Structure and production method of weft-knitted jacquard shoe upper material

A technology for weft knitting jacquard and shoe upper, which is applied in the directions of weft knitting, footwear, textiles and paper making, etc., can solve the problems of difficulty in realizing jacquard shoe upper, low output, etc., so as to reduce equipment investment and labor costs, and shorten the production process. , Lightweight and soft upper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

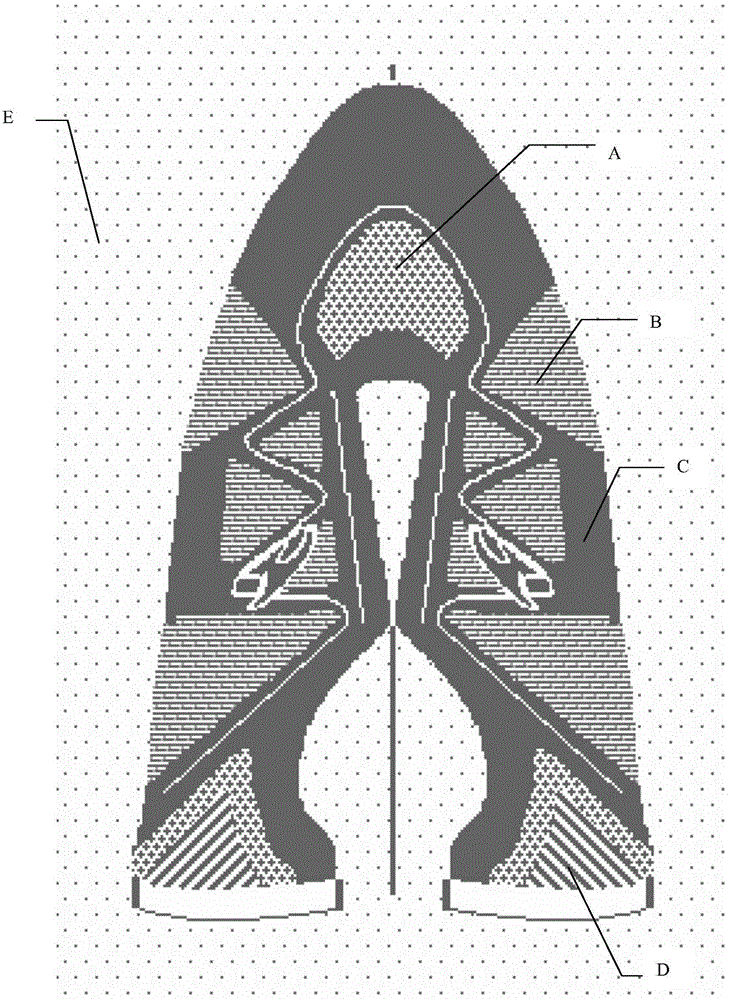

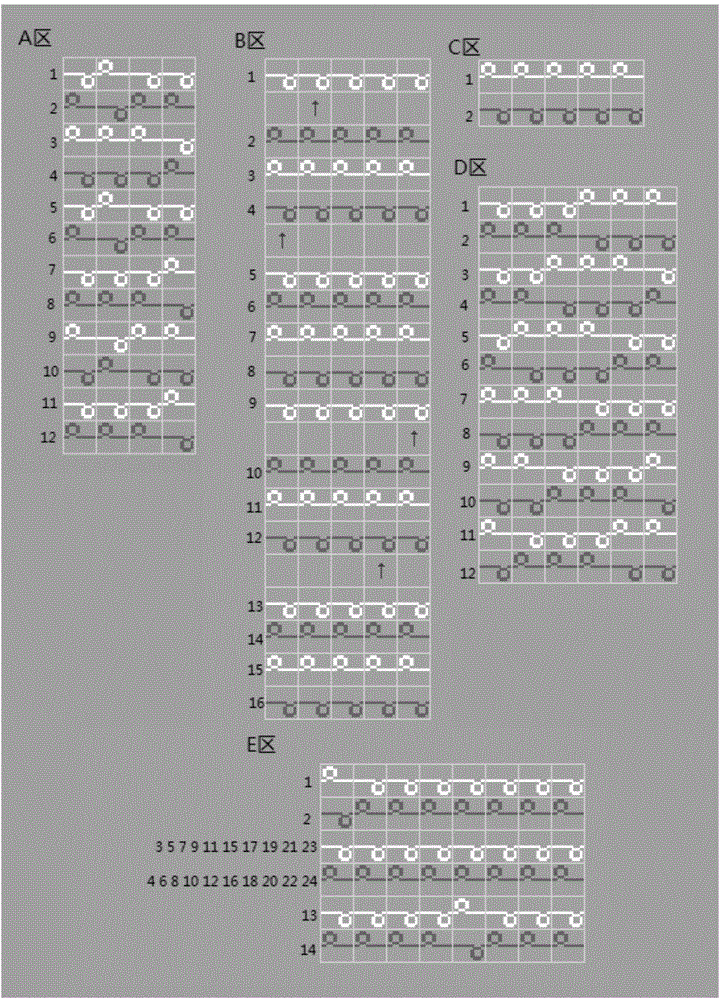

[0022] figure 1 It is a functional partition diagram of a weft-knitted jacquard upper material, figure 2 It is the weaving diagram of the organizational structure of each partition of the jacquard upper material. It is knitted on a bidirectional jacquard double-sided transfer circular weft machine, using low-melting point sheath-core colored silk as the raw material, and the air layer jacquard weave as the basic organization. Combined with the functional partitions of the upper Different organizational structures meet the performance requirements of the upper material, and the weft-knitted jacquard upper material is obtained through post-finishing processing.

[0023] The weft-knitted jacquard shoe upper material is characterized in that it is woven with polyester low-melting-point dyed yarn with a skin-core structure, the melting point of the skin-core structure of the skin-core yarn is 180°C, and the fineness is 600D. Melted under temperature and pressure, the coils of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com