Pulp box and paper-form wet base forming equipment

A technology of sizing and feeding, which is applied in the direction of textiles and papermaking, can solve the problems of difficulty in accurately controlling the concentration of sizing, low pass rate of pulp molded products, and affecting the quality of wet paper molds, so as to improve market competitiveness and increase the concentration of sizing Uniform and consistent, solve the effect of unstable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

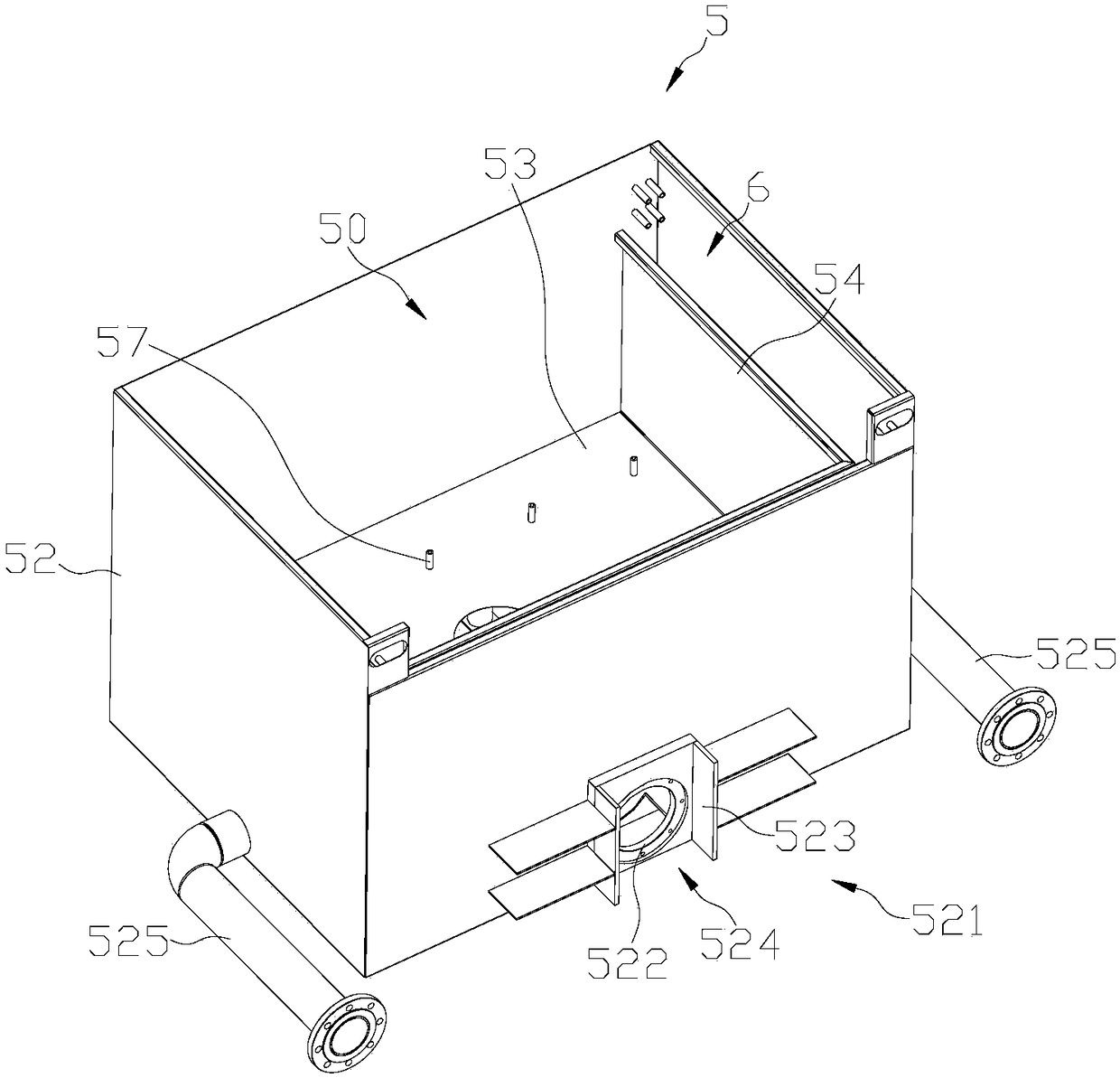

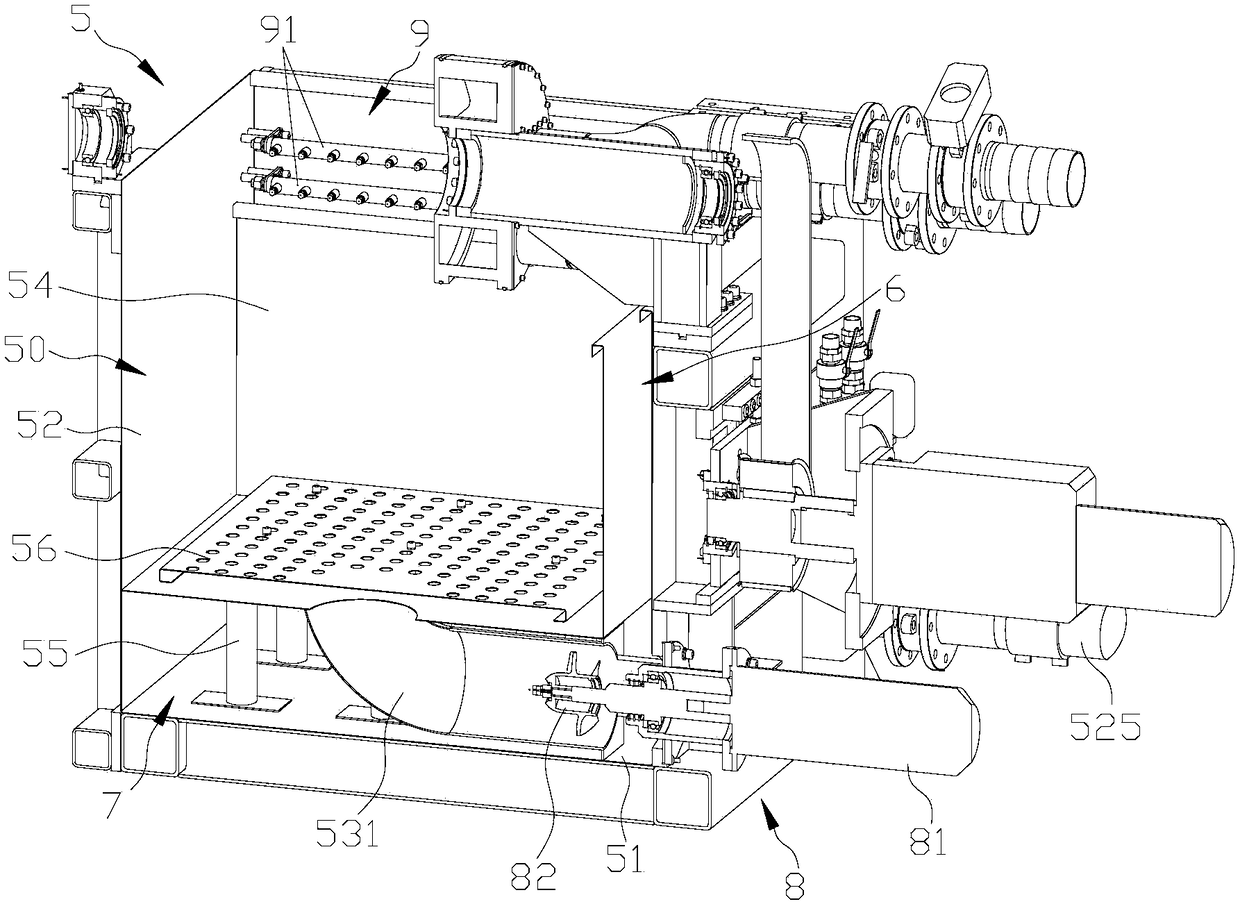

[0027] see Figure 1 to Figure 2 , the slurry tank 2 of the present embodiment includes a box body 5, a first slurry feeding device and a second slurry feeding device; the box body 5 includes a bottom wall 51 and a side wall 52 extending upward from the bottom wall 51 around; the The upper side of the bottom wall 51 is provided with a bottom plate 53, the bottom plate 53 divides the inner cavity of the box body 5 into an upper cavity 50 and a lower cavity 7, the bottom plate 53 is rectangular, and three sides of the bottom plate 53 extend upwards A vertical wall 54 is formed, and the remaining edge of the bottom plate 53 is connected to the corresponding side wall 52; an overflow groove 6 is formed between the vertical wall 54 and the side wall 52, and the overflow groove 6 communicates with the upper cavity 50 and the lower cavity 7; the first slurry feeding device is in the lower cavity 7, and communicates the lower cavity 7 with the upper cavity 50; the second slurry feedin...

Embodiment 2

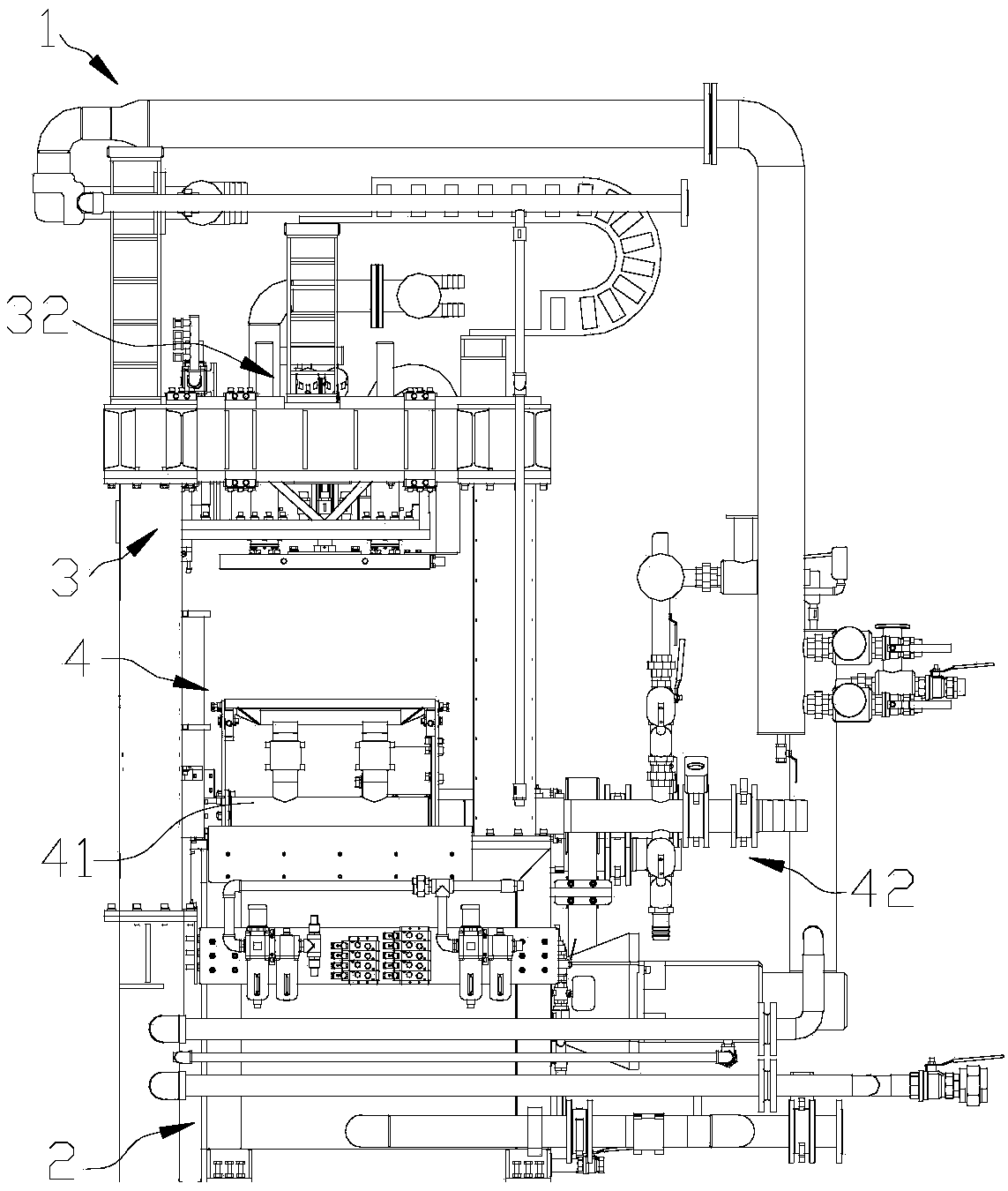

[0054] see image 3 Another object of the present invention is to provide a paper mold wet blank forming equipment using the above-mentioned slurry box 2, which includes a frame 1, a slurry box 2, an upper mold mechanism 3 and a lower mold mechanism 4, and the slurry box 2 is set At the bottom of the frame 1, the lower mold mechanism 4 is arranged above the slurry tank 2, and the upper mold mechanism 3 is arranged on the top of the frame 1 corresponding to the lower mold mechanism 4; the upper mold mechanism 3 includes an upper mold (not shown in the figure) and a lifting device 32, the upper mold is arranged at the lower part of the lifting device 32, and the lifting device 32 can drive the upper mold to close the mold with the lower mold mechanism 4 or Die-parting; the lower mold mechanism 4 includes a rotating shaft 41, a pneumatic control structure 42 and a lower mold (not shown in the figure), the lower mold is fixedly connected with the rotating shaft 41, and the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com