Micro suede artificial leather and manufacturing method thereof

A manufacturing method and technology of artificial leather, applied in the field of artificial leather, can solve the problems of easy shedding, poor scratch resistance, touch, air permeability and fluffy feeling, etc., and achieve good scratch resistance, improved scratch resistance, and good air permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

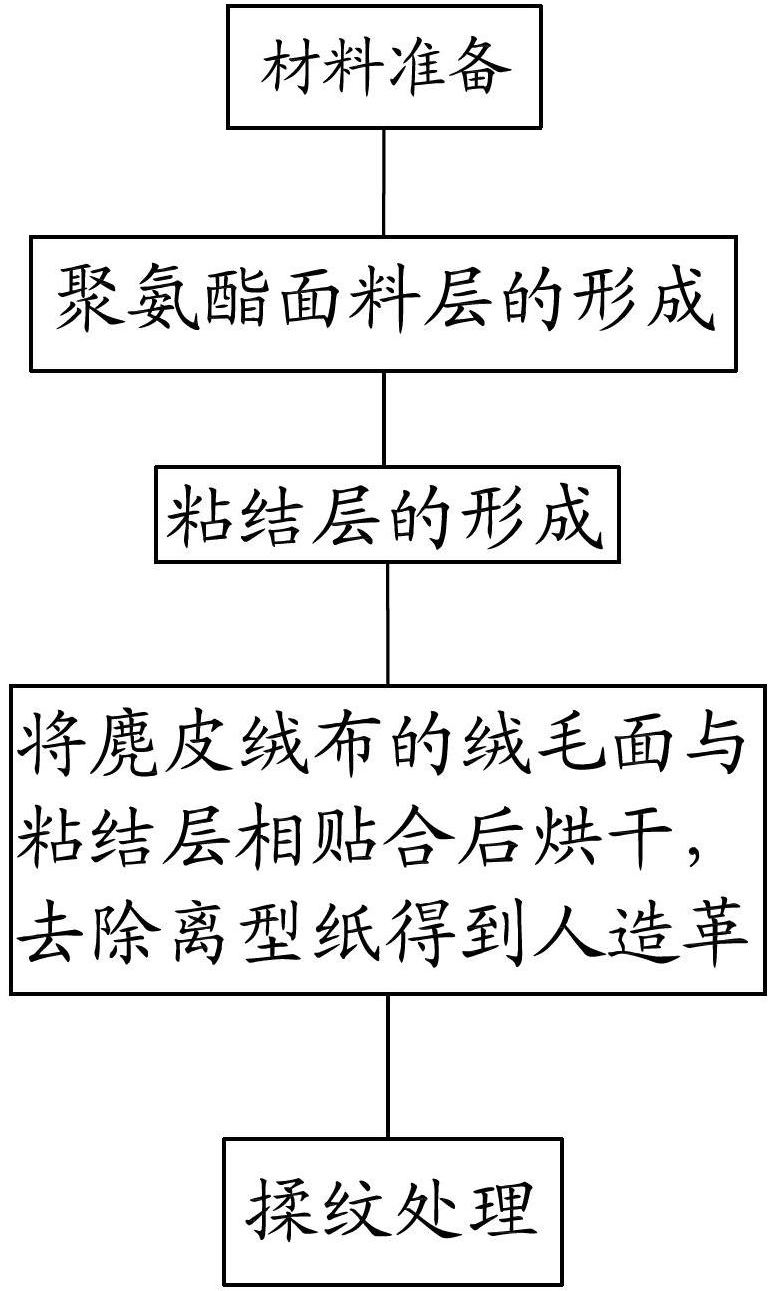

[0027] refer to figure 1 Prepare suede-like artificial leather of the present invention as shown, specifically include:

[0028] 1. Material preparation;

[0029] (1) Suede fabric: 75D144F raised base fabric;

[0030] Texture release paper: American SAPPI release paper;

[0031] Leveling agent: BYK-9565, BYK, Germany;

[0032] Water-soluble hand feeling agent: RX-110, Luoxing Chemical;

[0033] (2) Prepare polyurethane fabric slurry: mix 100 parts by weight of polyurethane resin, 50 parts by weight of dimethylformamide-butanone mixture and 0.1 part by weight of leveling agent and stir evenly for later use;

[0034] (3) Prepare polyurethane adhesive material: mix 100 parts by weight of polyurethane resin, 20 parts by weight of dimethylformamide-butanone mixture and 0.1 parts by weight of leveling agent, stir evenly and set aside;

[0035] 2. The formation of polyurethane fabric layer;

[0036] The prepared polyurethane fabric slurry is coated and scraped on the textured r...

Embodiment 2

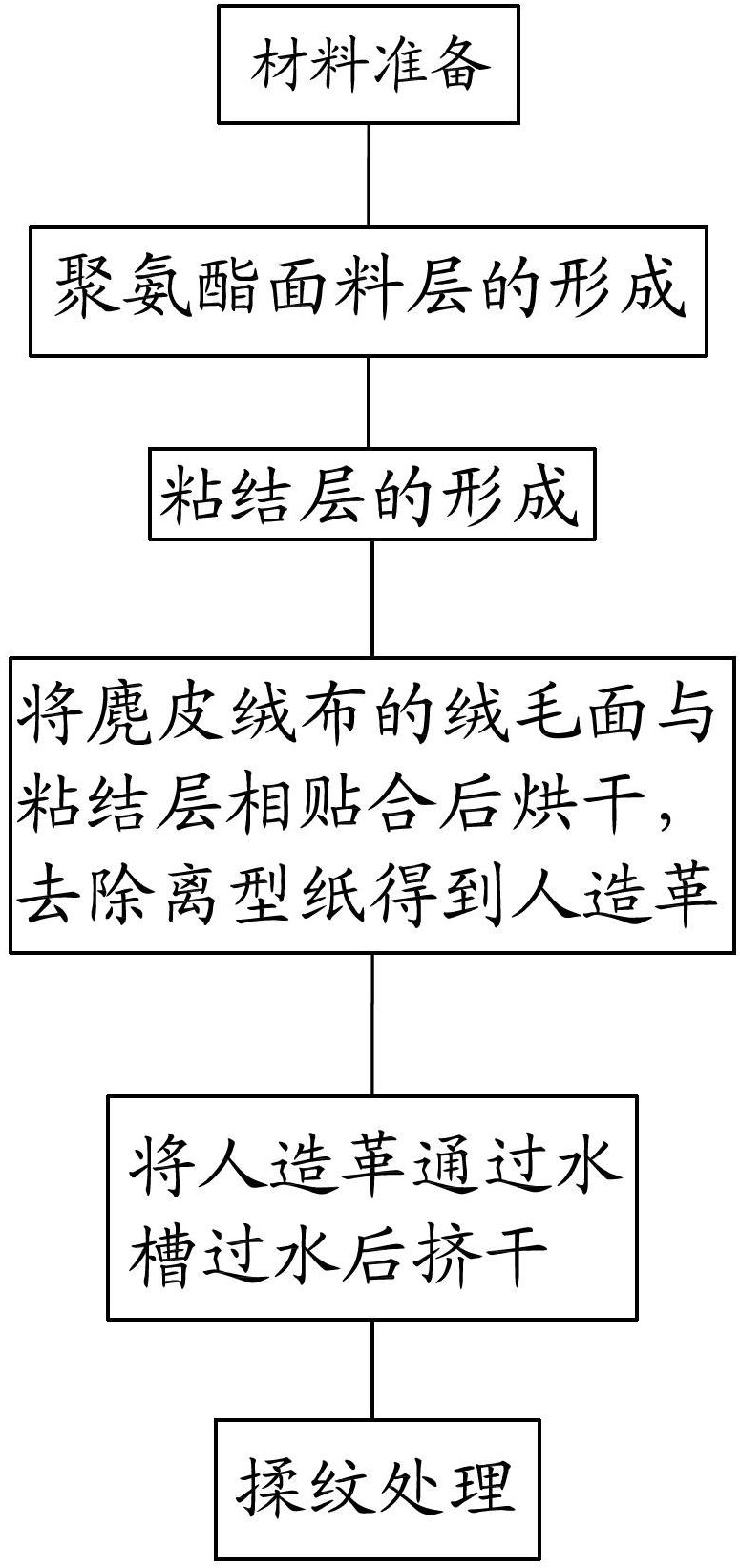

[0043] refer to figure 2 Prepare suede-like artificial leather of the present invention as shown, specifically include:

[0044] 1. Material preparation;

[0045] (1) Suede fabric: 75D144F raised base fabric;

[0046] Texture release paper: American SAPPI release paper;

[0047] Leveling agent: BYK-9565, BYK, Germany;

[0048] Water-soluble hand feeling agent: RX-110, Luoxing Chemical;

[0049] (2) Prepare polyurethane fabric slurry: mix 100 parts by weight of polyurethane resin, 80 parts by weight of dimethylformamide-butanone mixture and 0.3 parts by weight of leveling agent and stir evenly for later use;

[0050] (3) Prepare polyurethane adhesive material: mix 100 parts by weight of polyurethane resin, 50 parts by weight of dimethylformamide-butanone mixture and 0.3 parts by weight of leveling agent and stir evenly for later use;

[0051] 2. The formation of polyurethane fabric layer;

[0052] The prepared polyurethane fabric slurry is coated and scraped on the texture...

Embodiment 3

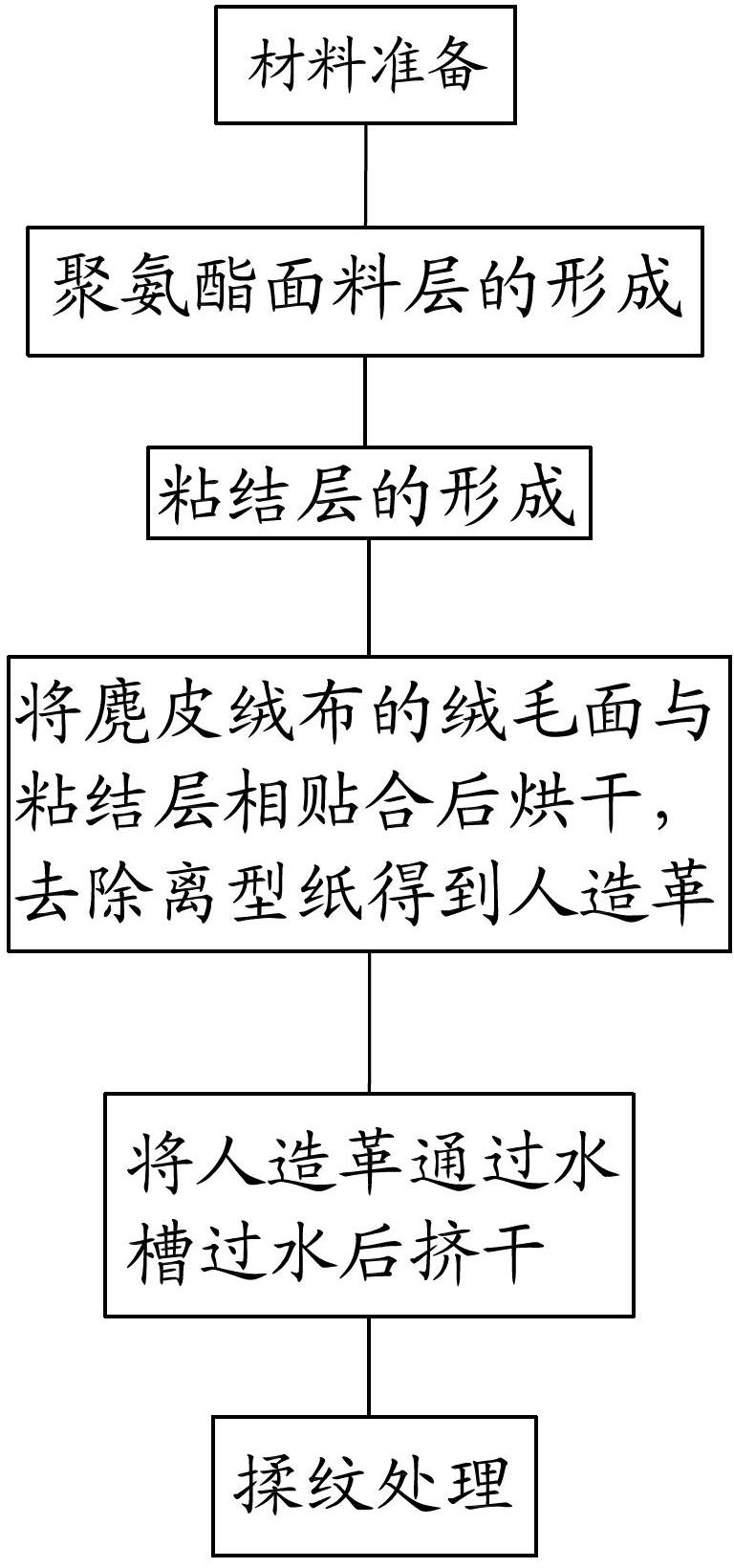

[0061] refer to figure 2 Prepare suede-like artificial leather of the present invention as shown, specifically include:

[0062] 1. Material preparation;

[0063] (1) Suede fabric: 75D144F raised base fabric;

[0064] Texture release paper: American SAPPI release paper;

[0065] Leveling agent: BYK-9565, BYK, Germany;

[0066] Water-soluble hand feeling agent: RX-110, Luoxing Chemical;

[0067] (2) Prepare polyurethane fabric slurry: mix 100 parts by weight of polyurethane resin, 60 parts by weight of dimethylformamide-butanone mixture and 0.2 parts by weight of leveling agent and stir evenly for later use;

[0068] (3) Prepare polyurethane adhesive material: mix 100 parts by weight of polyurethane resin, 30 parts by weight of dimethylformamide-butanone mixture and 0.2 parts by weight of leveling agent and stir evenly for later use;

[0069] 2. The formation of polyurethane fabric layer;

[0070] The prepared polyurethane fabric slurry is coated and scraped on the textu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com