Motor assembly for intelligent electronic door lock

A technology of smart door locks and motor components, applied in the mechanical field, can solve problems such as motor jamming and burnout, large spring wire contact area, electronic smart door locks cannot be used, etc., and achieve the effect of reducing the risk of stopping work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

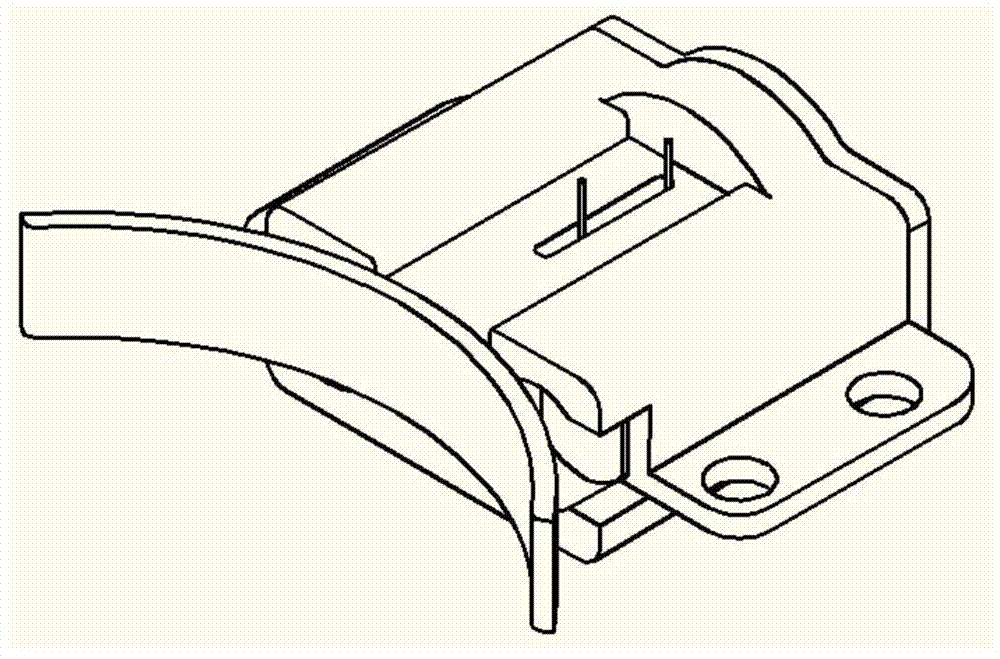

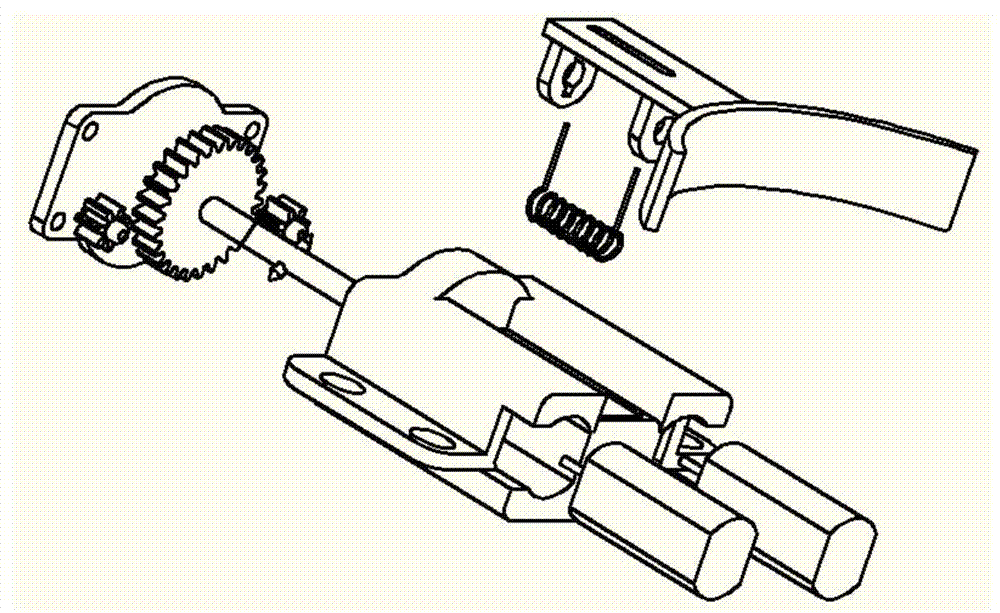

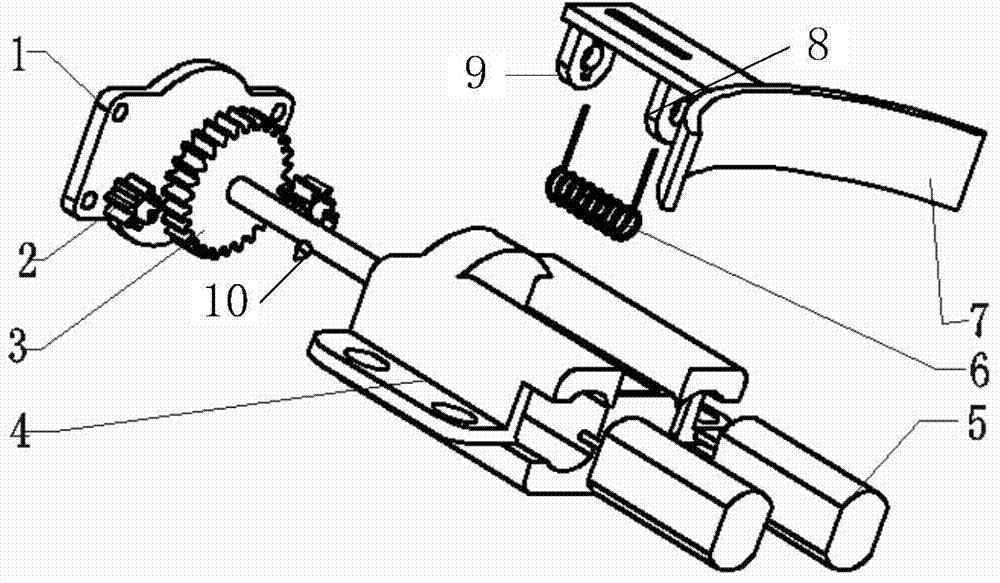

[0024] Such as Figure 1 to Figure 3 Shown, the motor assembly for electronic smart door lock of the present invention, it comprises:

[0025] Cover plate 1, two pinions 2, gear shaft 3, motor housing 4, two identical motors 5, torsion spring 6, arc push plate 7, front push plate 8, rear push plate 9 and cross bar 10 ;

[0026] The gear shaft 3 includes a bull gear and a journal, and the bull gear and the journal are integrally designed;

[0027] Such as Figure 6A and Figure 6B As shown, one end of the motor housing 4 is provided with two motor mounting holes 15 having the same shape as the motor 5 and a second gear shaft hole 14 matched with the gear shaft journal, and the second gear shaft hole 14 is located at Between the two motor mounting holes 15, the other end is provided with two motor shaft holes 12 matched with the motor shaft of the motor 5, the first gear shaft hole 11 matched with the top of the gear shaft journal and a plurality of covers Plate mounting ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com