Lifting device for circulating grain dryer

A grain dryer, circulating technology, applied in grain drying, drying solid materials, dry cargo handling, etc., can solve the problems of inability to transport grains, dead ends of elevator storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

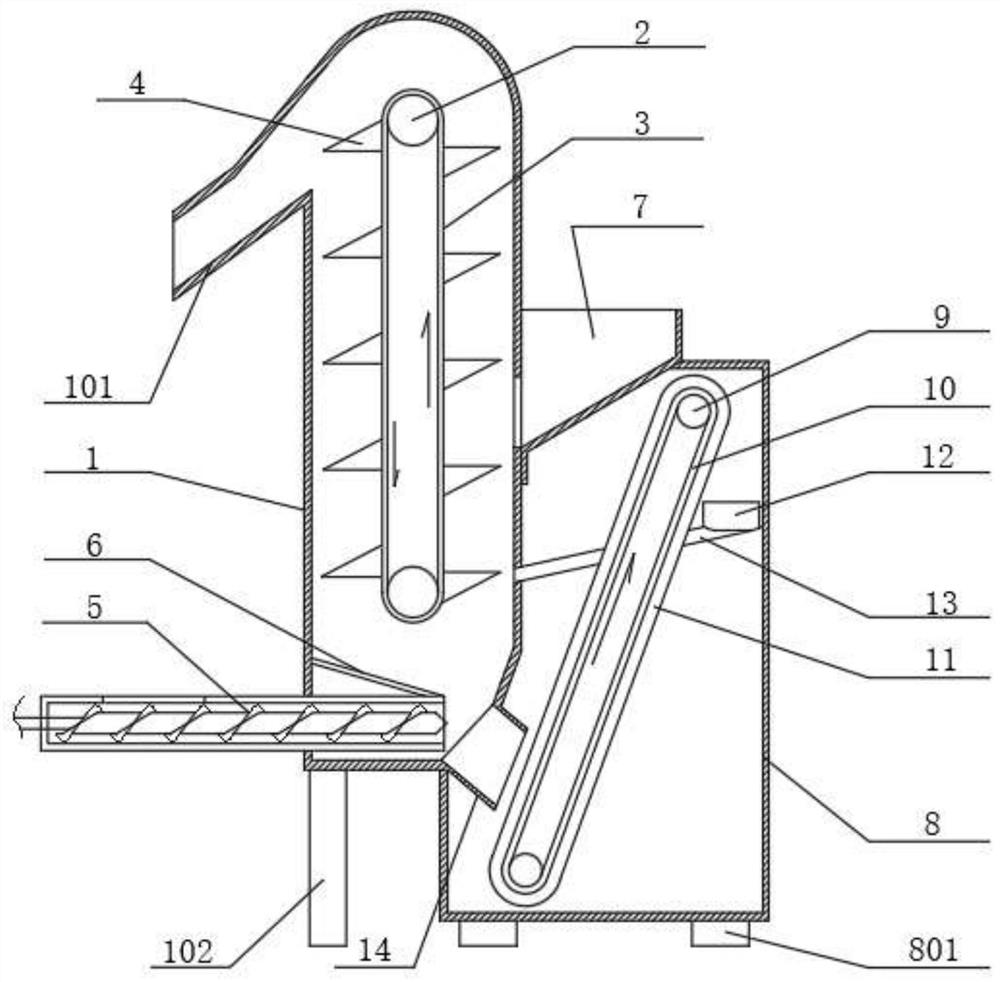

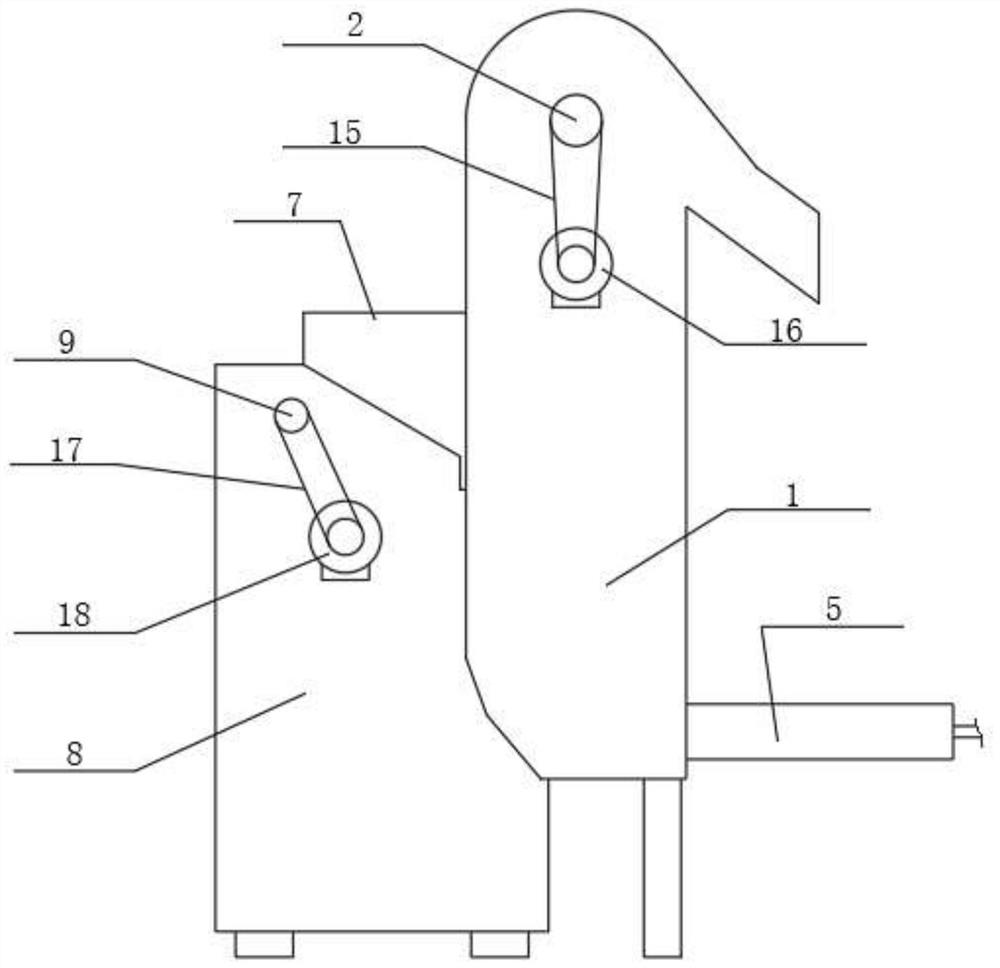

[0026] Such as Figure 1-4 As shown, a lifting device for a circulating grain dryer includes a body shell 1 and a lower auger structure 5, the lower auger structure 5 is embedded in the side wall of the body shell 1, and the lower end of the body shell 1 is connected to There are support legs 102, the feed opening opened on the body shell 1 is connected with the feed hopper 7, the upper end of the body shell 1 is provided with an extension pipe 101, and the inner wall of the body shell 1 is rotatably connected with two first rollers 2 , the two first rollers 2 are located on the same vertical line, the two first rollers 2 are connected by the first transmission belt 3, and the outer ring of the first transmission belt 3 is connected with a bucket 4,

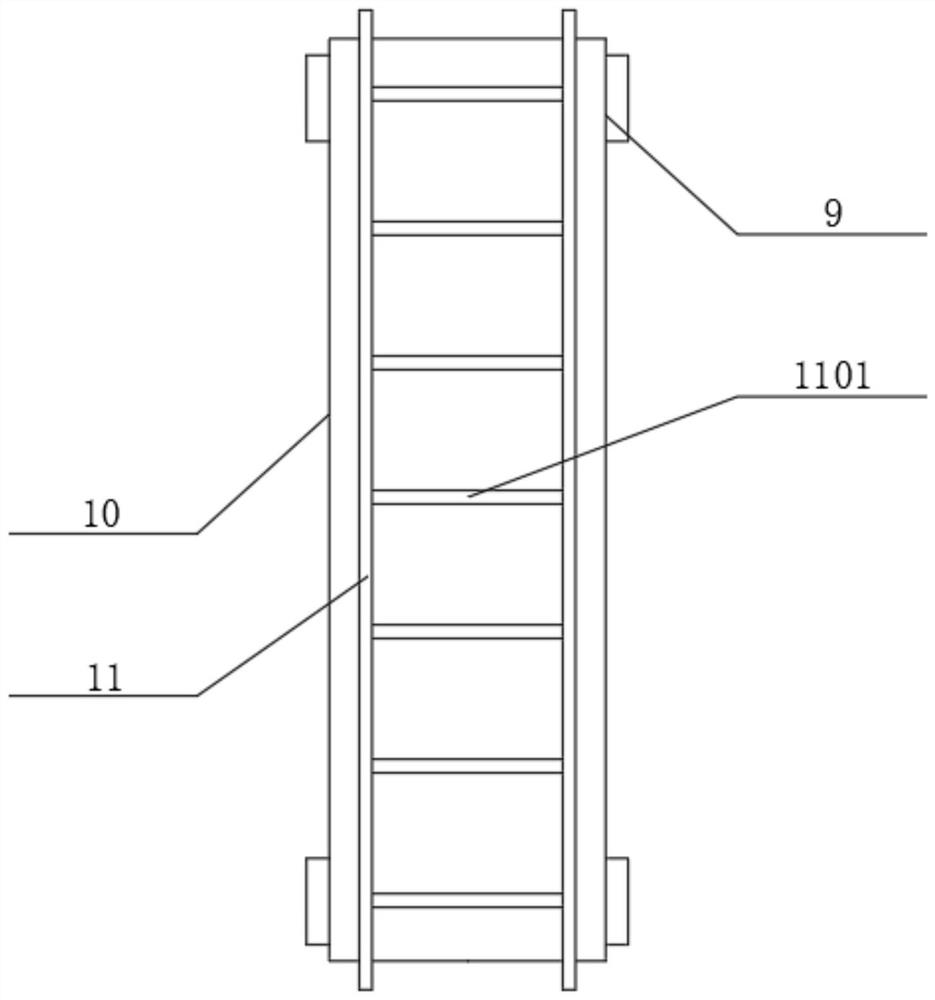

[0027] The main body shell 1 is connected with a protective shell 8, the lower end of the protective shell 8 is connected with a support block 801, the protective shell 8 is connected with the main body shell 1 through the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com