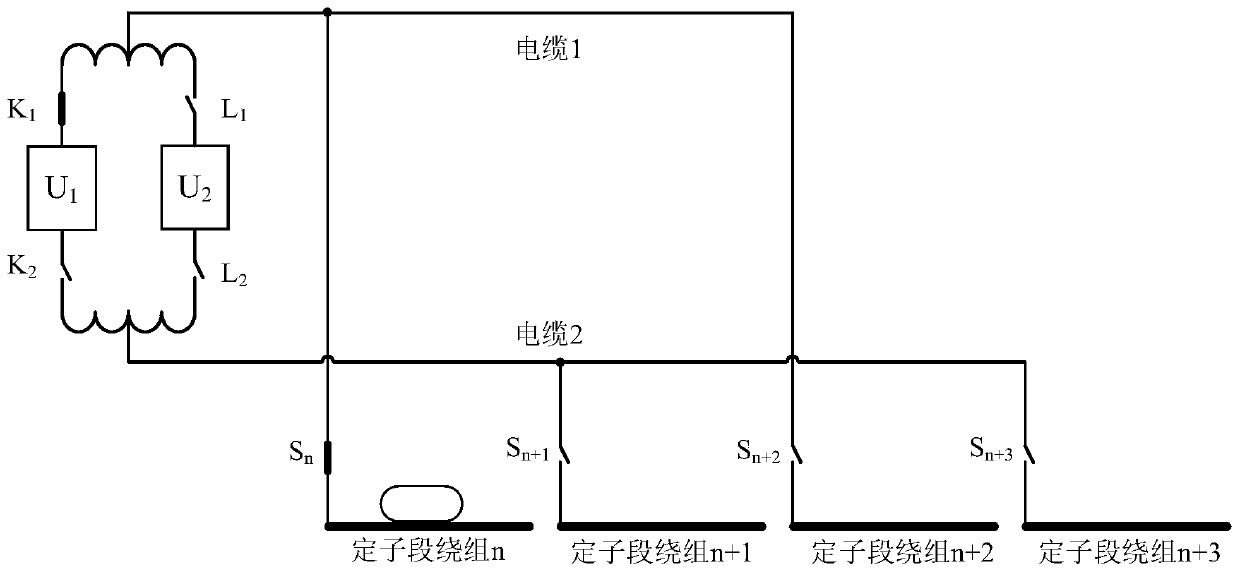

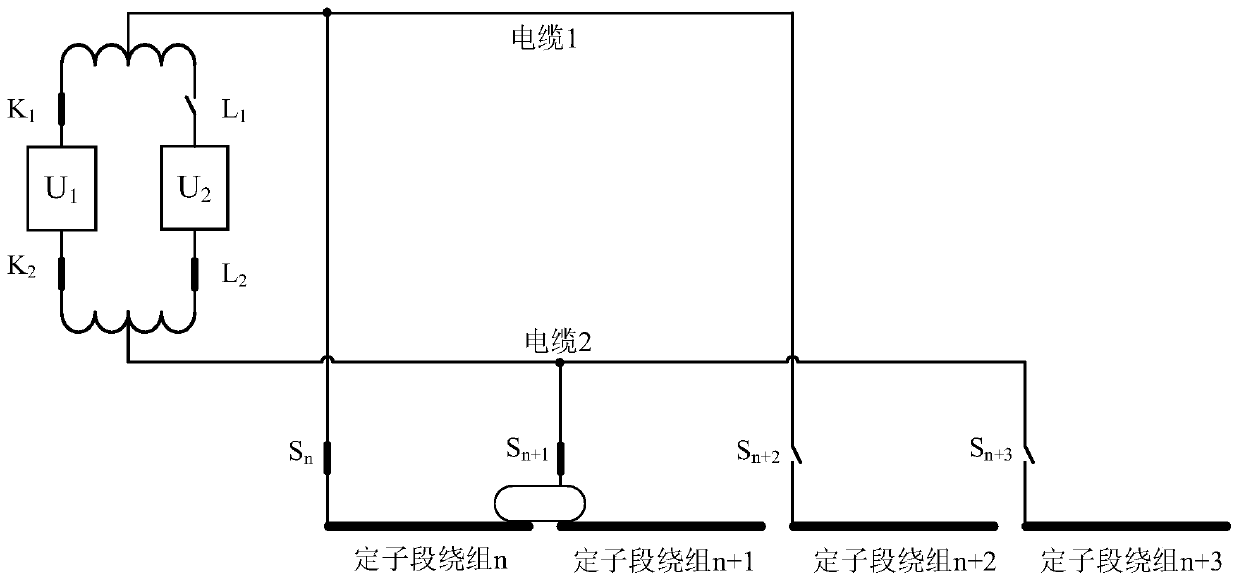

[0021] figure 1 Shown is the connection relationship between the winding of the stator section of the long stator linear synchronous motor of the medium-speed maglev train applying the method of the present invention, the converter unit and the switch. Such as figure 1 As shown, the main converter unit U 1 It is a large-capacity converter that meets the power output requirements under traction acceleration and other states. Auxiliary converter unit U 2 The capacity is smaller than the main converter unit U 1 The converter is used for the current regulation of the next stator winding during the step change process. Main converter unit U 1 with auxiliary converter unit U 2 Each has two outputs. Main converter switch K 1 One end is connected to the main converter unit U 1 One of the output terminals of the auxiliary converter switch L 1 One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com