Fabric structure

a fabric and fabric technology, applied in the field of fabric structure, can solve the problems of low warmth keeping effect of sweat fabric, inability to easily discharge or remove sweat from inability to absorb sweat easily by the pure cotton fabric, etc., to achieve excellent warmth keeping, high cohesion, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]The technical characteristics of the present invention will become apparent with the detailed description of preferred embodiments and the illustration of related drawings as follows.

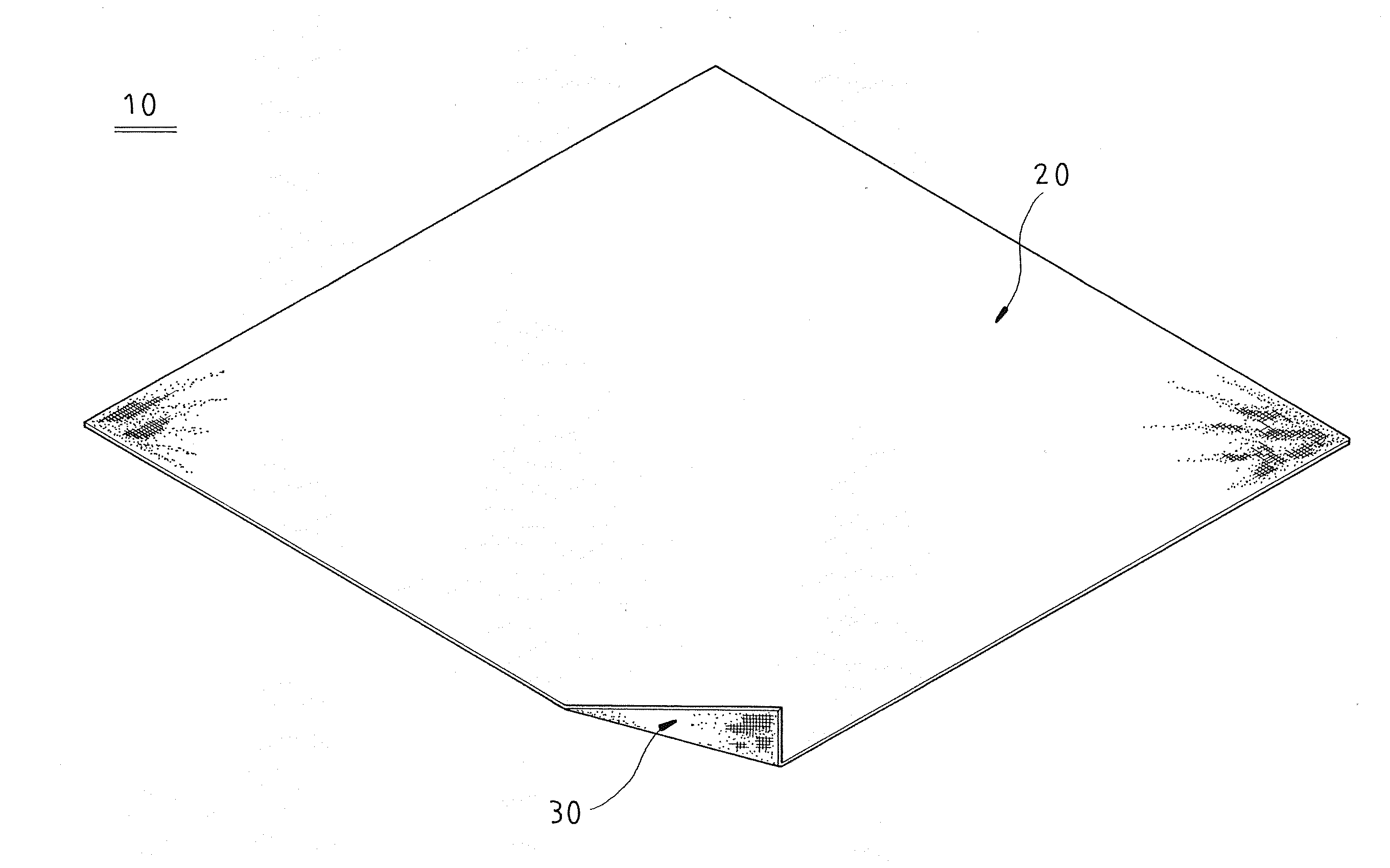

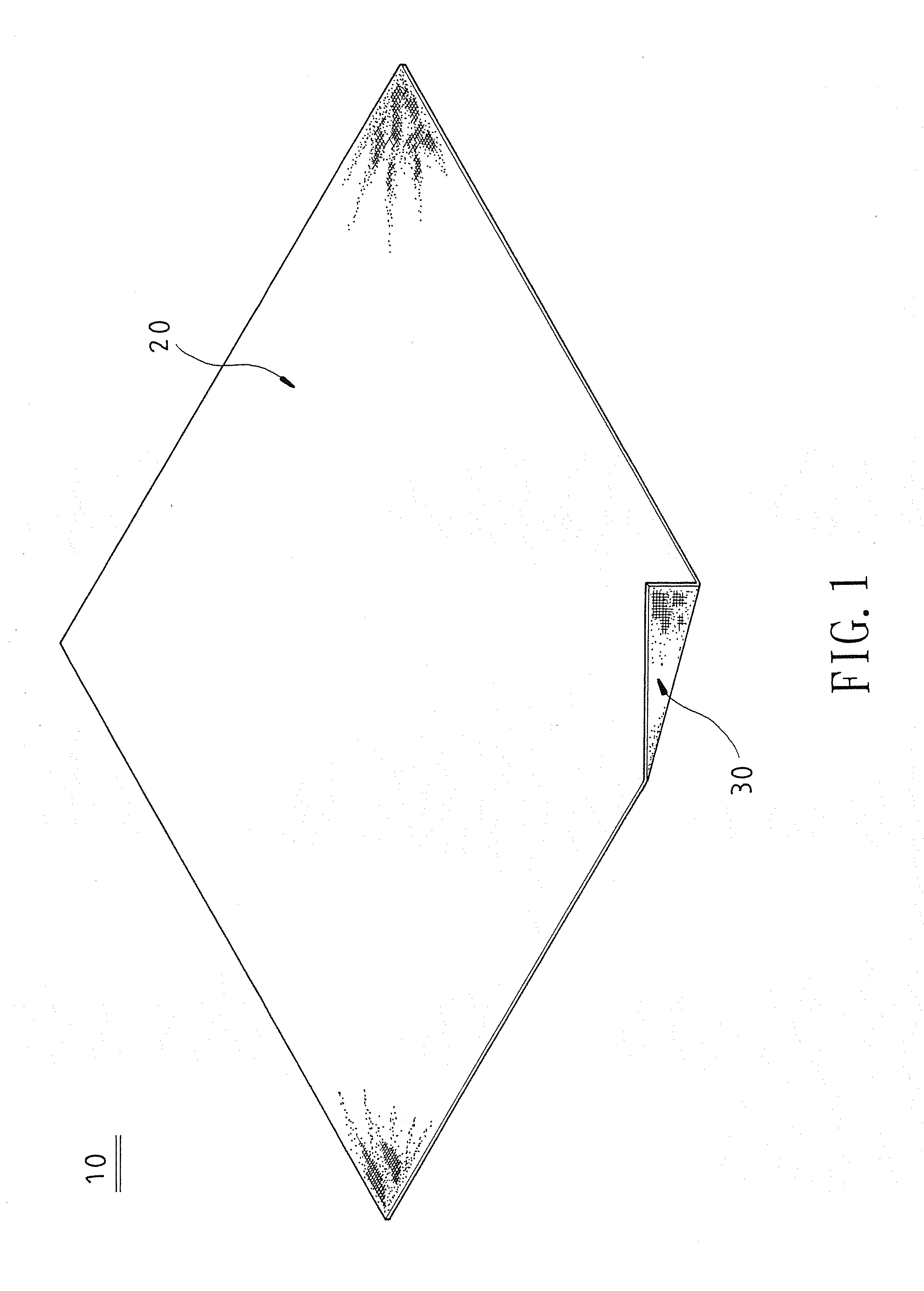

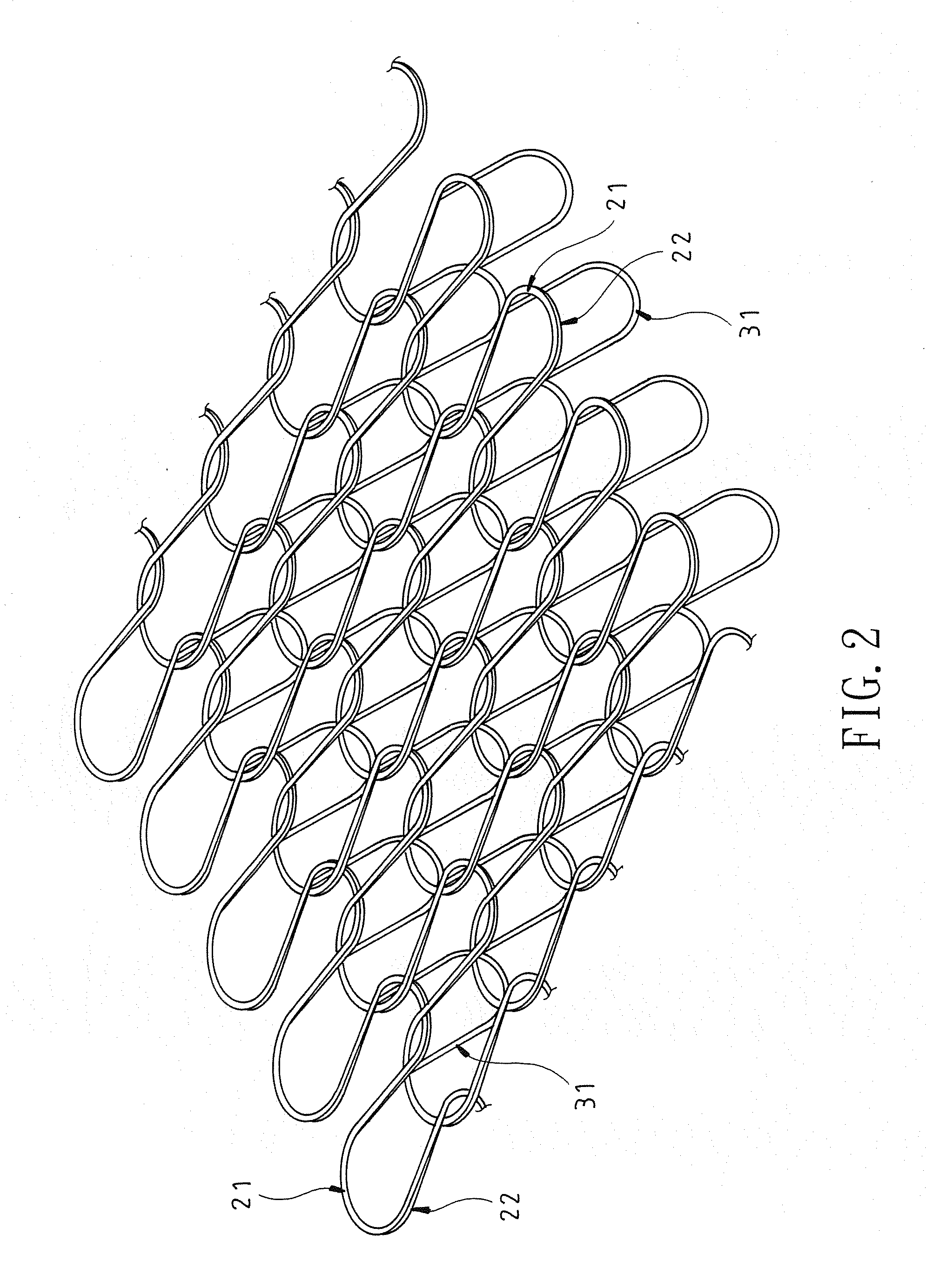

[0017]With reference to FIGS. 1 and 2 for a fabric structure in accordance with the present invention, the fabric structure (10) comprises a surface-layer textile (20) and an inner-layer textile (30), characterized in that the surface-layer textile (20) is a yarn combination formed by stacking two cotton yarns (21, 22); and the inner-layer textile (30) is made of a cashmere yarn (31) which is the best-quality cashmere processed by a plurality of manufacturing procedures such as selecting, washing, carding, dyeing and twisting yarns to manufacture a high-end cashmere product.

[0018]By a circular knitting method, two stacked cotton yarns (21, 22) and the 100% cashmere yarn (31) are knitted alternately to form the fabric structure with a cotton surface-layer textile and a cashmere inner-layer textile....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com