An outcase of refrigerator and method for manufacturing the same

A technology for housings and refrigerators, used in household refrigeration devices, printing, lighting, and heating equipment, etc., can solve problems such as difficulty in forming user images, and achieve the effect of increasing product value, improving productivity and cost efficiency, and ensuring price competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

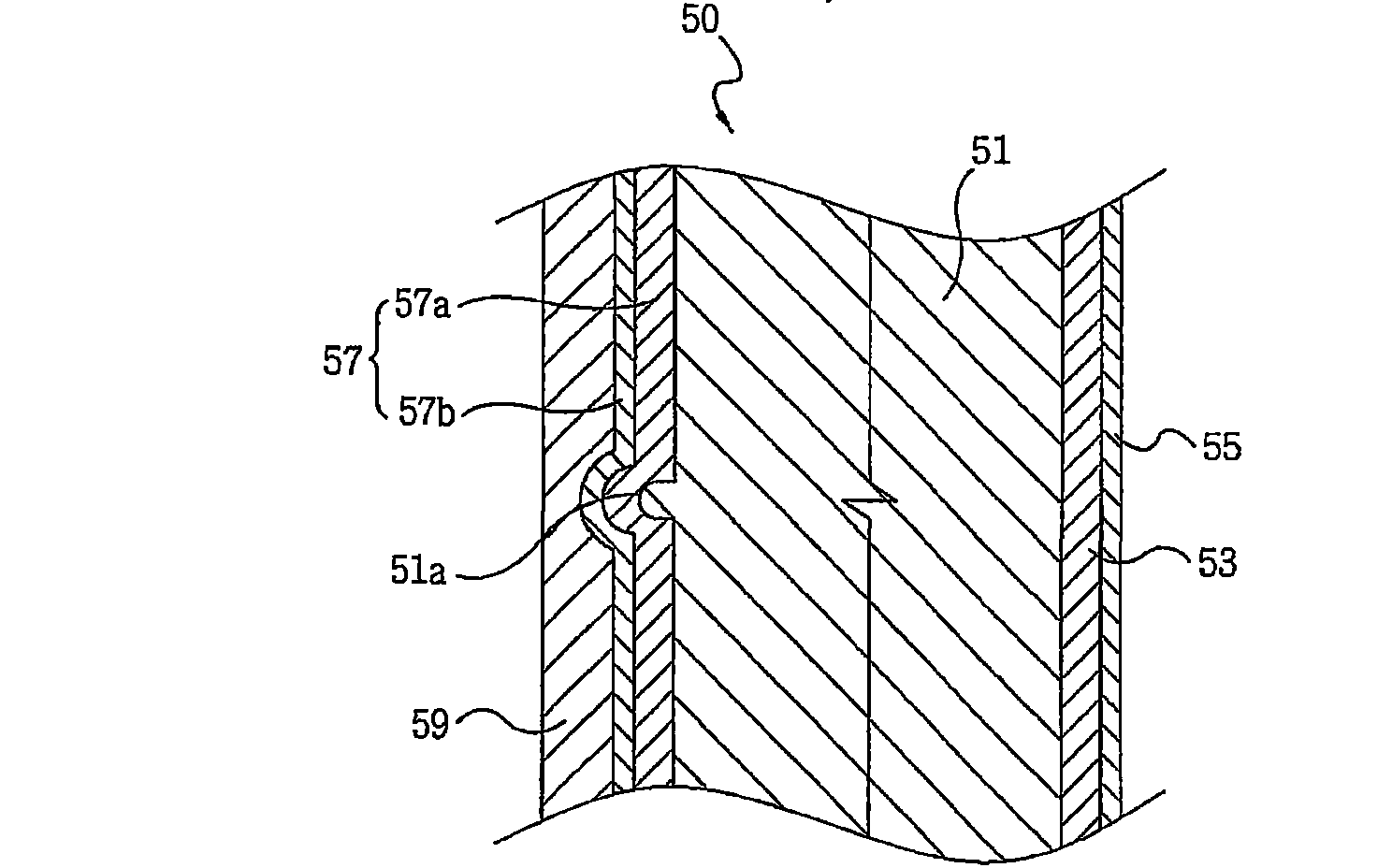

[0066] image 3 Shown is a refrigerator housing according to a preferred embodiment of the present invention. In the following description, for the figure 1 The same elements are given the same reference numerals.

[0067] refer to image 3 , the base plate 51 of the case 50 defining the appearance of the refrigerator is made of an iron plate with a thickness of about 3 mm to 10 mm. A predetermined pattern 51 a is formed on the front surface of the case 50 . When substrate 51 is rolled (60 and 60 ', see Figure 4 ) rolling, the front surface of the substrate 51 is pressed into the shape of the uneven portion 61 of the outer periphery of the roller 60 that is closely attached to the front surface of the substrate 51, thus providing the pattern 51a.

[0068] For example, if the uneven portion 61 of the roll 60 is formed in waves, the pattern 51 a is formed in waves on the front surface of the substrate 51 . Here, the thickness of the pattern 51 a of the substrate 51 is det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com