Glass fiber tape feeding system facilitating replacement of glass fiber tape roll

A glass fiber tape and glass fiber technology, which is applied in the field of epoxy glass fiber pipe drilling and processing, can solve the problems of reduced production efficiency, low production efficiency, and heavy glass fiber tape workload, so as to reduce frictional resistance and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

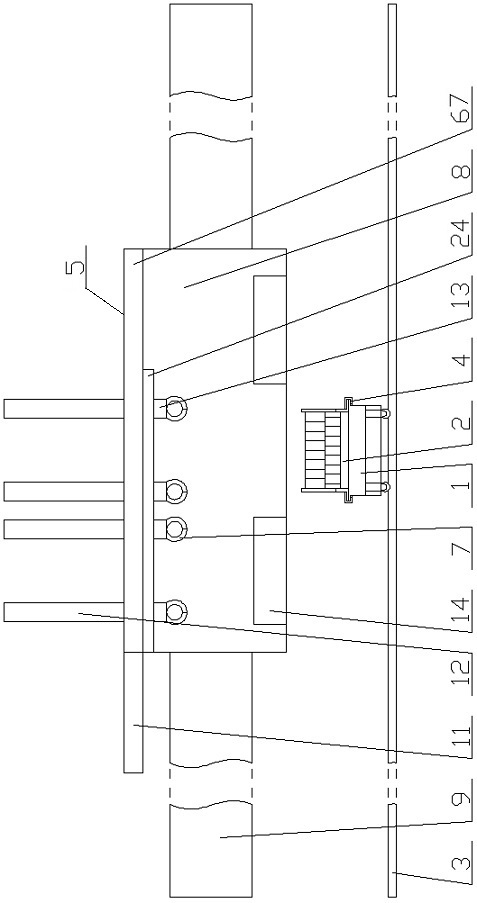

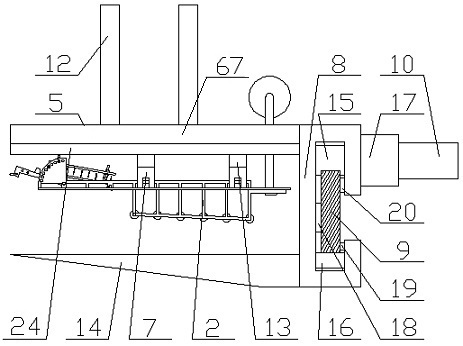

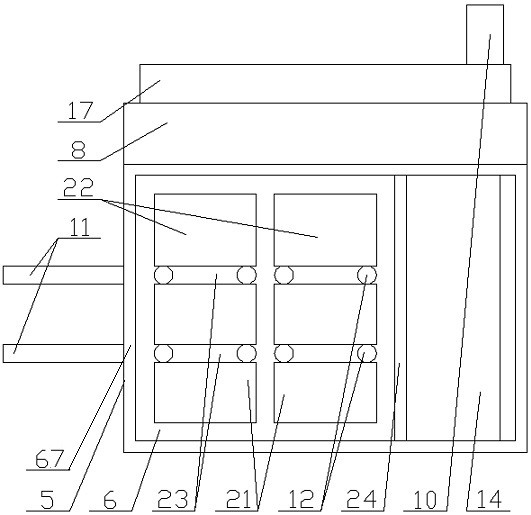

[0061] Combine Figure 1 ~ 5Found, facilitate feeding system fiberglass tape fiberglass tape roll transducer comprising a rail A by the drive means 3 to reciprocate epoxy dipping tank 1, the epoxy dip tank detachably fixedly connected at the notch along a 1 unwinding of fiberglass tape 68 feed frame 2, the unreeling feed 1 is located in the range of 2 epoxy dipping tank feeder, and further comprising an epoxy impregnated above the tank 1, the beam 9 reciprocates along the rail by a driving device B10 of unwinding feed carrier changing device 5, the rail beam 9 is located epoxy dipping tank and unwinding feed carrier changing device rearward 5 and with three parallel tracks is provided, the unreeling feed carrier changing device 15 includes a horizontally disposed the base frame 67, the bottom side of the base frame 67 is fixedly connected with a slide 9 connected to the active groove track beam 8, the base frame 67 equipped with sliding frame 6, frame 6 by the reciprocating drive m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com