Automatic unloading device of drop test machine

A drop test, automatic technology, used in measuring devices, impact testing, machine/structural component testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

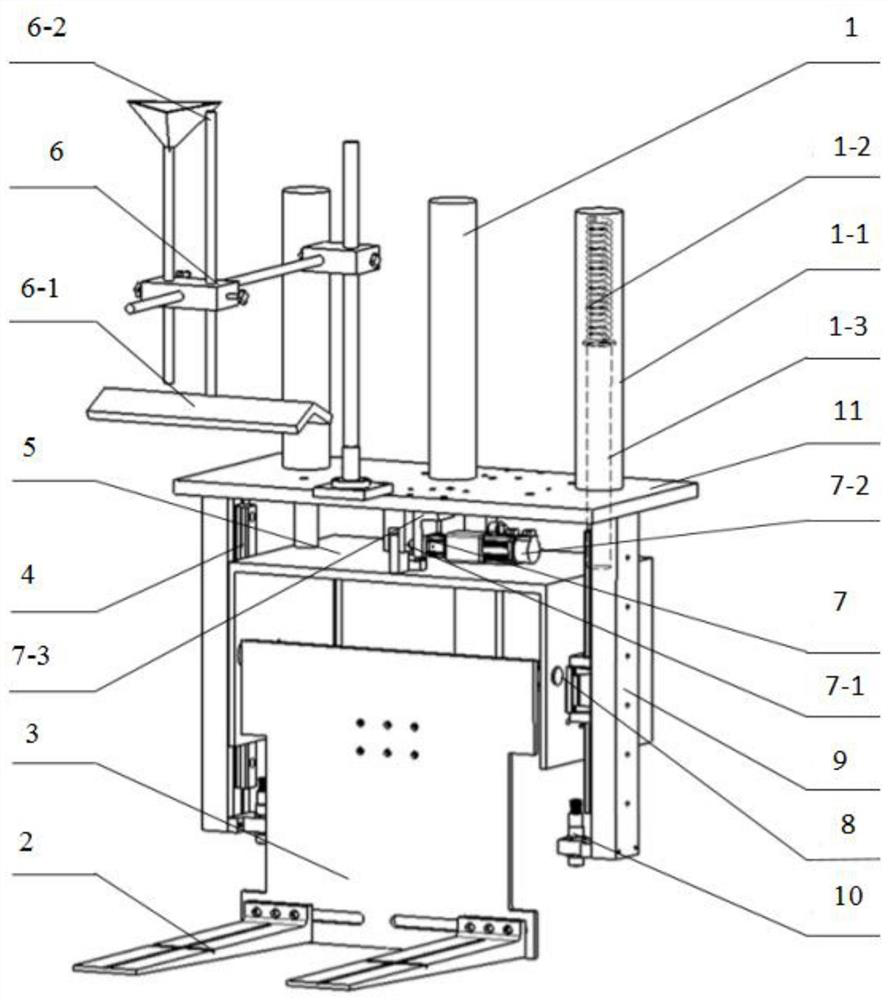

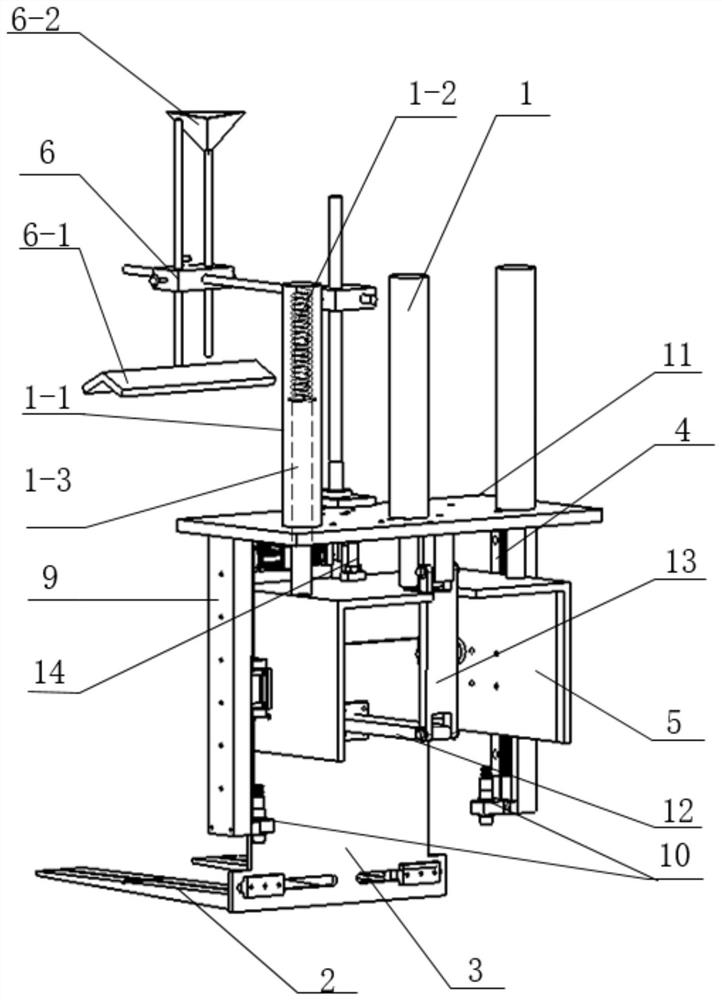

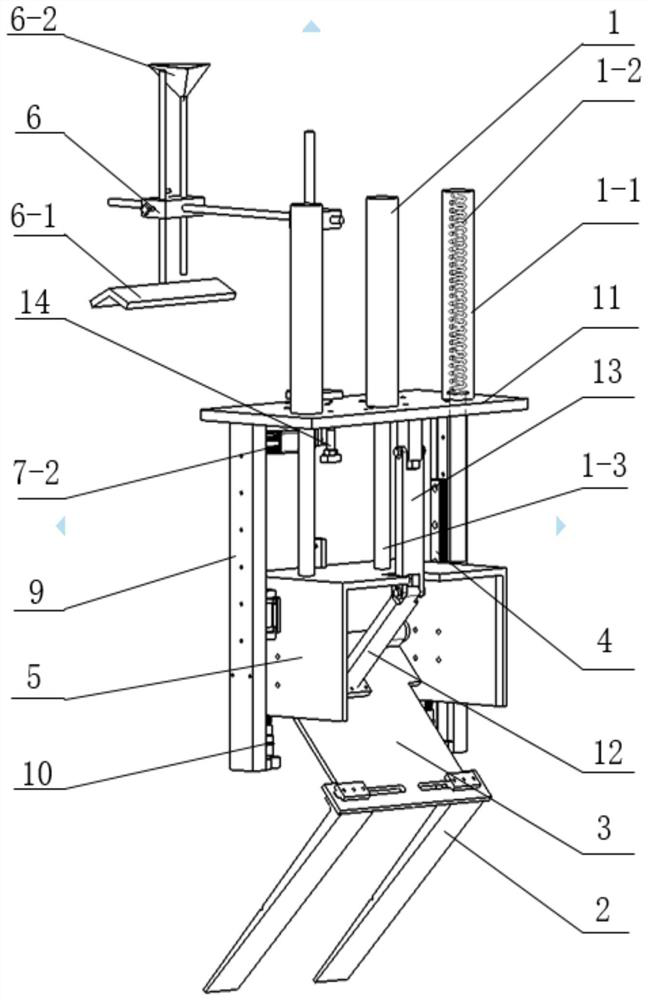

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0016] like figure 1 and image 3 As shown, an automatic unloading device for a drop test machine, including three sets of spring accumulator 1, bracket 2 for the tested product, flip plate 3, slide rail 4, box body 5, attitude fixing frame 6, and locking mechanism 7. Rotating shaft 8, support frame 9, buffer 10, top plate 11, pull rod 12, connecting rod 13 and limit nut 14. Three sets of spring accumulators 1 are equidistantly installed on the top plate 11, the bottom of the top plate 11 is connected to the support frame 9, and slide rails 4 are respectively installed on both sides of the support frame 9, and the sliders on the slide rails 4 are connected with the box body 5 to realize the box body. Body 5 moves vertically. The lower part of three groups of spring accumulators 1 is in contact with the top of box body 5, and two buffers 10 are installed on the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com