Improved bending device of automatic wire stripping machine

A technology of automatic wire stripping and bending device, applied in circuit/collector parts, electrical components, circuits, etc., can solve the problems of low work efficiency, slow speed, single finished product style, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

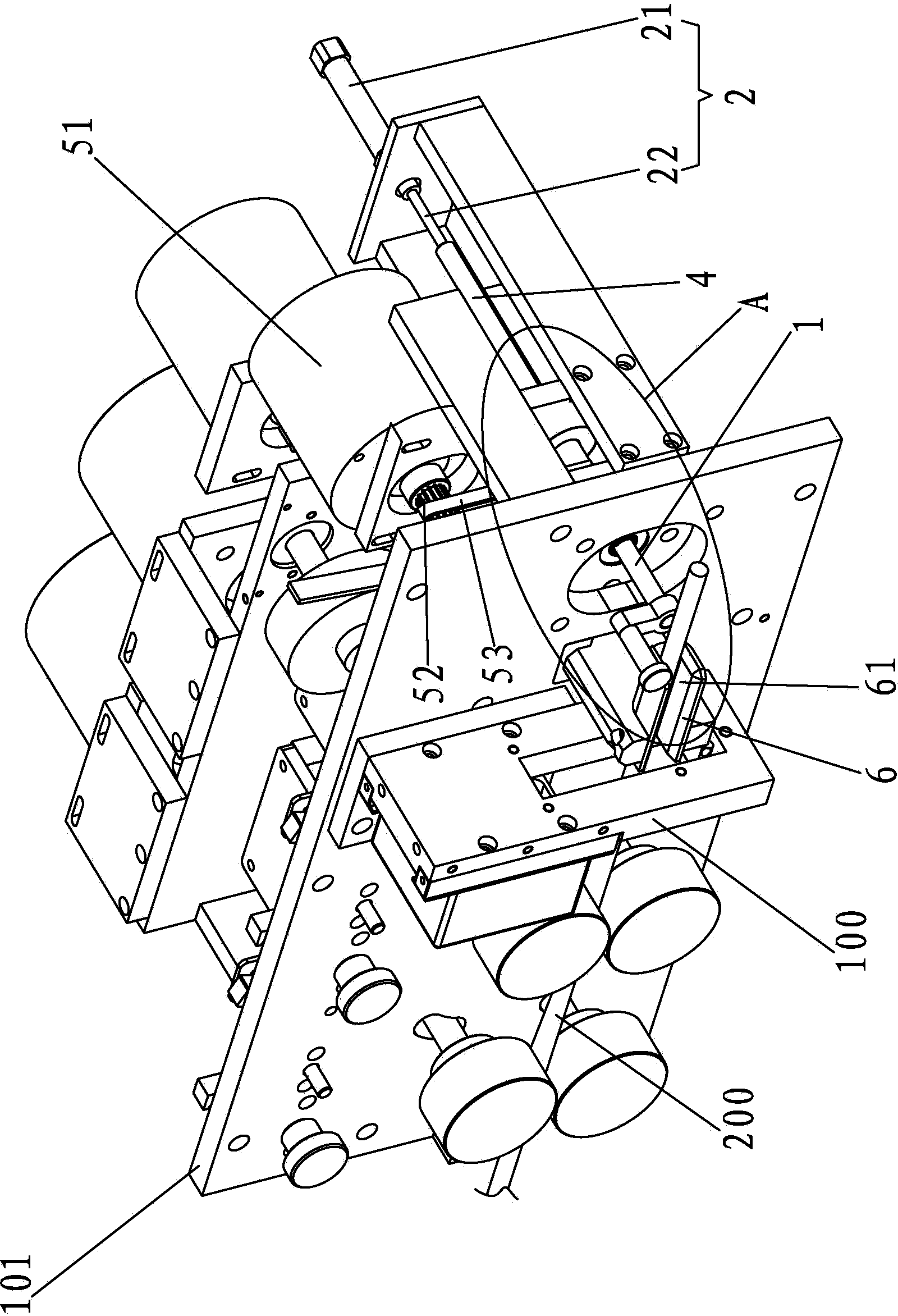

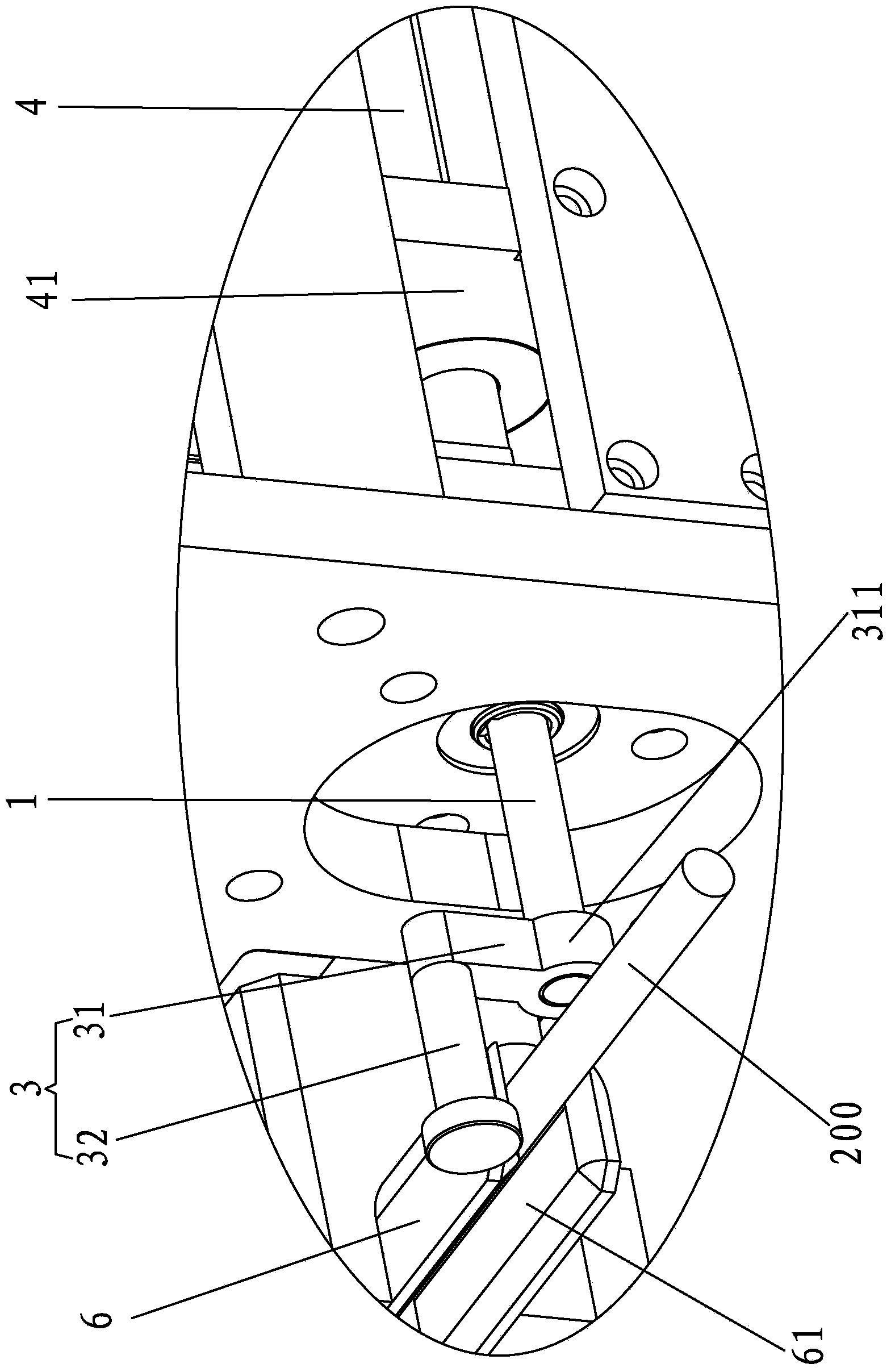

[0028] An improved bending device of an automatic wire stripping machine of the present invention, such as figure 1 , 2 As shown, it includes a bending rod 1, a telescopic control mechanism 2 for controlling the expansion and contraction of the bending rod 1, and a rotation control mechanism for controlling the rotation of the bending rod 1. The bending rod 1 is placed horizontally, and the first end of the bending rod 1 Located at the exit of the tool holder assembly 100 of the automatic wire stripping machine, the second end of the bending rod 1 is movably inserted into the casing 101 of the automatic wire stripping machine, and a sleeve is fixed inside the casing 101 of the automatic wire stripping machine. Set outside the second end of the bending rod 1, it is used to support the support block of the bending rod 1, and the longitudinal axis of the bending rod 1 is perpendicular to the forward input direction of the electric wire 200 on the automatic wire stripping machine,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com