a heat exchanger

A heat exchanger, rectangular technology, applied in the field of new heat exchangers, can solve the problems of uneven air scouring of the heating surface, affecting the wide use of the heating surface, and limited space for expansion, achieving ideal heat exchange effect and reducing investment costs. , the effect of reducing the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a further understanding and understanding of the structural features of the present invention and the effects achieved, the preferred embodiments and accompanying drawings are used in conjunction with detailed descriptions, and the descriptions are as follows:

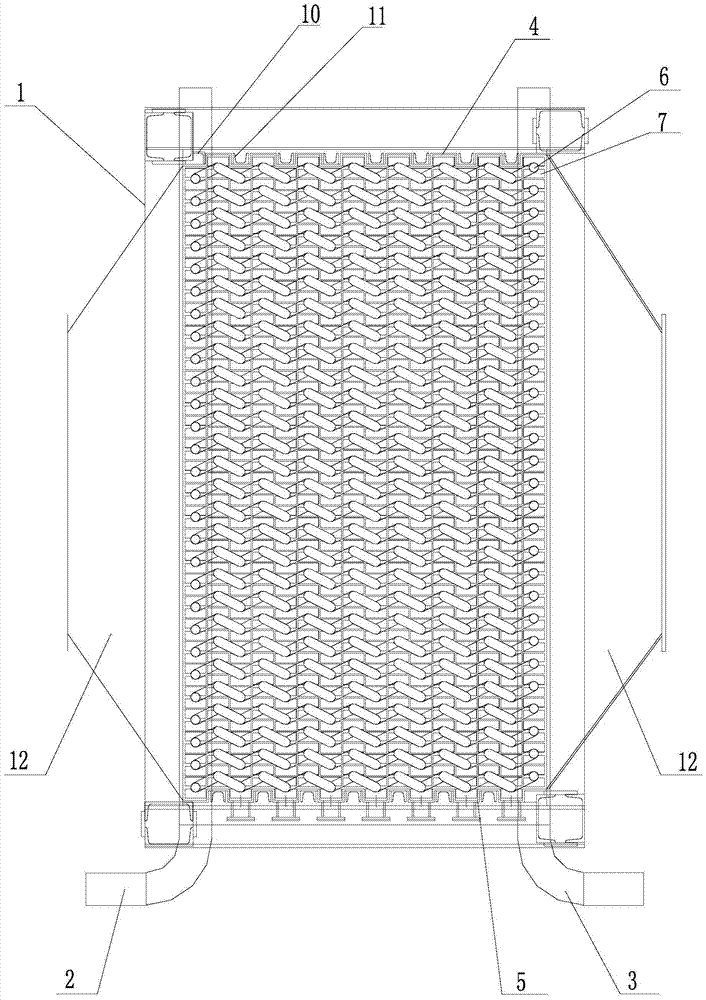

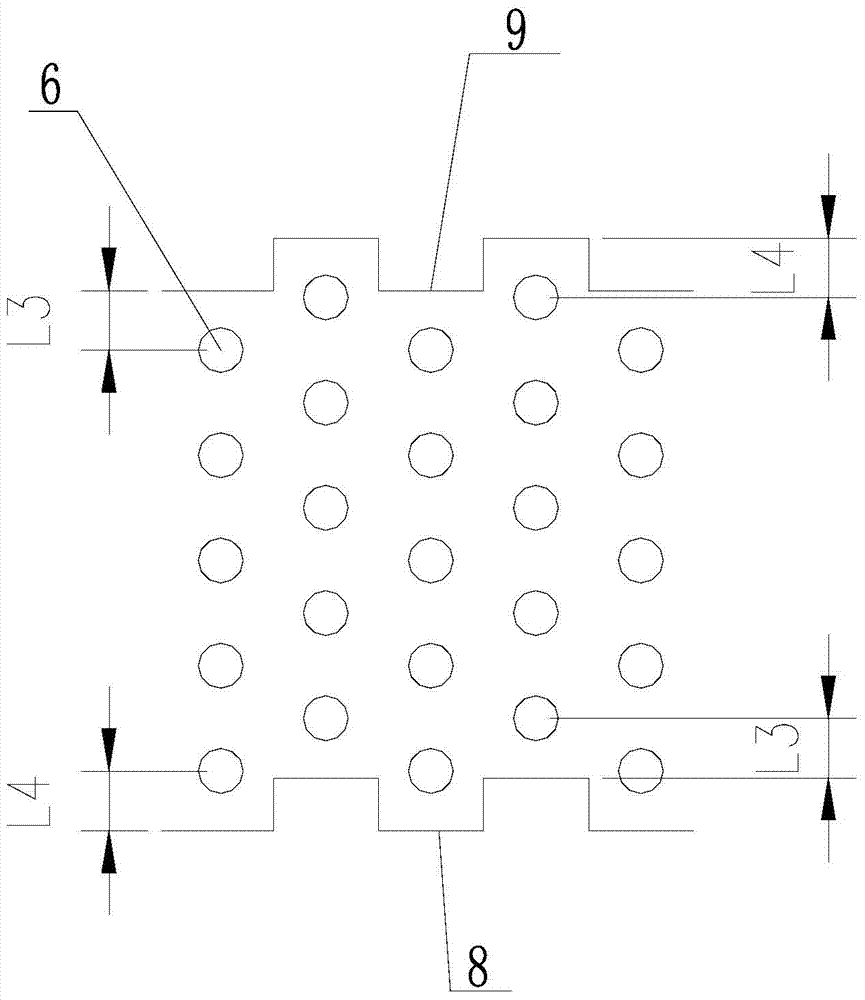

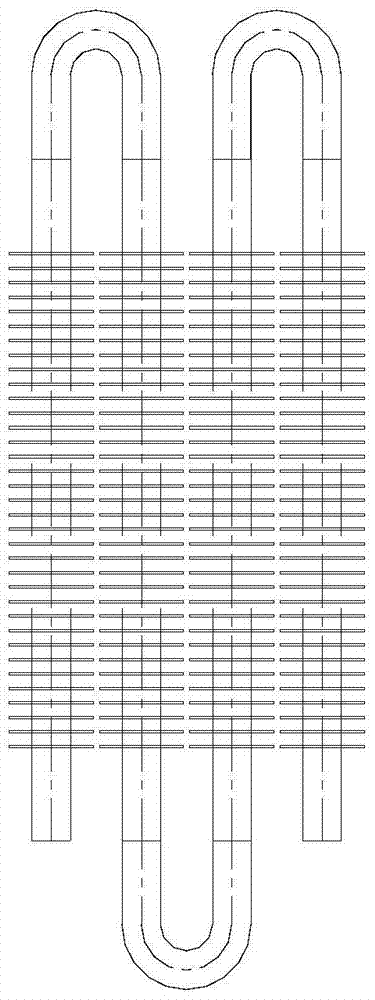

[0026] see Figure 1-Figure 3 As shown, a new type of heat exchanger includes a frame 1, an inlet header 2, an outlet header 3, a rectangular wave-shaped upper guard 4, a rectangular wave-shaped lower guard 5 and several serpentine tubes, an inlet header 2 And the outlet header 3 is vertically arranged on both sides of the frame, the rectangular wave upper guard plate 4 and the rectangular wave lower guard plate 5 are arranged on the upper and lower ends of the frame 1, and the wave crest of the rectangular wave upper guard plate 4 is the same as the rectangular wave. The wave valleys of the lower guard plate 5 are arranged vertically correspondingly. During installation, the rectangular wave lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com