Preparation method of dry-sheepskin-imitated polyurethane sofa leather

A technology of polyurethane and sofa leather, which is applied in the direction of textiles and papermaking, etc., which can solve the problems of unfavorable animal protection, heavy metal content easily exceeding the standard, and low yield of genuine leather products, etc., to achieve close tactile and visual effects, improve formula and process, and color uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

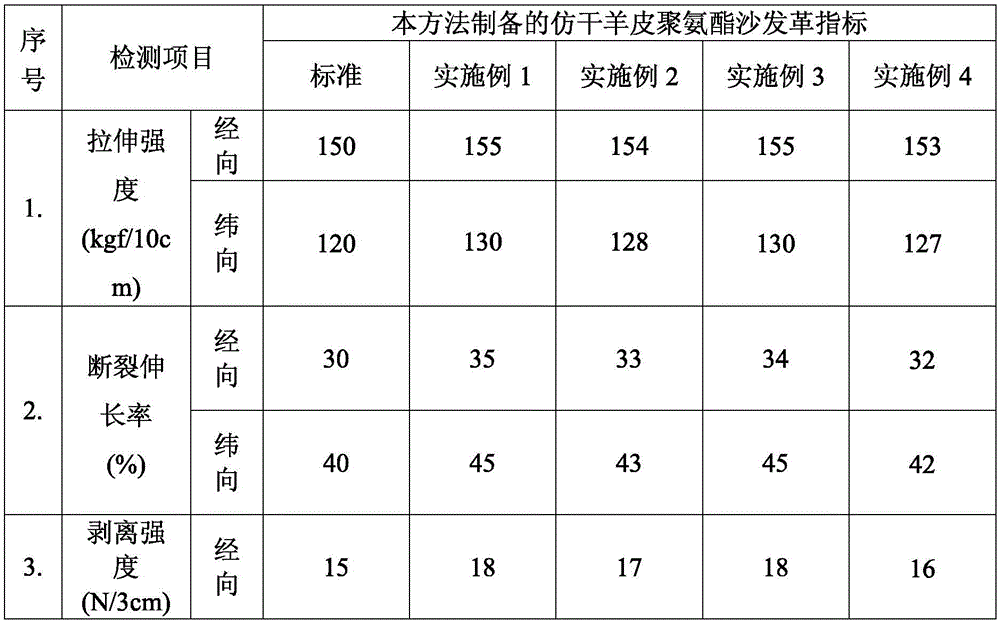

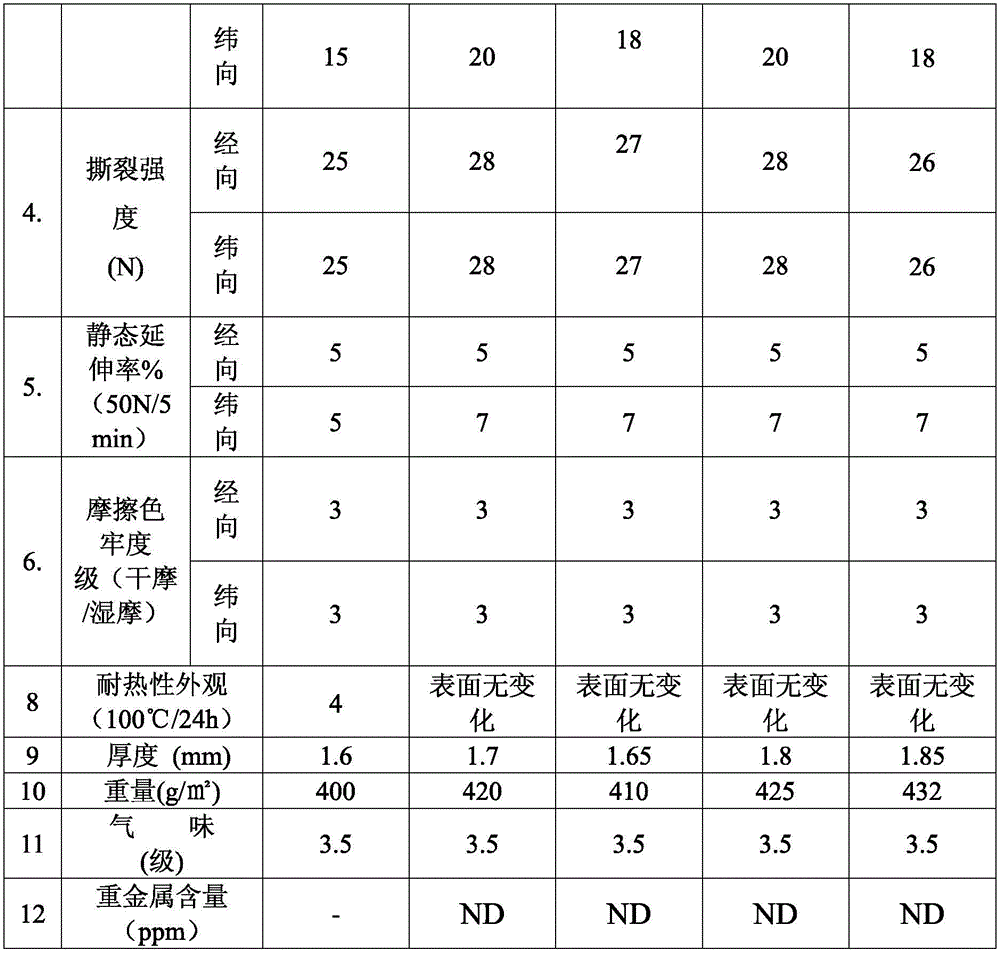

Examples

preparation example Construction

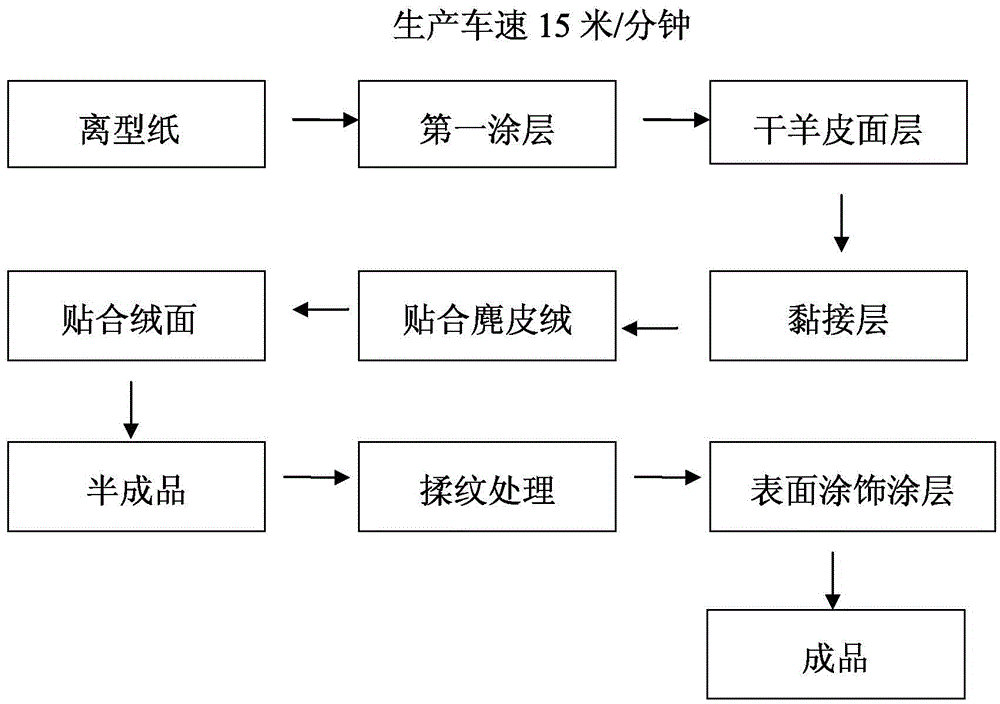

[0025] refer to figure 1 , the preparation method of imitation dry sheepskin polyurethane sofa leather provided by the invention comprises the following steps:

[0026] 1) Mix 40-60 parts by weight of 7010 polyurethane resin with a modulus of 80 and 40-60 parts by weight of RX220 cracking resin with a modulus of 80 in a ratio of 1:1, and add 40-70 parts by weight of dimethyl The combination of formamide, 30-50 parts by weight of ethyl acetate, 5-15 parts by weight of 6637 brown color paste and 2RN yellow color paste is mixed into slurry one by a mixer with a speed of 1000 rpm, and the slurry is coated with Form the first coating on the release paper, the thickness of the first coating is 0.12-0.15 mm; temperature gradient heating and drying: the oven temperature is set in steps from 80 degrees to 90 degrees to 100 degrees to 110 degrees, and the drying The drying time is 3 minutes, and the production speed is controlled at 15 m / min; the dry sheepskin surface layer with two-co...

Embodiment 1

[0037] 1) Mix 50 parts by weight of 7010 polyurethane resin with a modulus of 80 and 50 parts by weight of RX220 cracking resin with a modulus of 80 in a ratio of 1:1, add 50 parts by weight of dimethylformamide, 40 parts by weight ethyl acetate, the 6637 brown color paste of 5 parts by weight and the 2RN yellow color paste of 5 parts by weight are mixed into a slurry one by a stirrer at a speed of 1000 rpm, and the slurry is coated on the release paper to form the second One coating, the thickness of the first coating is 0.135 mm; temperature gradient heating and drying: the oven temperature is set in steps from 80 degrees to 90 degrees to 100 degrees to 110 degrees, the drying time is 3 minutes, and the production speed is controlled at 15 meters / minute; make the dry sheepskin surface layer of two-color pattern;

[0038] 2) Apply scraping slurry on the dry sheepskin surface layer prepared in step 1) to form an adhesive layer with a thickness of 0.14 mm, attach 120 grams of...

Embodiment 2

[0047] 1) Mix 40 parts by weight of 7010 polyurethane resin with a modulus of 80 and 40 parts by weight of RX220 cracking resin with a modulus of 80 in a ratio of 1:1, add 40 parts by weight of dimethylformamide, 30 parts by weight ethyl acetate, the 6637 brown color paste of 3 weight parts and the 2RN yellow color paste of 2 weight parts are mixed into a slurry one by a stirrer rotating at 1000 rpm, and the slurry is coated on the release paper to form the second One coating, the thickness of the first coating is 0.12 mm; temperature gradient heating and drying: the oven temperature is set in steps from 80 degrees to 90 degrees to 100 degrees to 110 degrees, the drying time is 3 minutes, and the production speed is controlled at 15 meters / minute; make the dry sheepskin surface layer of two-color pattern;

[0048] 2) Apply scraping slurry on the dry sheepskin surface layer prepared in step 1) to form an adhesive layer with a thickness of 0.12 mm, attach 110 grams of suede to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com