Manufacturing method of color concrete fancy permeable terrace

A technology of colored concrete and permeable floor, applied in the direction of building structure, building, floor, etc., can solve the problems of rough surface structure, no pattern, pattern, rigid shape of permeable floor, etc., and achieve high water permeability. , rich patterns, simple construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

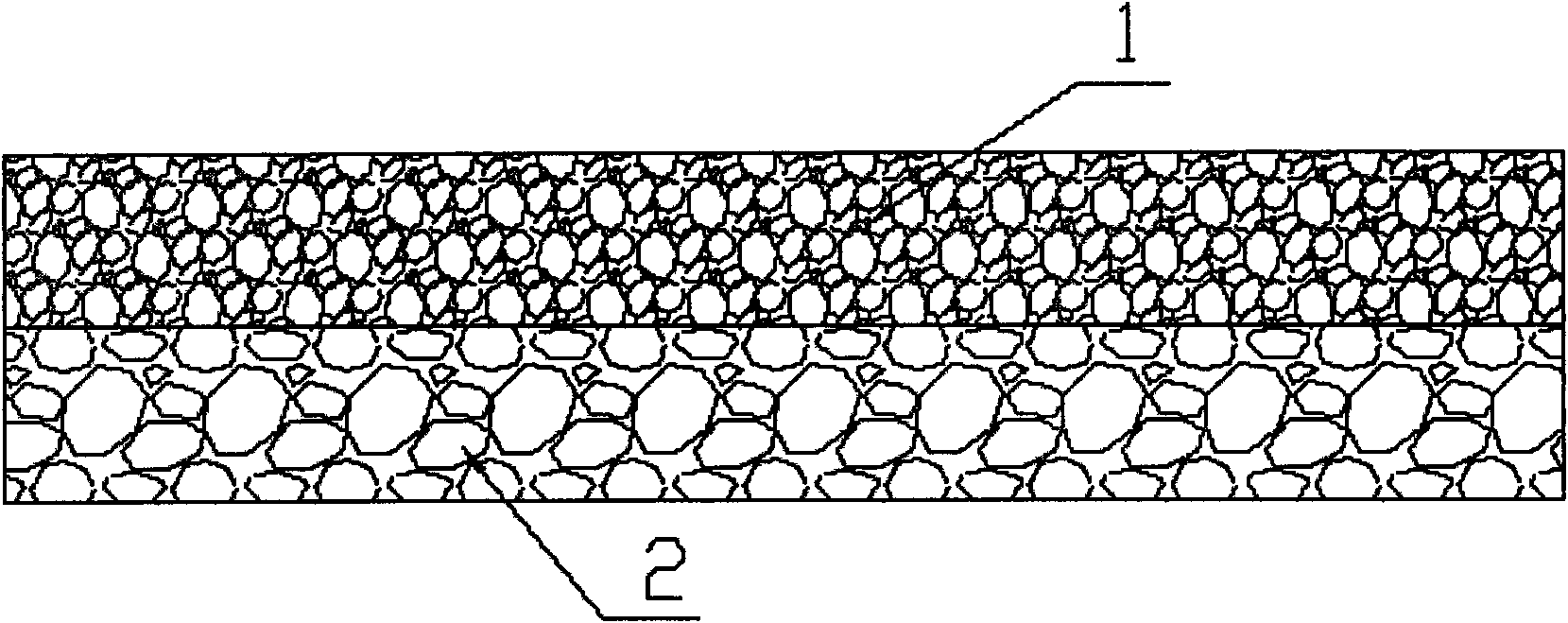

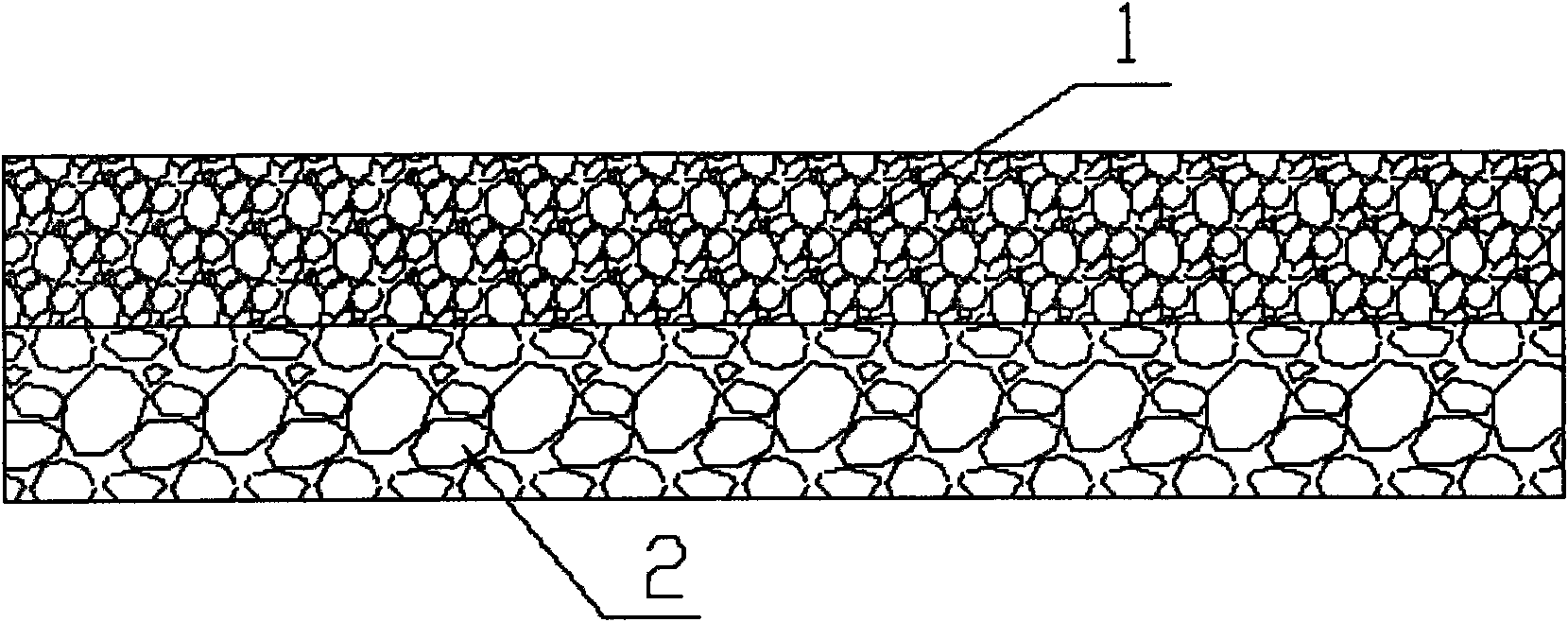

[0023] like figure 1 As shown, the manufacturing method of colored concrete fancy permeable floor, its manufacturing steps are:

[0024] (1) Compact the plain soil on the ground: first use a compactor to compact the plain soil so that there is no empty shell and no air bubbles;

[0025] (2) Sand and stone at the base: the surface of plain soil is laid with sand frame stones, and the thickness of the sand frame stones is 10 cm, which makes the base layer of the floor more stable;

[0026] (3) The flat-plate vibrator vibrates the ground base layer, and the vibration frequency of the permeable concrete leveler is 48hz, and all the time depends on the thickness.

[0027] (4) Water-permeable material base paving: The weight ratio of raw materials used in the base is: 1000 stones, 300 gray cement, 81 water, 1.5 Nai series water reducing agent, 15 silica powder, 3 disperse latex powder, Wacker rubber powder 1.5, water-based resin 1.5, polypropylene monofilament fiber 1.5; stir the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com