Optical fiber laying device for leakage detection of concrete pool, and laying method

A technology of laying device and concrete, applied in the direction of measuring device, optical fiber/cable installation, measuring heat, etc., can solve the problems of poor unwinding effect and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The application will be described in further detail below in conjunction with the accompanying drawings.

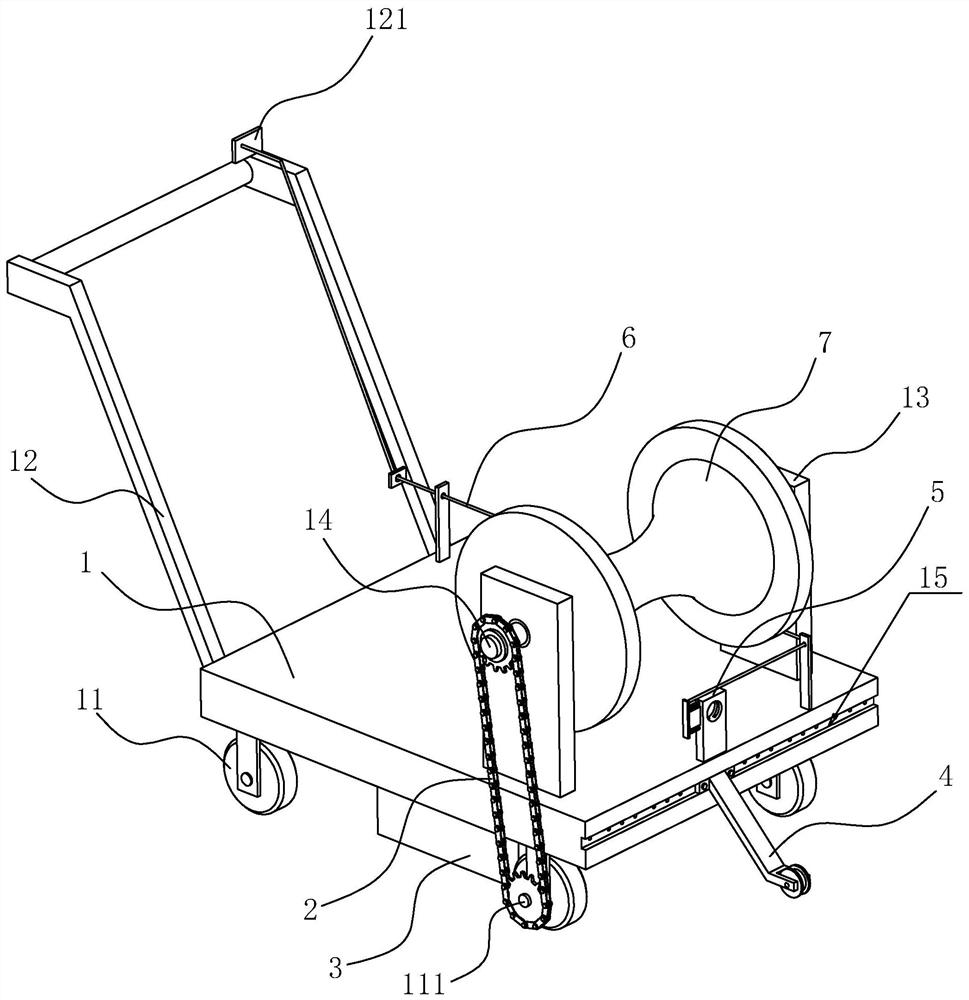

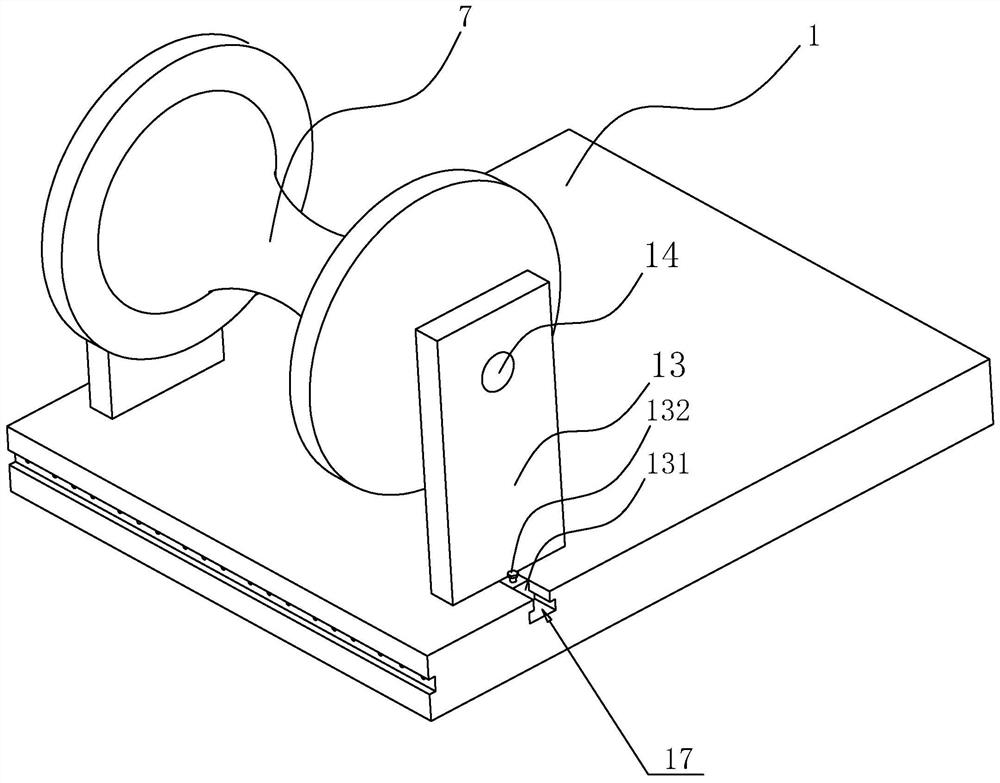

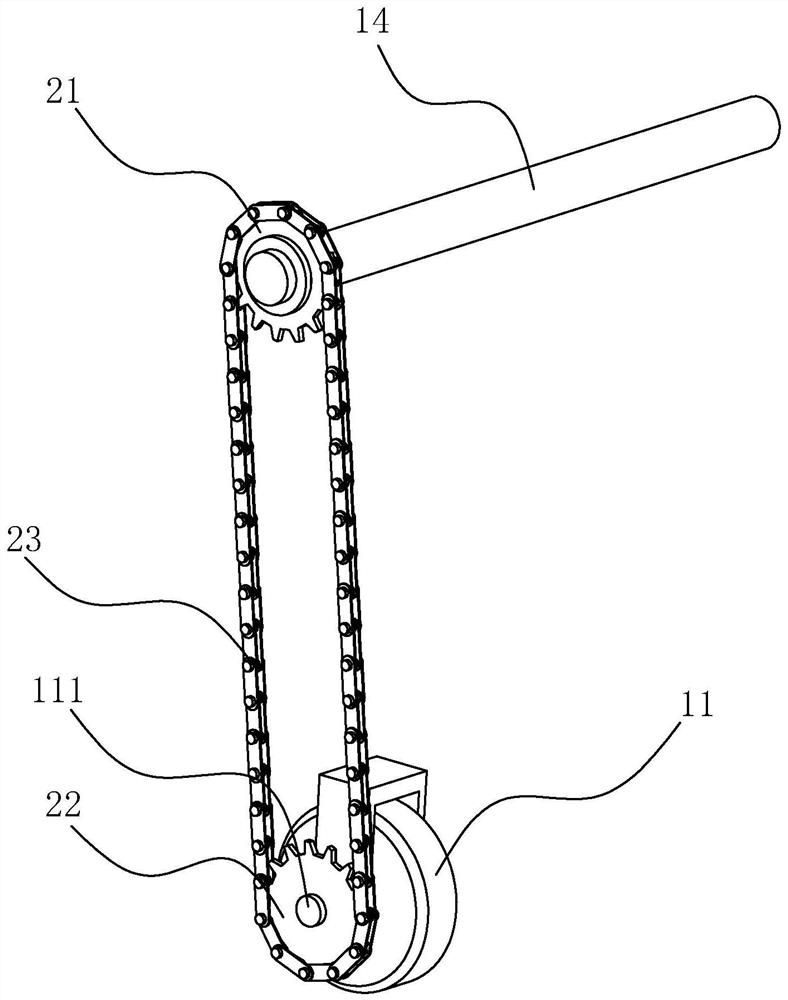

[0044] The embodiment of the present application discloses an optical fiber laying device for leak detection of concrete pools, referring to figure 1 , including a base 1, the four corners of the bottom of the base 1 are equipped with rollers 11, one end of the base 1 is welded with a push-pull handle 12, so that the base 1 can be pushed or pulled, and the base 1 is provided with two support seats 13, two support The unwinding shaft 14 for installing the optical fiber reel 7 is rotatably connected between the seats 13, and a linkage assembly 2 is installed between the unwinding shaft 14 and one of the rollers 11, and the synchronous rotation of the unwinding shaft 14 and the rollers 11 is realized by the linkage assembly 2. One end of the base 1 close to the unwinding shaft 14 is equipped with a wire mechanism 4, and the optical fiber is placed on the wire mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com