Super-soft, stereoscopic and heat-preservation suedette knitted fabric and preparation method thereof

A technology of knitted fabrics and suede, which is applied in the field of knitted fabrics, can solve problems such as horizontal roads on the fabric surface, uneven fiber opening, etc., and achieve good gloss, good warmth retention effect, excellent touch and luster effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

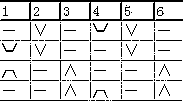

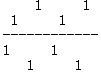

[0016] Example 1, such as figure 1 and figure 2 As shown, a supersoft, three-dimensional, warm suede-like knitted fabric and its preparation method include the following steps: Step A: select composite yarns and spandex yarns with different shrinkage ratios to be woven with an intermediate air layer by weaving equipment The blank of the structure; in step A, the composite yarn of different shrinkage ratios and spandex yarn are woven into an air layer structure by a multi-track double-sided circular weft machine. DTY)(S), the 1st route is the weaving cycle of floating thread, tuck, tuck, floating thread, the 4th road is the cycle of tuck, floating thread, floating thread, tuck weaving structure, the 2nd and 5th roads are selected 75D / 36F(DTY)(S)+20D spandex yarn, the 2nd and 5th routes are looping, looping, floating and floating weaving structure loops, the 3rd and 6th routes use 80D / 156F (DTY with different shrinkage ratios) Composite yarn) (S) + 20D spandex blended yarn, t...

Embodiment 2

[0023] Example 2, such as figure 1 and figure 2 As shown, a supersoft, three-dimensional, warm suede-like knitted fabric and its preparation method include the following steps: Step A: select composite yarns and spandex yarns with different shrinkage ratios to be woven with an intermediate air layer by weaving equipment The blank of the structure; in step A, the composite yarn of different shrinkage ratios and spandex yarn are woven into an air layer structure by a multi-track double-sided circular weft machine. DTY)(S), the 1st route is the weaving cycle of floating thread, tuck, tuck, floating thread, the 4th road is the cycle of tuck, floating thread, floating thread, tuck weaving structure, the 2nd and 5th roads are selected 75D / 36F(DTY)(S)+20D spandex yarn, the 2nd and 5th routes are looping, looping, floating and floating weaving structure loops, the 3rd and 6th routes use 80D / 156F (DTY with different shrinkage ratios) Composite yarn) (S) + 20D spandex blended yarn, t...

Embodiment 3

[0030] Example 3, such as figure 1 and figure 2As shown, a supersoft, three-dimensional, warm suede-like knitted fabric and its preparation method include the following steps: Step A: select composite yarns and spandex yarns with different shrinkage ratios to be woven with an intermediate air layer by weaving equipment The blank of the structure; in step A, the composite yarn of different shrinkage ratios and spandex yarn are woven into an air layer structure by a multi-track double-sided circular weft machine. DTY)(S), the 1st route is the weaving cycle of floating thread, tuck, tuck, floating thread, the 4th road is the cycle of tuck, floating thread, floating thread, tuck weaving structure, the 2nd and 5th roads are selected 75D / 36F(DTY)(S)+20D spandex yarn, the 2nd and 5th routes are looping, looping, floating and floating weaving structure loops, the 3rd and 6th routes use 80D / 156F (DTY with different shrinkage ratios) Composite yarn) (S) + 20D spandex blended yarn, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com