Rear adjustable three-hole composite type waterproof hammer air group valve

An air valve and composite technology, applied in valve details, multi-way valves, valve devices, etc., can solve problems such as pipe wall corrosion, inability to adjust control, incomplete exhaust of pipelines or containers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

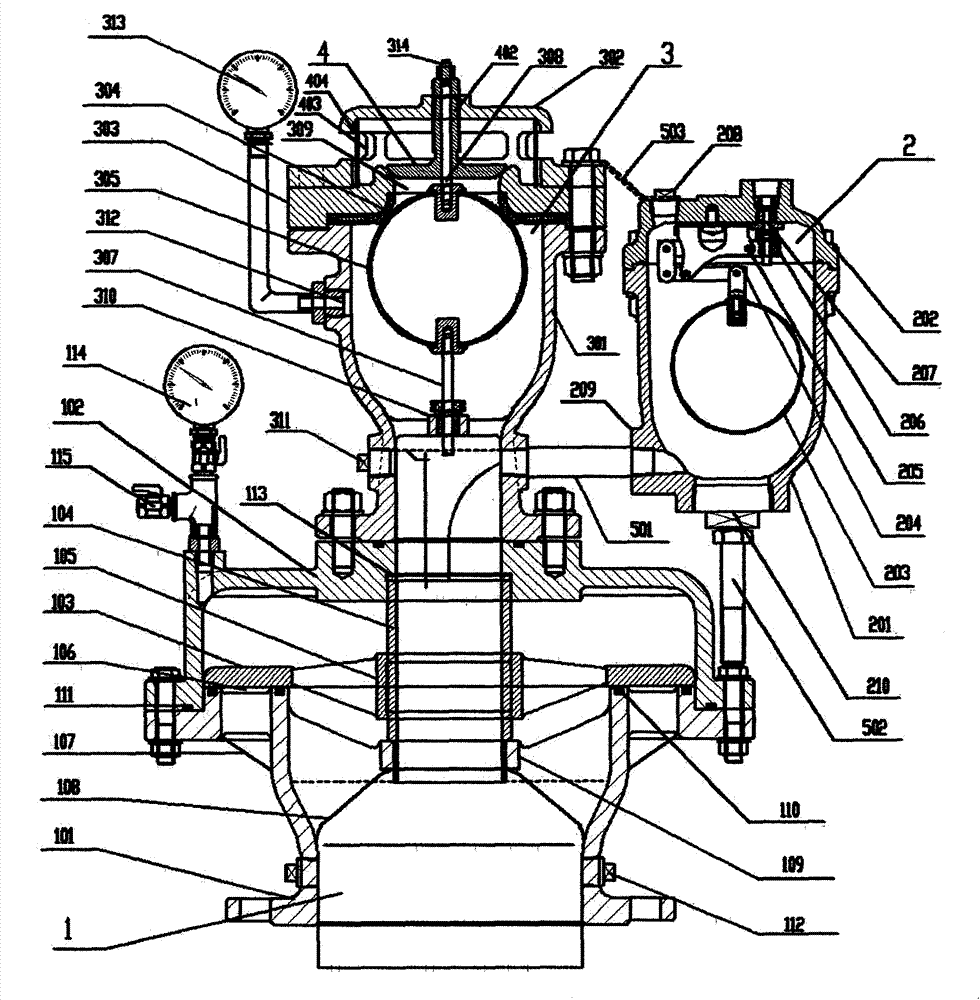

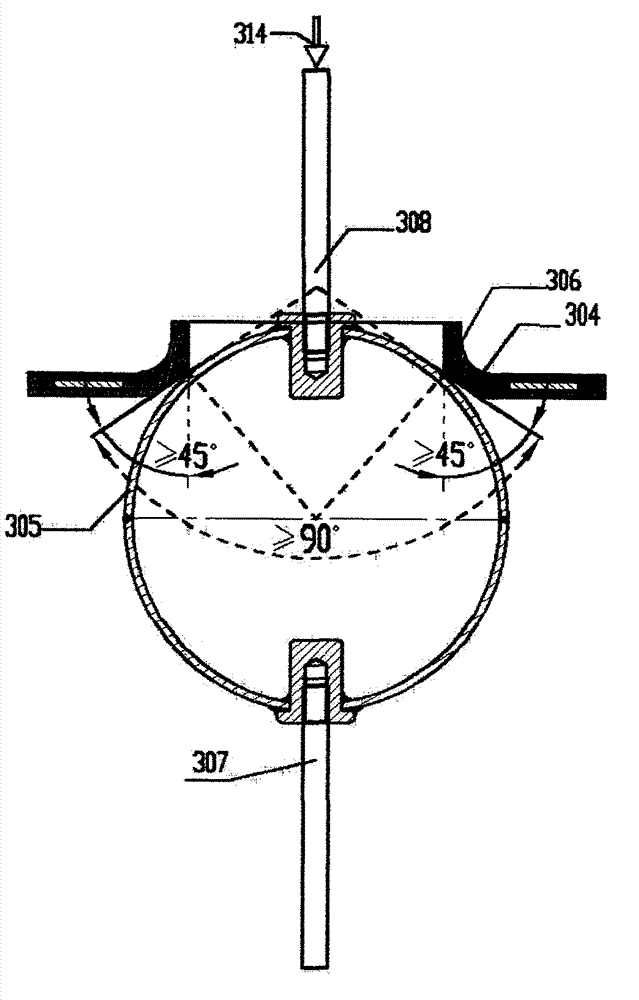

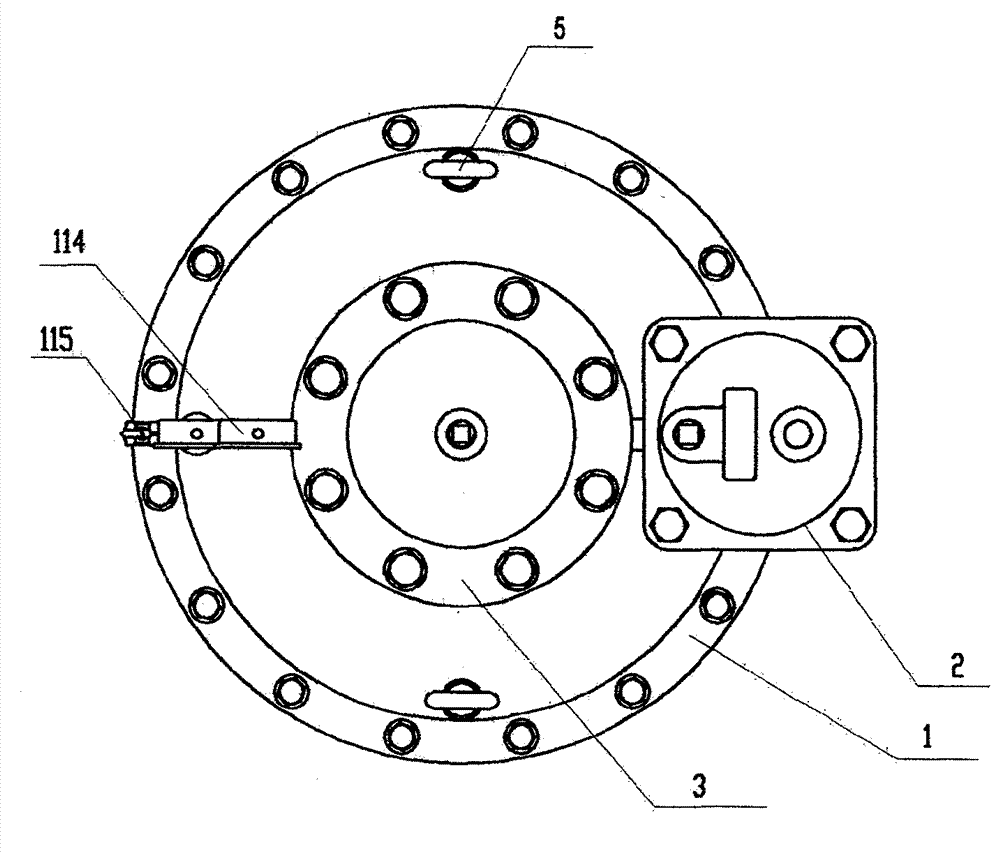

[0051] Example: such as figure 1 , figure 2 , image 3 As shown, a post-adjustable three-orifice compound anti-hammer air valve group is installed on the infusion pipeline or container system, which includes a negative pressure suction valve 1, a micro exhaust valve 2 and a high-speed Exhaust valve 3 and post-regulating valve 4 at the outlet; the high-speed exhaust valve 3 is directly connected to the top or side of the negative pressure suction valve 1 through threads or flanges, and the negative pressure suction valve 1 is connected to the infusion pipeline T-shaped neck interface, the micro exhaust valve 2 is connected to the side wall of the high-speed exhaust valve 3 or the top cover or side of the negative pressure suction valve 1; the high-speed exhaust orifice of the air valve group can be adjusted and controlled , and set up separately, set separately from the high-speed suction orifice 106 instead of sharing with each other, which allows independent selection and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com