Cork composite thermal insulation powder coating material, preparation method thereof and coating

A technology of powder coating and cork powder, which is applied in powder coatings, coatings, anti-corrosion coatings, etc., and can solve problems such as poor protection function, lack of elasticity and shock absorption, and poor comfort in cold winter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]Softwood composite temperature cycle powder coating material, this embodiment contains a powder coating material containing biological cork, and its mass percentage is:

[0040] raw material percentage(%) Bisphenol A epoxy resin 72.9 Curing agent (phenolic resin) 14.5 2-methylimidazole 0.40 Polyacrylate 3.20 Pigment titanium dioxide 0.50 Peaceful 0.9 Cork powder7.6

[0041]The method of preparing the cork composite temperature impact powder coating material of the present embodiment is:

[0042](1) According to the formulation standard, bisphenol A-type epoxy resin, phenolic resin, 2-methylimidazole, polyacrylate, titanium dioxide, and restoration, and thoroughly mixed a mixed premixed material.

[0043](2) The mixed premixing material is added to the twin screw extruder for melt extrusion. A zone temperature of the extruder is set between 80-100 ° C, and the second region temperature is set between 110-120 ° C.

[0044](3) After the extruded material is cooled, after the tablet, the hig...

Embodiment 2

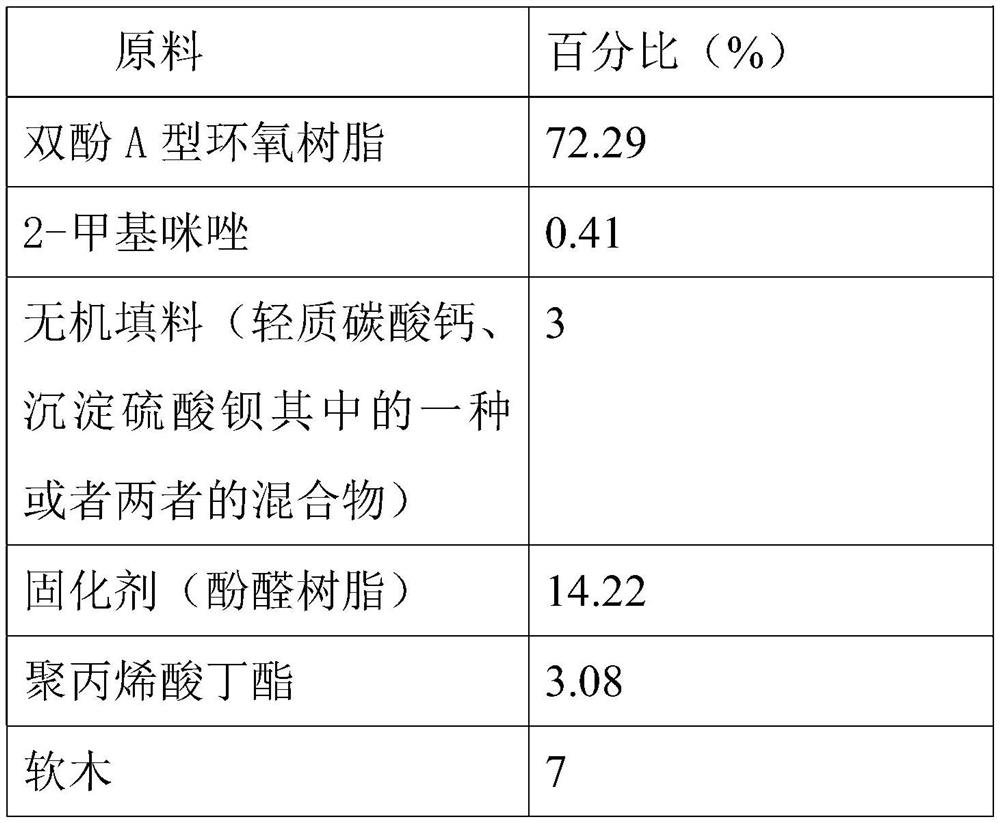

[0047]A cork composite temperature cycle powder coating material and preparation method thereof, the powder coating material containing biocaricone, in this example, its mass percentage:

[0048]

[0049]The method of preparing the cork composite temperature impact powder coating material of the present embodiment is:

[0050](1) According to the formulation standard, the bisphenol A-type epoxy resin, phenolic resin, 2-methylimidazole, polyacrylate, and inorganic filler each component are obtained, and the mixed uniform premixed material is thoroughly mixed.

[0051](2) The mixed premixing material is added to the twin screw extruder for melt extrusion. A zone temperature of the extruder is set between 80-100 ° C, and the second region temperature is set between 110-120 ° C.

[0052](3) After the extruded material is cooled, after the tablet, the high-speed pulverizer is used to be pulverized, and then grinded by the ball mill, then the sieve is sieved by 160 mesh sieve to obtain an epoxy powder c...

Embodiment 3

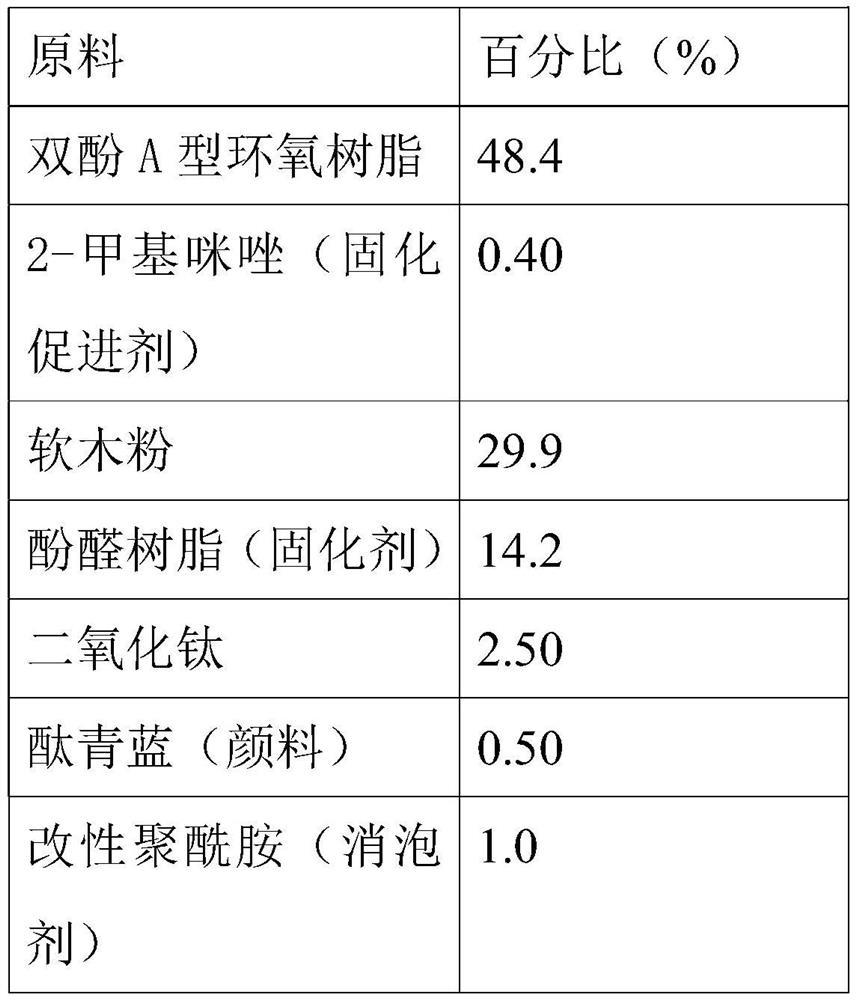

[0055]A cork composite temperature cycle powder coating material and preparation method thereof, the powder coating material containing biocaricone, in this example, its mass percentage:

[0056]

[0057]The method of preparing the coating material of the cork composite temperature cycle of this example is:

[0058](1) According to the formulation standard, the bisphenol A-type epoxy resin, a curing agent, a curing promoter, a leveling agent, a cork, a cork, and thoroughly mixed a mixed material.

[0059](2) Adding a mixed material is added to the twin screw extruder for melt extrusion. A zone temperature of the extruder is set between 80-100 ° C, and the second region temperature is set between 110-120 ° C.

[0060](3) After the extruded material is cooled, after the press, the high-speed pulverizer is pulverized, and then the sieve is sieved by the sieve of greater than or equal to 160 mesh, and the cork composite temperature cycle powder coating material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com