Automatic laying production line and control method of wind turbine blade root preform

A preform and automatic laying technology, which is applied in the automatic laying production line and control field of wind power blade root preforms, can solve the problems of increasing the production time of wind power blade root preforms and reducing production efficiency, and achieves the goal of reducing interlayer wrinkles Probability, improvement of production efficiency, and improvement of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

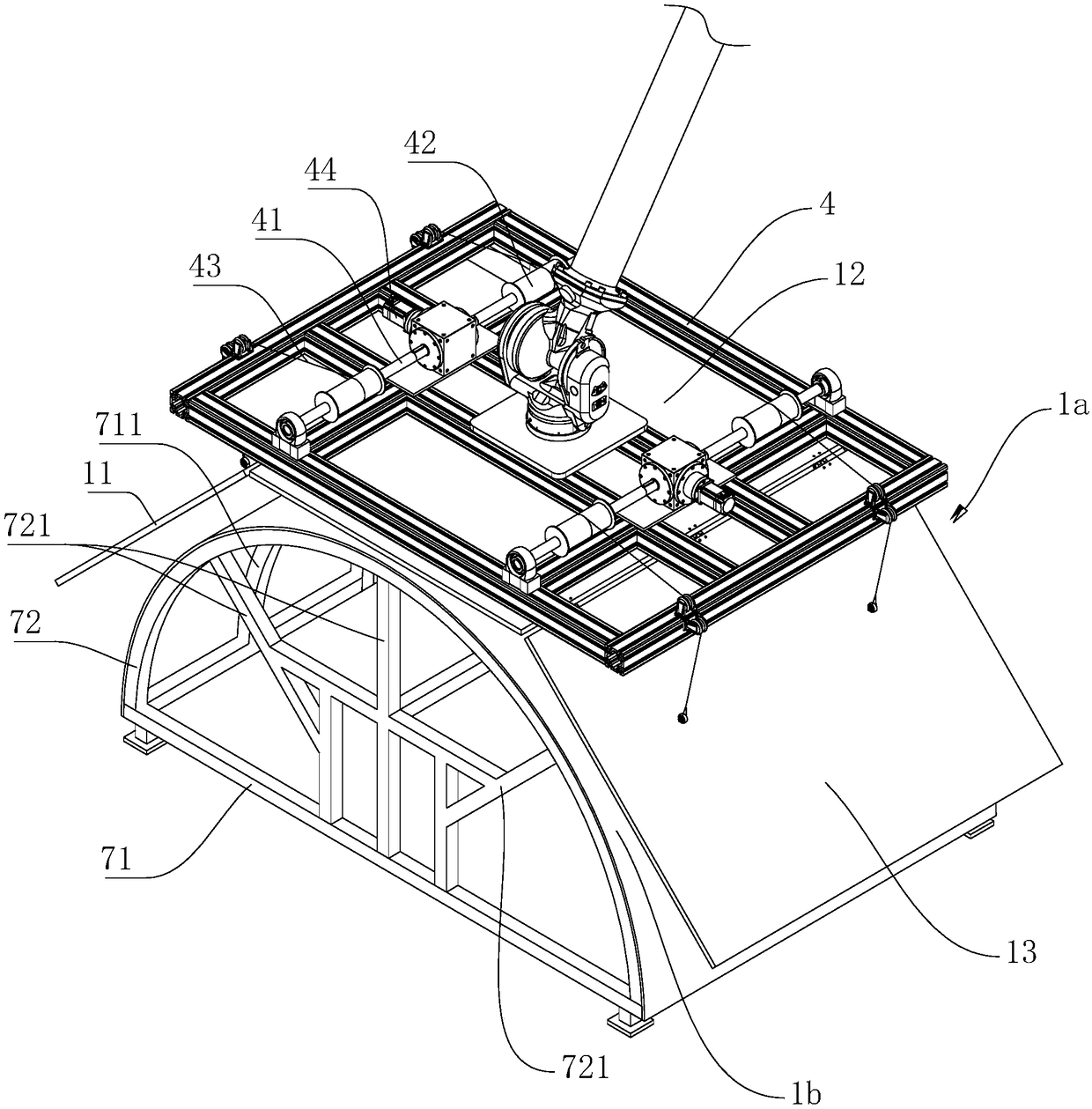

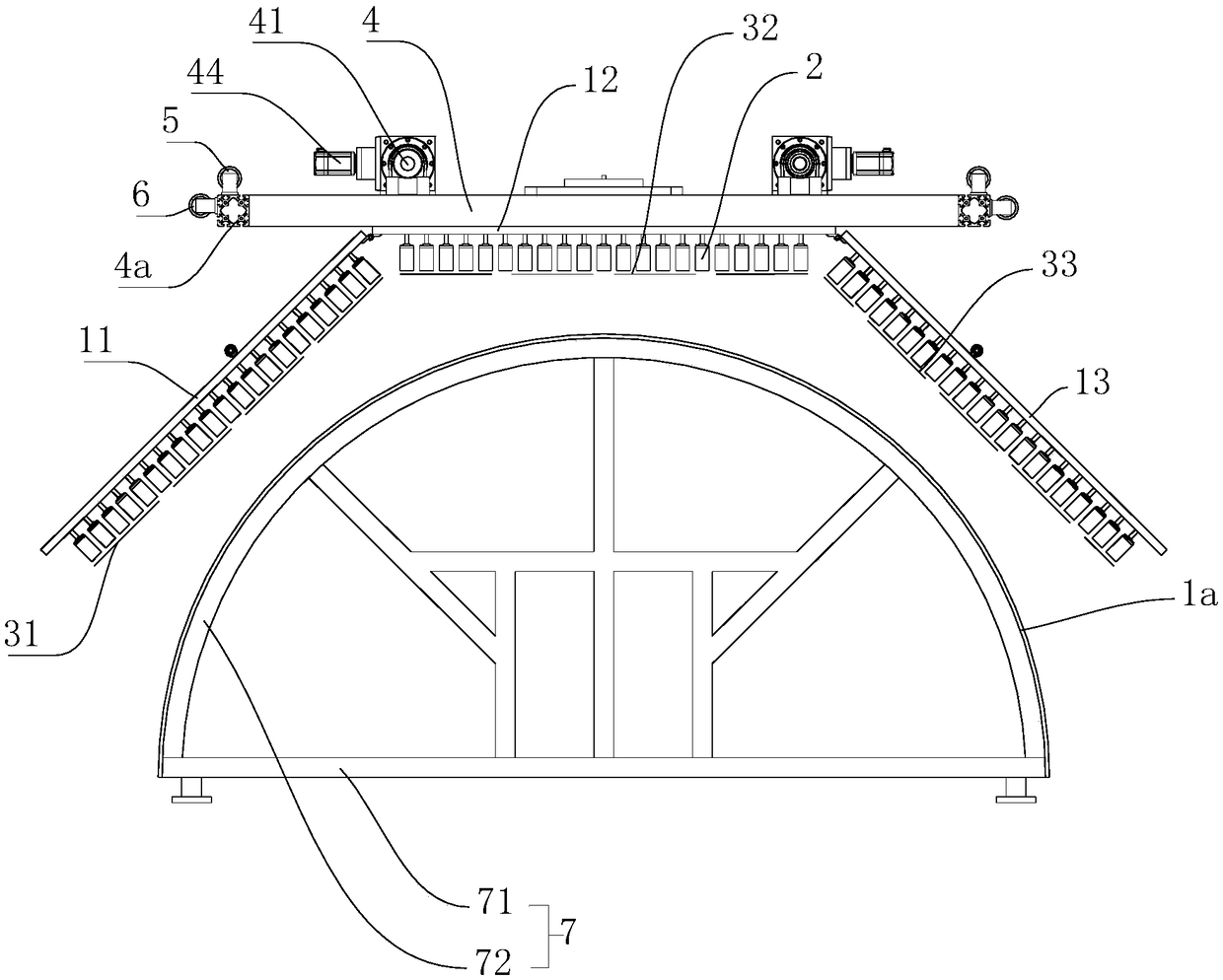

[0048] Embodiment 1: An automatic laying production line for wind power blade root preforms, including a cutting station for carrying and cutting cloth; a conveying device for conveying the cloth on the cutting station; variant structure 1 for preforming Deformation and forming of molded parts.

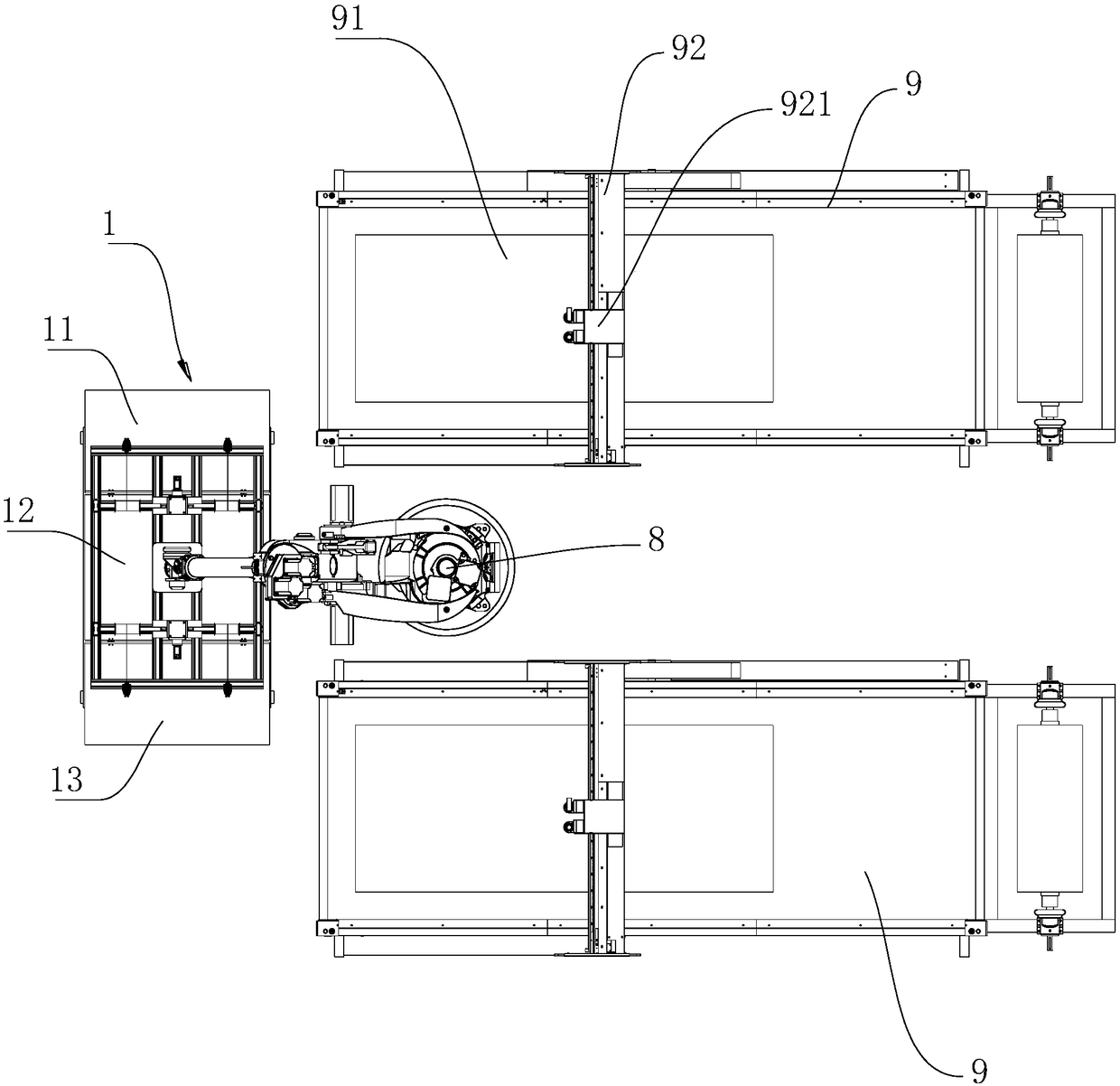

[0049] like figure 1As shown, the cutting station includes one or more than one cutting platform 9. In this embodiment, there are two cutting platforms 9. The cutting platform 9 is equipped with a belt transmission structure, which drives the cloth to move to the cutting area. 91. The cutting platform 9 is equipped with a gantry 92 , and the gantry 92 performs linear reciprocating motion along the length direction of the cutting platform 9 . A cutting machine 921 is installed on the gantry 92, and the cutting machine 921 performs linear reciprocating motion along the length direction of the gantry 92. The structure of the linear reciprocating motion can be realized by a screw struct...

Embodiment 2

[0059] Embodiment 2: A control method for an automatic laying production line of wind power blade root preforms, such as Figure 1 to Figure 3 shown, including the following steps:

[0060] 1.1 Unwinding: the unwinding device actively unwinds the fabric forward, the distance between the end of the cutting platform 9 away from the modified structure 1 and the unwinding shaft forms the fabric storage section, and the conveyor belt of the cutting platform 9 rotates to drive the fabric Move forward to the cutting area 91;

[0061] 1.2 Cutting: Through the calculation of the size of the figure to be cut, the cutting machine 921 corresponds to the coordinates of the cloth in the cutting area 91 according to the shape of the figure to be cut, so that the center point of the circumscribed rectangle of the figure to be cut falls on the center line of the cutting area 91 , cut the fabric along each cutting line of the graphics to be cut;

[0062] 1.3 Deformation of the cloth frame bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com