Tension-free, dust-removing leather unwinding device

An unwinding device, tension-free technology, applied in the direction of winding strips, transportation and packaging, cleaning methods and utensils, etc., can solve the problems of occupation of labor, unguaranteed unwinding quality, and poor dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

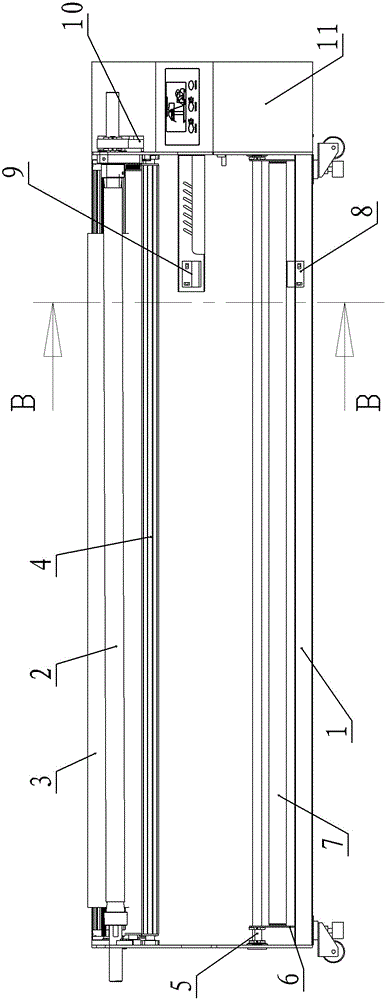

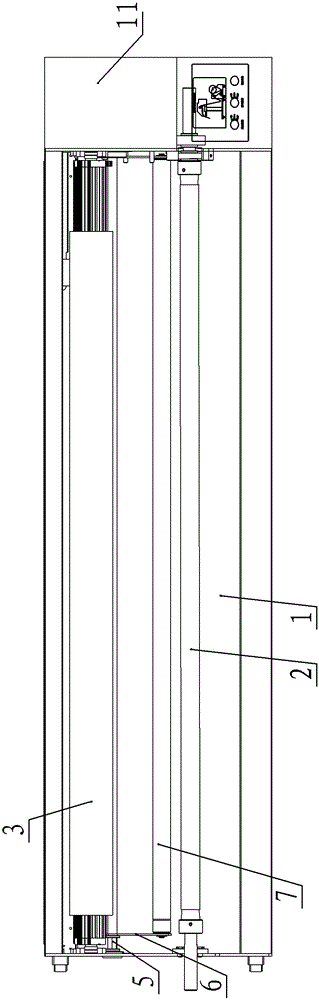

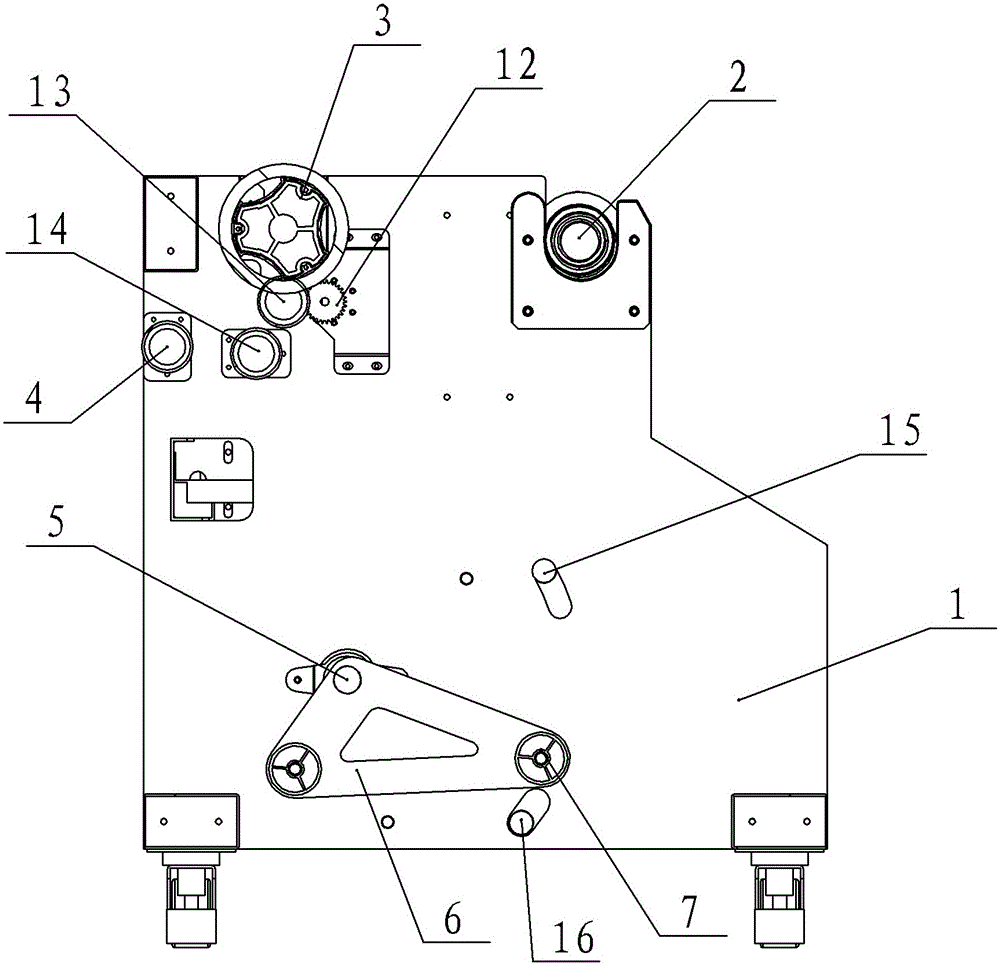

[0018] Example: see Figure 1-7 , a tension-free, dust-removing leather unwinding device in the figure, including a frame, a load-bearing roller set on the upper part of the frame, a drive roller, and a dust-sticking roller. It is characterized in that: the surfaces of the drive roller and the dust-sticking roller are tangent For installation, an upper leather detection probe and a lower leather detection probe are arranged on the outside of the lower frame of the transmission roller, and the shaft ends of the transmission roller and the bearing roller are respectively connected with a driving mechanism; an adjustment mechanism is also provided at the bottom of the frame, and the adjustment The mechanism includes a swing frame, a fixed roller, and an adjustment roller. The fixed roller is installed on the frame, one end of the swing frame is set on the fixed roller, and the other end of the swing frame is equipped with an adjustment roller. The center swings, and the upper adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com