Artificial stone producing process

A technology of artificial stone and production process, applied in manufacturing tools, clay preparation devices, mixing operation control devices, etc., can solve the problems of influence, obvious joints, and easy growth of mold in joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

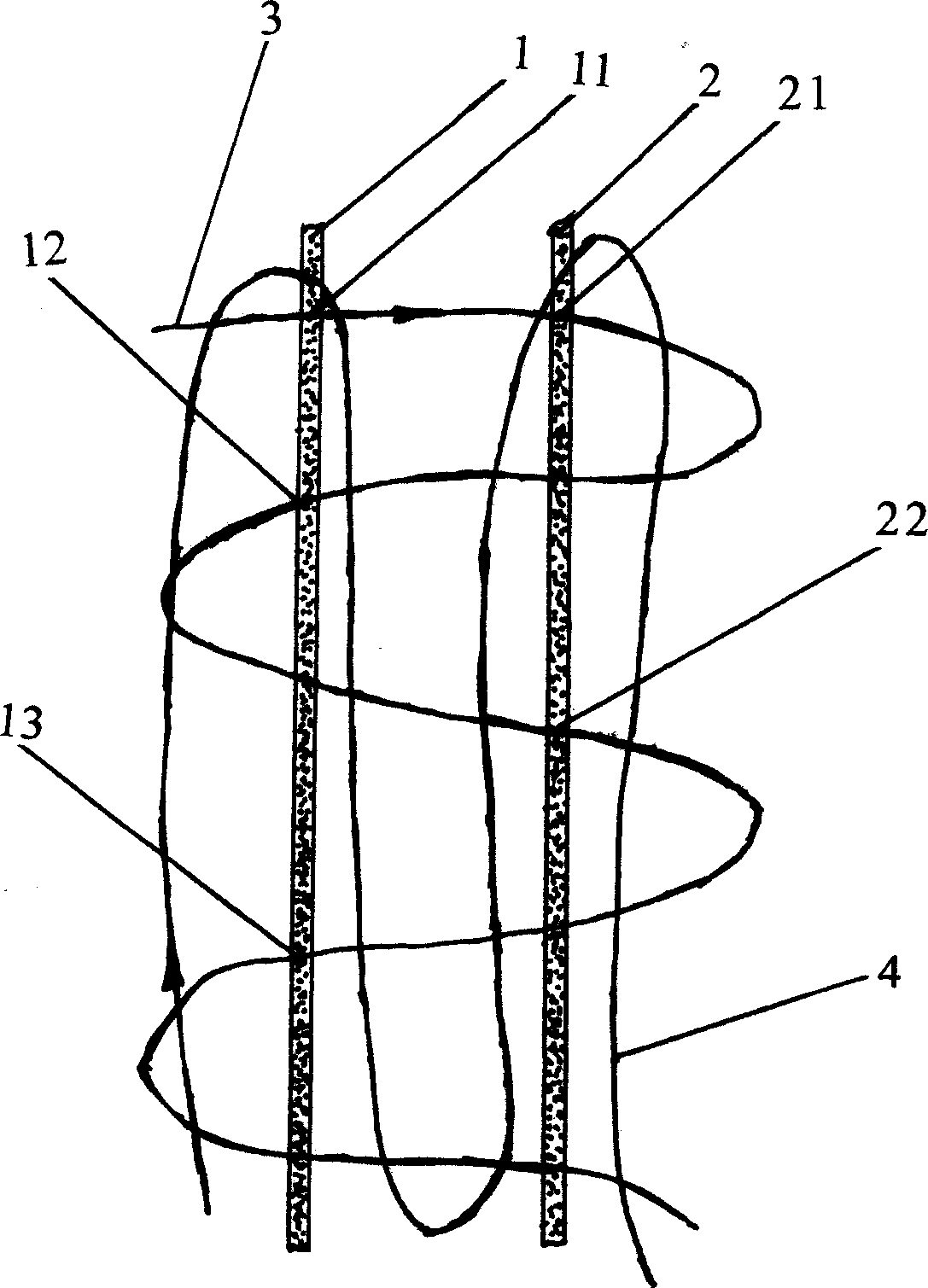

Method used

Image

Examples

Embodiment 1

[0052] Example 1: Production process of imitation white wood-grain board stone

[0053] Take a rough board whose dimensions are 2.44 meters x 0.76 meters x 0.014 meters in length x width x height and weighs 49 kg as an example, wherein the weight ratio of flower material to base material is 1:500.

[0054] (1) with base material

[0055] (1) According to the weight ratio of resin and powder 1: 2.2, the ratio of coarse powder and fine powder in powder is 1: 1, the ratio of adding 2 grams of color paste in every 1 kg of resin takes by weighing 15.3 kg of resin, Aluminum hydroxide coarse powder 16.8 kilograms, aluminum hydroxide fine powder 16.8 kilograms, white pulp 30.6 grams. The amount of accelerator and curing agent added is inversely proportional to the ambient temperature. When the temperature rises by 1°C ± 0.2°C, the amount of accelerator or curing agent added is reduced by 0.2 grams to 2 grams. When the temperature drops by 1°C ± 0.2°C, the accelerator Or the amount o...

Embodiment 2

[0072] Example 2: Imitation of Daqian Shanshui stone production process

[0073] Take a rough board whose dimensions are 2.44 meters x 0.76 meters x 0.014 meters in length x width x height and weighs 49 kg as an example, wherein the weight ratio of flower material to base material is 1:500.

[0074] The difference between the second embodiment and the first embodiment is that the artificial stone in this embodiment has patterns of two different colors, white and yellow. Therefore, in step (2), it is necessary to use white and yellow two different colors. pulp to prepare two types of flower materials respectively, and in step (3), pick up the prepared flower materials with the index finger and middle finger, and when adding them to the surface of the prepared base material in strips, the added strips of flower materials are similar The colors of the adjacent two flowers are different.

[0075]Another difference in the operation process of embodiment two and embodiment one is: ...

Embodiment 3

[0080] Example 3: Production process of imitation blue sky and white cloud stone

[0081] Take a rough board whose dimensions are 2.44 m x 0.76 m x 0.014 m in length x width x height and weighs 48 kg as an example, wherein the weight ratio of the base material to the flower material is 1:1.

[0082] (1) with base material

[0083] (1) Take by weighing 7.8 kilograms of resin, 17.2 kilograms of aluminum hydroxide coarse powder, 39 grams of white pulp. The amount of accelerator and curing agent added is inversely proportional to the ambient temperature. When the temperature rises by 1°C ± 0.2°C, the amount of accelerator or curing agent added is reduced by 0.2 grams to 1 gram. When the temperature drops by 1°C ± 0.2°C, the accelerator Or the amount of curing agent added is increased by 0.2 grams to 1 gram. When the room temperature is 25°C ± 0.2°C, the amount of accelerator added per 1 kg of resin is 6.2 grams to 6.5 grams, and the amount of curing agent added is 6.5 grams to 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com