RFID electronic label laminating equipment for tires

An electronic label and equipment technology, applied in the field of lamination equipment, can solve the problems of manual feeding and low production efficiency, and achieve the effect of improving efficiency, good consistency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

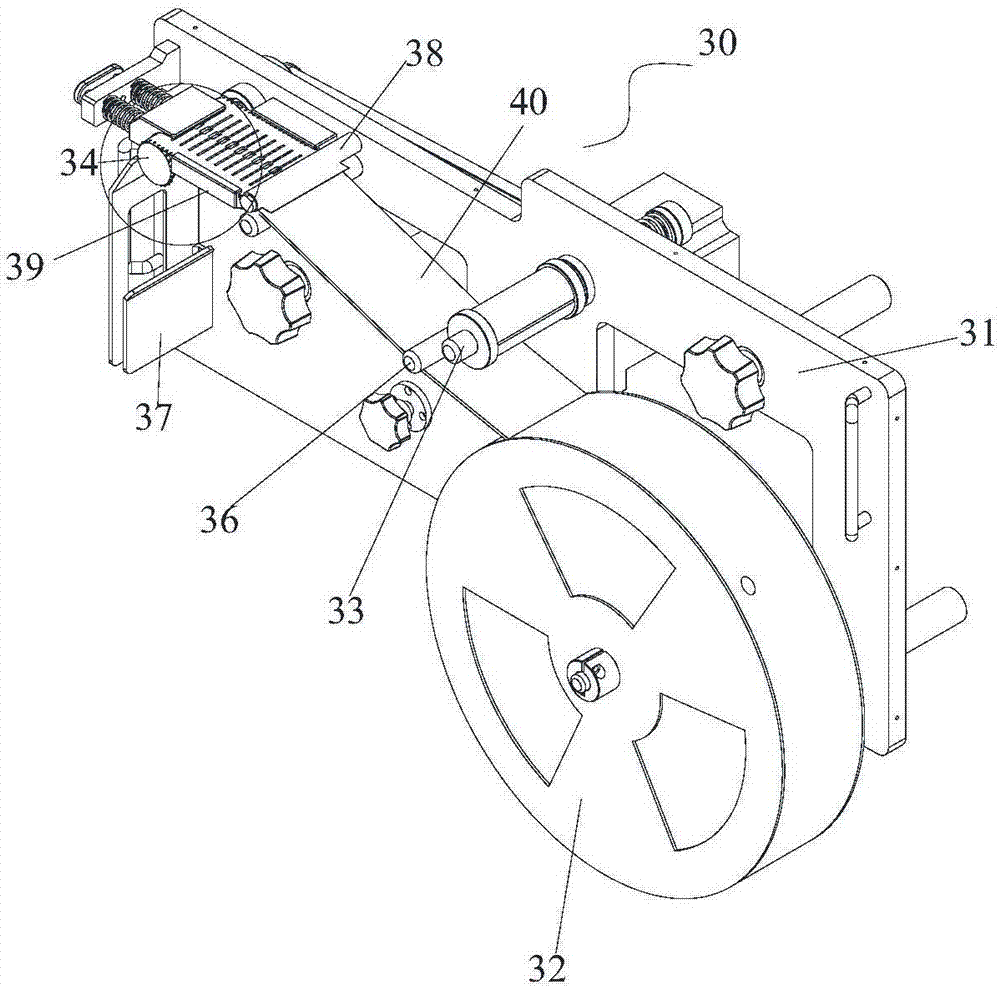

[0036] In the present invention and the embodiments of the present invention, the material 40 to be conveyed is the material including the electronic chip 42 , and the component to be picked up is the electronic chip 42 . This electronic chip 42 is a radio frequency identification chip for the tyre. The components laminated by the lamination equipment are RFID (Radio Frequency Identification, radio frequency identification) electronic tags for tires.

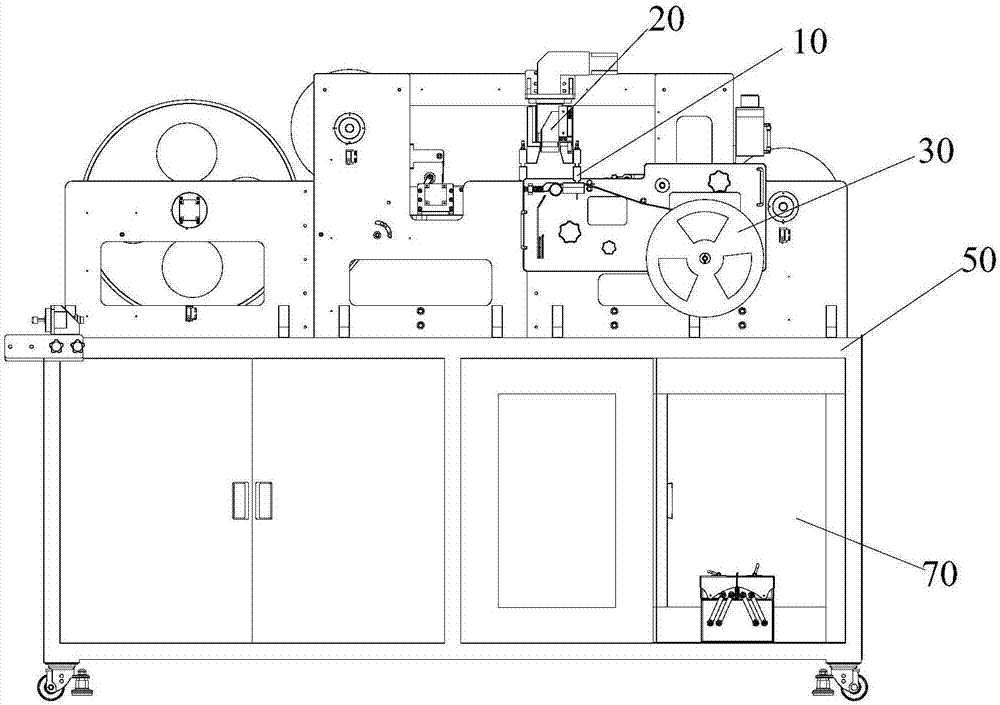

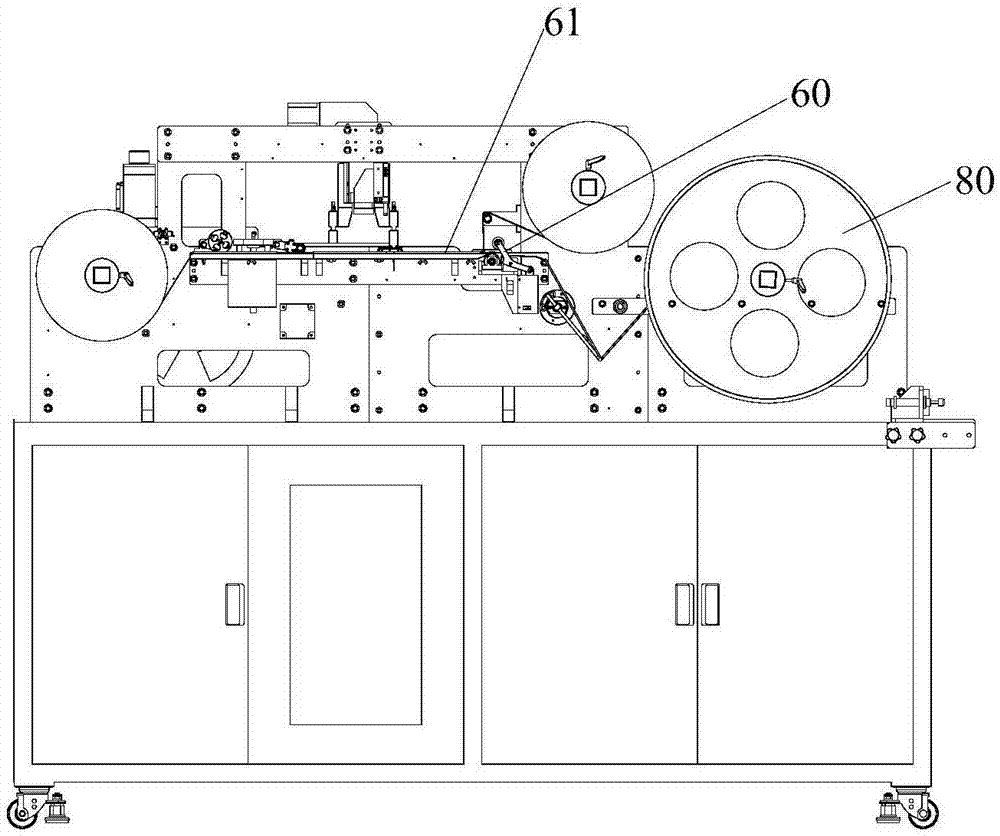

[0037] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a lamination equipment for RFID electronic tags for tires. The lamination equipment includes a frame 90 , a feeding mechanism 30 disposed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com