Clamping width-adjustable mandrel grinder

A technology of mandrel width and mandrel, which is applied in the field of mandrel grinding machine with adjustable clamping width, can solve the problems of skin and respiratory tract injury, poor grinding precision and low work efficiency, and achieve high grinding precision, high processing efficiency, The effect of preventing human injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

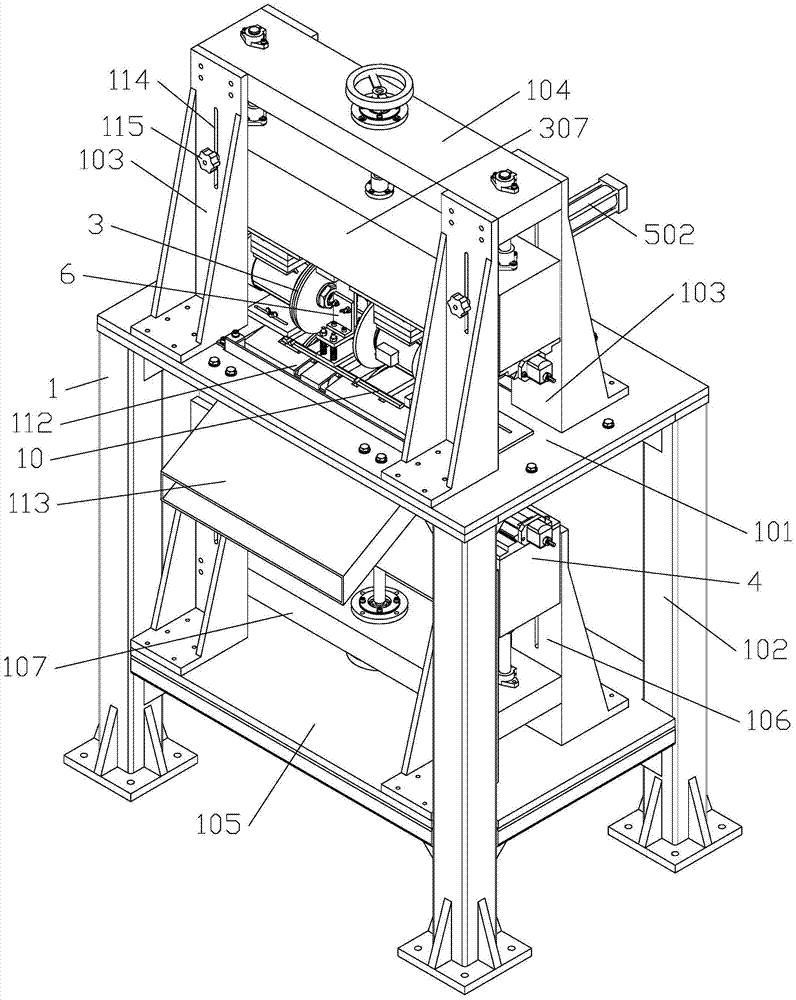

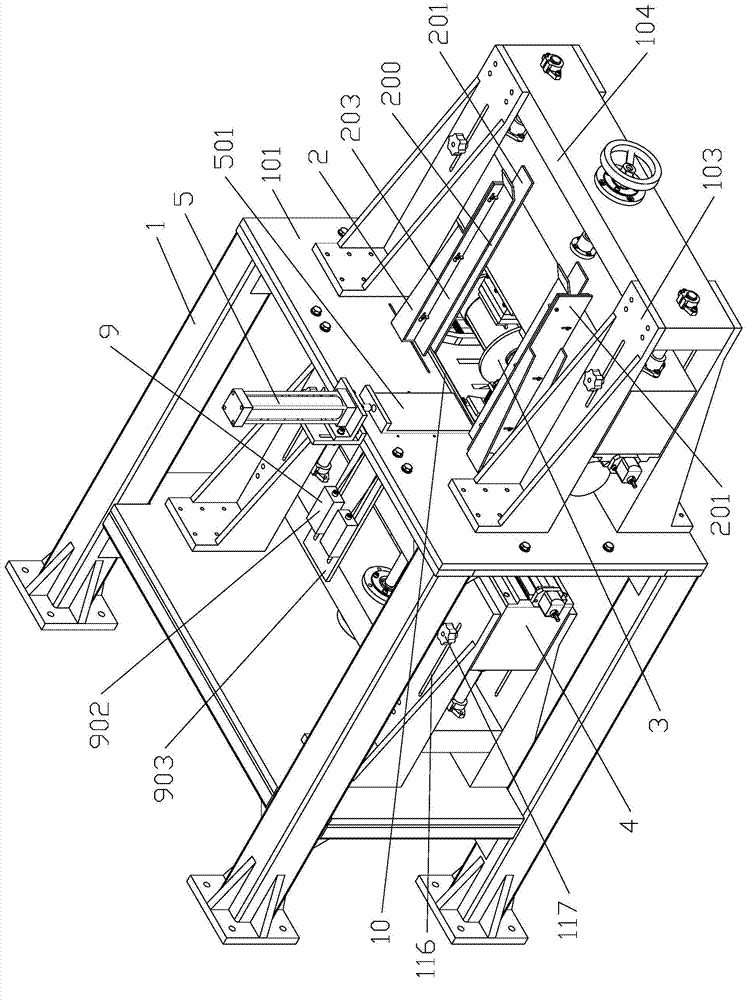

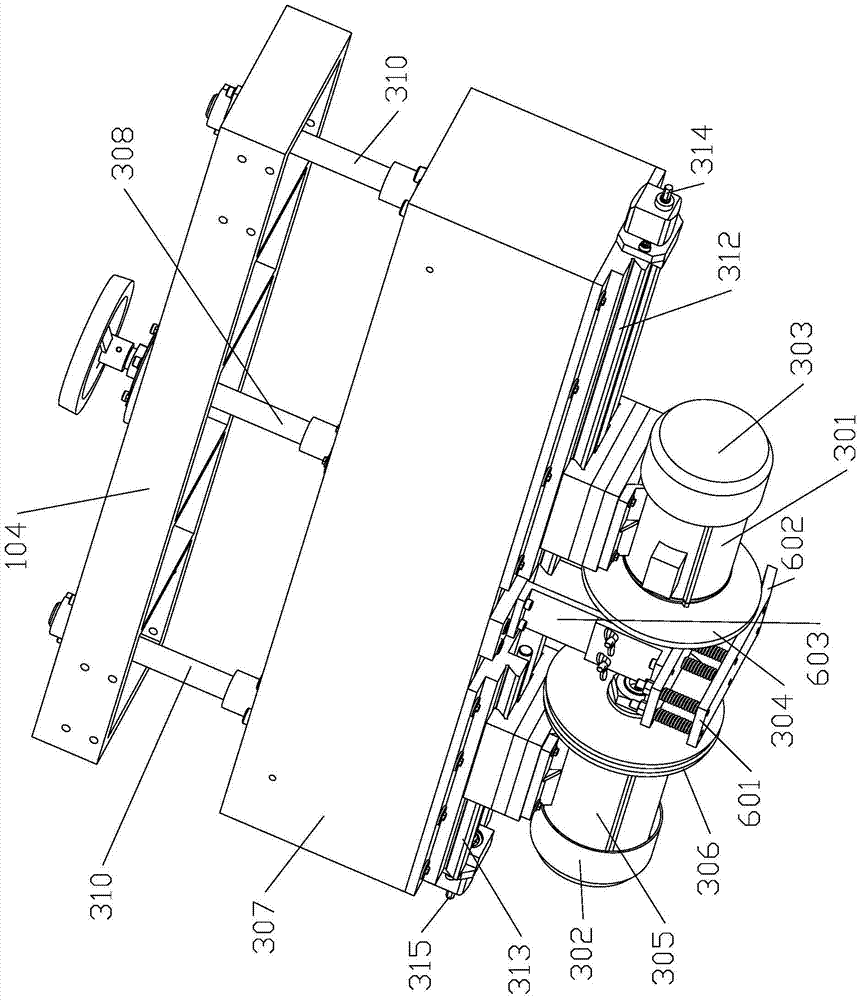

[0049] see figure 1 The shown mandrel grinding machine with adjustable clamping width includes body 1, feed box 2, upper grinding mechanism 3, lower grinding mechanism 4, feeding mechanism 5, upper pressing mechanism 6, side pressing Mechanism 7, clamping mechanism 8, gravity turning device 9.

[0050] Fuselage 1 is the basis of the whole equipment, including workbench, bed legs, upper column, lower column, upper beam, lower beam and so on. Four bed legs 102 support the workbench 101, and the top of the workbench is fixed with four upper columns 103, and the upper beam 104 is fixedly connected with the upper ends of the four upper columns. There is a platen 105 fixed on the four bed legs below the workbench, four lower columns 106 are fixed on the platen 105, and the lower crossbeam 107 is fixedly connected with the lower ends of the four upper columns.

[0051] The feed box comprises two vertical channels 200 in which the two ends of the mandrel 10 are located. The vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com