Waterborne light-curing oil treating agent for synthetic leather and preparation method of waterborne light-curing oil treating agent

A technology of synthetic leather and treatment agent, which is applied in the direction of improved hand feeling fibers, etc., can solve the problems of poor gloss and color, unsatisfactory color development, poor storage stability, etc., and achieve clear color, safe and reliable processing, and relatively good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

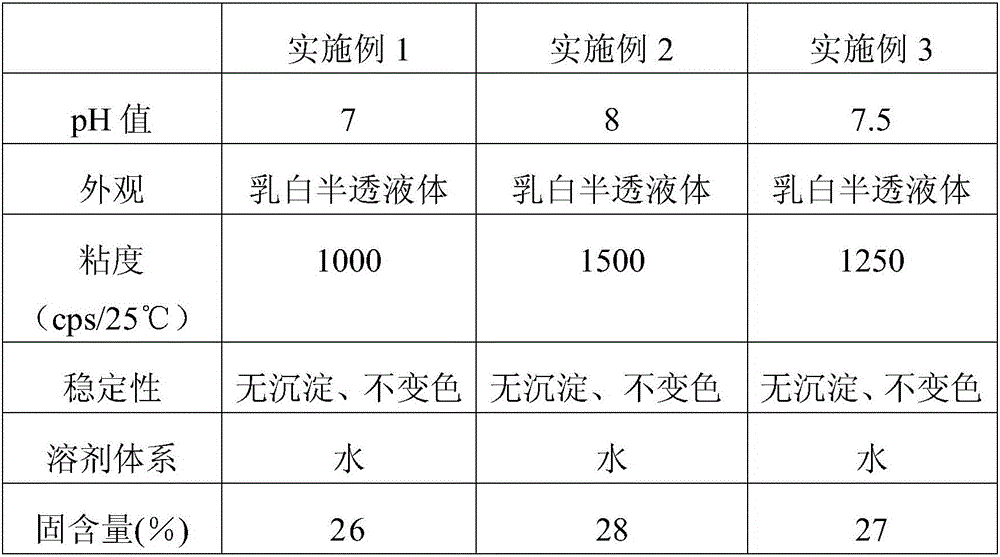

[0029] The water-based high-solid varnish treatment agent for synthetic leather includes 75 parts by mass of water-based resin, 0.05 parts by mass of a defoamer, 0.3 parts by mass of a wetting agent, 0.4 parts by mass of a Deqian thickener, 2 parts by mass of BCS, and 22.25 parts by mass of water.

[0030] The preparation method of the above-mentioned water-based high-solid varnish treatment agent for synthetic leather is: 75 parts by mass of water-based resin in the formula, 0.05 parts by mass of defoamer, 0.3 parts by mass of wetting agent, 0.4 parts by mass of Deqian thickener, 2 Parts by mass of BCS and 22.25 parts by mass of water were uniformly stirred to obtain the water-based high-solid varnish treatment agent for synthetic leather. The performance indexes of the obtained synthetic leather water-based high-solid varnish treatment agent are shown in Table 1.

[0031] The methods such as stirring used in the above preparation process are all conventional methods in the a...

Embodiment 2

[0033] The water-based high-solid varnish treatment agent for synthetic leather includes 78 parts by mass of water-based resin, 0.03 parts by mass of a defoamer, 0.3 parts by mass of a wetting agent, 0.27 parts by mass of a Deqian thickener, 1.4 parts by mass of BCS, and 20 parts by mass of water.

[0034] The preparation method of the above-mentioned water-based high-solid varnish treatment agent for synthetic leather is: 78 parts by mass of water-based resin in the formula, 0.03 parts by mass of defoamer, 0.3 parts by mass of wetting agent, 0.27 parts by mass of Deqian thickener, 1.4 parts by mass Parts by mass of BCS and 20 parts by mass of water are uniformly stirred to obtain the water-based high-solid varnish treatment agent for synthetic leather. The performance indexes of the obtained synthetic leather water-based high-solid varnish treatment agent are shown in Table 1.

[0035] The methods such as stirring used in the above preparation process are all conventional met...

Embodiment 3

[0037] The water-based high-solid varnish treatment agent for synthetic leather includes 75 parts by mass of water-based resin, 0.02 parts by mass of a defoamer, 0.2 parts by mass of a wetting agent, 0.28 parts by mass of a Deqian thickener, 1.5 parts by mass of BCS, and 23 parts by mass of water.

[0038] The preparation method of the above-mentioned water-based high-solid varnish treatment agent for synthetic leather is: 75 parts by mass of water-based resin in the formula, 0.02 parts by mass of defoamer, 0.2 parts by mass of wetting agent, 0.28 parts by mass of Deqian thickener, 1.5 parts by mass Parts by mass of BCS and 23 parts by mass of water were uniformly stirred to obtain the water-based high-solid varnish treatment agent for synthetic leather. The performance indexes of the obtained synthetic leather water-based high-solid varnish treatment agent are shown in Table 1.

[0039] The methods such as stirring used in the above preparation process are all conventional me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com