Environment-friendly wallpaper polystyrene foam and preparation method thereof as well as wallpaper

A styrofoam and environmentally friendly technology, applied in the field of decorative materials, can solve problems that are contrary to the concept of residents' healthy life, do not meet the requirements of environmental protection policies, and migration of plasticizers on the surface of wallpaper, so as to reduce the cost of manpower cleaning and improve stability and scrub resistance, the effect of improving product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

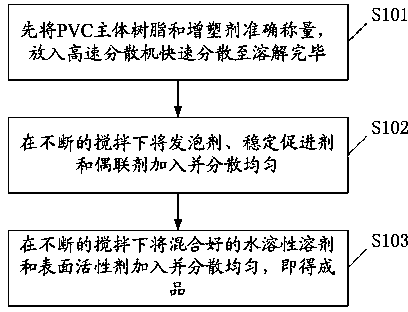

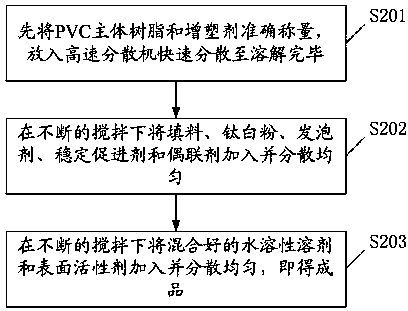

[0124] As a better embodiment of the present invention, the raw material of the environment-friendly wallpaper foam glue also includes 5-10% filler and 3-8% titanium dioxide, when the raw material also includes filler and titanium dioxide, the preparation method can be see figure 2 ,include:

[0125] S201. Accurately weigh the main PVC resin and plasticizer, put them into a high-speed disperser and quickly disperse until the dissolution is complete;

[0126] S202. Add filler, titanium dioxide, foaming agent, stability accelerator and coupling agent under continuous stirring and disperse evenly;

[0127] S203, under continuous stirring, add the mixed water-soluble solvent and surfactant and disperse evenly to obtain the finished product.

[0128] figure 2 The main raw material formula of the environmentally friendly wallpaper foam glue shown is as follows:

[0129] PVC main resin 32-60%

[0130] Plasticizer 15-30%

[0131] Foaming agent 1-10%

[0132] Water-soluble sol...

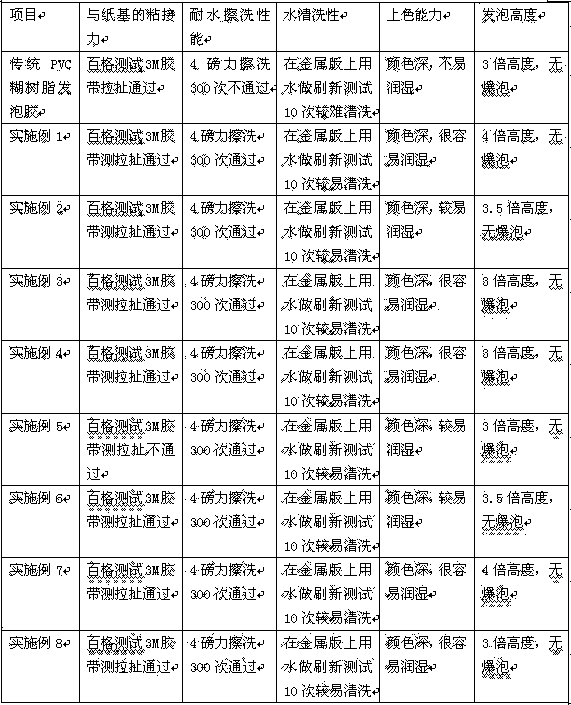

Embodiment 1

[0154] (1) Raw material formula

[0155] PVC main resin 32%

[0156] Plasticizer 30%

[0157] Foaming agent 10%

[0158] Water-soluble solvent 10%

[0159] Stabilizer 10%

[0160] Surfactant 7%

[0161] Coupling agent 1%;

[0162] Wherein, described plasticizer selects epoxy soybean oil for use;

[0163] Described tensio-active agent selects sodium lauryl sulfate for use;

[0164] Described water-soluble solvent selects ethylene glycol for use;

[0165] The PVC main resin is selected as a PVC paste resin with a degree of polymerization of 1200 and a PVC paste resin with a degree of polymerization of 1500, and the amount ratio of the PVC paste resin with a degree of polymerization of 1200 to the PVC paste resin with a degree of polymerization of 1500 is 1 :1;

[0166] Described foaming agent selects AC foaming agent for use;

[0167] Described stability accelerator selects barium stearate and calcium stearate for use, and the consumption ratio of barium stearate and c...

Embodiment 2

[0174] (1) Raw material formula

[0175] PVC main resin 45%

[0176] Plasticizer 25%

[0177] Blowing agent 8%

[0178] Water-soluble solvent 8%

[0179] Stabilizer 8%

[0180] Surfactant 5.5%

[0181] Coupling agent 0.5%;

[0182] Wherein, described plasticizer selects dioctyl terephthalate for use;

[0183] The surfactant glyceryl stearate;

[0184] Described water-soluble solvent selects propylene glycol for use;

[0185] The PVC main resin is selected as a PVC paste resin with a degree of polymerization of 1200 and a PVC paste resin with a degree of polymerization of 1300, and the amount ratio of the PVC paste resin with a degree of polymerization of 1200 to the PVC paste resin with a degree of polymerization of 1300 is 1 :1;

[0186] Described foaming agent selects H foaming agent for use;

[0187] Described stability accelerator selects calcium stearate and zinc stearate for use, and the consumption ratio of barium stearate and calcium stearate is 1:1;

[0188...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com