Fiber reinforced biomass material and preparation method thereof

A biomass material and fiber-reinforced technology, which is applied in the field of new materials, can solve problems such as intolerance to creases and scratches, hard surfaces, and difficulty in ensuring strength and toughness, and achieve the effect of improving toughness, texture affinity, and comfortable texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

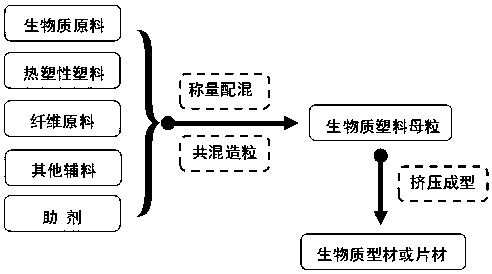

[0026] A kind of preparation method of fiber reinforced biomass material, described preparation method comprises the steps:

[0027] (1) Grind the biomass raw material to 20-120 mesh, and dry it at 105°C for 4-8 hours;

[0028] (2) Mix the biomass raw material powder processed in step (1) with thermoplastics, fiber raw materials, other auxiliary materials and auxiliaries according to the mass fraction, and mix evenly, wherein the biomass raw material powder is 5%~30% %, thermoplastics 20%~50%, fiber raw materials 5%~30%, other auxiliary materials 10%~20%, additives: 1%~10%;

[0029] (3) Process and pelletize the components after compounding in step (2) by a twin-screw granulator to obtain biomass plastic masterbatch;

[0030] (4) Process the biomass plastic masterbatch obtained in step (3) into biomass plates and sheets through a profile extruder or a sheet machine.

Embodiment 1

[0032] The present invention is a kind of preparation method of fiber-reinforced biomass material, and described preparation method comprises the following steps:

[0033] (1) Grind the wheat straw to 80 mesh, dry it at 105°C for 4 hours, and set aside;

[0034] (2) Take 25% dried wheat straw powder, 40% polyethylene, 15% glass fiber, 8% talcum powder, 5% thermoplastic elastomer POE, 3% maleic anhydride grafted polypropylene, 2% silicone, 1.5% stearic acid, 0.5% anti-ultraviolet aging agent UV-531, after weighing and compounding according to the mass percentage, place it in a high-speed mixer at 1000 rpm and mix thoroughly for 10 minutes;

[0035] (3) Prepare “biomass plastic masterbatch” by melting and blending the homogeneously mixed raw materials of each component through a twin-screw granulator, and the processing temperature is 160°C~190°C;

[0036] (4) Process the above obtained biomass plastic masterbatch into a biomass plate and sheet through a profile extruder or a s...

Embodiment 2

[0039] The present invention is a kind of preparation method of fiber-reinforced biomass material, and described preparation method comprises the following steps:

[0040] (1) Dry 80-mesh wood flour at 105°C for 4 hours, and set aside;

[0041] (2) Take 20% dried wood powder, 45% polyethylene, 15% glass fiber, 5% EPDM, 8% talcum powder, 2% silicone, 3% maleic anhydride grafted Polypropylene, 1.5% stearic acid, 0.5% anti-ultraviolet aging agent UV-531, after weighing and compounding according to the mass percentage, placed in a high-speed mixer at 1000 rpm and fully mixed for 10 minutes;

[0042] (3) Prepare “biomass plastic masterbatch” by melting and blending the homogeneously mixed raw materials of each component through a twin-screw granulator, and the processing temperature is 160°C~190°C;

[0043] (4) Process the above obtained biomass plastic masterbatch into a biomass plate and sheet through a profile extruder or a sheet machine, and the processing temperature is 180°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com