Cushion case frame

A cushion shell frame and a shell frame technology are applied in the field of seat cushion shell frames, and can solve the problem that the shock absorption function of the seat cushion cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

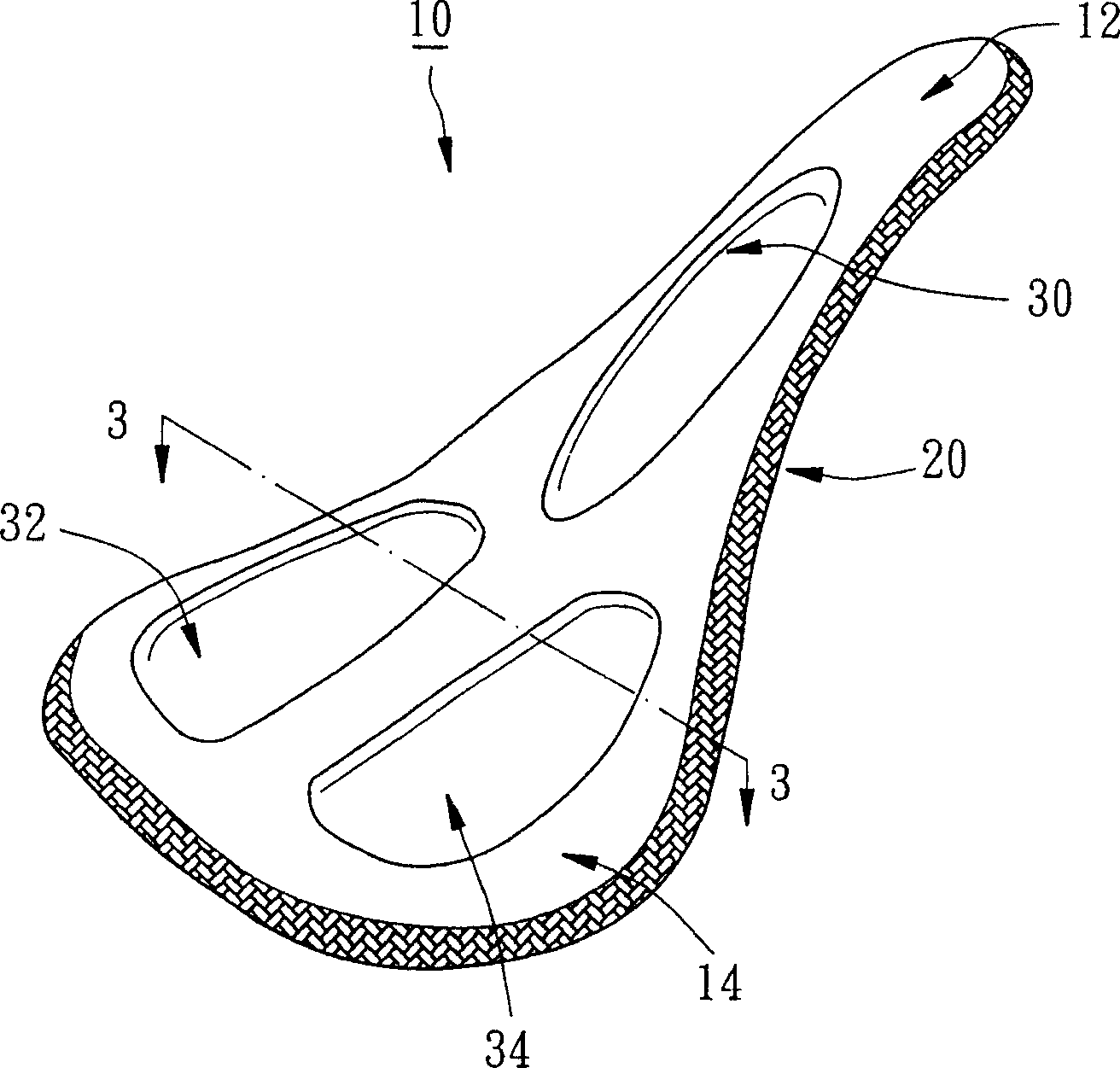

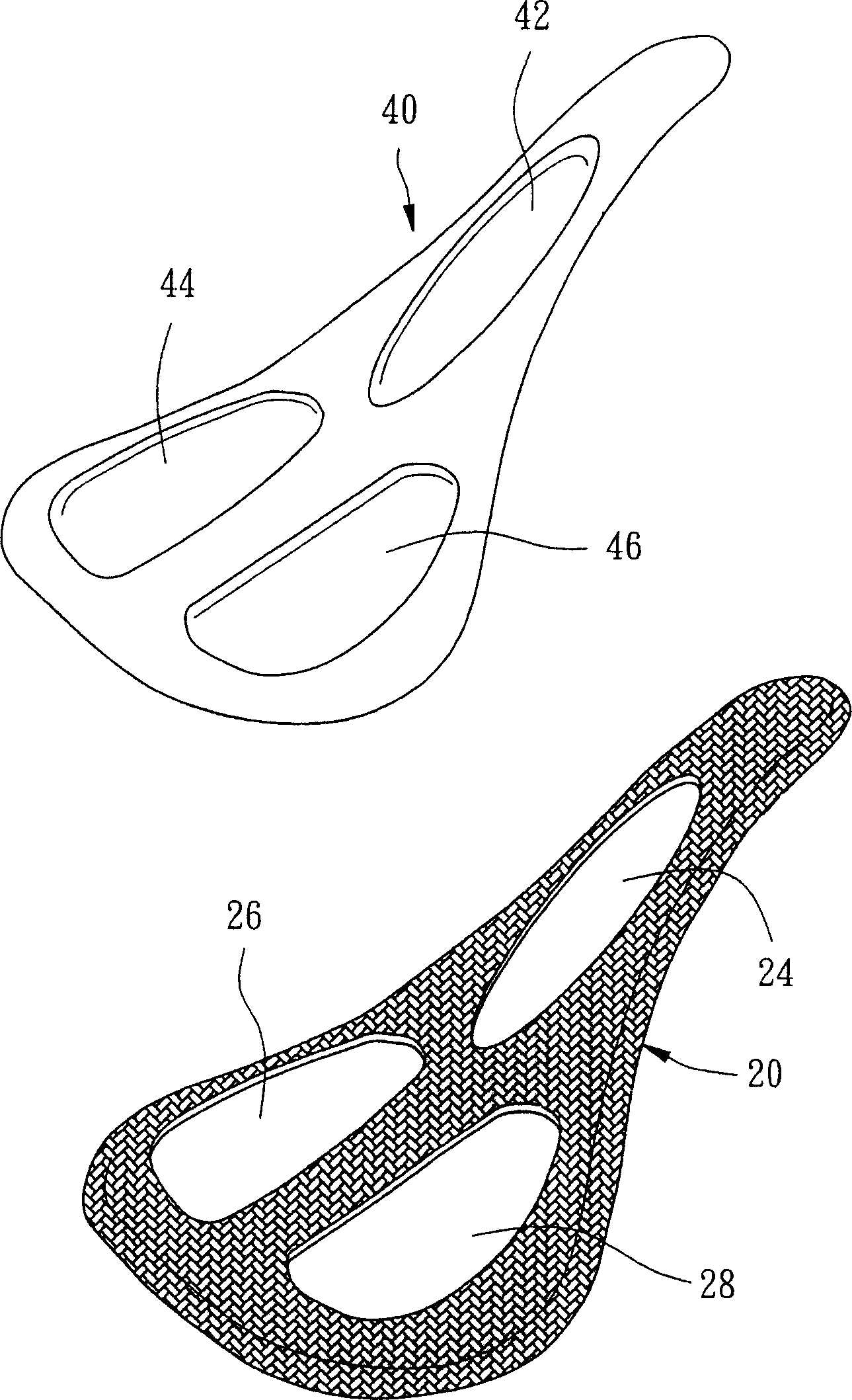

[0033] See first Figure 1 to Figure 3 10 is a bicycle seat cushion frame of a preferred example of the present invention, and the seat cushion frame 10 has a narrow and long portion 12 and a wide portion 14 in terms of overall outline. As far as the composition is concerned, it has a body 20 with high rigidity, and three elastic shock-absorbing regions 30, 32, and 34 corresponding to the seating area of the seat cushion.

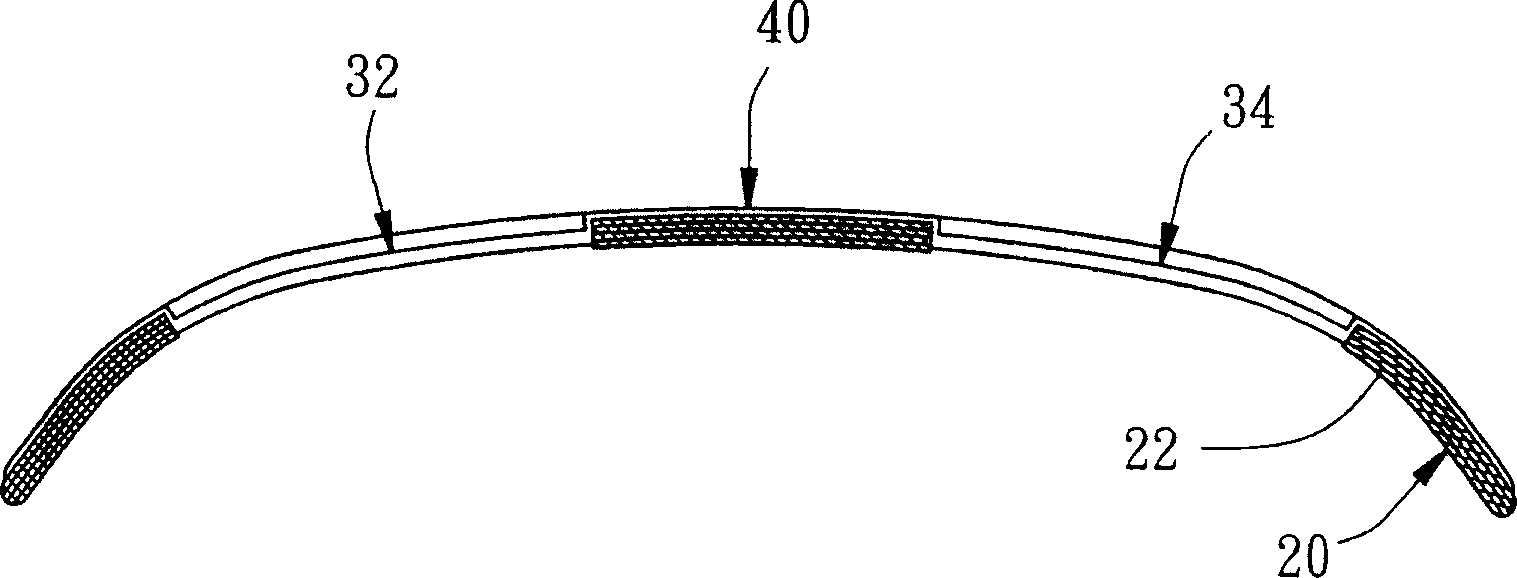

[0034] The body 20 is formed by stacking one or more layers of carbon fiber woven boards 22 pre-impregnated with epoxy resin. Negative 45 degrees or 90 degrees.

[0035] In order to form the deformation area of each elastic shock-absorbing area, before the main body is heated, pressurized and solidified, three hollow areas 24, 26 and 28 are punched out on each of the fiber-reinforced plastic woven boards 22, and then the uppermost layer is woven A layer of film 40 made of thermoplastic polyurethane (Thermoplastic Urethane, TPU) is laid on the top surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com