Automatic bypass cable conveying system

A bypass cable and automatic conveying technology, applied in the direction of overhead lines/cable equipment, cable suspension devices, etc., can solve the problems of high operation difficulty, high cost, and complicated laying methods, and achieve simple structural design, low cost, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

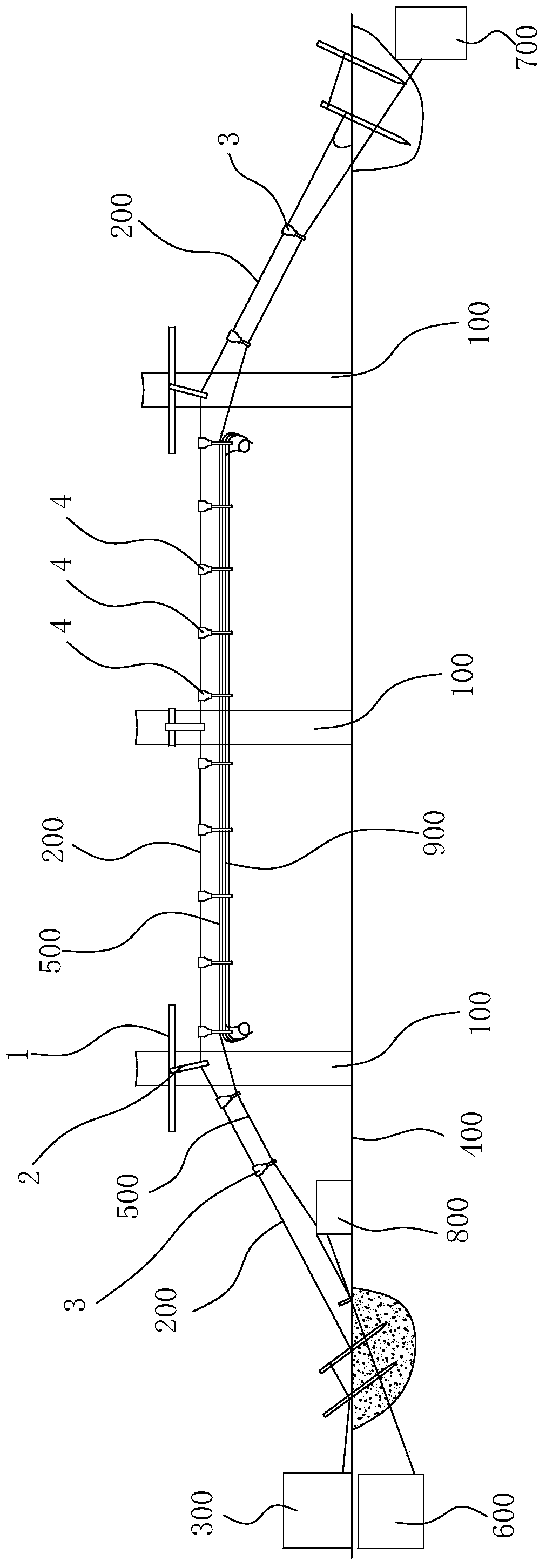

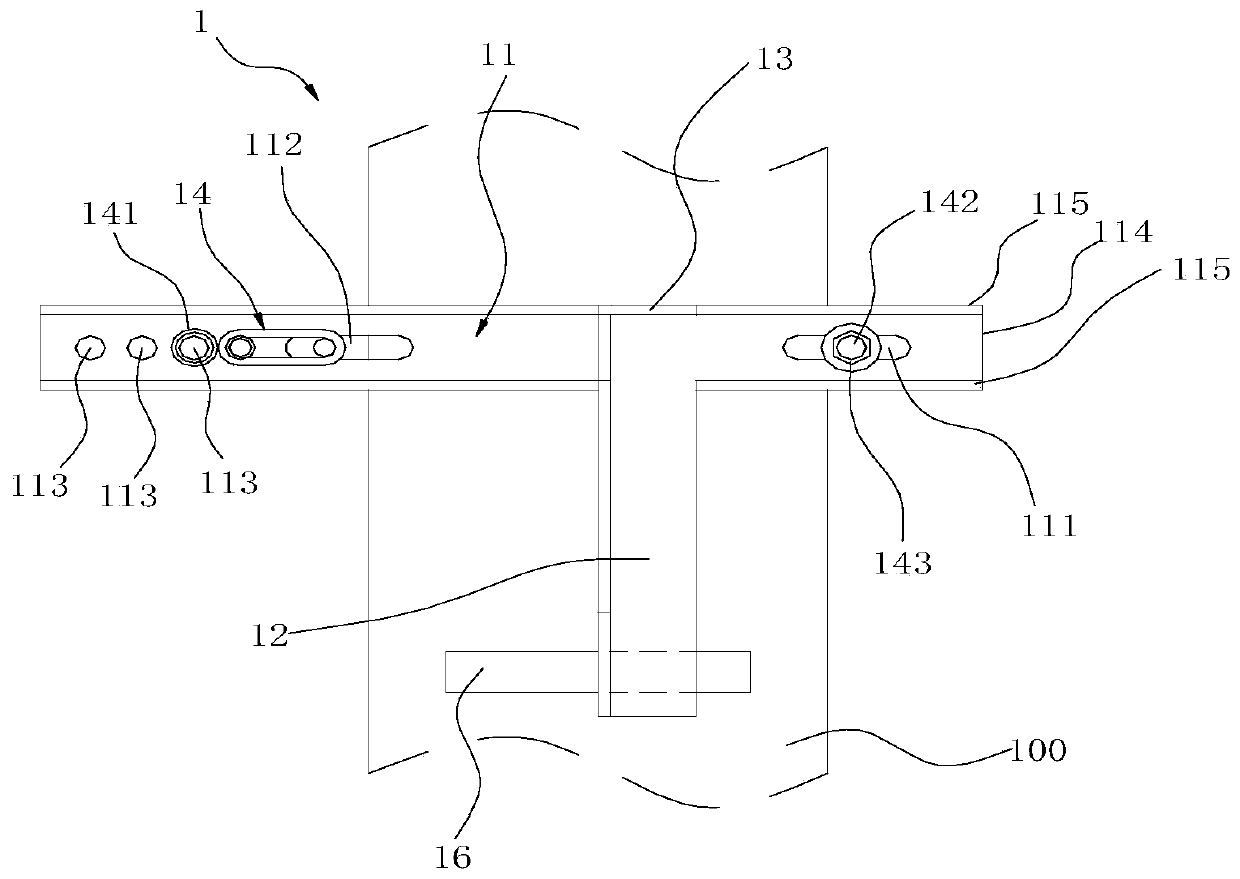

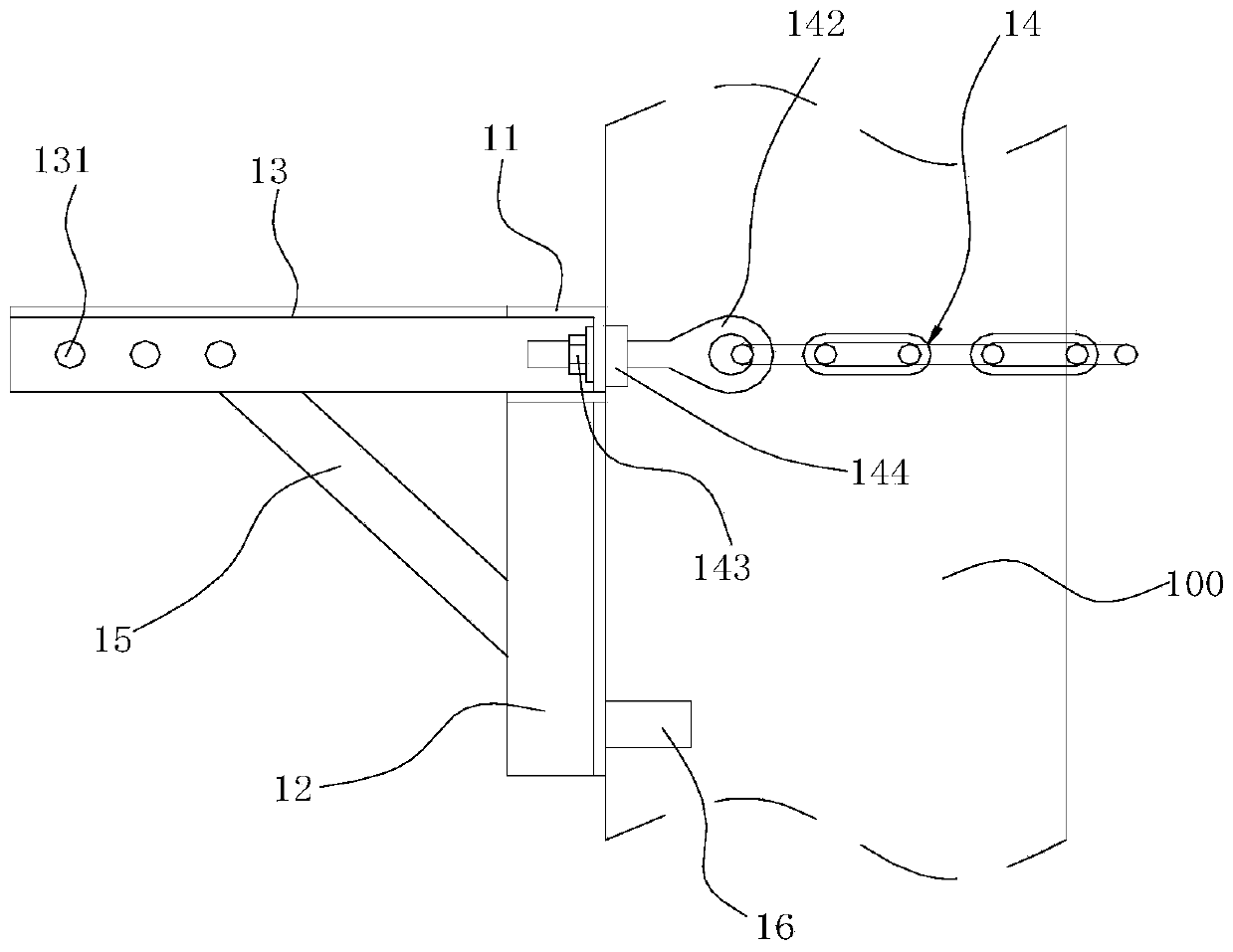

[0040] like figure 1 As shown, the bypass cable automatic conveying system of the embodiment of the present invention includes a pole 100, a track 200, a traction assembly 3 and a cable assembly 4, wherein the pole 100 is an existing pole 100 in the current grid system environment, The pole 100 is provided with a support assembly 1, the support assembly 1 is connected with a suspension assembly 2, the track 200 is arranged as a rope structure, and one end of the track 200 is wound on the first pay-off frame 300, The other end passes through the suspension assembly 2 in turn and is fixed on the ground 400, the track 200 is in a tight state; there are multiple traction assemblies 3, and multiple traction assemblies 3 are slidably arranged on the track 200 Above, all the traction components 3 are connected by a traction rope 500, one end of the traction rope 500 is wound on the second pay-off frame 600, and the other end passes through all the traction components 3 and is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com