Manufacture of high absorption conjugated yarn by special yarn working technology and textile thereof

A high-absorbency, composite yarn technology, applied in the field of composite yarn, can solve the problems of restricting the development of various products and difficulties in the development of fiber materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (manufacturing and weaving of composite yarn)

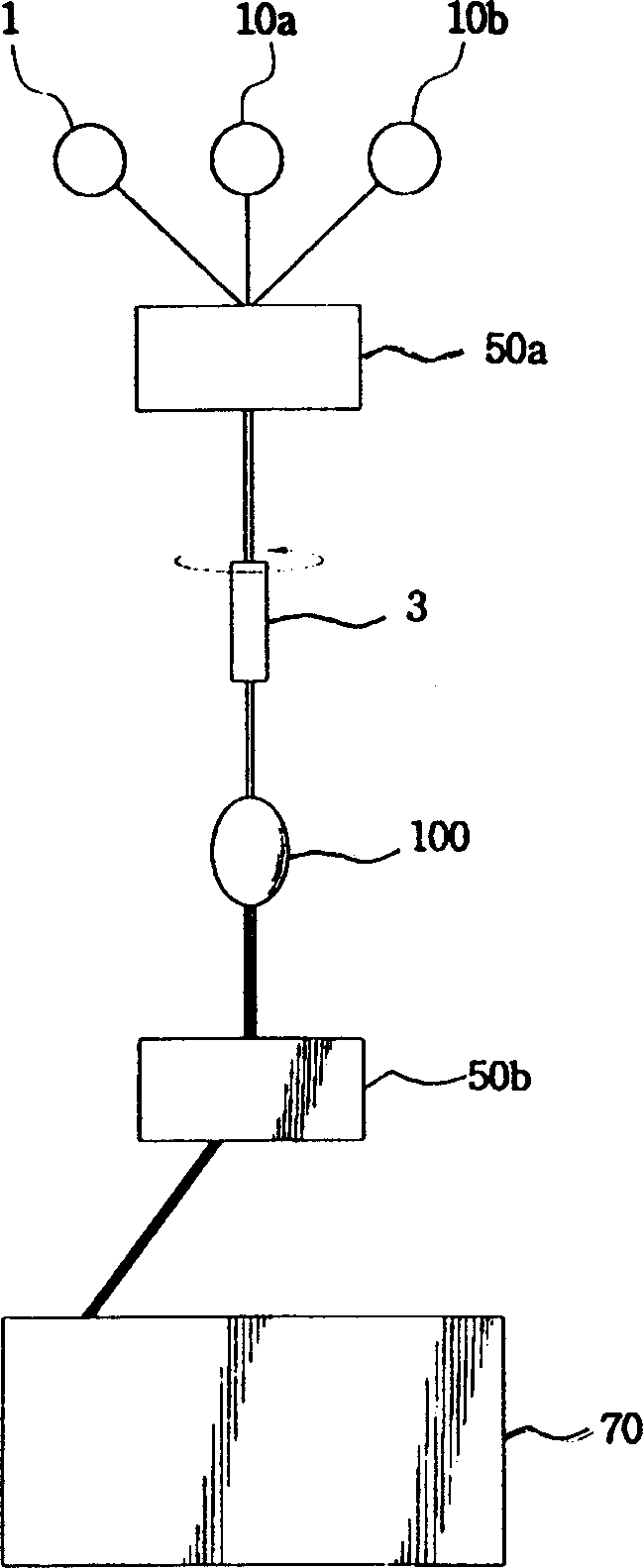

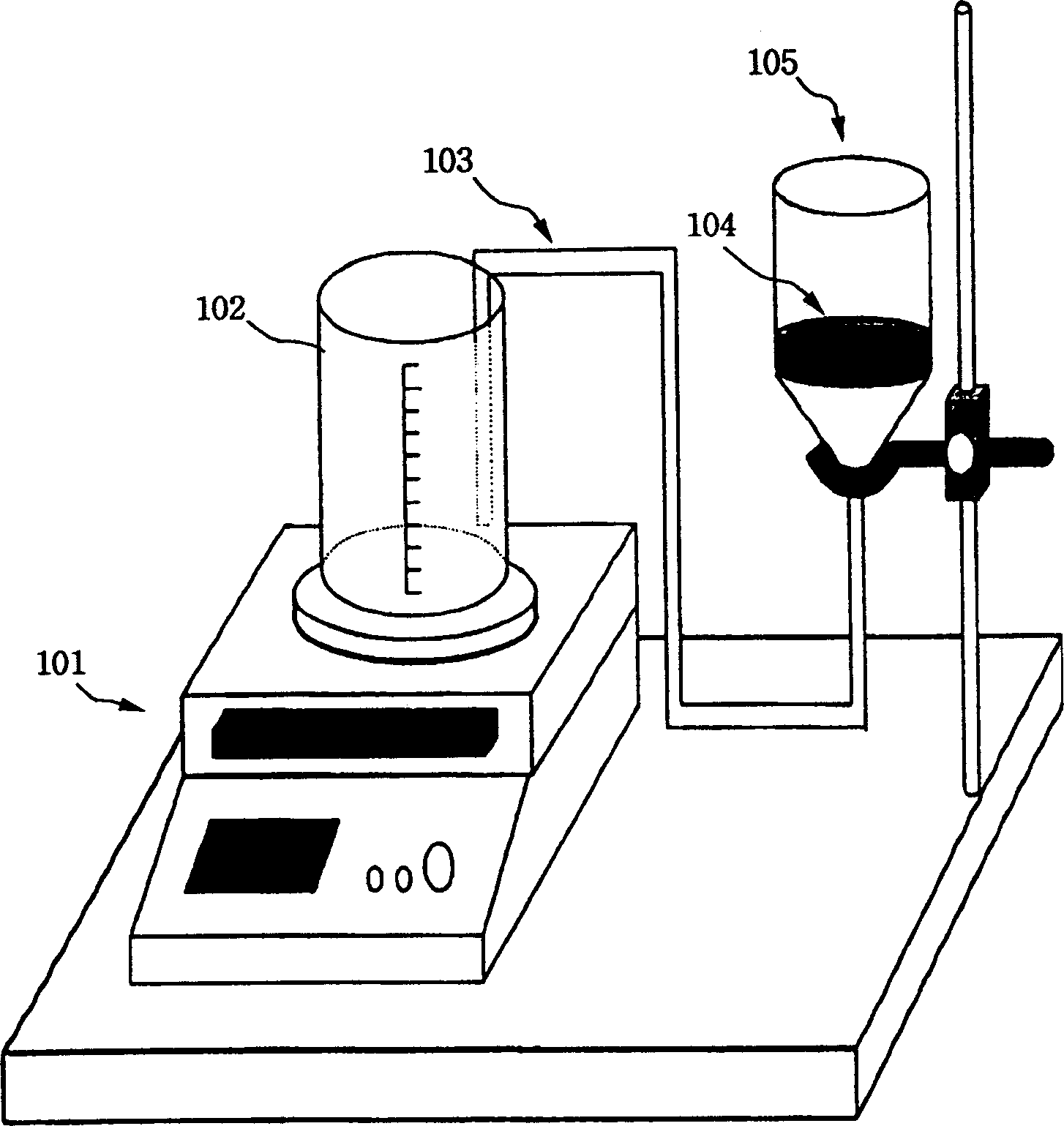

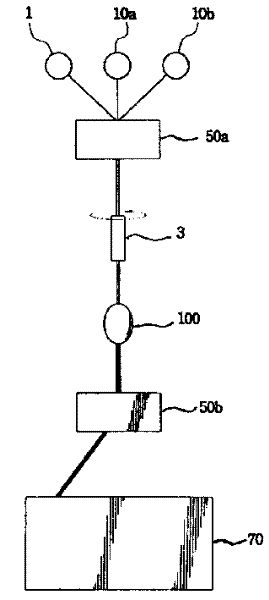

[0050] With 2000TM polyester false twist yarn (Hyosung Co., Ltd. product) 75D / 36F (75 denier 36 single bundle yarn) as the core yarn, composed of 30% polyamide and 70% polyester Ultra-fine split yarn (PET / nylon split yarn) (false twist number 2000TM) 150 / 72 (manufactured by Hyosung Co., Ltd.) is the first outer wrapping yarn and the second outer wrapping yarn, and is fed at a ratio of 2.5 times that of the core yarn In the twisting machine, it is combined to make it produce wrapping yarn on the surface of the silk; in order to prevent the excessive accumulation of the wrapping yarn layer, the composite of the fixed yarn adopts false twist polyester filament 75 / 36 (Hyosung Co., Ltd. Club products).

[0051] Ordinary twisting machine, the silk production speed is 6-12 m / min. In the present embodiment, the input speed of the silk (core silk, outer wrapping silk, fixed silk) is adjusted to make the coiling speed of the fi...

Embodiment 2

[0080] Except that the weave of the fabric is satin weave, it is manufactured by the same process as in Example 1.

Embodiment 3

[0082] It was manufactured by the same process as in Example 1 except that polyester false twisted yarn 750D (manufactured by Hyosung Co., Ltd.) was used for the wrapping yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com