Modified epoxy group acrylic acid matting resin and preparing method

An epoxy-based acrylic and matte resin technology, applied in the direction of coating, can solve the problems of poor adhesion and flexibility of the coating film, and achieve the effect of large economic effect and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

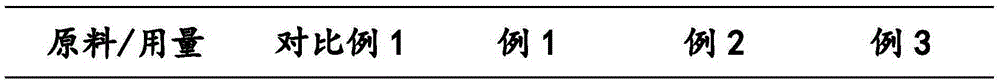

Synthetic example 1

[0023] Add 200g dioxane and methoxypolyethylene glycol acrylate in the 1000ml four-necked flask equipped with stirring device, condenser, dropping funnel, thermometer and nitrogen inlet, charge into nitrogen, be heated to reflux, Add the monomer mixture dropwise, and the dropping time is controlled to be 3.5 hours. After the dropping is completed, keep the temperature at reflux for 3 hours, dissolve 0.04g of 2,2′-azobisisobutyronitrile with 20g of dioxane, and add it within 10 minutes Into the reaction system, heat preservation and reflux reaction for 1.5 hours (recipe is shown in Table 1). Use normal pressure distillation to remove most of the solvent. When a small amount of solvent remains, you can use reduced pressure distillation to remove the solvent, discharge while hot, cool, and pulverize. Finally, the product modified epoxy acrylic resin 1 was obtained.

[0024] Synthesis Example 2 and Synthesis Example 3

[0025] The preparation method is the same as that of Exampl...

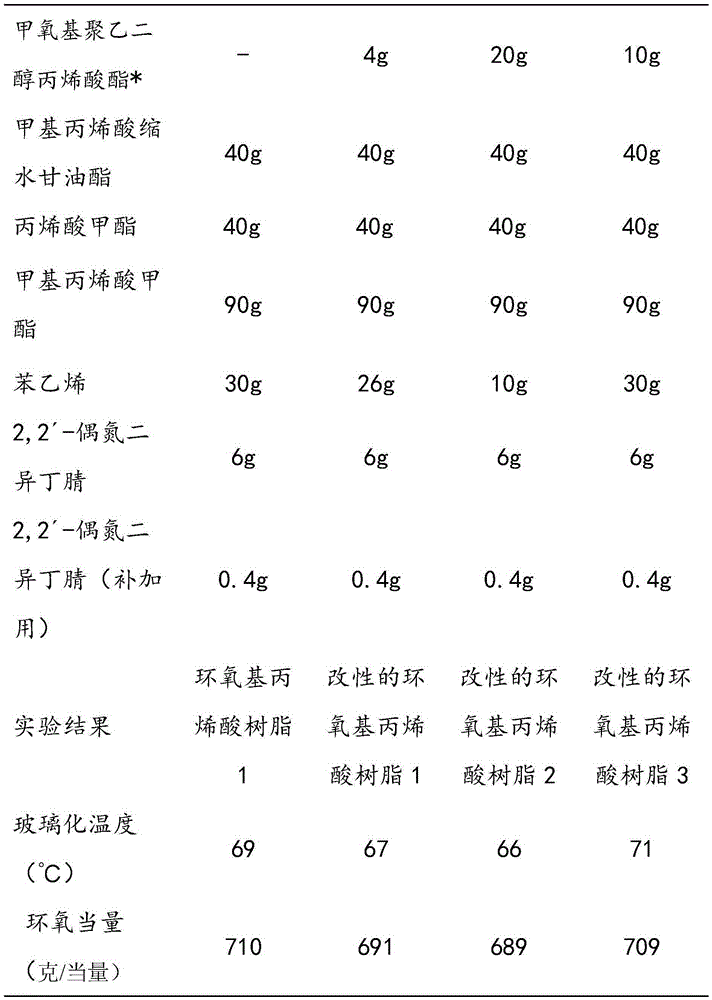

Synthetic example 4

[0033] Add 260g of methyl ethyl ketone and methoxy polyethylene glycol acrylate to a 1000ml four-necked flask equipped with a stirring device, a condenser, a dropping funnel, a thermometer and a nitrogen inlet, fill with nitrogen, heat to reflux for 1 hour, drop Add the monomer mixture, and the dropping time is controlled to be 2.5 hours. After the dropping is completed, the reflux temperature is kept for 2 hours, and 1g of benzoyl peroxide is dissolved with 20g of methyl ethyl ketone, and added to the reaction system within 10 minutes, and then kept at reflux for 1.5 Hour (recipe is shown in Table 1). Use normal pressure distillation to remove most of the solvent. When a small amount of solvent remains, you can use reduced pressure distillation to remove the solvent, discharge while hot, cool, and pulverize. Finally, the product-modified epoxy-based acrylic resin 4 was obtained.

[0034] Synthesis Example 5 and Synthesis Example 6

[0035] The preparation method is the same...

Embodiment 1-6

[0040] The modified epoxy-based acrylic resins prepared in Synthesis Examples 1-6 were applied to carboxyl polyester powder coatings according to the formula in Table 3, and a small amount of TGIC (triglycidyl isocyanurate) was added as a co-curing agent. The preparation steps of the powder coating are: dry mix the components in the formula evenly according to the proportion, then extrude through the melt kneader, the mixing temperature is 100°C, the extruded product is pressed into tablets, cooled, crushed, and passed through a 180 mesh sieve to obtain For powder coatings 1-6, the obtained powder coatings were coated on galvanized iron plates and stainless steel plates by electrostatic spraying method, and baked at 200°C for 15 minutes to obtain coating films. The properties of the coating film were measured according to the prescribed method, and the results are shown in Table 3.

[0041] The performance test methods and evaluation criteria of the coating film are as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com