An integrated water jet propulsion system

A water-jet propulsion and integrated technology, which is applied in the field of thrusters and integrated water-jet propulsion systems, can solve the problems of lack of sensitive steering system, complex mechanical transmission mechanism, and large volume, so as to avoid emission pollution and reduce stoppage The risk of work, the effect of increasing the promotion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

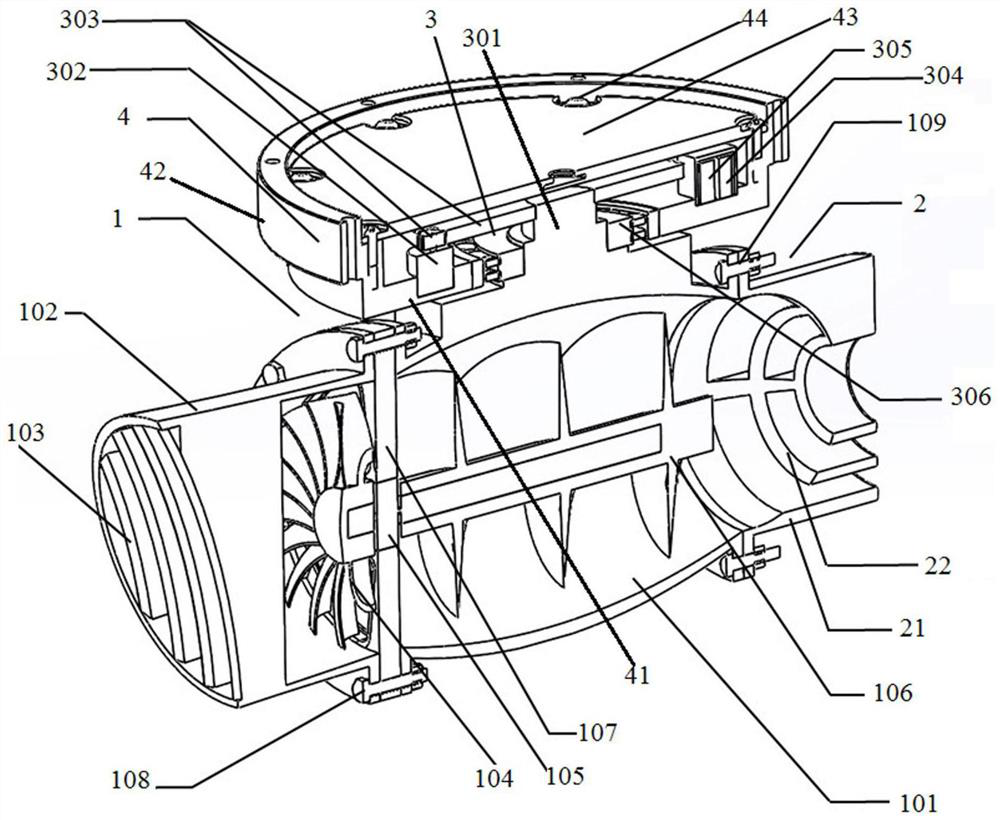

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

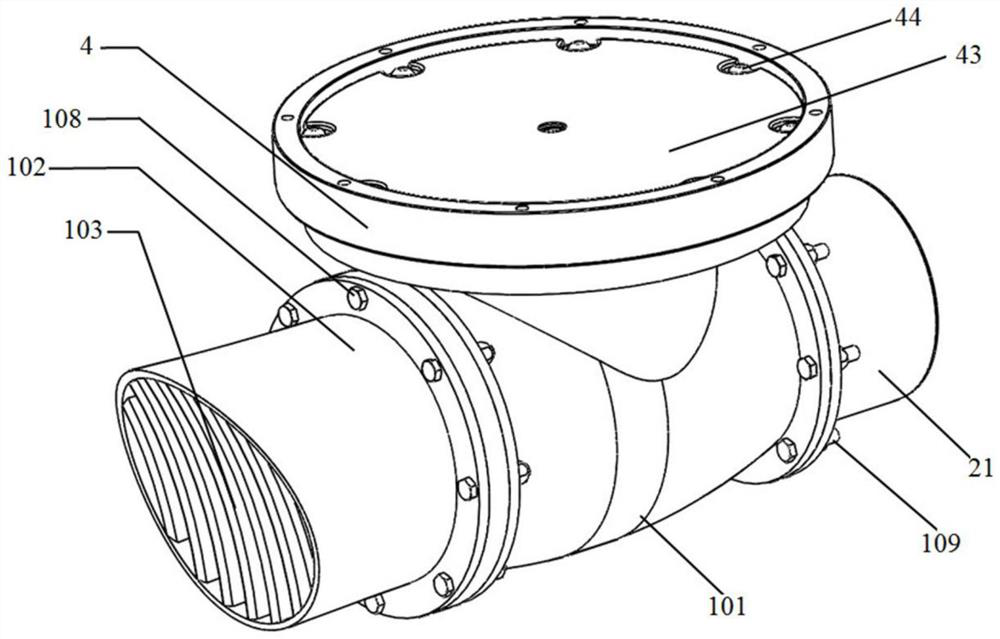

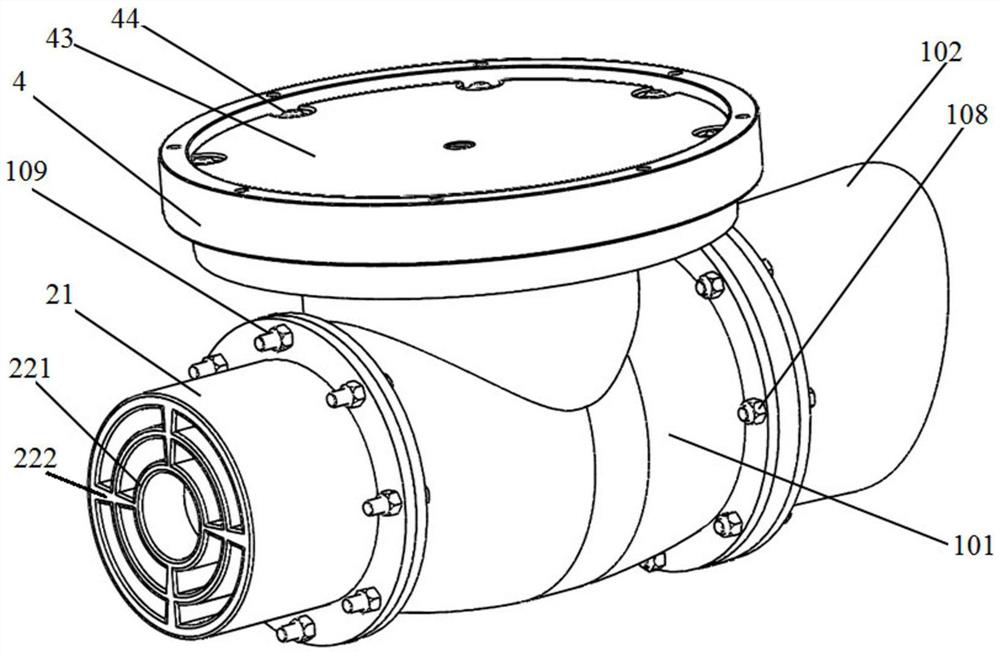

[0030] Such as Figure 1 to Figure 5 As shown, an integrated water jet propulsion system designed by the present invention includes a water inlet system 1 , a drainage system 2 , a fixed support 4 and a control system 3 .

[0031] The water intake system 1 includes a water suction port 102, a main duct 101, a fence 103, a water suction turbine 104, a submersible motor 105, a bracket 107 and a booster paddle 106, the water suction port 102 is installed at the front end of the main duct 101, and the fence 103 , water suction turbine 104, submersible motor 105 and booster paddle 106 are sequentially installed inside the water suction port 102 and the main duct 101 from front to back, and the bracket 107 is installed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com