Servo-valve-driven high-speed composite oil cylinder

A composite oil cylinder and servo valve technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of large nominal flow rate, large motor power, large required flow rate, etc., and achieve small effective cross-sectional area, large pressure capacity, and practical performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

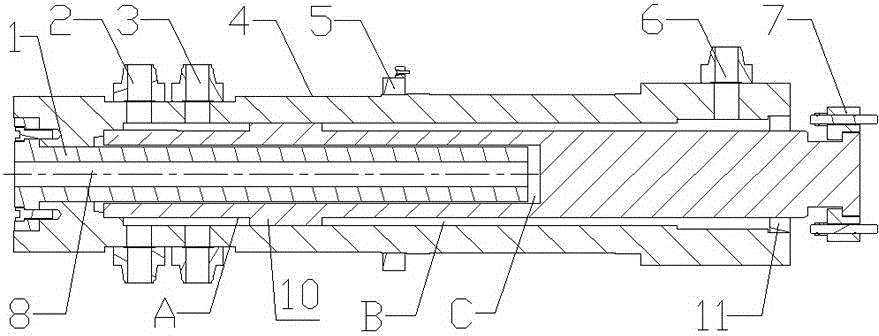

[0016] The present invention as figure 1 shown.

[0017] A high-speed composite oil cylinder driven by a servo valve, including a cylinder body 4, a piston rod 9 is assembled in the cylinder body 4, and a mounting flange 7 is arranged on the top of the piston rod 9, and the tail of the piston rod 9 is hollow, and There is an embedded composite plunger cylinder 1, and the other end of the embedded composite plunger cylinder 1 is fixedly connected with the cylinder body 4. The embedded composite plunger cylinder 1 is provided with a through fast lower chamber oil inlet 8, and the fast lower chamber The oil inlet 8 is connected with the external oil circuit;

[0018] A guide ring 10 is provided between the middle and lower part of the outer wall of the piston rod 9 and the inner wall of the cylinder body 4, and the piston rod 9 stretches out from the guide ring 2 2 at one end of the cylinder body 4, and the guide ring 10, guide ring 2 in the cylinder body 4 A return chamber B i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com