Manufacturing process of high-emulation chamois leather fabric

A manufacturing process and suede technology, which is applied in the field of manufacturing process of imitation suede fabrics, can solve the problems of limiting the application field of suede fabrics, cold resistance, air permeability to touch, unsatisfactory moisture permeability, and low added value, etc. To achieve the effect of bright color, high product added value and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

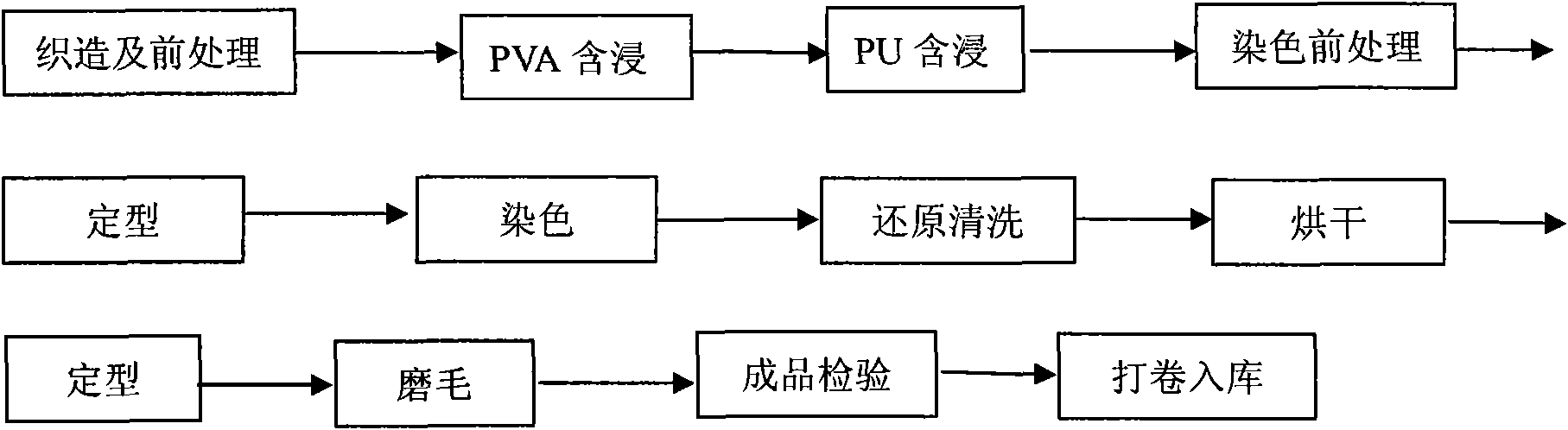

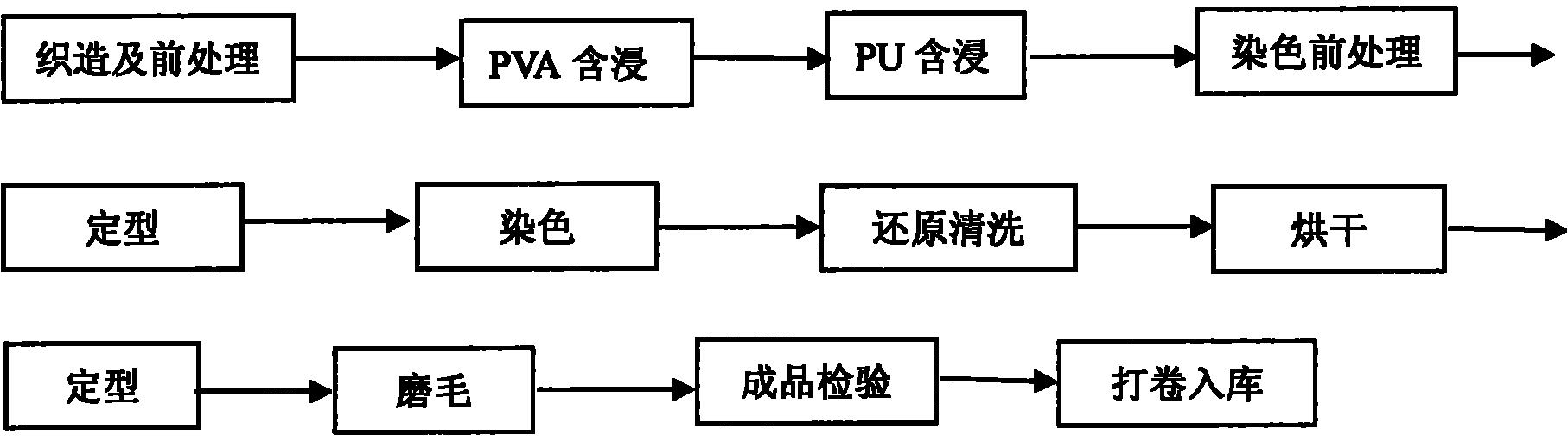

[0013] Embodiment 1: as figure 1 As shown, the manufacturing process of high-simulation suede fabric is: a. Weaving and pre-treatment: first use the loom to weave gray cloth, and then carry out fiber opening, shaping, napping and shearing pre-treatment on the gray cloth, b. PVA impregnation: in PVA The gray cloth is impregnated in the aqueous solution, the temperature of the PVA aqueous solution is controlled at 60°C, the impregnation speed of the gray cloth is 20 m / min, the pressure between the rolling pipes through which the impregnated cloth passes is 0.01MPa, and the drying temperature is controlled at 130°C, c .PU impregnation: In the mixture of PU resin and DMF, the gray cloth is impregnated with PU. The impregnation speed of the gray cloth is controlled at 15 m / min. The pressure between the rolling pipes through which the impregnated cloth passes is 0.02 MPa. The impregnated cloth is coagulated by a coagulation bath, washed and dried, d. pre-dyeing treatment, the above-...

Embodiment 2

[0014] Embodiment 2: as figure 1 As shown, the manufacturing process of high-simulation suede fabric is: a. Weaving and pre-treatment: first use the loom to weave gray cloth, and then carry out fiber opening, shaping, napping and shearing pre-treatment on the gray cloth, b. PVA impregnation: in PVA The gray cloth is impregnated in the aqueous solution, the temperature of the PVA aqueous solution is controlled at 98°C, the impregnation speed of the gray cloth is 6 m / min, the pressure between the rolling pipes through which the impregnated cloth passes is 0.2 MPa, and the drying temperature is controlled at 180°C, c .PU impregnation: In the mixture of PU resin and DMF, the gray cloth is impregnated with PU. The impregnation speed of the gray cloth is controlled at 7 m / min. The pressure between the rolling pipes through which the impregnated cloth passes is 0.15 MPa. The impregnated cloth is coagulated by a coagulation bath, washed and dried, d. pre-dyeing treatment, the above-me...

Embodiment 3

[0015] Embodiment 3: every 100 kilograms of PVA aqueous solution is made up of mixing 2 kilograms of PVA and 98 kilograms of water. Every 100 kilograms of PU resin and DMF mixture is composed of 5 kilograms of PU resin and 95 kilograms of DMF. Every 100 kg of DMF aqueous solution is composed of 10 kg of DMF and 90 kg of water. Every 100 kilograms of dyeing pre-treatment cleaning agents are made up of 1 kilogram of scouring agent, 1 kilogram of penetrating agent, 5 kilograms of liquid caustic soda, 1 kilogram of deoiling spirit and 92 kilograms of water, and all the other are with embodiment 1 or embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com