Patents

Literature

47results about How to "Comfortable texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

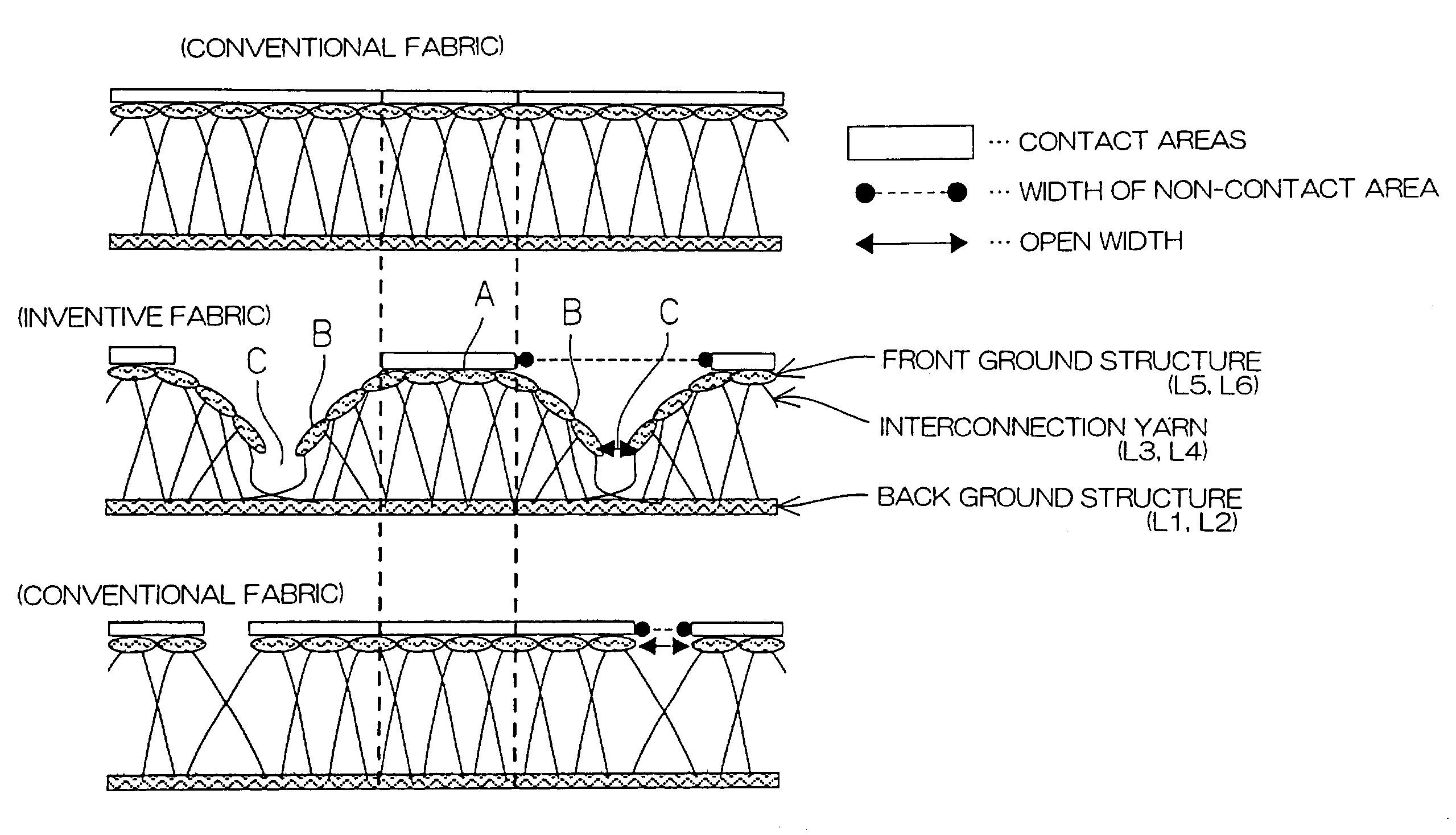

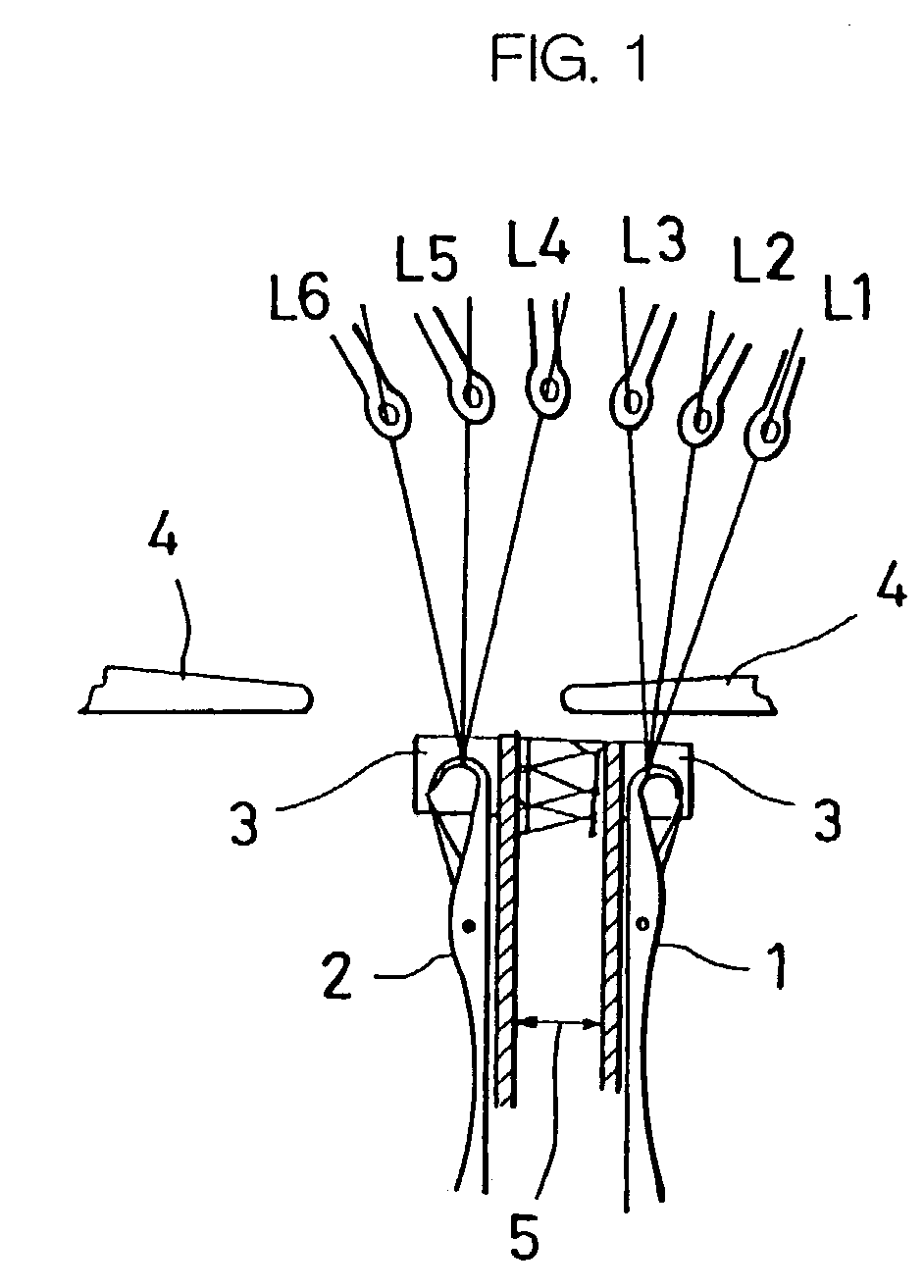

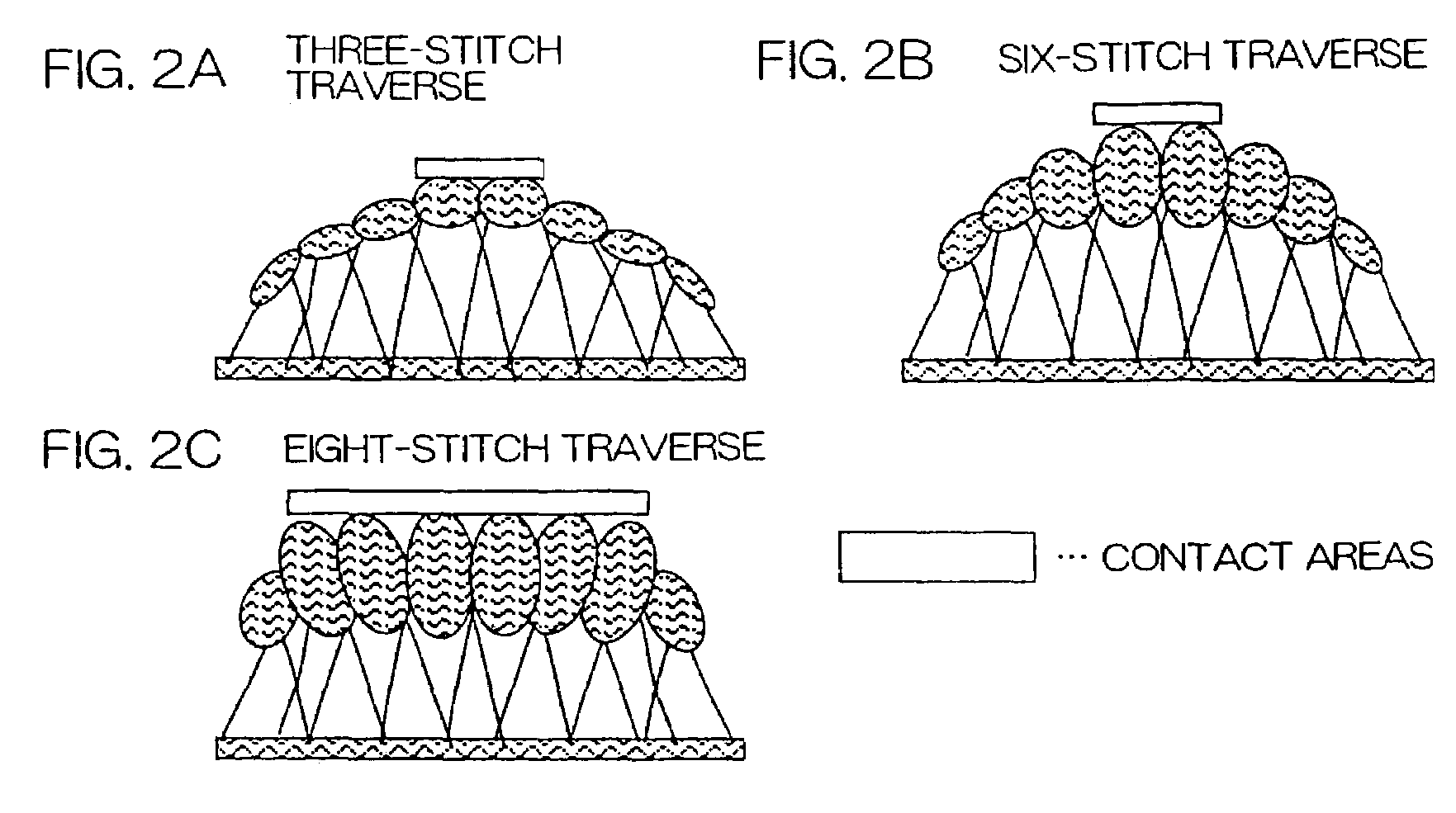

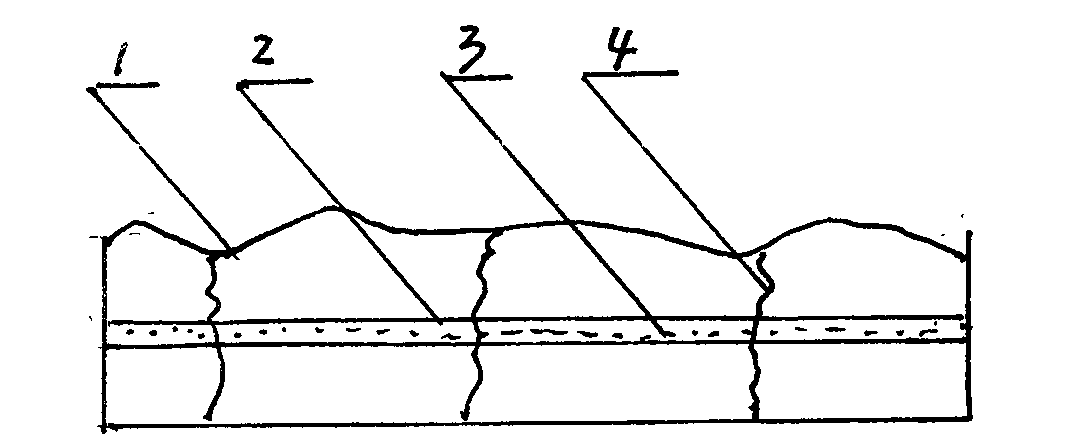

Three dimensional knitted fabric having unevenness

InactiveUS7235504B2Improve breathabilityGood cushioning propertiesOrnamental textile articlesLayered productsYarnCurve shape

A three-dimensional knitted fabric having front and back ground structures and an interconnection yarn uniting the ground structures. At least one of the front and back ground structures of the three-dimensional knitted fabric has an uneven pattern with projections and depressions having a great level difference. Ground yarns of the at least one ground structure are traversed by a predetermined traverse width so that the projections each have a curved shape having a distinct curvature in section, and cast off at predetermined intervals so that the depressions each have an opening.

Owner:SEIREN CO LTD

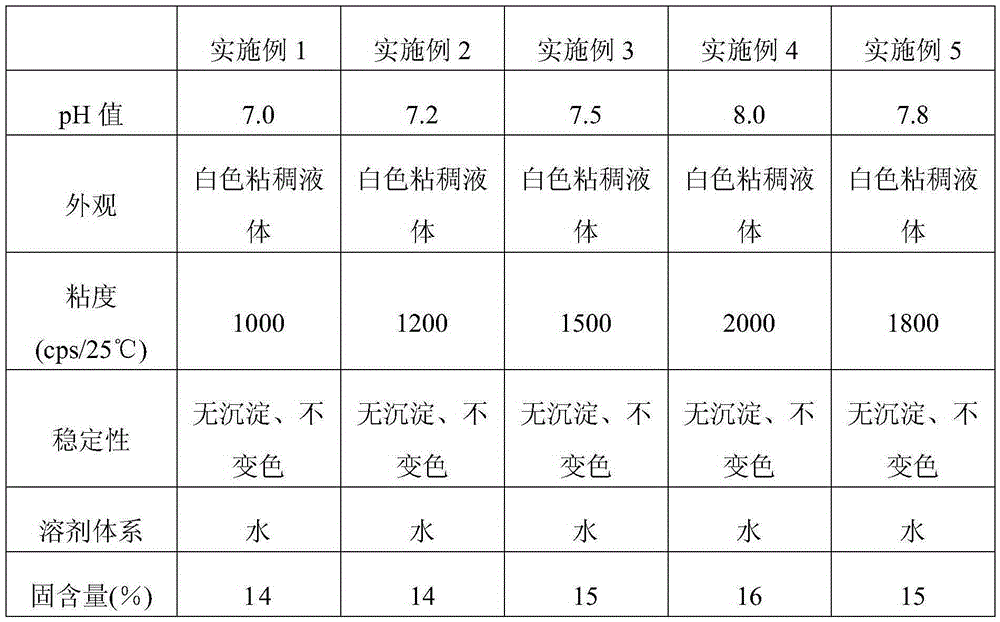

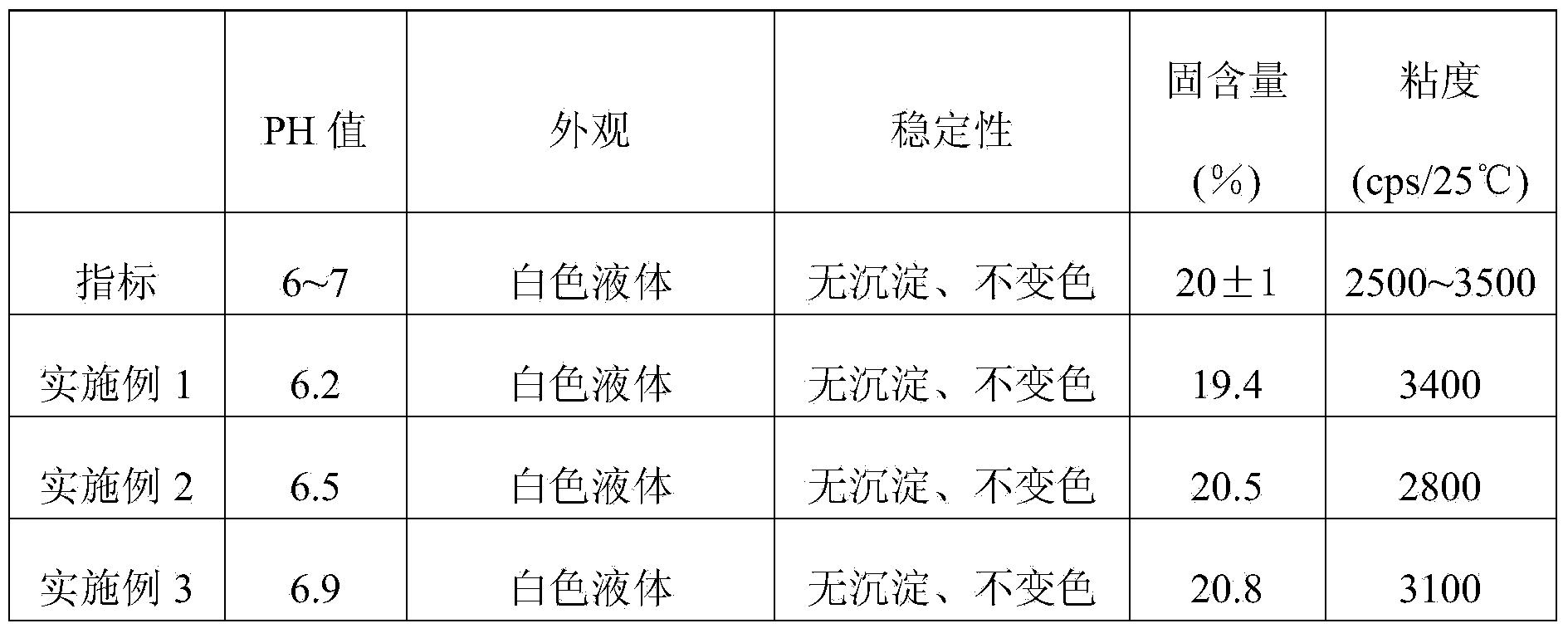

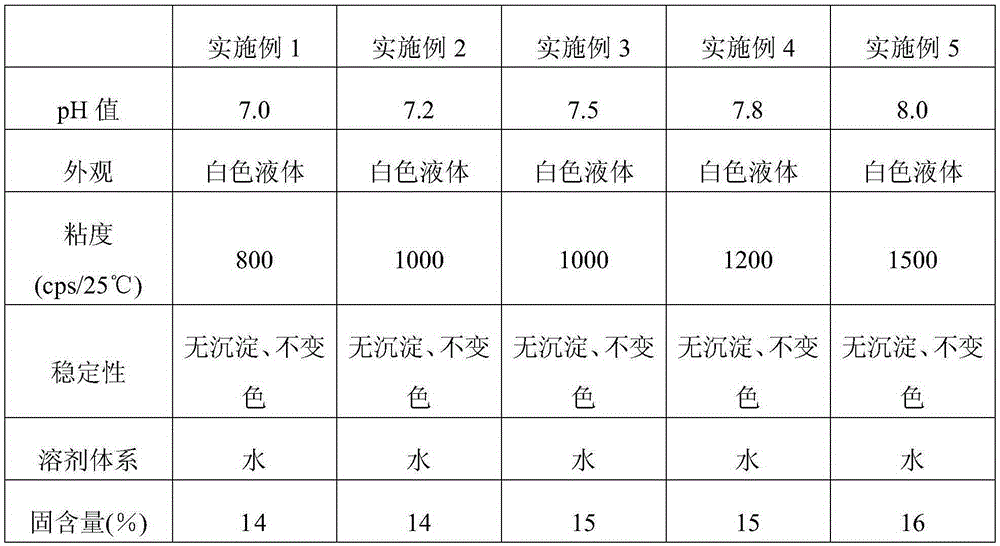

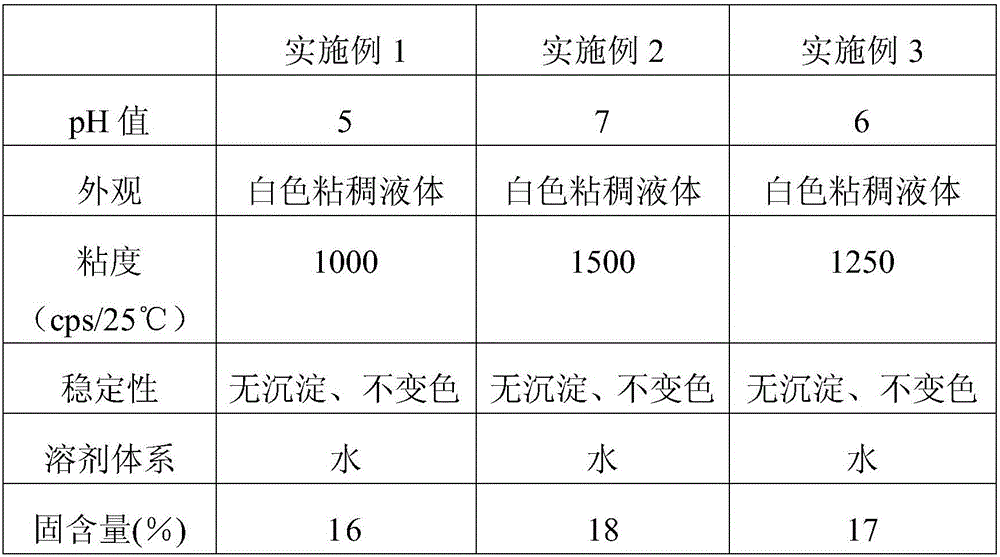

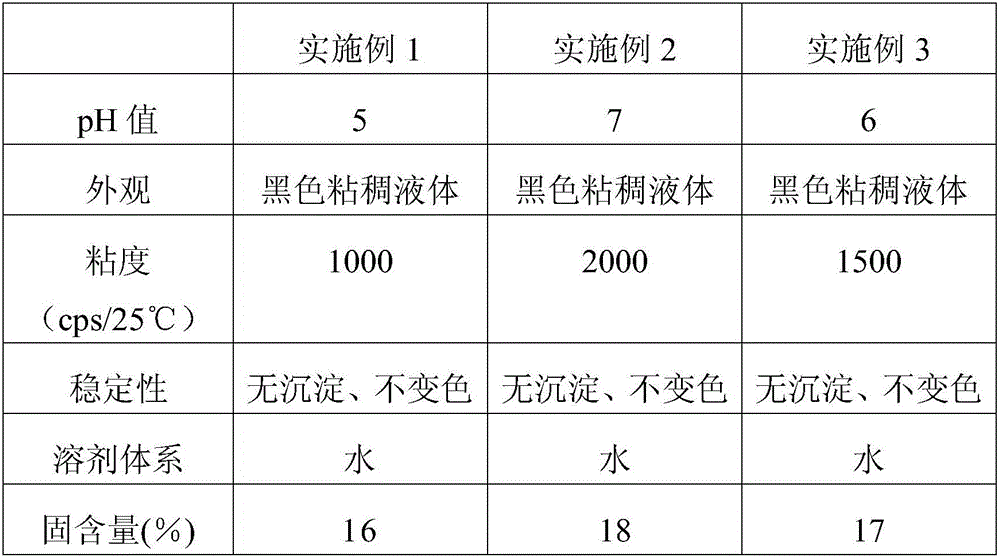

Water-based super-fogging super-blackening treating agent for synthetic leather and preparation method thereof

The invention relates to a water-based super-fogging super-blackening treating agent for synthetic leather, and the water-based super-fogging super-blackening treating agent is applied to a later period technology of the synthetic leather. The water-based super-fogging super-blackening treating agent is prepared from water-based resin, a water-based dispersing agent, a defoaming agent, silicon dioxide matting powder, a wetting agent, a Deuchem thickening agent and water. The invention further relates to a preparation method of the water-based super-fogging super-blackening treating agent for the synthetic leather. According to the water-based super-fogging super-blackening treating agent, all the components cooperate with one another and interact with one another, the synthetic leather is unique in handfeel after being treated, and the synthetic leather treated by the treating agent is natural in gloss, clear in color and luster, better in color developing and excellent in comprehensive effect, meanwhile, a prepared spraying dilute solution has the very good storage stability, and pigments are not prone to sedimentation. The water-based super-fogging super-blackening treating agent for the synthetic leather is a novel material in later period treatment and can be applied to an existing synthetic leather production line, the technology is simple, production equipment does not need to be changed, and the production cost cannot be increased.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Seamless knitting anti-electromagnetic radiation clothing and manufacturing method thereof

The invention relates to seamless knitting anti-electromagnetic radiation clothing and a manufacturing method thereof. The seamless knitting anti-electromagnetic radiation clothing consists of two layers of fabrics which are outer knitting fabric and inner shielding fabric. The outer knitting fabric comprises the following fiber compositions by weight percentage: 80-90 percent of chinlon 6 stretch yarns, 5-10 percent of chinlon 66 stretch yarns and 5-10 percent of spandex elastic fiber yarns; and the inner knitting fabric comprises the following fiber compositions by weight percentage: 50-55 percent of chinlon 6 stretch yarns and 45-50 percent of silver metal conductive fiber yarns; and after assistants such as 3 percent of leveling agents, 4 percent of detergents, 4 percent of creasing agents, 2 percent of penetrants and 0.5 percent of ammonium sulfate are added, an appropriate amount of dyes is added again. The seamless knitting anti-electromagnetic radiation clothing has the advantages of anti-electromagnetic radiation and good shielding effect and is comfortable to wear.

Owner:GUANGDONG RUIYUAN TECH

Water-based polishing treatment agent for synthetic leather and preparation method of agent

InactiveCN105442323ASmall smellProcess safetyHeat resistant fibresGrip property fibresDefoaming AgentsChemistry

The invention relates to a water-based polishing treatment agent for synthetic leather. The water-based polishing treatment agent is applied to the back-end process of the synthetic leather and comprises components as follows: water-based resin, a water-based dispersing agent, a defoaming agent, silica matting powder, a water-based brightener, a wetting agent, a Deuchem thickening agent and water. The invention further relates to a preparation method of the water-based polishing treatment agent for the synthetic leather. All components of the water-based polishing treatment agent coordinate with one another and have the combined action, the synthetic leather is unique in hand feeling after treatment and has the advantages of avoidance of cracking during baking at the high temperature and the like, meanwhile, a prepared spraying diluted solution has the good storage stability, a pigment does not deposit easily, and the leather treated with the treatment agent has the natural gloss, the clear color, the good color developing property and the good comprehensive effect. The water-based polishing treatment agent for the synthetic leather is a novel material for back-end treatment and can be applied to an existing synthetic leather production line, the process is simple, production equipment is not required to be changed, and the production cost cannot be increased.

Owner:JIANGSU BAOZE POLYMER MATERIAL

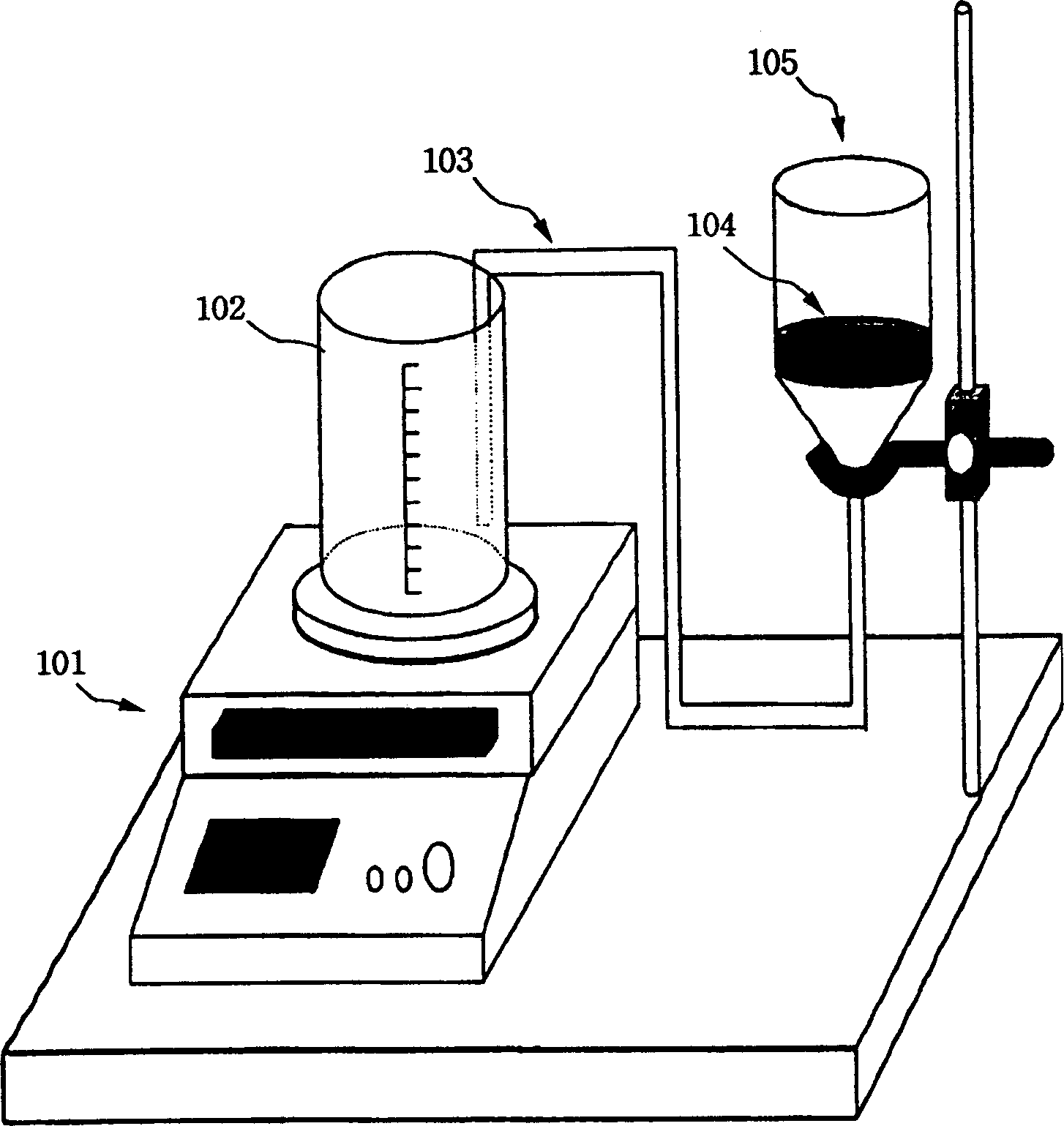

Preparation method and application of nano chitosan

ActiveCN105037582AMild preparation conditionsImprove securityProsthesisChemical reactionMicroparticle

Preparation of nano chitosan in the invention almost has no chemical reaction, chitosan is mainly dissolved and dispersed, and chitosan is not dissolved in a sodium hydroxide solution, so that chitosan particles are separated out. Meanwhile, preparation conditions are mild, the safety is high, and preparation raw materials are common and nontoxic. The obtained nano chitosan is an ideal raw material for preparing artificial skin, the prepared artificial skin is soft in texture and is comfortable, the laminating performance between the prepared artificial skin and a wound surface is good, and the prepared artificial skin is breathable, can absorb water, has antibacterial and anti-inflammatory effects, and has the functions of stopping pain, arresting bleeding and promoting wound healing. Along with the healing of the wound of a patient and the growth of the skin of the patient, the chitosan artificial skin can be automatically dissolved and absorbed by the body, scraps cannot be left so as to avoid the delay of wound healing, and skin regeneration can be promoted. Moreover, the operation is simple, the safety is improved, and preparation processes are simplified. Required instruments are relatively common so as to be favorable for reducing the cost, and thus the nano chitosan has important application value in the field of artificial skin.

Owner:SHANDONG ANTE BIOTECH CO LTD

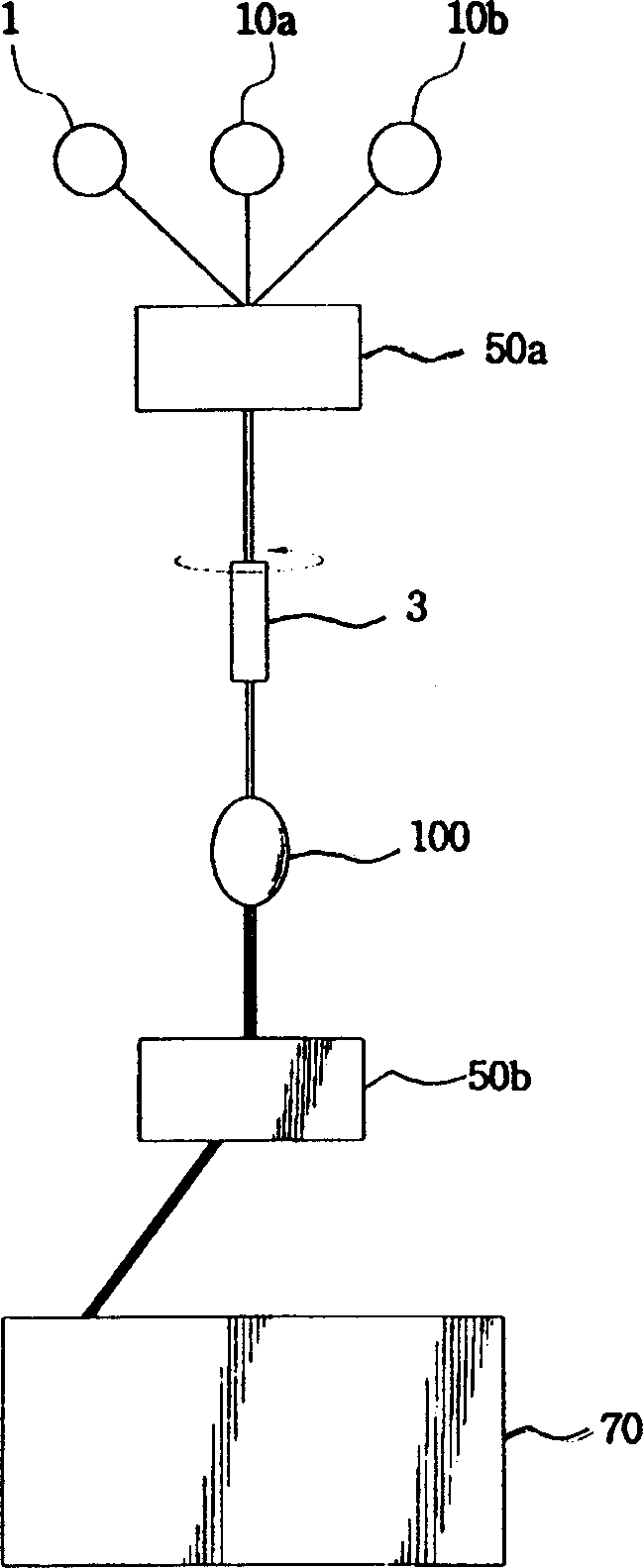

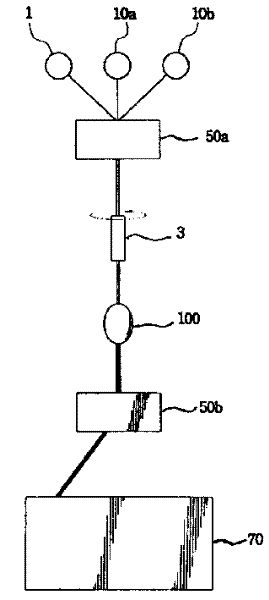

Manufacture of high absorption conjugated yarn by special yarn working technology and textile thereof

InactiveCN1418994AImprove performanceComfortable textureWeft knittingFibre typesCompound aHigh absorption

Disclosed is a compound yarn with high absorbency, which is manufactured by twisting and compounding a plurality of yarns, and a fabric made therefrom. The compound yarn is characterized in that a core yarn of a polyester false twist yarn is compounded with floating yarns selected from the group consisting of a PET / nylon split yarn, a polyester false twist yarn and a natural fiber, around the core yarn, in which one strand of the core yarn is compounded with 5 or fewer strands of the floating yarns, and then the resulting yarn is compounded with a binder yarn of a polyester filament. Such a compound yarn of the invention imparts a high absorbency to a yarn or its fabric, thereby being applied for manufacture of clothes including bath robes, daily products including general cleaners such as washcloths and hair towels, and other cleaning cloths.

Owner:银星株式会社

Waterborne oily leather treatment agent for synthetic leather and preparation method of leather treatment agent

InactiveCN104032578AComply with environmental standardsImprove mechanical propertiesFibre treatmentMedicineScratching

The invention relates to a waterborne oily leather treatment agent for synthetic leather and a preparation method of leather treatment agent. The treatment agent is prepared from the following components: modified waterborne polyurethane, water, a waterborne leveling agent and a waterborne thickening agent. The waterborne oily leather treatment agent is a novel material for later printing of the synthetic leather, and the treatment agent can enable the synthetic leather to have smooth hand feeling; the synthetic leather treated by the treatment agent has strong glossiness and crystalline effect, cannot be broken when baked at high temperature and has good surface scratching resistance.

Owner:JIANGSU BAOZE POLYMER MATERIAL

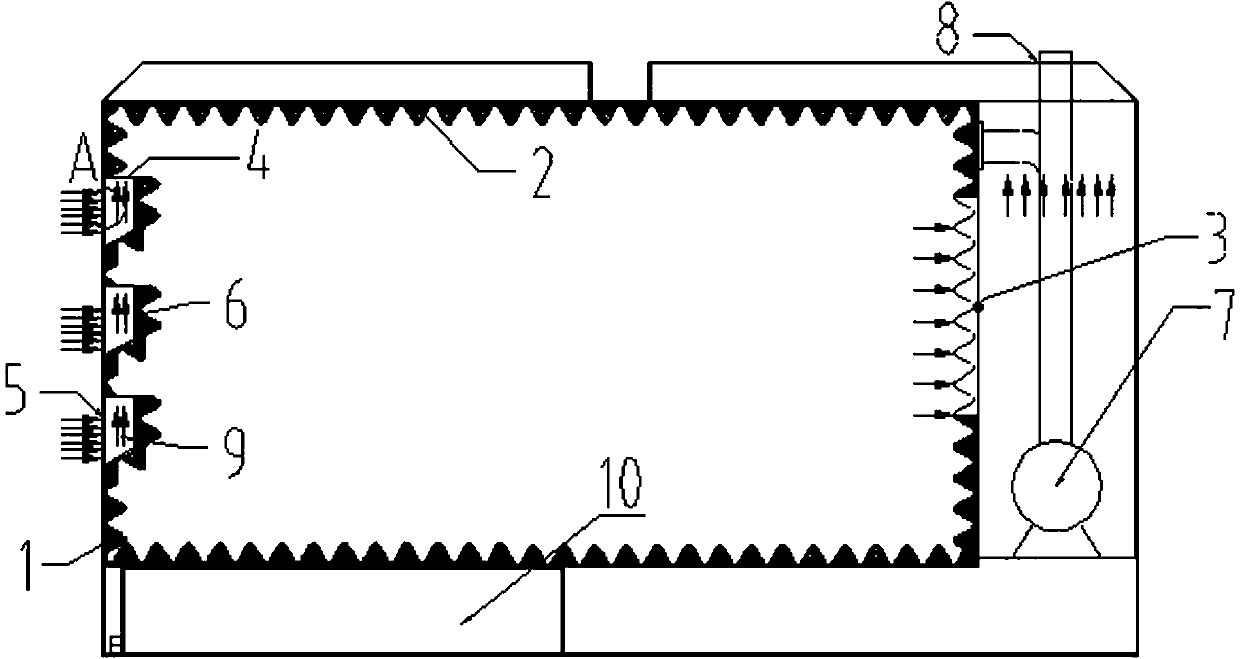

Mute box type diesel generating set

ActiveCN105508043AGlamorous appearanceImprove aestheticsMachines/enginesEngine componentsWorking temperatureSmall footprint

The invention relates to a mute box type diesel generating set, and belongs to the technical field of generating sets. Soundproof cotton is arranged on the inner wall of a mute box body, the surface of the soundproof cotton is in a crest type; and wave mode arrangements of the soundproof cotton on each two adjacent surfaces according to the air inlet direction are different completely. By the technical scheme of the invention, the diesel generating set is good in mute effect, and the average value of pressure of noises of a position distant from the generating set by 1 m is 21 decibel; the box body is high in anti-damage strength, wherein the yield strength of the mute box body reaches 236 MPa, and the tensile strength of the mute box body reaches 367 MPa; the generating set is bright in appearance, has relatively high attractiveness, smooth surfaces and comfortable texture, and is high-end and elegant; the insulating effect is good, and stability of work temperature of the generating set is guaranteed; occupied area is small; and compared with the traditional diesel generating set, the mute box type diesel generating set saves space by 15% under the condition of the same power.

Owner:赵立增

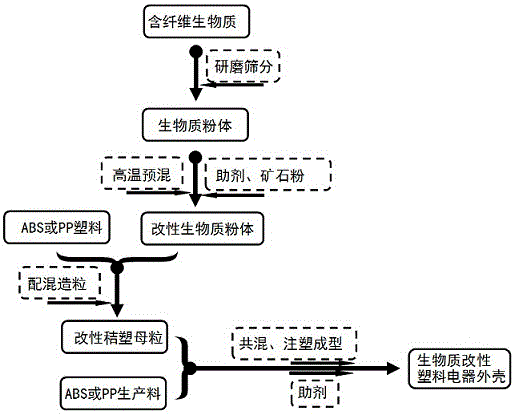

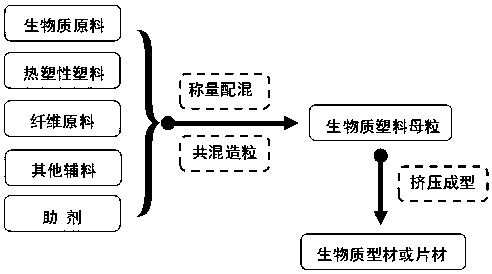

Preparation method and application of biomass-containing plastic electric appliance casing

The invention relates to a preparation method of a biomass-containing plastic electric appliance casing. The preparation method comprises the steps as follows: (1) preparing raw materials; (2) preparation of biomass powder: milling biomass containing natural fibers with a ball mill, and performing drying to obtain the biomass powder; (3) modification of the biomass powder: placing the biomass powder prepared in step (2) in a high-speed mixer, adding an additive and mineral powder, performing premixing, and performing heating drying at the heating temperature of 70-170 DEG C for 10-15 min to obtain the modified biomass powder; (4) mixing and granulation: mixing and granulating the obtained modified biomass powder with PP (polypropylene) in granulation equipment at the granulation temperature of 165-250 DEG C; (5) injection molding: mixing the obtained biomass modified PP material with a PP injection molding production material, adding an additive for injection molding, and performing product preparation to obtain the biomass-containing modified plastic electric appliance casing.

Owner:南京维思创新材料科技有限公司

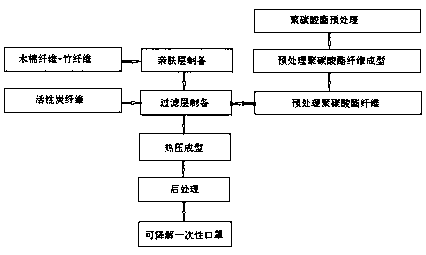

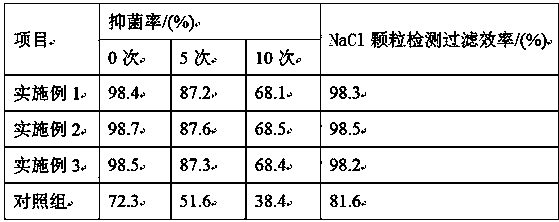

Preparation method of skin-friendly, bacteriostatic and degradable disposable mask

InactiveCN110983615AComfortable textureAvoid rigiditySevering textilesHeating/cooling textile fabricsPolycarbonateWoven fabric

The invention mainly relates to the technical field of mask processing, and discloses a preparation method of a skin-friendly, bacteriostatic and degradable disposable mask, which comprises the following steps of polycarbonate pretreatment, pretreated polycarbonate fiber forming, skin-friendly layer preparation, filter layer preparation, hot press molding and post-treatment. The preparation methodof the skin-friendly, bacteriostatic and disposable mask provided by the invention is simple to prepare, the prepared disposable mask is soft and skin-friendly, the effective filtration and bacteriostatic effects can be achieved, the stiff feeling of an existing disposable non-woven fabric mask is avoided, the wearing comfort is improved, the disposable mask can be quickly and completely biodegraded after the disposable mask is discarded, the generation of residues in the environment is avoided, the pressure of the discarded disposable mask to the environment is reduced, and the self-cleaningability of the environment is recovered and improved.

Owner:安徽鑫科生物环保有限公司

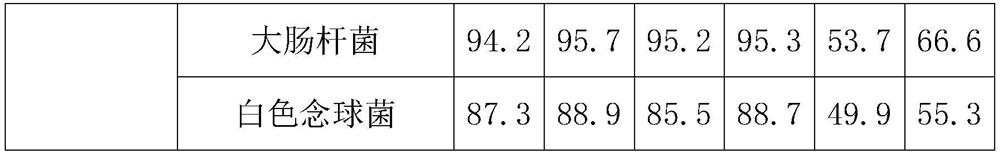

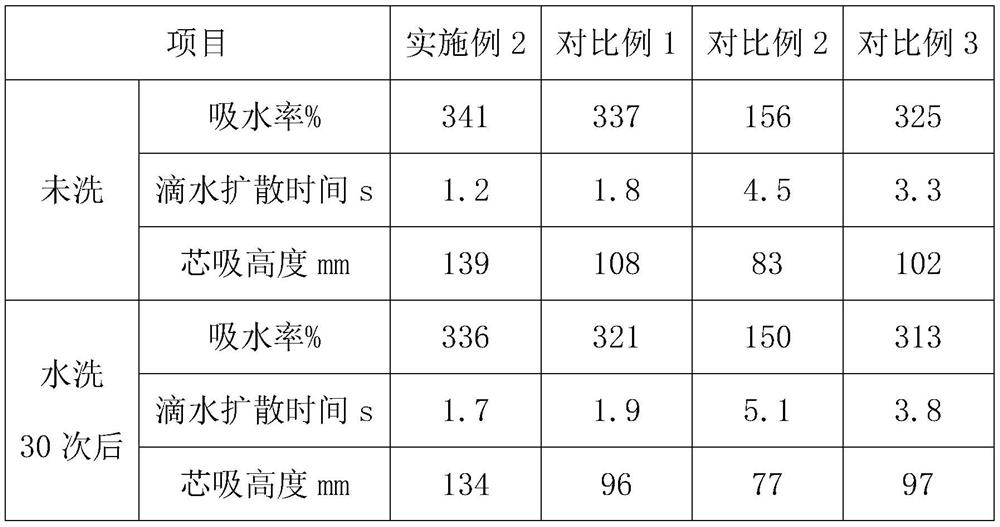

Production method of antibacterial moisture-absorbing and quick-drying fabric

InactiveCN111926440ASimple production processGood antibacterialBiochemical fibre treatmentFibre typesCotton fibreDyeing

The invention provides a production method of antibacterial moisture-absorbing and quick-drying fabric. The production method comprises the following steps that S1, sea-island fiber is used as first warp yarn, polyester long fiber of 300D is used as second warp yarn, and weaving is carried out to obtain warp yarn; S2, the warp yarn is immersed in a sodium hydroxide solution, modified with polyquaternium-7 and propylene glycol monolaurate, then immersed in a functional modification solution for modification, taken out, and dried to obtain modified warp yarn; S3, cotton fiber is used as first weft, the polyester long fiber of 300D is used as second weft, and weaving is carried out to obtain weft; S4, a group of modified warp yarn and two groups of weft are used to weave to obtain a quick-drying fabric blank; and S5, dyeing, wet scutching, shaping and drying of the quick-drying fabric blank are carried out to obtain the antibacterial moisture-absorbing and quick-drying fabric. The production method is simple in production process, and the produced fabric is good in antibacterial property, moisture absorption and moisture conductivity, soft and comfortable in texture, and superior in quick-drying performance.

Owner:李庆

Flexible and elastic natural rubber material and preparation method thereof

The invention discloses a flexible and elastic natural rubber material which is prepared from, by weight, 0.1-0.2 part of trimethylolpropane, 0.8-1 part of stannous sulfide, 2-3 parts of pentaerythritol, 1-2 parts of an anti-aging agent RD, 100-140 parts of natural rubber, 20-30 parts of kolinite powder, 400-500 parts of dimethyl sulfoxide, 900-1000 parts of dimethyl sulfoxide, 70-80 parts of N-methylimidazole, 100-120 parts of bromoethane, 4-6 parts of nanosized silica, 1-1.6 parts of nanosized silica, 2-3 parts of polyethylene benzene sulfonic acid, 1-2 parts of ammonium molybdate and 5-7 parts of tricresyl phosphate. The rubber material is good in suppleness, good in rebound resilience and comfortable in texture and can be used as a buffer material for toys and cars and a ball surface material and the like.

Owner:HEFEI JIEMING NEW MATERIAL TECH CO LTD

Fiber reinforced biomass material and preparation method thereof

The invention discloses a fiber reinforced biomass material and a preparation method thereof. The fiber reinforced biomass material consists of the following components in percentage by mass: 5%-50% of a biomass raw material, 20%-80% of thermoplastic plastic, 5%-40% of a fiber raw material, 10%-30% of other auxiliary materials and 0.5%-20% of aids. According to the preparation method, a biologicalmaterials is pelletized by a double-screw rod pelletizer to prepare a biomass plastic master batch, and the master batch is further prepared into biomass plates and sheets with a profile extruder ora sheet machine. The fiber reinforced biomass material has the beneficial effects of affine textures, water and corrosion resistance, aging resistance, high strength, good flexibility and fracture andscraping resistance, has both the natural texture of natural wood and the strength and durability of a complete plastic material, and is a comprehensive substitutive material of natural wood and complete plastic materials.

Owner:南京维思创新材料科技有限公司

Water-based fog-washing and brightening treating agent for synthetic leather and preparation method thereof

InactiveCN105316946ANo pollution in the processNo health hazardFibre treatmentProduction lineWater based

The invention relates to a water-based fog-washing and brightening treating agent for synthetic leather, and the water-based fog-washing and brightening treating agent is applied to a later period technology of the synthetic leather. The water-based fog-washing and brightening treating agent is prepared from water-based resin, a water-based thickening agent, a defoaming agent, silicon dioxide matting powder, a levelling agent, propylene glycol monomethyl ether and water. The invention further relates to a preparation method of the water-based fog-washing and brightening treating agent for the synthetic leather. According to the water-based fog-washing and brightening treating agent, all the components cooperate with one another and interact with one another, the synthetic leather is unique in handfeel after being treated, and the synthetic leather treated by the treating agent is natural in gloss, clear in color and luster and excellent in comprehensive effect after being washed; meanwhile, a prepared spraying dilute solution has the very good storage stability, and pigments are not prone to sedimentation. The water-based fog-washing and brightening treating agent for the synthetic leather is a novel material in later period treatment and can be applied to an existing synthetic leather production line, the technology is simple, production equipment does not need to be changed, and the production cost cannot be increased.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Vinyl acetate resin sheet material and printing and laminating process

The invention relates to the technical field of sheet material, and in particular, relates to a vinyl acetate resin sheet material and a printing and laminating process; the vinyl acetate resin sheet material includes a matte fine-stripe surface layer and a groined-shaped stripe bottom layer, wherein the matte fine-stripe surface layer comprises the following raw materials in parts by weight: 80-120 parts of EVA resin, 80-100 parts of PE resin, 5-15 parts of an elastomer, 1-5 parts of a compatibilizer and 1-3 parts of an antibacterial agent; the groined-shaped stripe bottom layer comprises the following raw materials in parts by weight: 80-120 parts of EVA resin, 83-90 parts of PE resin, 10-15 parts of an elastomer, 1-5 parts of a compatibilizer, and 1-3 parts of a mildewproof agent. The vinyl acetate resin sheet material has the advantages of good antibacterial and mildewproof effects, beautiful patterns, soft texture, comfortable hand feeling, environmental protection, no toxicity, and good transparency and surface glossiness, and also has the advantages of good chemical stability, softness, elasticity, flexibility, slip resistance, abrasion resistance, high temperature resistance, printability, aging prevention, ozone resistance and the like, and has excellent comprehensive performance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Antibacterial and anti-allergic healthcare fiber fabric and preparation method

InactiveCN110106569AEnsure safetyImprove securityMonocomponent cellulose artificial filamentArtifical filament manufactureMedicinal herbsFreeze-drying

The invention relates to the field of fiber fabric production, in particular to an antibacterial and anti-allergic healthcare fiber fabric and a preparation method. The preparation method includes thesteps that firstly, a pickering emulsion polymerization method is adopted to prepare a porous material; then, an ultrasonic extraction technology is adopted to extract antibacterial and anti-allergiccomponents from flos impatientis balsaminae, astmgali radix, flos magnoliae and folium artemisiae argyi, and the antibacterial and anti-allergic components are loaded in the porous material to obtainan antibacterial and anti-allergic material; finally, the antibacterial and anti-allergic material, nano-carbon fibers, aloe polyphenol extract and nano-cotton fibers disperse in a glycerol aqueous solution, antibacterial and anti-allergic fibers are obtained after electrostatic spinning and freeze drying, and the antibacterial and anti-allergic healthcare fiber fabric is obtained by blending theantibacterial and anti-allergic fibers, the cotton fibers and wool fibers. The prepared antibacterial and anti-allergic healthcare fiber fabric is comfortable in texture and high in antibacterial andanti-allergic property and safety; besides, amino acids and polysaccharide substances in the components extracted from the traditional Chinese medicinal herbs also have healthcare effects.

Owner:唐卫兵

Health maintenance composite shirt

InactiveCN103478912AComfortable textureElasticSynthetic resin layered productsUndergarmentsSurface layerChitin formation

The invention discloses a health maintenance composite shirt, which comprises a smooth fabric layer on the surface layer and a health care fabric layer on the inner layer, wherein the smooth fabric layer is formed by weaving warp wires and weft wires, the warp wires are formed by weaving tribute silk fiber, the weft wires are formed by weaving acrylic fiber, the health care fabric layer is formed by weaving chitin fiber and soybean fiber via blending, and the smooth fabric layer and the health care fabric layer are woven together in a weaving manner. According to the health maintenance composite shirt, the surface layer is woven into a smooth fabric by the tribute silk fiber and the acrylic fiber, the fabric is comfortable in texture and smooth without being wrinkled, and has elasticity; the inner layer is formed by weaving the chitin fiber and the soybean fiber via blending, and is rich in protein required by human bodies, so that various health care effects are realized for human bodies, and the human body health is kept.

Owner:WUJIANG QINBANG TEXTILE

Water-borne skin-touch lustering material treating agent for synthetic leather and preparing method thereof

InactiveCN106367973ANatural lusterClear colorHeat resistant fibresGrip property fibresSilicon dioxidePigment

The invention relates to a water-borne skin-touch lustering material treating agent for synthetic leather and a preparing method thereof. The water-borne skin-touch lustering material treating agent is prepared from water-borne resin, smooth hand feeling agent, antifoaming agent, silicon dioxide matting agent, wetting agent, German thickener, water and BCS. The components of the water-borne skin-touch lustering material treating agent mutually coordinate and act together, the treated material has the advantages of a unique hand feeling and no occurrence of crack at high baking temperature, meanwhile, a prepared spray finished dilute solution has good storage stability, and a pigment is not prone to sedimentation. Leather prepared by the treating agent is natural in luster, clear in color, and good in color developing and general effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Seamless knitting anti-electromagnetic radiation clothing and manufacturing method thereof

The invention relates to seamless knitting anti-electromagnetic radiation clothing and a manufacturing method thereof. The seamless knitting anti-electromagnetic radiation clothing consists of two layers of fabrics which are outer knitting fabric and inner shielding fabric. The outer knitting fabric comprises the following fiber compositions by weight percentage: 80-90 percent of chinlon 6 stretch yarns, 5-10 percent of chinlon 66 stretch yarns and 5-10 percent of spandex elastic fiber yarns; and the inner knitting fabric comprises the following fiber compositions by weight percentage: 50-55 percent of chinlon 6 stretch yarns and 45-50 percent of silver metal conductive fiber yarns; and after assistants such as 3 percent of leveling agents, 4 percent of detergents, 4 percent of creasing agents, 2 percent of penetrants and 0.5 percent of ammonium sulfate are added, an appropriate amount of dyes is added again. The seamless knitting anti-electromagnetic radiation clothing has the advantages of anti-electromagnetic radiation and good shielding effect and is comfortable to wear.

Owner:GUANGDONG RUIYUAN TECH

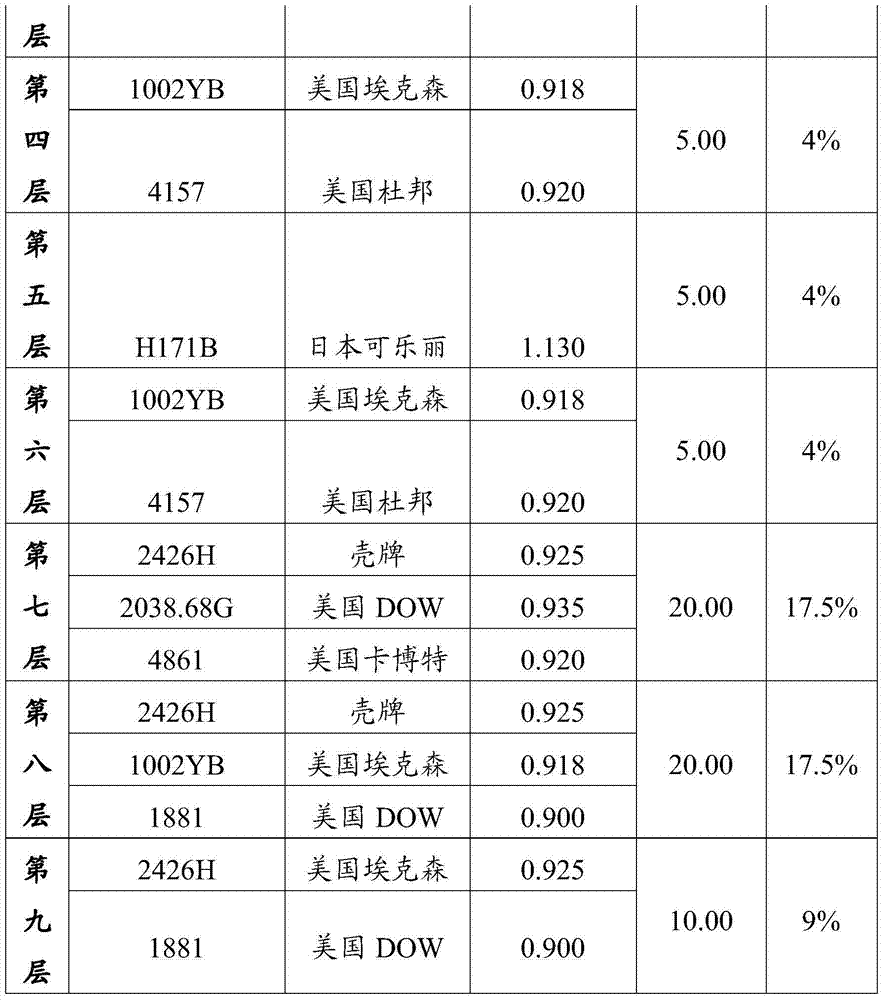

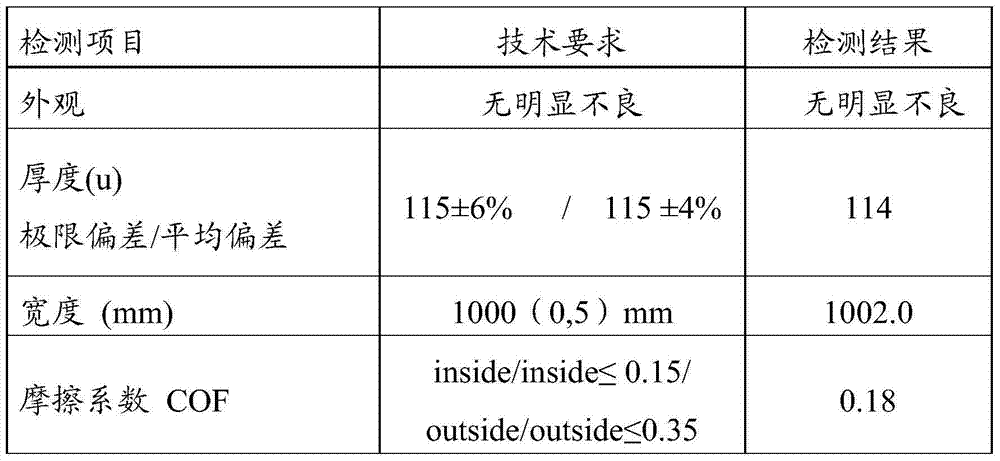

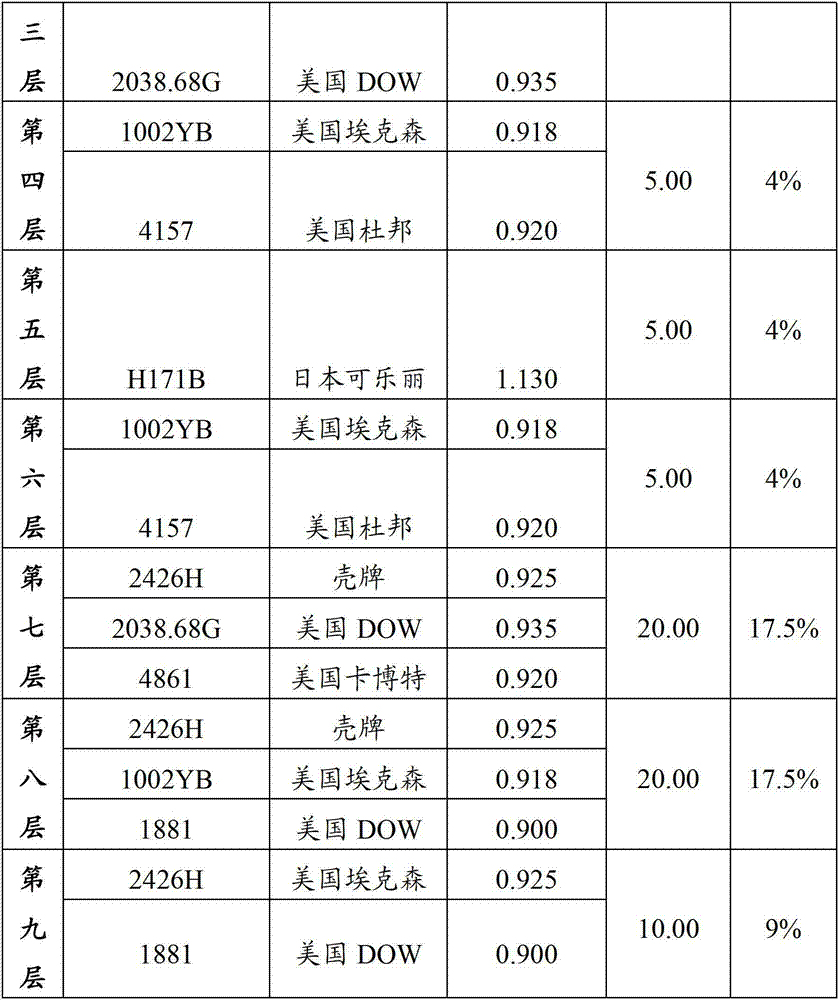

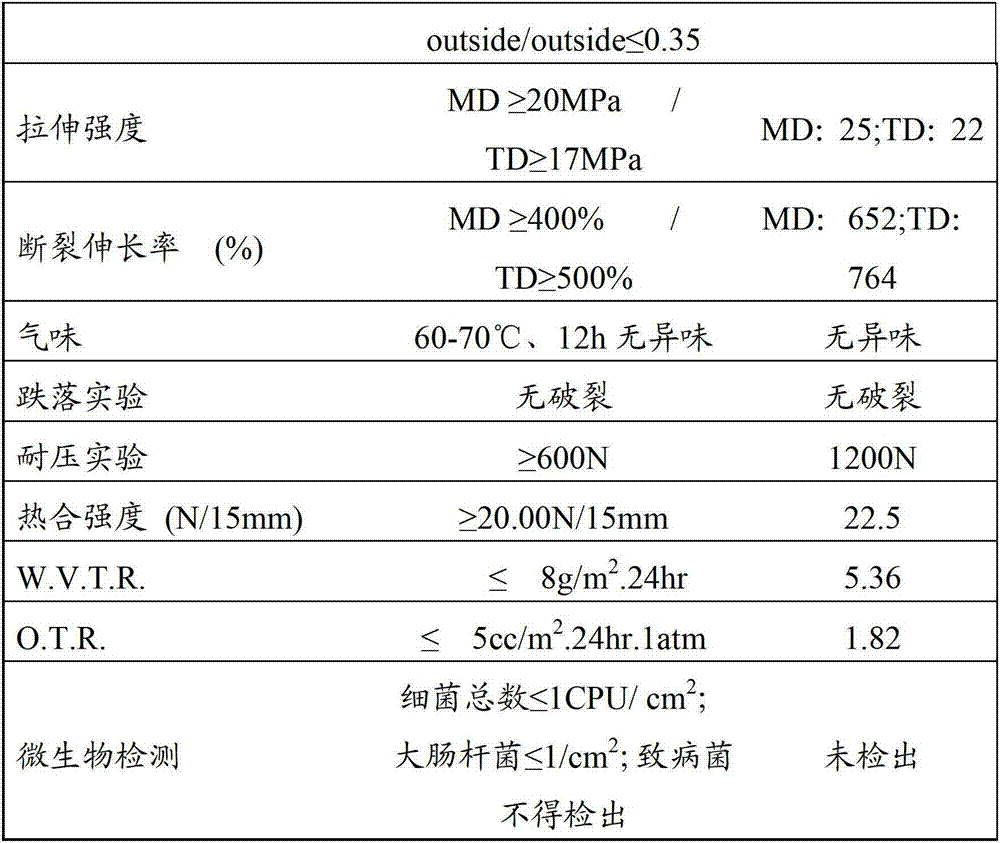

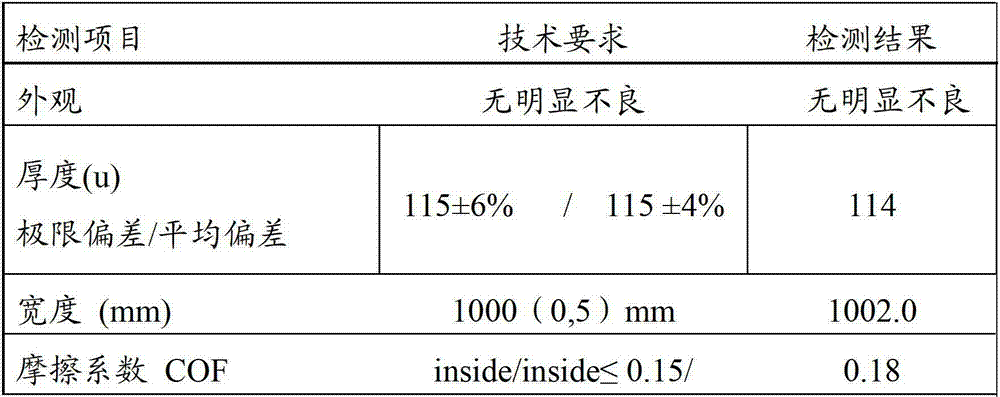

Easily degradable paper-like novel high-barrier packaging film for UHT liquid milk

ActiveCN102729563BHas a papery lookImprove the packaging gradeFlexible coversWrappersEngineeringCo extrusion

The invention discloses an easily degradable paper-like novel high-barrier packaging film for UHT liquid milk. The packaging film is a nine-layer composite structure processed by a nine-layer co-extrusion apparatus in one shot. The packaging film has paper-like appearance and can be written like book paper; meanwhile, the film has high-barrier performance and enables a shelf life to be prolonged to 3 months, and the greatest advantage of the film is that the film is degradable.

Owner:朝阳佛瑞达科技有限公司

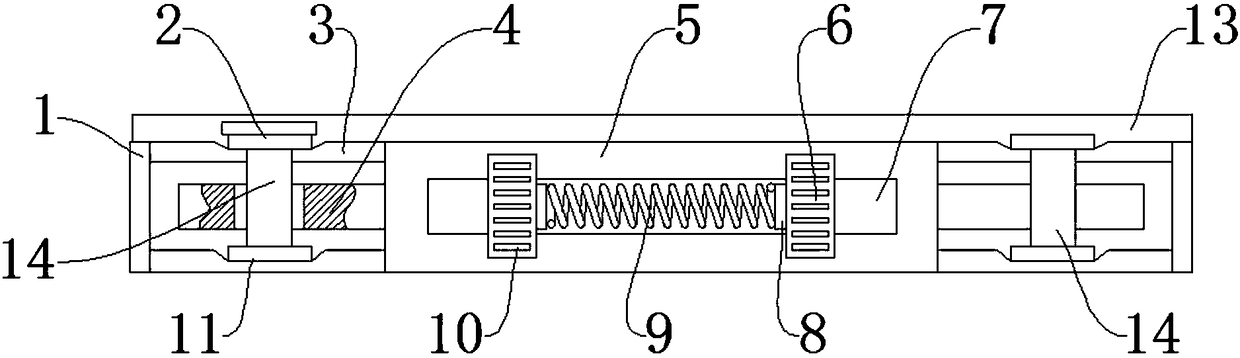

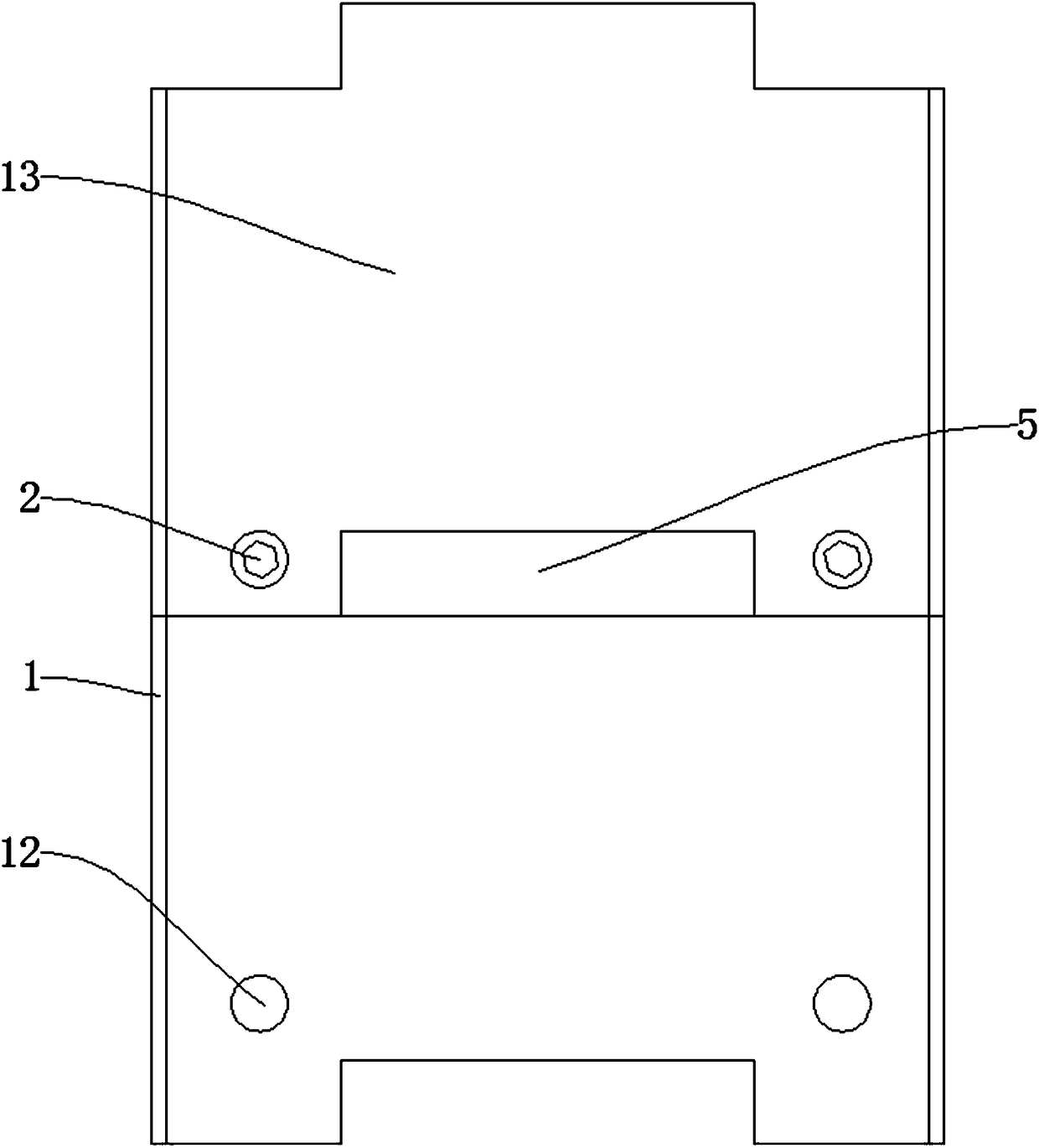

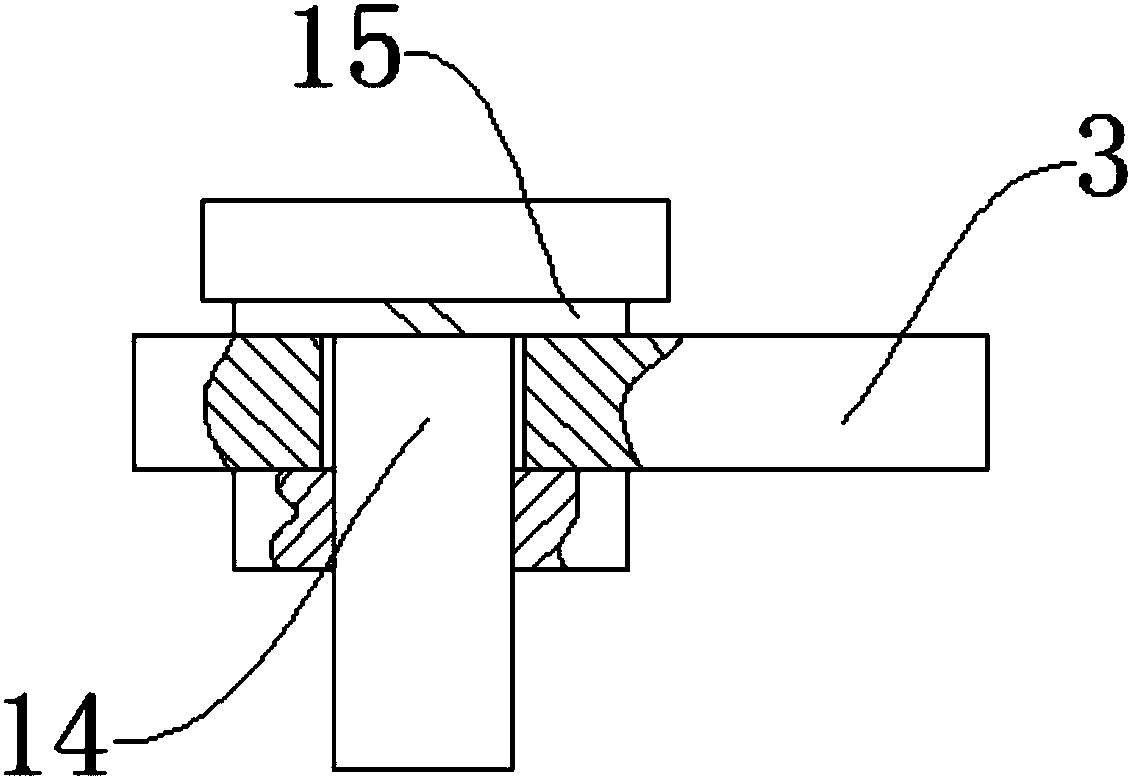

Spliced PVC carpet

PendingCN108542237AReasonable structural designGood elasticityCarpet fastenersStructural stabilityEngineering

The invention discloses a spliced PVC carpet. The spliced PVC carpet comprises a connecting rod, limiting blocks, a spring, splicing holes and fastening shafts, wherein the fastening shafts are arranged inside the connecting rod, a mounting plate is arranged on the outer sides of the fastening shafts, gaskets are arranged at the connecting positions of the mounting plate and the fastening shafts,knobs are arranged above the gaskets, a spring is arranged at the inner sides of the limiting blocks, the side, close to the limiting blocks, of the mounting plate is provided with a fixing plate, anda slide rail is arranged inside the fixing plate. The spliced PVC carpet has the beneficial effects that the structural design is reasonable, the splicing mounting is adopted, so that the use is facilitated, in addition, the elasticity is good, thus the treading resistance is realized, no deformation occurs, the texture is soft, the foot feeling is comfortable, the use safety is high, meanwhile,the sound absorption and insulation effects are good, so that the comfort of the use environment is guaranteed, moreover, a water-proof plate is adopted, so that the damage caused to the carpet afterwater enters the carpet can be effectively prevented, the structural stability is strong, the service life is long, the manufacturing cost is low, and the cost performance is high.

Owner:安吉艺科装饰材料科技有限公司

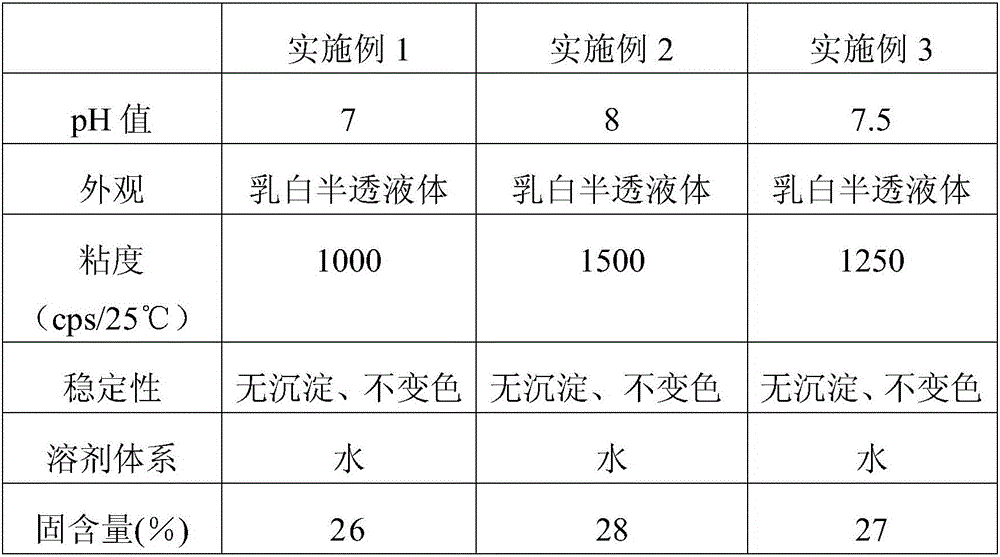

Aqueous high-gloss gloss oil used for artificial leather and preparation method thereof

InactiveCN105421076ANo pollution in the processNo health hazardGrip property fibresEthylene diaminePolymer science

The invention provides aqueous high-gloss gloss oil used for artificial leather, which is used in after processes of the artificial leather and includes the following components: BG-AA diol being 1000 in molecular weight, DMPA, BDO, reactive dimethyl silicone oil, IPDI, acetone, triethylamine, ethyl diamine, water, an aqueous defoamer, a flatting agent and a thickening agent. The invention also provides a preparation method of the aqueous high-gloss gloss oil used for the artificial leather. The components in the aqueous high-gloss gloss oil cooperate and achieve synergistic effects, so that the aqueous high-gloss gloss oil can achieve a unique hand filling after treatment, is high in gloss and transparency, can form a clear color and has excellent comprehensive effects. A diluted solution for spray coating is excellent in storage stability and pigments are not liable to deposit. The aqueous high-gloss gloss oil is a novel material for after processes of the artificial leather, can be used in an artificial leather production line in the prior art, is simple in preparation process and is free of change on production equipment, and is free of increase on production cost.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Layer pad production method

InactiveCN103963361AImprove skid resistanceSoft textureLayered productsSurface layerMethods of production

The present invention discloses a layer pad production method, wherein the layer pad is divided into a surface layer and an inner layer, and an adhesive is adopted to adhere between the inner layer and the inner layer and between the inner layer and the surface layer. The production method comprises: 1, placing a fabric with preset layers in a stacking manner, and adhering between the adjacent two layers with an adhesive; 2, sewing the adhered fabric; 3, cutting the sewed fabric into patterns; 4, stripping one or more than one layers of cloth materials from the surface of the fabric; 5, sewing a layer of a cloth material on the other surface of the fabric; 6, carrying out deburring on the ring edge of the fabric; 7, making a smooth layer on the surface of the fabric; and 8, coating a surface glue on the surface of the fabric. According to the present invention, the fluff similar to the blanket fluff can be formed on the surface of the layer pad so as to enhance the slip resistance; and the layer pad can be used for industrial layer pads or daily necessity layer pads or furniture layer pads.

Owner:李军

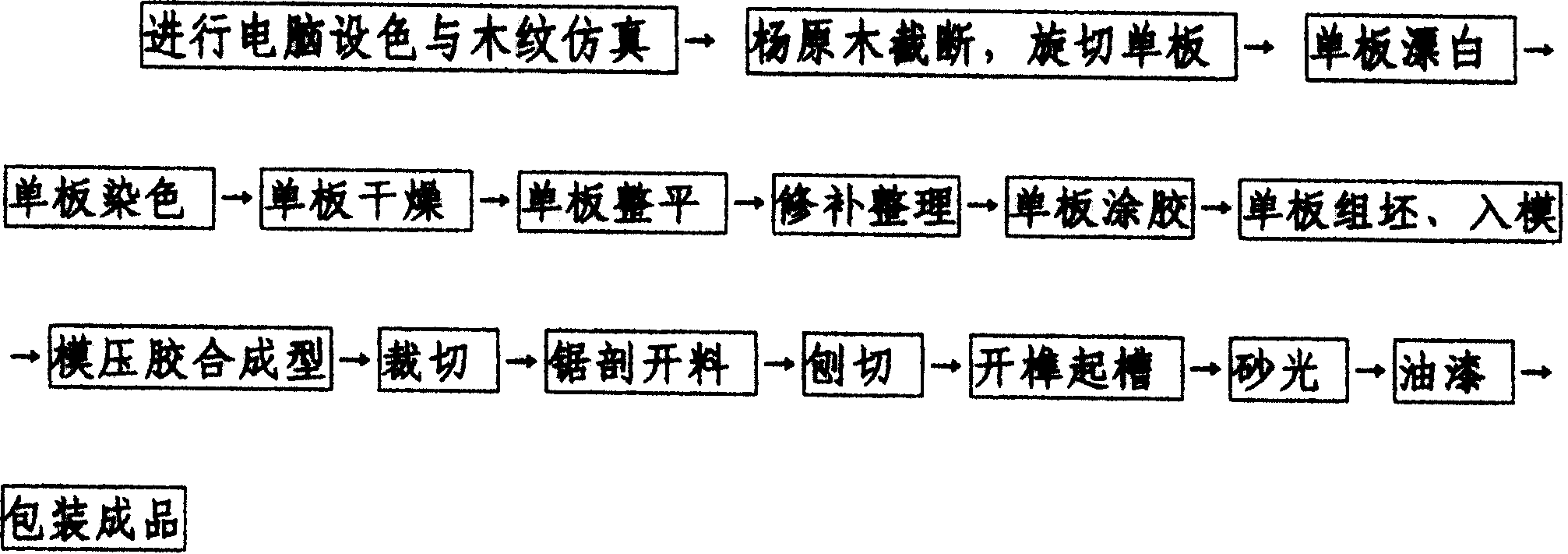

Method for making wood floor by pure poplar

InactiveCN100379537CSoft materialRough textureWood treatment detailsWood veneer joiningSolid woodSingle plate

The invention discloses a facture that uses pure poplar to make wood floor. The facture comprises the following procedures: (1) implement computer color design and wood grain emulation; (2) truncate the raw poplar and rotary cut it into the veneer; (3) the veneer blanching; (4) the veneer dyeing; (5) the veneer drying; (6) the veneer flattening; (7) repair and trim; (8) the veneer coating; (9) the veneer base gathering, and moulding,; (10) the module pressing and pasting form; (11) the cutting; (12) the saw splitting; (13) the plane cutting; (14) open splineway; (15) sand polishing; (16) the painting; (17) the packaging. The invention saves the rigid wood resources and solves the problem that other raw materials have high rigidity and are not comfortable.

Owner:丁冠真

Easily degradable paper-like novel high-barrier packaging film for UHT liquid milk

ActiveCN102729563AHas a papery lookImprove the packaging gradeFlexible coversWrappersEngineeringCo extrusion

The invention discloses an easily degradable paper-like novel high-barrier packaging film for UHT liquid milk. The packaging film is a nine-layer composite structure processed by a nine-layer co-extrusion apparatus in one shot. The packaging film has paper-like appearance and can be written like book paper; meanwhile, the film has high-barrier performance and enables a shelf life to be prolonged to 3 months, and the greatest advantage of the film is that the film is degradable.

Owner:朝阳佛瑞达科技有限公司

Water-based brilliant black fog burning and brightening treatment agent for synthetic leather and preparation method thereof

InactiveCN106367972ANatural lusterClear colorHeat resistant fibresGrip property fibresWater basedBrilliant black

The invention relates to a water-based brilliant black fog burning and brightening treatment agent for synthetic leather and a preparation method thereof. The water-based brilliant black fog burning and brightening treatment agent for the synthetic leather is prepared from the following ingredients of water-based resin, a defoaming agent, silicon dioxide extinction powder, a wetting agent, a smooth feeling agent, a deuchem thickening agent, water and BCS. According to the water-based brilliant black fog burning and brightening treatment agent for the synthetic leather, all the ingredients are in intercoordination and combined action; the water-based brilliant black fog burning and brightening treatment agent has the advantages of being unique in hand feeling after treatment and free of crack when being roasted in a high temperature; meanwhile, prepared spray dilute solution has good storage stability, and pigment is not prone to deposite; the leather treated by the treatment agent is natural in gloss, clear in color, good in show color and excellent in comprehensive effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Composite carpet capable of preserving heat

Owner:NANTONG HUAYIN WOOLEN PROD

Waterborne light-curing oil treating agent for synthetic leather and preparation method of waterborne light-curing oil treating agent

The invention relates to a waterborne light-curing oil treating agent for synthetic leather and a preparation method of the waterborne light-curing oil treating agent. The waterborne light-curing oil treating agent for the synthetic leather comprises the following components: waterborne resin, a defoamer, a wetting agent, a Deqian thickening agent, BCS and water. Various components of the waterborne light-curing oil treating agent for the synthetic leather cooperate with one another and interact, and after being treated, the synthetic leather feels unique, and does not crack after being baked at high temperature. Meanwhile, a prepared spraying dilute solution has good storage stability, pigment cannot settle easily, and the leather manufactured by using the treating agent is natural in gloss, clear in color and luster, good in color developing and good in comprehensive effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

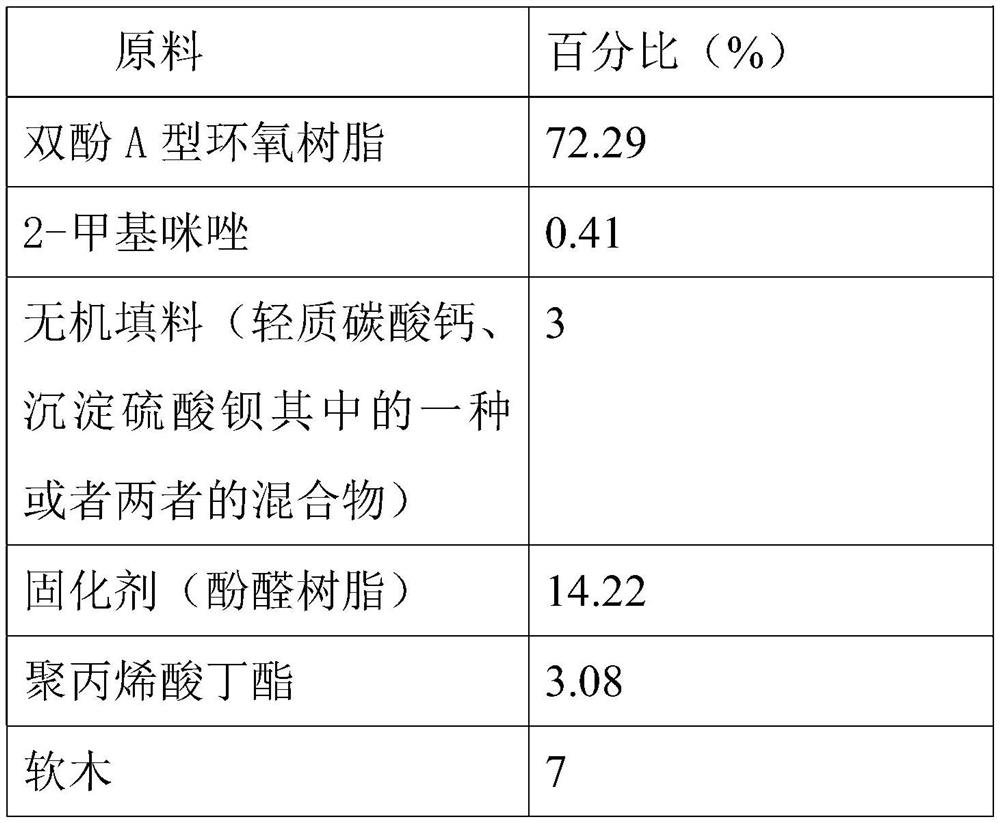

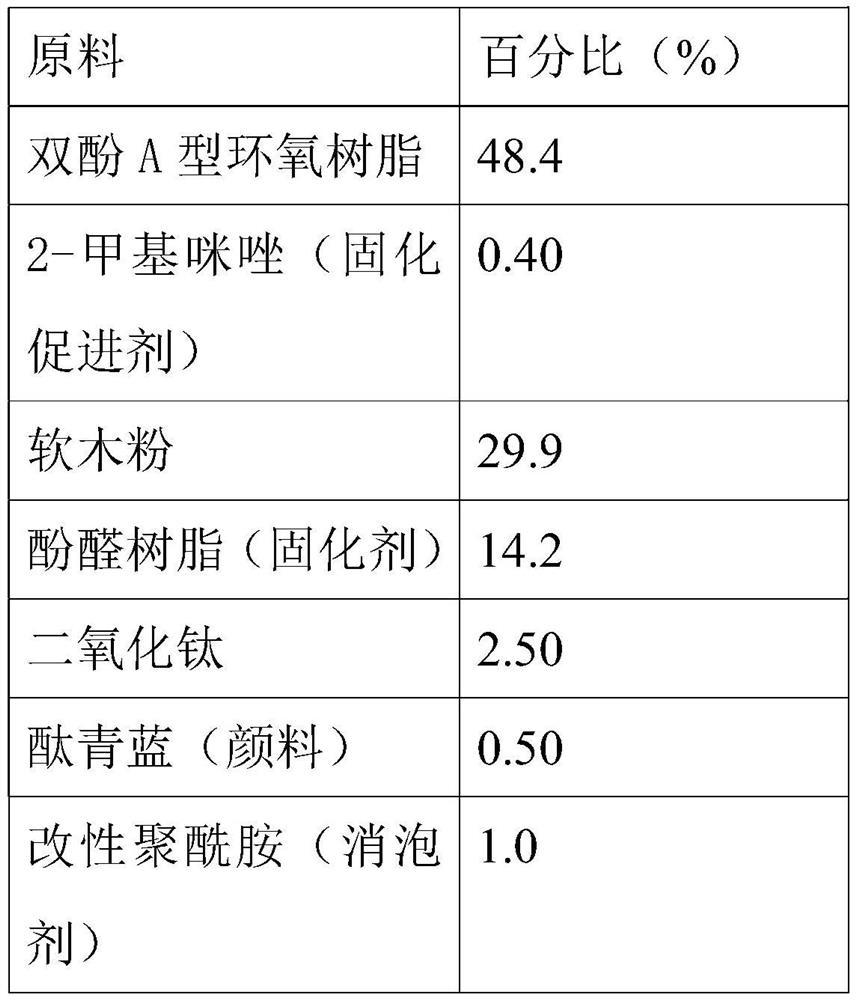

Cork composite thermal insulation powder coating material, preparation method thereof and coating

InactiveCN112592641AWith elastic shock absorptionWith insulationLiquid surface applicatorsAnti-corrosive paintsMeth-Cork

The invention discloses a cork composite thermal insulation powder coating material, a preparation method thereof and a coating. The coating is prepared from the following raw material components: 15-75.5% of bisphenol A epoxy resin, 14.2-14.5% of a curing agent, 2-60% of cork, 3.08-3.20% of polybutyl acrylate, 0.4-0.41% of 2-methylimidazole, 0-1% of a pigment, 0-1% of a defoaming agent and 0-20%of an inorganic filler; And the cork is one or a mixture of more of natural cork powder, puffed semi-carbonized softened cork, decolorized cork and colored cork. The cork composite powder coating material with light weight, corrosion resistance, heat insulation and aging resistance is prepared, the coating material is applied to a metal object, the high strength of the metal object is kept, the attractiveness, heat preservation and comfort of cork furniture are improved, and the advantages of metal and cork are complemented and integrated.

Owner:郑林义

Human hair substitute goods and preparation method thereof

ActiveCN105484026AClose to textureImprove tensile propertiesGrip property fibresAnimal fibresSoft waterPyrophosphate

The invention relates to the technical field of hair products, in particular to human hair substitute goods and a preparation method thereof. The human hair substitute goods are prepared by carrying out scale stripping, stretching, shaping and aftertreatment on horsetail in sequence. In the stretching process, the horsetail with scales stripped is fixed to a stretcher, placed into a stretching solution and stretched at 10-80 DEG C till the stretching rate is 20-40%. According to 100 parts by weight of horsetail, the stretching solution is prepared form, by weight, 36-200 parts of hydrogen peroxide with the mass concentration of 20-50%, 17-50 parts of sodium pyrophosphate, 2-3 parts of fatty alcohol-polyoxyethylene ether, 3-6 parts of lauryl sodium sulfate and 800-3000 parts of soft water, and a pH regulating agent 1 is used for regulating the pH value of the stretching solution to 7.5-9. The performance of the human hair substitute goods is more approximate to in-vitro human hair, soft, comfortable, good in breathability and easy to manage. The preparation method is simple in preparation technology, easy to implement and suitable for industrial production.

Owner:HENAN RUIMEI HAIR PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com