Purified cotton linen-like bamboo joint twill and fabricating process

A technology of twill and slub, which is applied in textiles, papermaking, textiles, fabrics, etc. It can solve the problems that the slubs are not full enough, clear, poor air permeability, and not strong imitation hemp, so as to achieve good sizing effect and hemp imitation The effect of strong sense and reduction of cloth surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

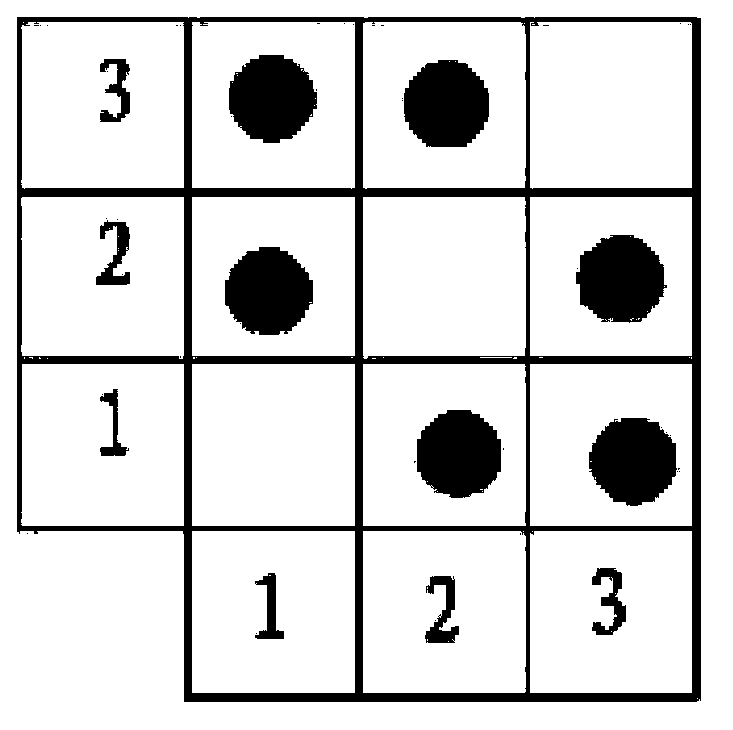

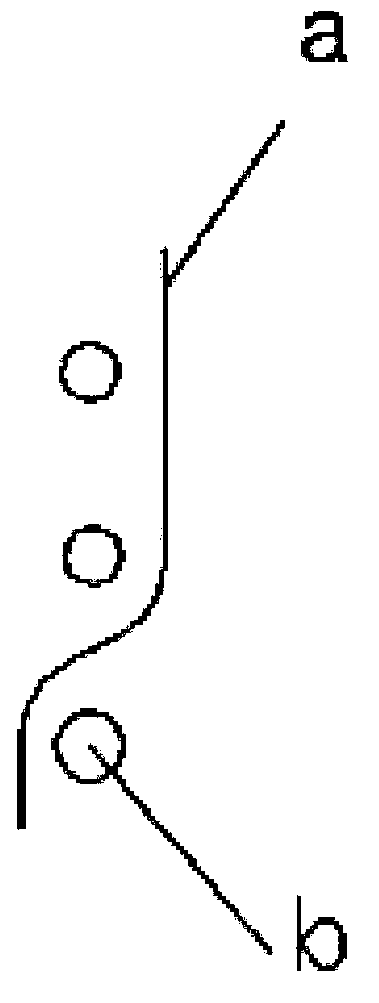

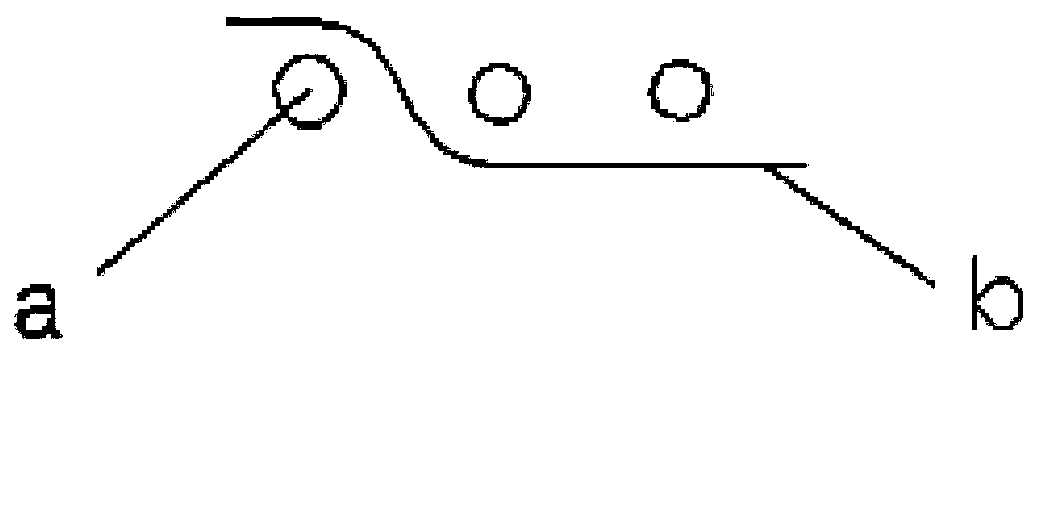

[0021] Such as Figure 1 to Figure 3 As shown, a kind of pure cotton imitation linen slub twill fabric of the present invention, warp yarn a selects cotton 58.3tex+cotton 72.9tex slub yarn for use, the slub thickness is 2 times, and the average pitch of the slub yarn is 10 centimeters to 12 centimeters , the slub length is 4 cm to 6 cm, the ratio of cotton 58.3tex and cotton 72.9tex slub yarn is 4:1, weft yarn b is cotton 58.3tex+7.8tex spandex covered yarn, warp density: 242 / 10 cm, weft density: 153.5 threads / 10 cm, machine width: 178 cm, fabric weave 2 up and 1 down to the right, see image 3 In , black dots indicate that warp yarns float on weft yarns, and blank dots indicate that weft yarns float on warp yarns. Fabric tightness: warp 69.7, weft 44.2, total tightness 83.09, breaking strength: warp 910.8N, weft 672.8N.

[0022] Weaving process: warp yarn, warping, sizing, reeding (warp knotting), adding weft yarn into weaving, cloth inspection, cloth folding, packing.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com