Waterborne oily leather treatment agent for synthetic leather and preparation method of leather treatment agent

A technology for synthetic leather and treatment agent, applied in the preparation of the synthetic leather water-based oily skin treatment agent, and the field of synthetic leather water-based oily skin treatment agent, can solve the problems of poor comprehensive treatment effect, poor synthetic leather feel, environmental pollution and the like, Achieve the effect of not easy to settle, good moisture permeability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

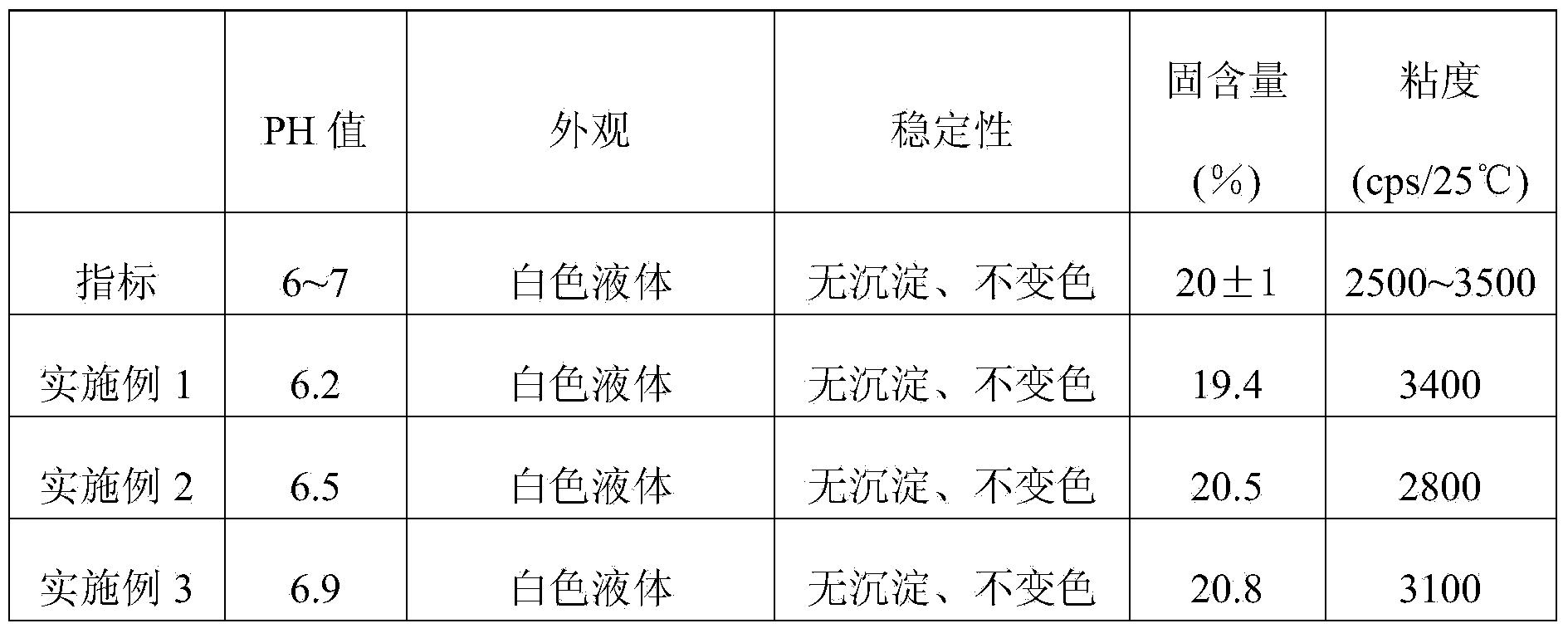

Embodiment 1

[0026] The synthetic leather water-based oily skin treatment agent is composed of the following components: 60 parts by weight of modified waterborne polyurethane, 38 parts by weight of water, 0.5 parts by weight of water-based leveling agent, and 1.5 parts by weight of water-based thickener.

[0027] The preparation method of the above-mentioned velvet treatment agent for synthetic leather is: under normal temperature and pressure, 30 parts by weight of modified water-based polyurethane resin, 0.75 parts by weight of water-based thickener, 38 parts by weight of water and 0.5 parts by weight of water-based Mix the leveling agent and stir for at least 30 minutes; add the remaining 30 parts by weight of the aqueous polyurethane resin and the remaining 0.75 parts by weight of the aqueous thickener to the obtained mixture, and stir for at least 30 minutes until the mixture is uniformly mixed to obtain the present invention Synthetic leather water-based oily skin treatment agent, the p...

Embodiment 2

[0030] The synthetic leather water-based oily skin treatment agent is composed of the following components: 61 parts by weight of modified waterborne polyurethane, 36 parts by weight of water, 1 part by weight of water-based leveling agent, and 2 parts by weight of water-based thickener.

[0031] The preparation method of the above-mentioned suede treatment agent for synthetic leather is: under normal temperature and pressure, 30.5 parts by weight of modified water-based polyurethane resin, 1 part by weight of water-based thickener, 36 parts by weight of water and 1 part by weight of water-based Mix the leveling agent and stir for at least 30 minutes; add the remaining 30.5 parts by weight of the aqueous polyurethane resin and the remaining 1 part by weight of the aqueous thickener to the obtained mixture, and stir for at least 30 minutes until the mixture is uniformly mixed to obtain the present invention Synthetic leather water-based oily skin treatment agent, the performance in...

Embodiment 3

[0034] The synthetic leather water-based oily skin treatment agent consists of the following components in the following proportions: 63 parts by weight of modified water-based polyurethane, 35 parts by weight of water, 0.5 parts by weight of water-based leveling agent, and 1.5 parts by weight of water-based thickener.

[0035] The preparation method of the above-mentioned suede treatment agent for synthetic leather is: under normal temperature and pressure, 31.5 parts by weight of modified water-based polyurethane resin, 0.75 parts by weight of water-based thickener, 35 parts by weight of water and 0.5 parts by weight of water-based Mix the leveling agent and stir for at least 30 minutes; add the remaining 31.5 parts by weight of the aqueous polyurethane resin and the remaining 0.75 parts by weight of the aqueous thickener to the obtained mixture, and stir for at least 30 minutes until the mixture is uniformly mixed to obtain the present invention Synthetic leather water-based oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com