Preparation method of skin-friendly, bacteriostatic and degradable disposable mask

A disposable, mask technology, applied in the manufacture of rayon, cutting of textile materials, conjugated rayon, etc., can solve the problems of inability to satisfy the comfort of use, inability to fit the skin tightly, and the texture of disposable masks is hard. To restore and improve self-cleaning ability, avoid stiff feeling, and ensure the effect of human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

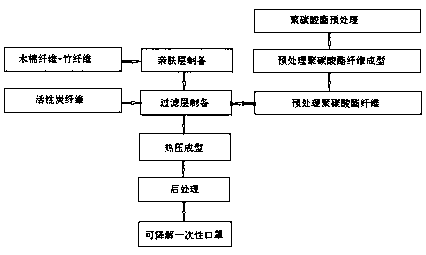

Method used

Image

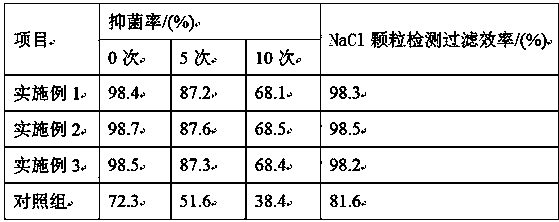

Examples

Embodiment 1

[0026] A kind of preparation method of skin-friendly antibacterial degradable disposable mask, comprises the following steps:

[0027] (1) Polycarbonate pretreatment: Put the polycarbonate in the reaction kettle, heat it at a rate of 2°C / min until it is completely melted, keep stirring for 25 minutes, then add pregelatinized starch and diethylaminohydroxybenzoylbenzene Hexyl formate, the addition amount of pregelatinized starch is 17% of polycarbonate weight, the addition amount of diethylamino hydroxybenzoyl hexyl benzoate is 11% of polycarbonate weight, with 70r / min insulation stirring 40min , so that the raw materials are fully mixed and grafted, the fiber formability and softness of polycarbonate are improved, the mask is soft, skin-friendly and comfortable, and polycarbonate is pretreated;

[0028] (12) Forming of pretreated polycarbonate fibers: put the pretreated polycarbonate in the spinning machine for wet spinning with a linear density of 2dtex to improve the fiber f...

Embodiment 2

[0034] A kind of preparation method of skin-friendly antibacterial degradable disposable mask, comprises the following steps:

[0035] (1) Polycarbonate pretreatment: put the polycarbonate in a reaction kettle, heat it at a rate of 2.5°C / min until it is completely melted, keep it warm and stir for 30 minutes, then add pregelatinized starch and diethylaminohydroxybenzoylbenzene Hexyl formate, the addition of pregelatinized starch is 18% of polycarbonate weight, the addition of diethylamino hydroxybenzoyl hexyl benzoate is 12% of polycarbonate weight, with 75r / min heat preservation and stirring for 45min , so that the raw materials are fully mixed and grafted, the fiber formability and softness of polycarbonate are improved, the mask is soft, skin-friendly and comfortable, and polycarbonate is pretreated;

[0036] (12) Pretreatment polycarbonate fiber forming: put the pretreatment polycarbonate in the spinning machine for wet spinning, the linear density is 2~3dtex, improve the ...

Embodiment 3

[0042] A kind of preparation method of skin-friendly antibacterial degradable disposable mask, comprises the following steps:

[0043] (1) Polycarbonate pretreatment: put the polycarbonate in a reaction kettle, heat it at a rate of 3°C / min until it is completely melted, keep it warm and stir for 35 minutes, then add pregelatinized starch and diethylaminohydroxybenzoylbenzene Hexyl formate, the addition amount of pregelatinized starch is 19% of polycarbonate weight, the addition amount of diethylamino hydroxybenzoyl hexyl benzoate is 13% of polycarbonate weight, with 80r / min insulation stirring 50min , so that the raw materials are fully mixed and grafted, the fiber formability and softness of polycarbonate are improved, the mask is soft, skin-friendly and comfortable, and polycarbonate is pretreated;

[0044] (12) Pretreatment polycarbonate fiber forming: put the pretreatment polycarbonate in the spinning machine for wet spinning, the linear density is 2~3dtex, improve the fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com