Patents

Literature

69results about How to "Shrink big" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

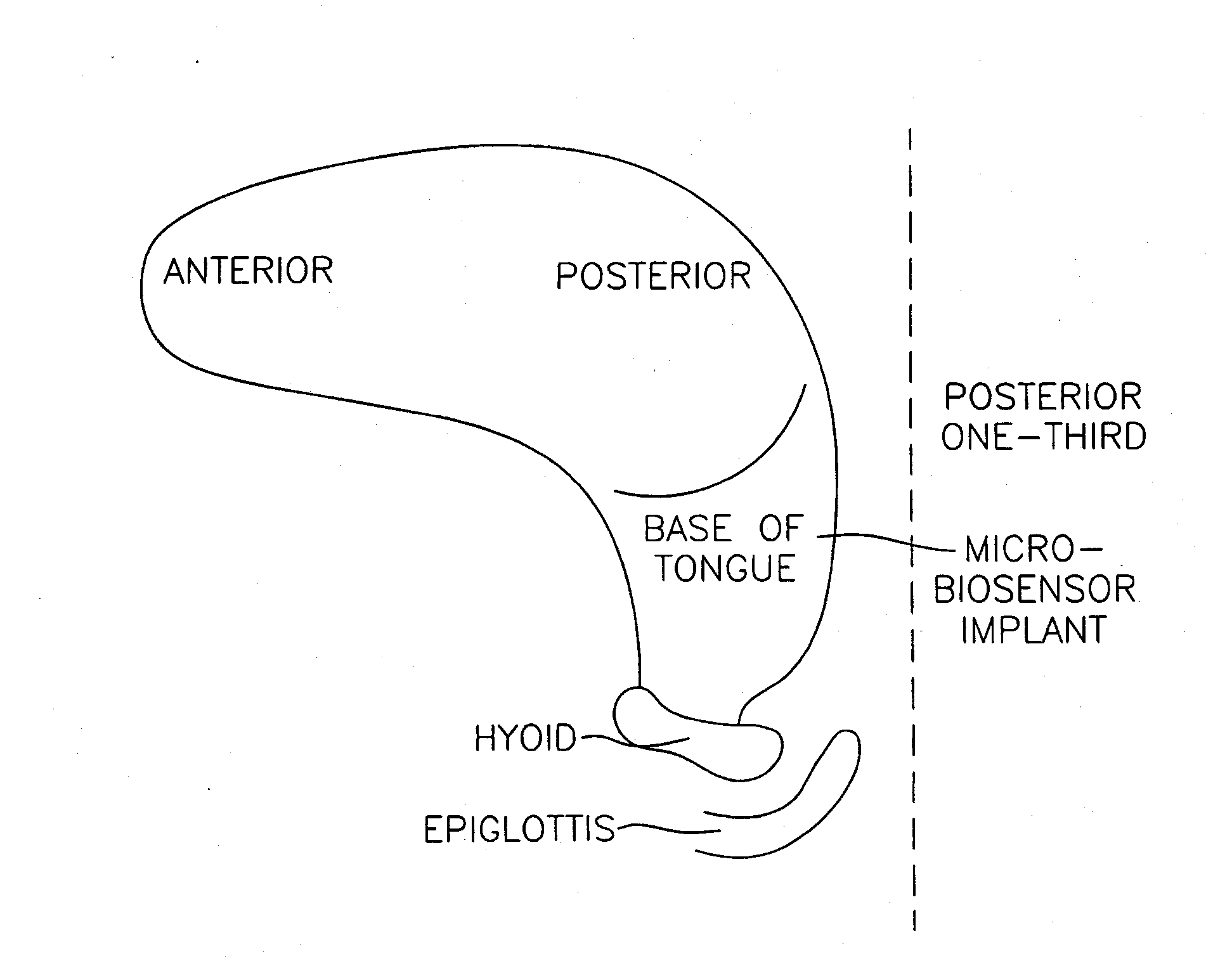

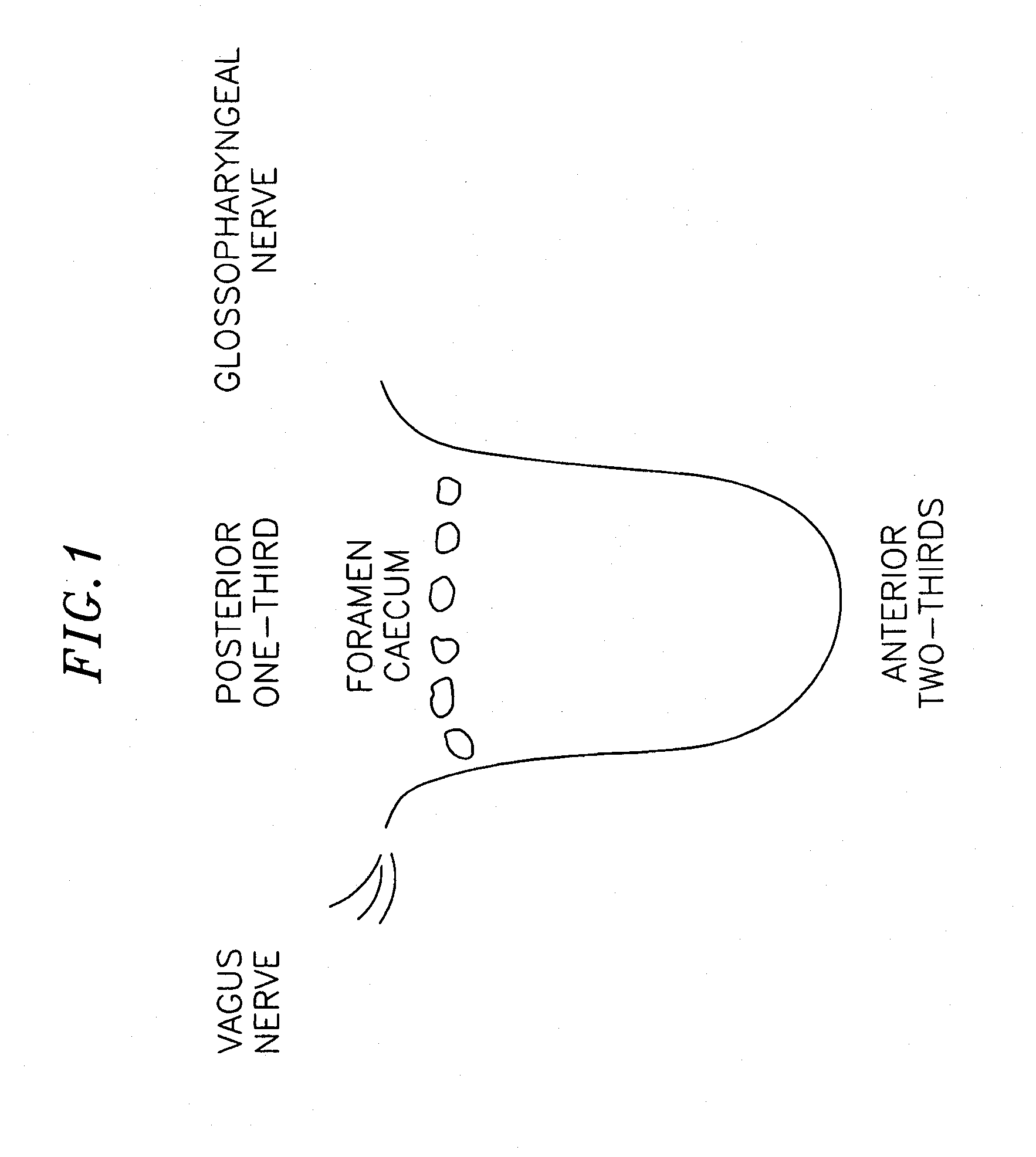

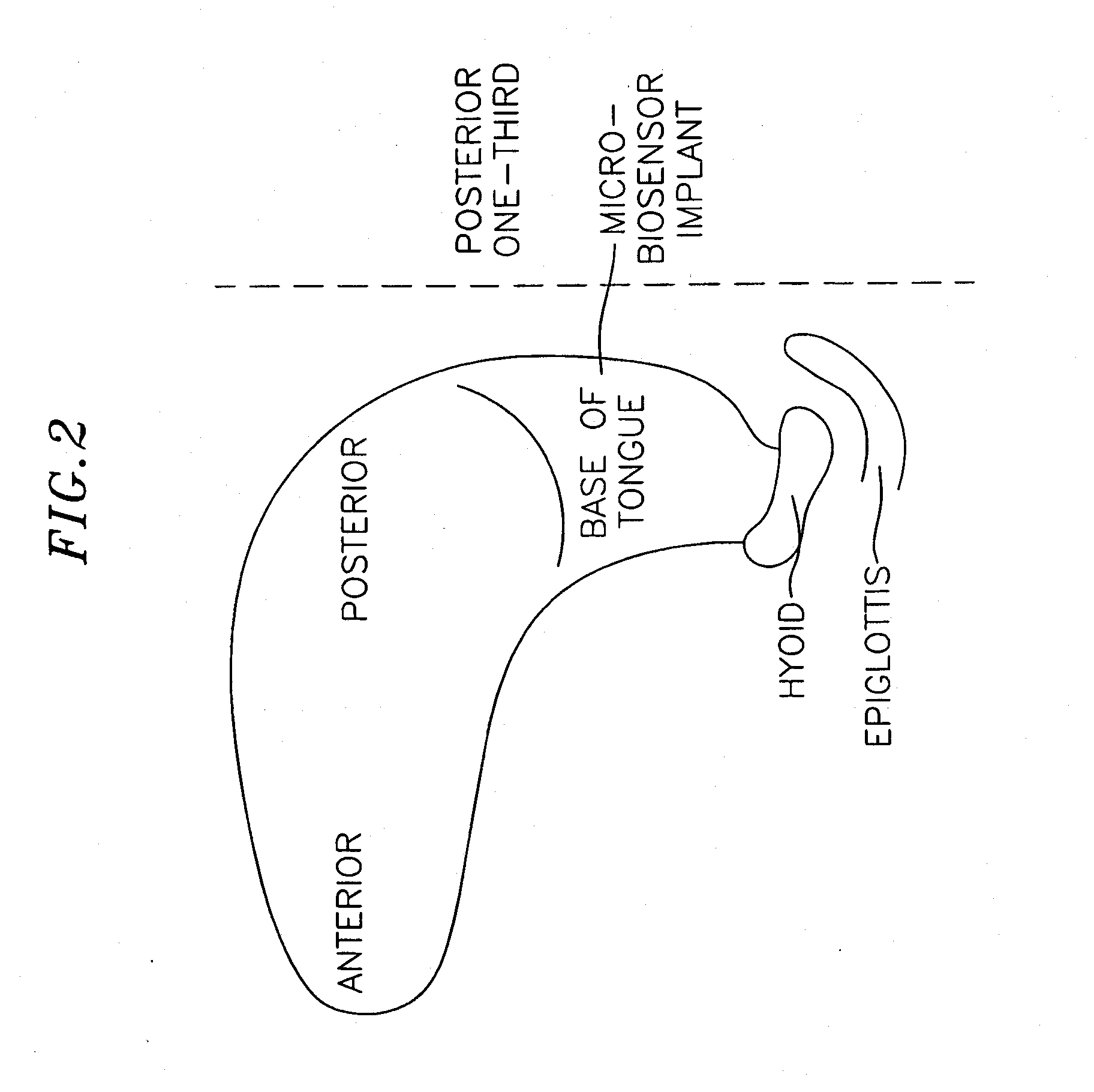

Method and apparatus for preventing obstructive sleep apnea

InactiveUS20070173893A1Patient compliance is goodRelieve symptomsElectrotherapyArtificial respirationMuscle toneGenioglossus muscle

A method and device for creating an afferent stimulus for preventing obstructive sleep apnea are disclosed. The device includes at least one electrode and a stimulator, of which at least one electrode stimulates the genioglossus muscle of a patient having obstructive sleep apnea. The electrode is capable of conducting selected electrical stimulation generated by the stimulator, and the system is capable of delivering the selected electrical stimulation during a selected time of day. The electrical stimulation is selected to maintain sufficient muscle tone of the genioglossus muscle to prevent it from obstructing the airway during sleep, preferably at a stimulus intensity low enough to avoid awakening the patient during sleep. A removable mouthpiece having a battery, at least one electrode, and a controller, and optionally a sensor, can be used for providing the stimulation.

Owner:PITTS WALTER C

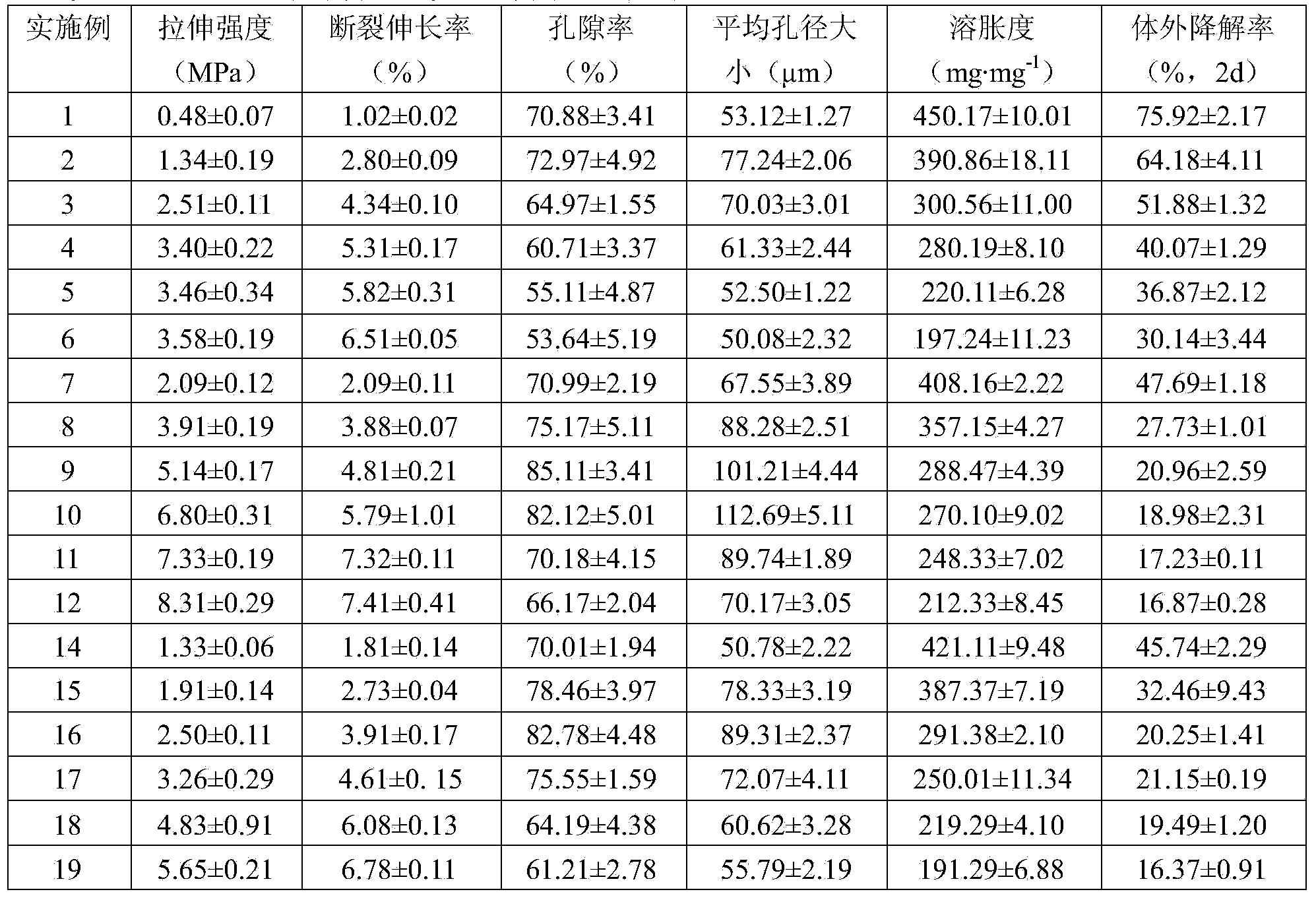

Method for preparing collagen protein/silica membrane double-layer stent

ActiveCN103961749AImprove mechanical propertiesGood antibacterial effectAbsorbent padsProsthesisWound healingInsertion stent

The invention relates to a method for preparing a collagen protein / silica membrane double-layer stent. According to the invention, a collagen sponge with a porous network structure is prepared through different crosslinking methods, and a layer of silica membrane with different thicknesses is coated on the collagen sponge again, then the collagen protein / silica membrane double-layer stent is prepared. The collagen protein / silica membrane double-layer stent obtained in the invention has a good effect in an application of being used as an artificial skin stent material, and two layers of the material have different functions, namely the outer layer of the silica membrane has higher mechanical strength to be capable of supporting and protecting a wound, and a good gas-liquid permeability performance to be capable of effectively preventing fluid loss, and a moderate density performance to be capable of preventing bacterial infections and providing a moister environment for wound repair; the inner layer of the collagen sponge can effectively promote cell proliferation and differentiation, delay wound contraction and accelerate wound healing.

Owner:无锡贝迪生物工程股份有限公司

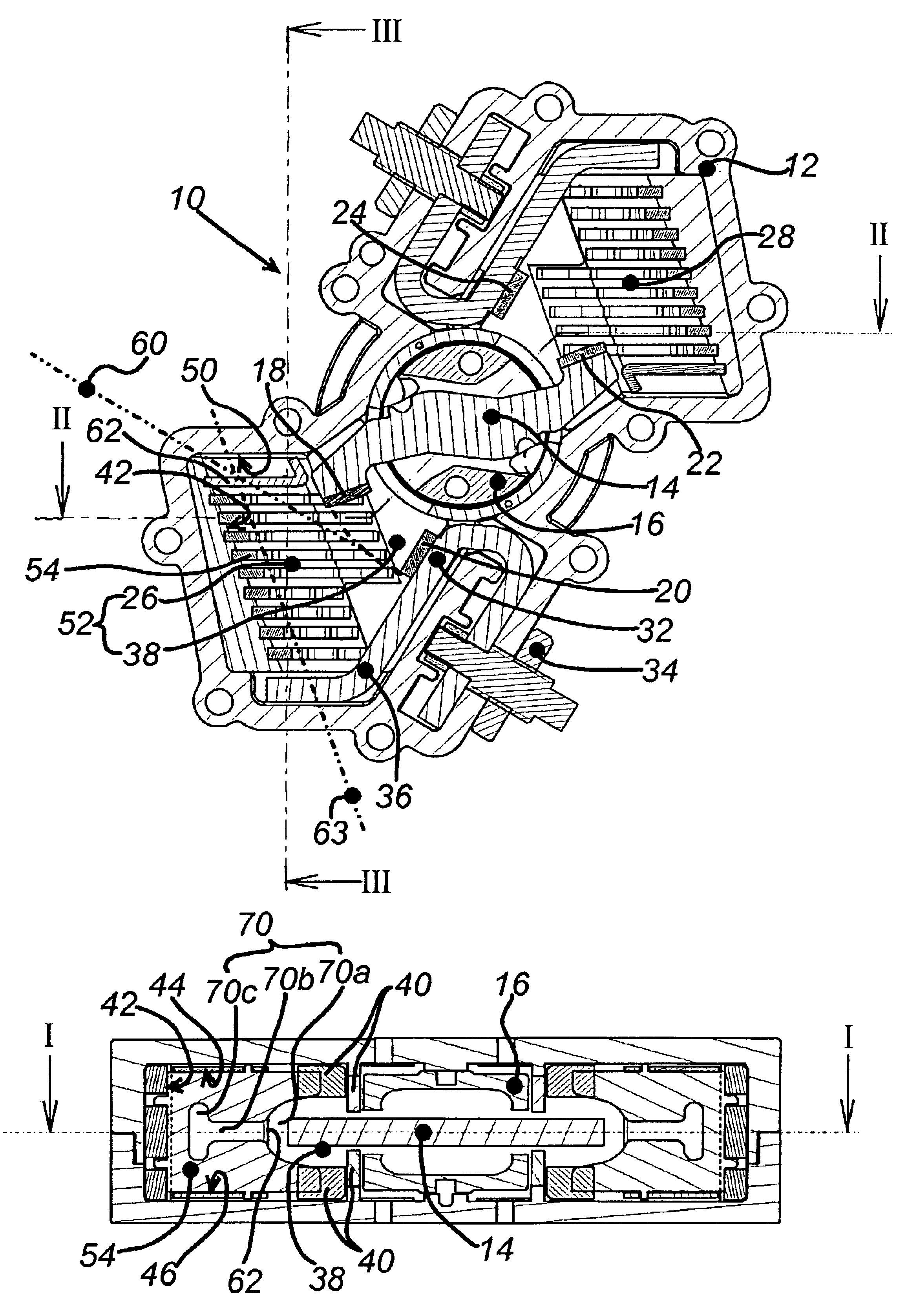

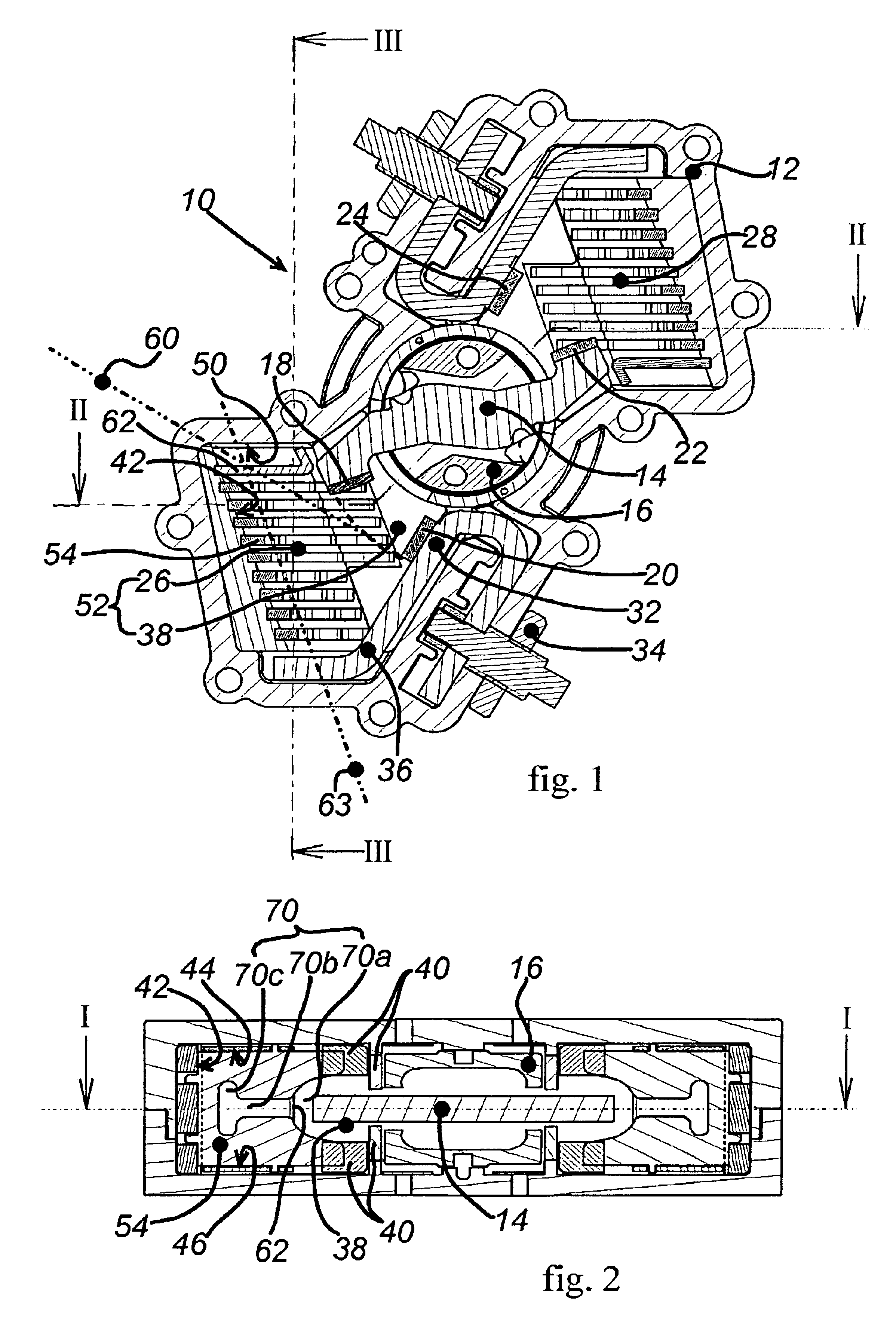

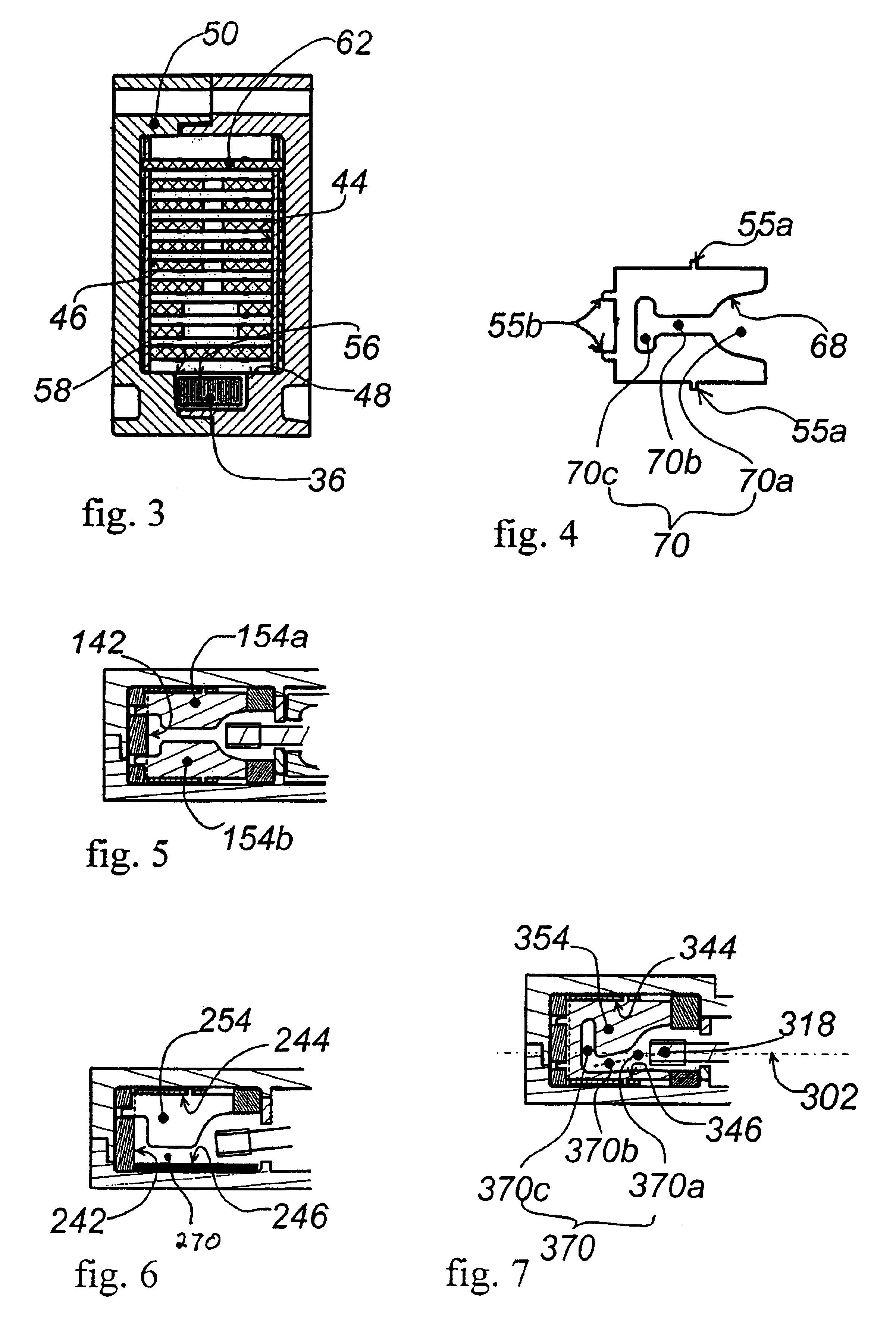

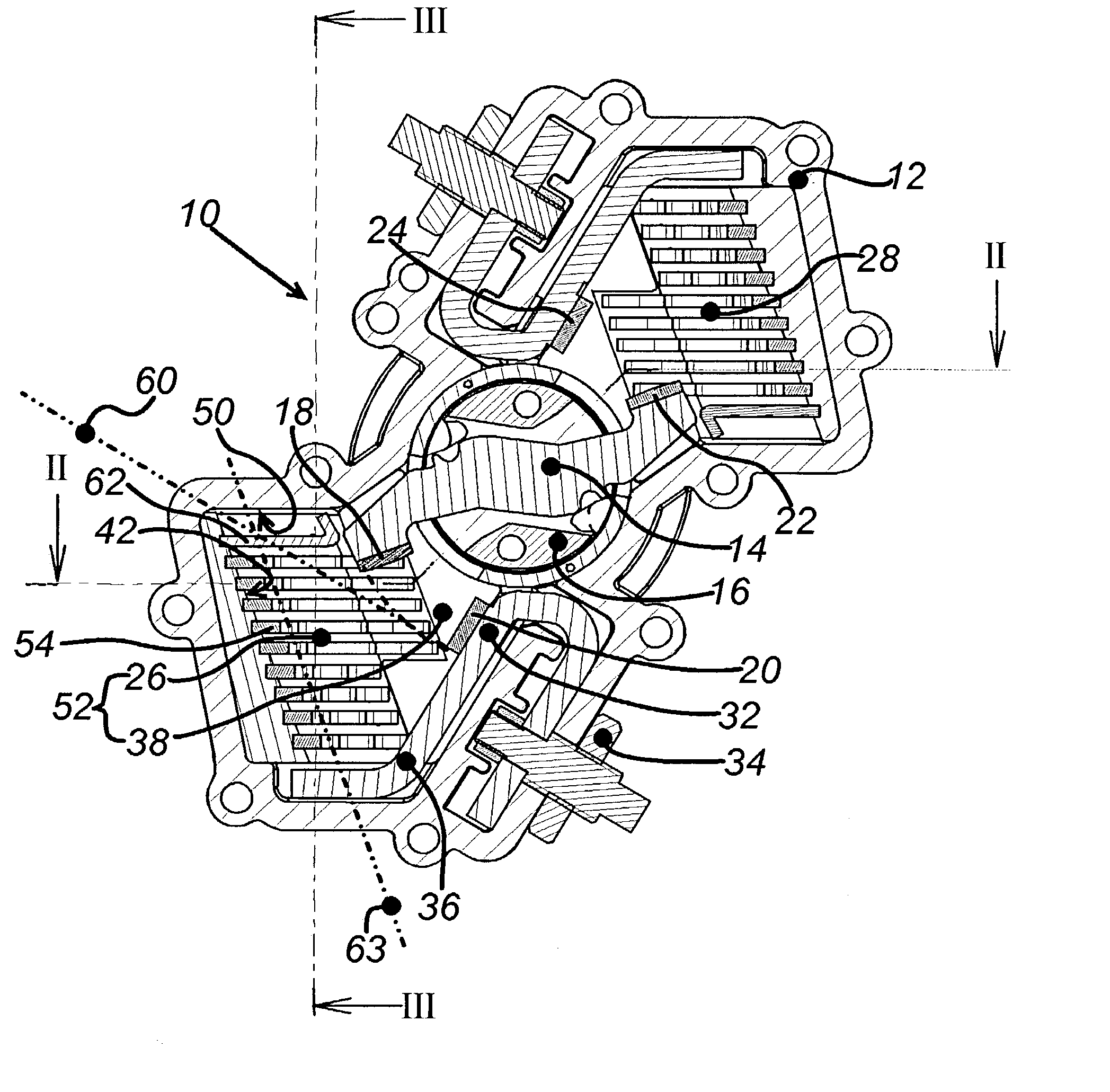

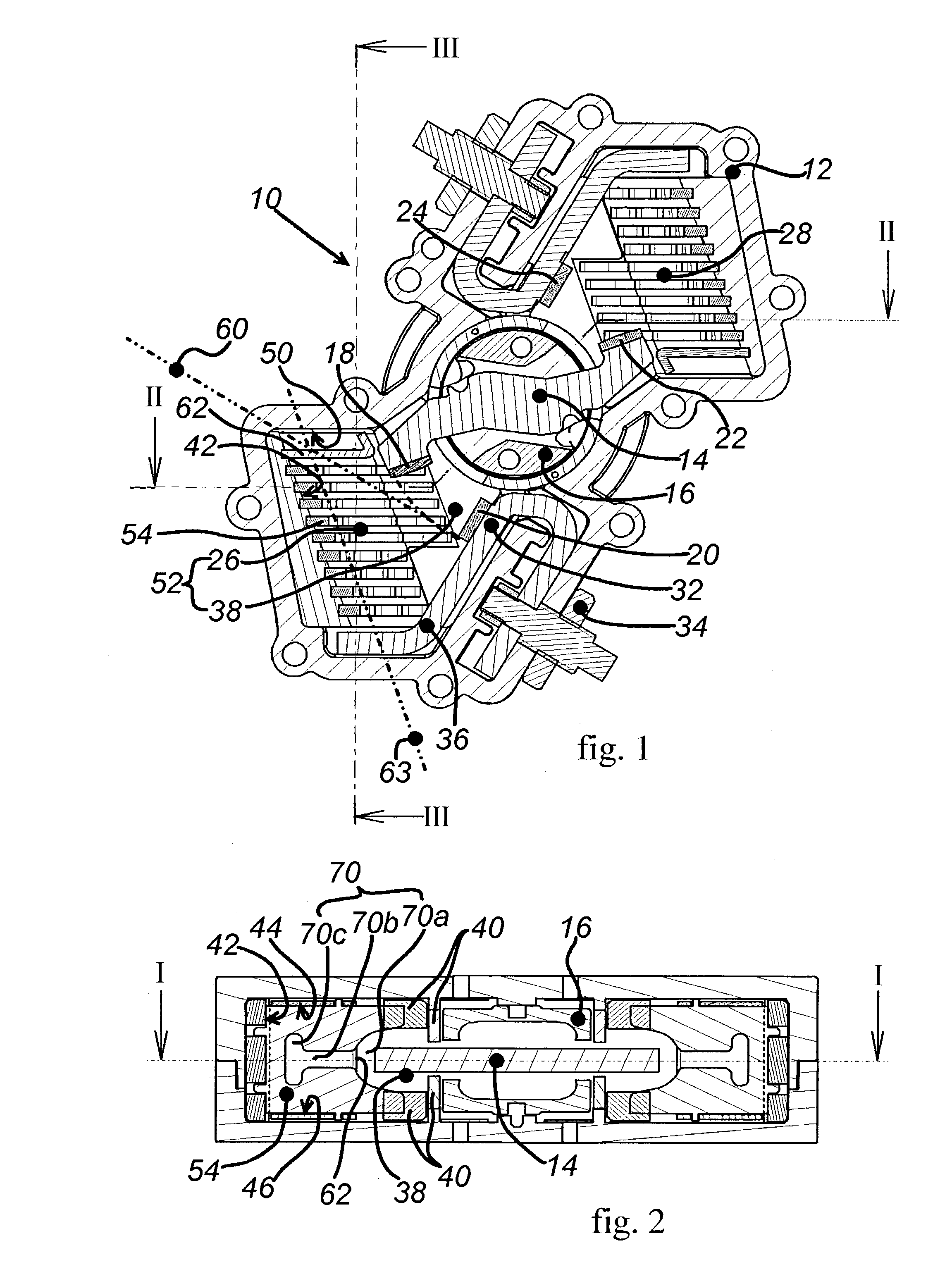

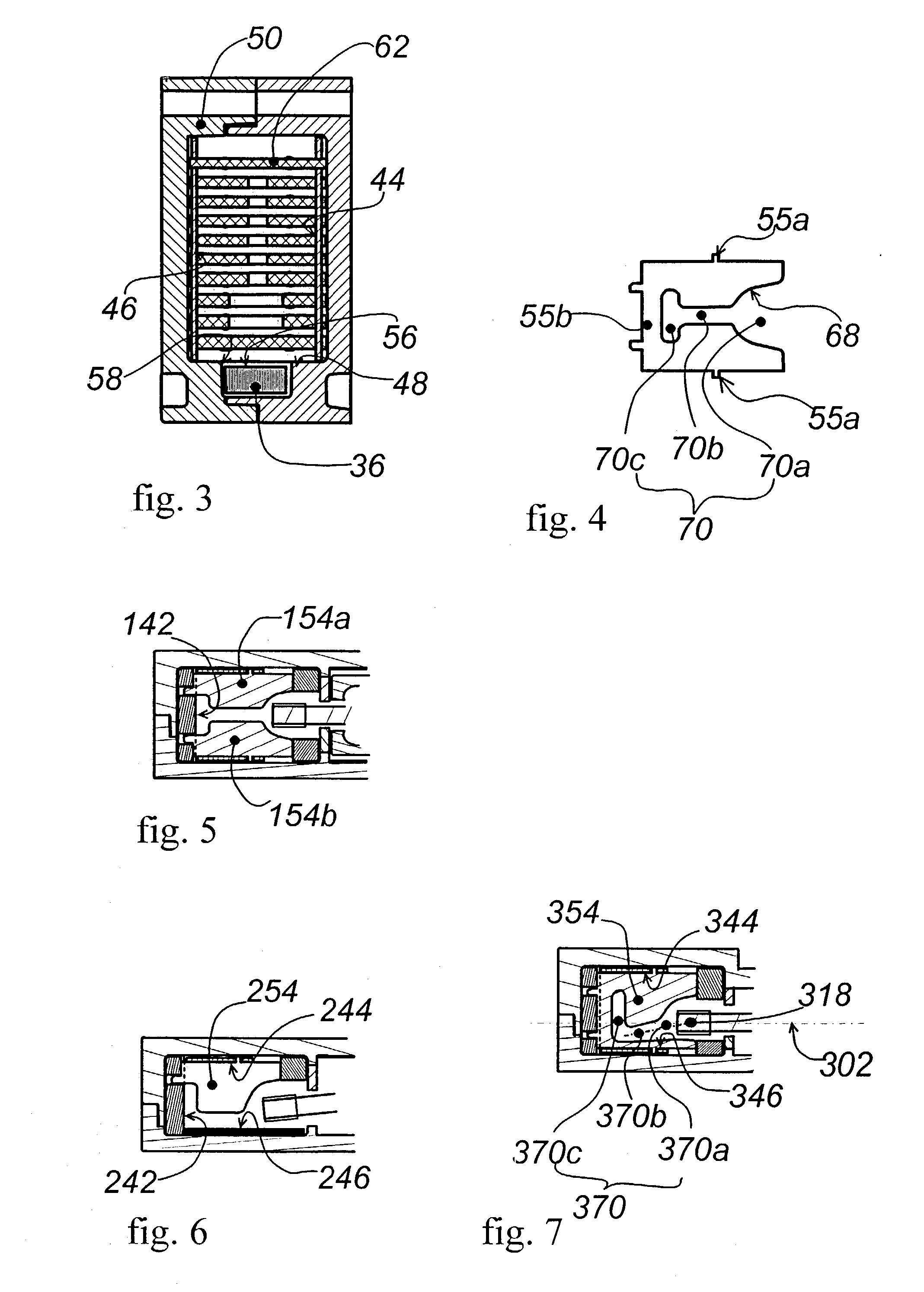

Electrical switchgear apparatus comprising an arc extinguishing chamber equipped with deionizing fins

InactiveUS6794595B2Good energyStable and fastCircuit-breaking switches for excess currentsProtective switchesFree edgeSwitchgear

A circuit breaker comprises a pair of separable contacts arranged in an opening volume. A plurality of flat de-ionization fins are arranged inside an arc extinguishing chamber opening out onto the opening volume. The chamber is bounded by two opposite side walls, a rear wall located away from the opening volume, a bottom wall and a top wall. Each fin has a free attack edge exposed to the arc. The free edges of the fins laterally bound a longitudinal gulley extending in a heightwise direction from the bottom electrode to the top wall, and longitudinally from a first longitudinal end opening out onto the opening volume at a second longitudinal end tapering to form a stack near to the rear wall, passing via a narrow intermediate portion. A bottom longitudinal electrode partially covers the bottom wall and extends longitudinally facing the gulley at least from the second contact up to the stack.

Owner:SCHNEIDER ELECTRIC IND SAS

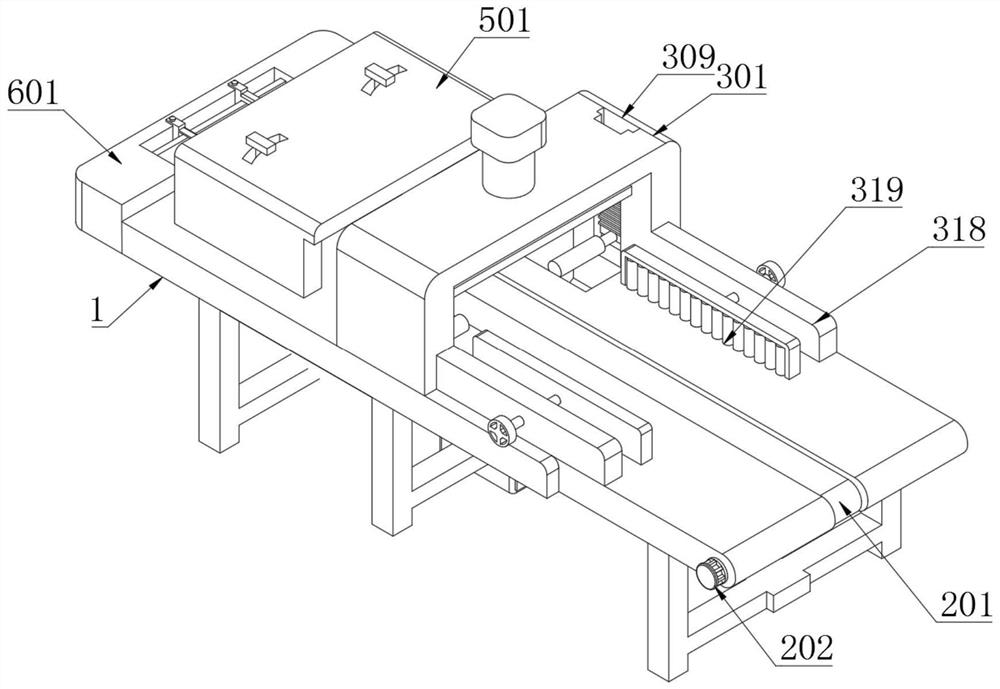

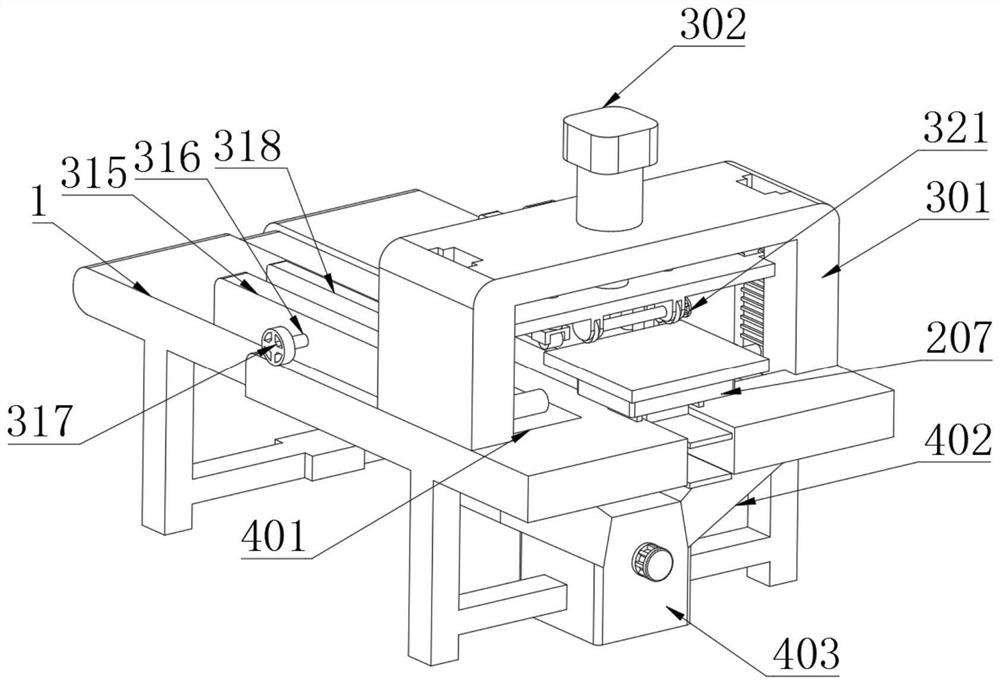

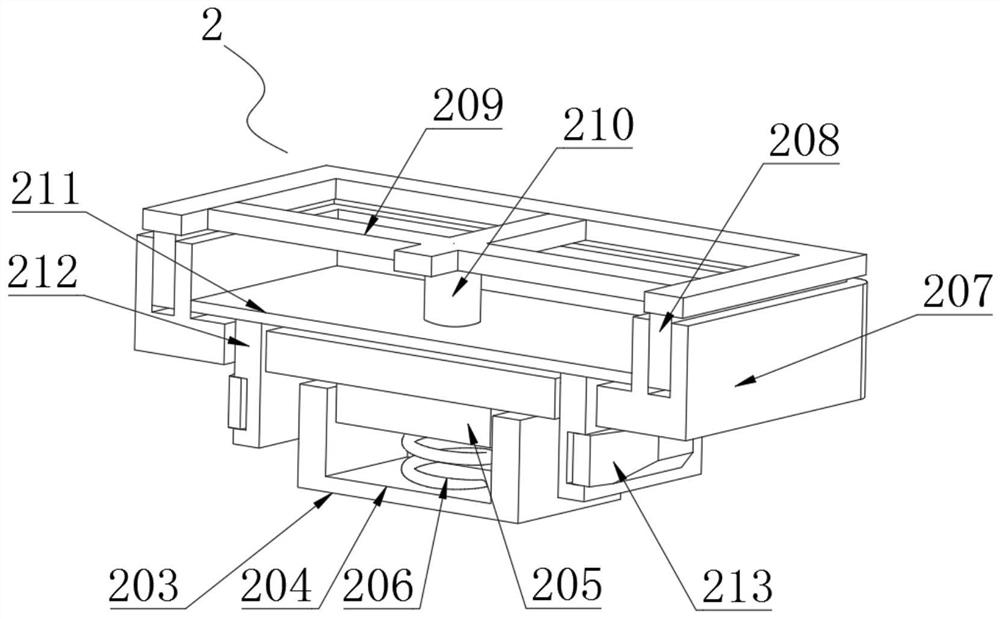

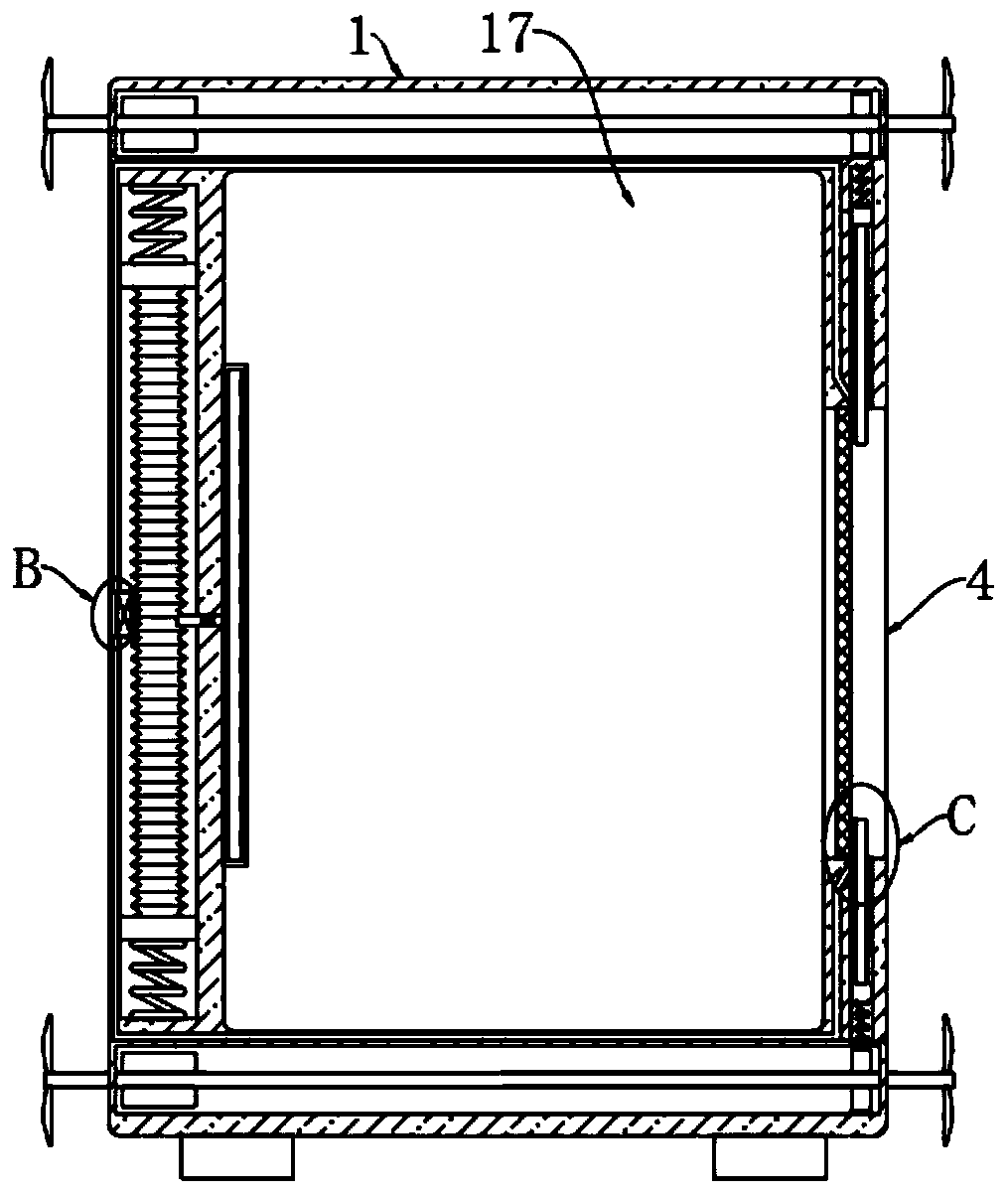

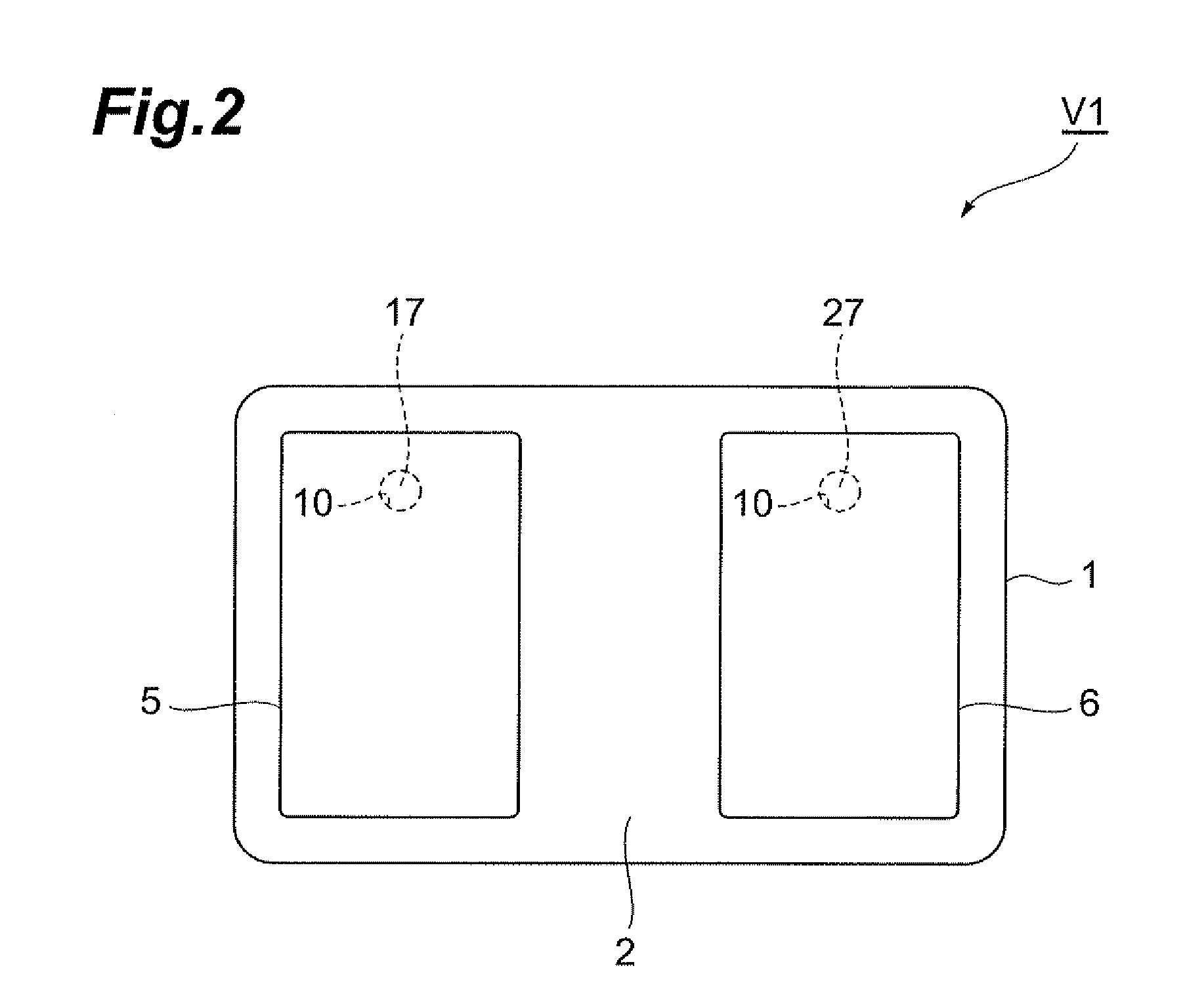

Flexible display screen and manufacturing method thereof

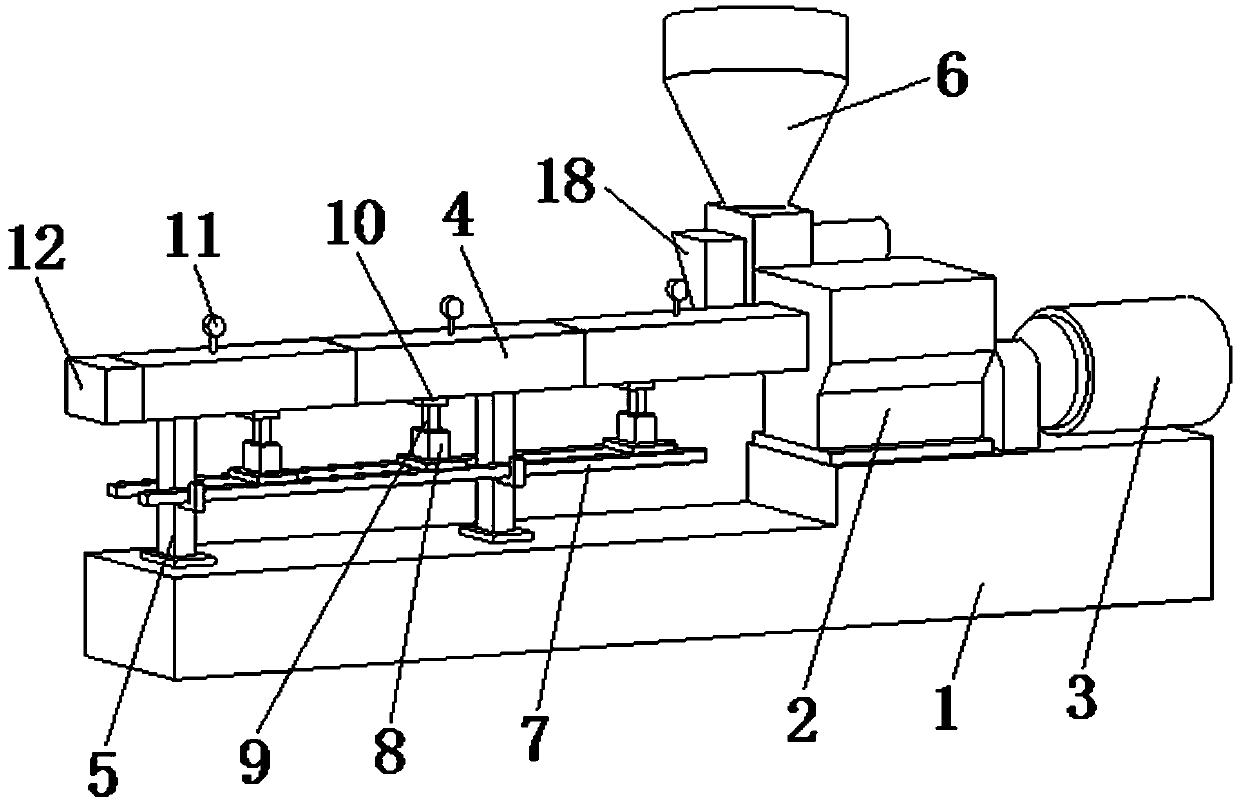

ActiveCN111882991AScientific and reasonable structureEasy to useEdge grinding machinesGrinding carriagesElectric machineryDrive motor

The invention discloses a flexible display screen and a manufacturing method thereof. The middle of the top end of a machine base is fixedly connected with a positioning cutting mechanism, the other side of the top end of the machine base is fixedly connected with a power conversion and grinding mechanism, and the middle of the machine base is rotationally connected with an adsorption fixing and moving mechanism; The adsorption fixing and moving mechanism comprises a conveying belt, a driving motor, a mounting base, an embedding groove, a movable plate, a supporting spring, a suction cup and arubber plate. The flexible display screen is scientific and reasonable in structure and safe and convenient to use, the adsorption fixing and moving mechanism is arranged, glass is adsorbed and fixedthrough the suction cups, the stability of the glass is improved, loss caused by falling of glass in moving machining process is avoided. The movable plug plate is driven to slide in the suction cupthrough cooperation of the rubber plate and the connecting rod in the glass adsorption process, and meanwhile the movable plug plate extrudes air pressure in the suction cup due to the fact that the movable plug plate is attached to the interior of the suction cup.

Owner:SHENZHEN RUGIN ELECTRONICS

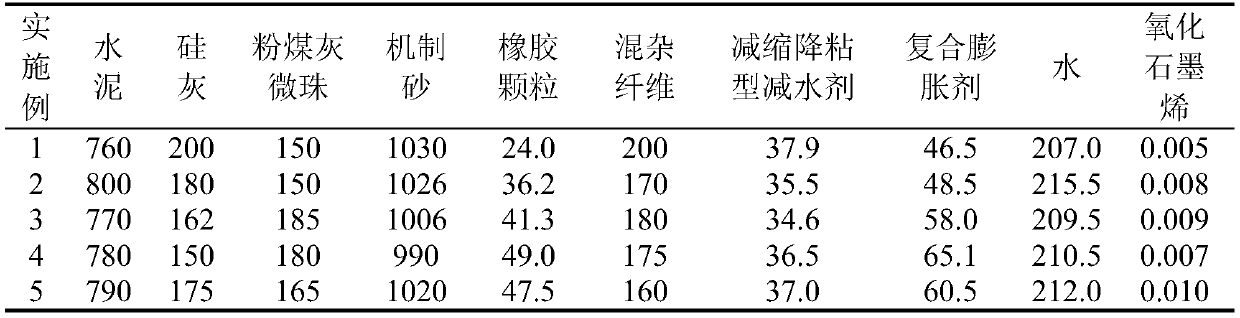

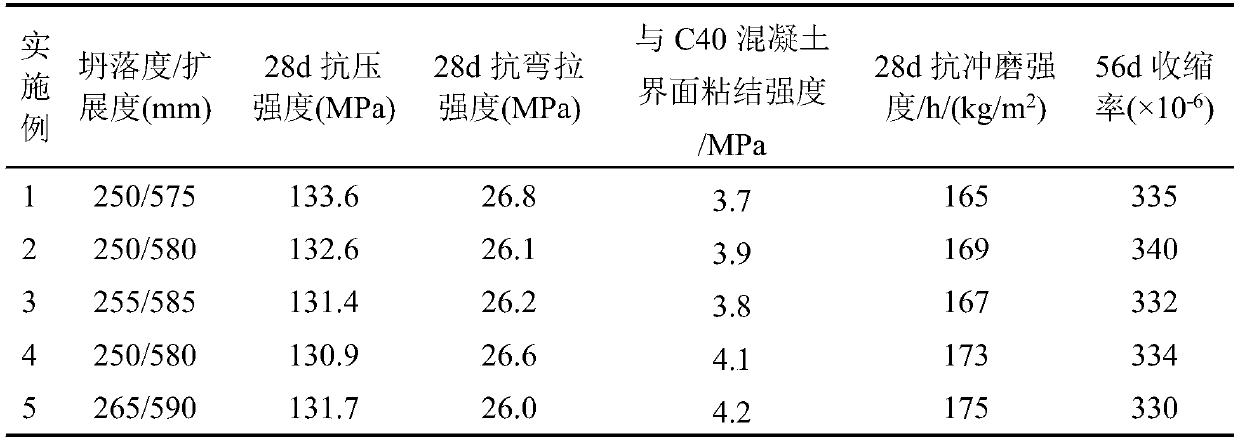

Graphene oxide anti-abrasion ultra-high toughness concrete and preparation method and application thereof

InactiveCN110683809AImprove impact toughnessImprove wear resistanceSolid waste managementWater reducerSilica fume

The invention discloses a graphene oxide anti-abrasion ultra-high toughness concrete. The concrete comprises the following raw materials in parts by weight: 700 to 800 parts by mass of cement, 150 to200 parts by mass of fly ash microbead, 150 to 200 parts by mass of silica fume, 900 to 1080 parts by mass of machine-made sand, 23 to 50 parts of hydrophilic rubber particle, 160 to 200 parts of hybrid fibers, 34.5 to 37.95 parts of shrinkage and viscosity reducing water reducing agent, 0.005 to 0.01 part of graphene oxide, 46 to 69 parts of composite expansion agent and 207 to 218.5 parts of water; the hybrid fiber is formed by mixing copper plated flat steel fiber, multi-anchor steel fiber and PVA fiber according to the mass ratio of 6-8: 1-2: 1-2. The graphene oxide anti-impact and anti-wear ultra-high toughness concrete prepared by the invention has excellent impact toughness and anti-wear performance, good volume stability and high interface bonding strength between new and old concrete.

Owner:湖北省高创公路工程咨询监理有限公司 +2

Damping sound-insulating spraying mortar

The invention discloses a damping sound-insulating spraying mortar. The damping sound-insulating spraying mortar is a bagged damping sound-insulating dry-blend spraying mortar prepared through mixing of an inorganic cementitious material, a filling material, an organic cementitious material and an additive under stirring; and the motor is stirred on site and uniformly sprayed on a base layer by using a spray coater. The motor comprises, by weight, 25 to 35 parts of cement, 5 to 15 parts of fly ash, 25 to 50 parts of fine and light aggregate, 10 to 40 parts of rubber powder, 0.6 to 5 parts of redispersible powder, 0.1 to 0.3 part of methylcellulose ether, 0.02 to 0.1 part of short fiber and 0.01 to 0.1 part of a water reducer. The damping sound-insulating spraying mortar can improve the sound reduction index of a wall and a ceiling when sprayed on the wall and the ceiling, and can replace a leveling layer of a floor and improve the impact sound reduction index of the floor when sprayed on the floor; and the damping sound-insulating spraying mortar can totally cover a variety of special-shape structures to form an effective sound-insulating layer and can be constructed in a variety of complex environments with narrow space.

Owner:XIAMEN JIADA GREEN CONSTRUCION ENG CO LTD

Porous carbon material and its preparation method

The invention discloses a porous carbon material and its preparation method. The preparation method provided by the invention successively comprises steps of: raw material and auxiliary material selection, pulverization, spheroidization, grading, burdening, mixing, molding, roasting and the like. Green petroleum coke and green pitch coke are creatively used as raw materials. A filtration materialprepared after spheroidization of a green coke powder has large contractility, high strength, uniform pore distribution, smooth pore path, high filtration precision and good transmissivity, is not easy to block during the purification process, is easy to regenerate, and has long service life. The porous carbon material prepared in the invention can be widely used as a filtration material, a thermal insulation material, a conductance electrode and the like.

Owner:ZIGONG YUXING CARBON PRODS

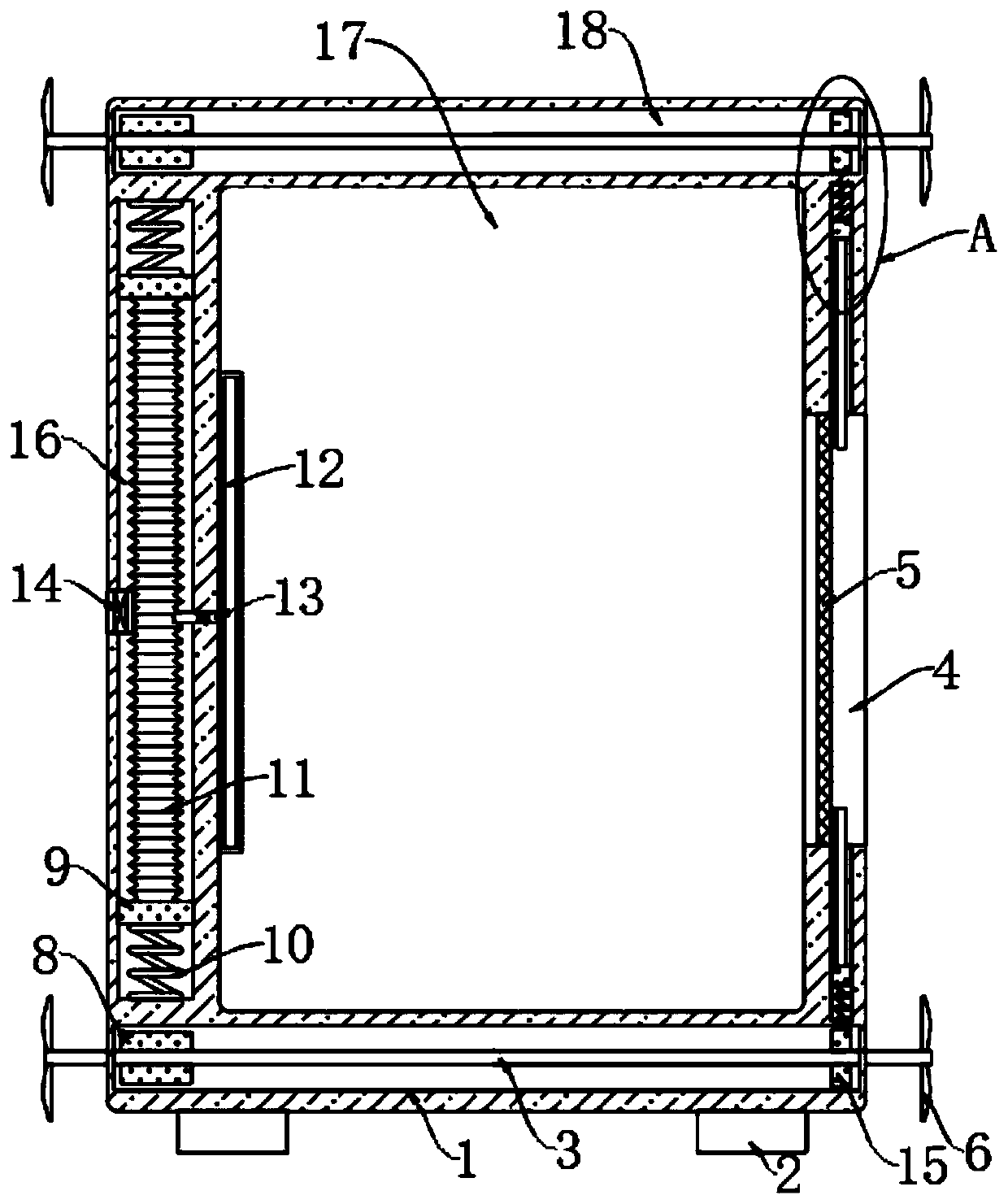

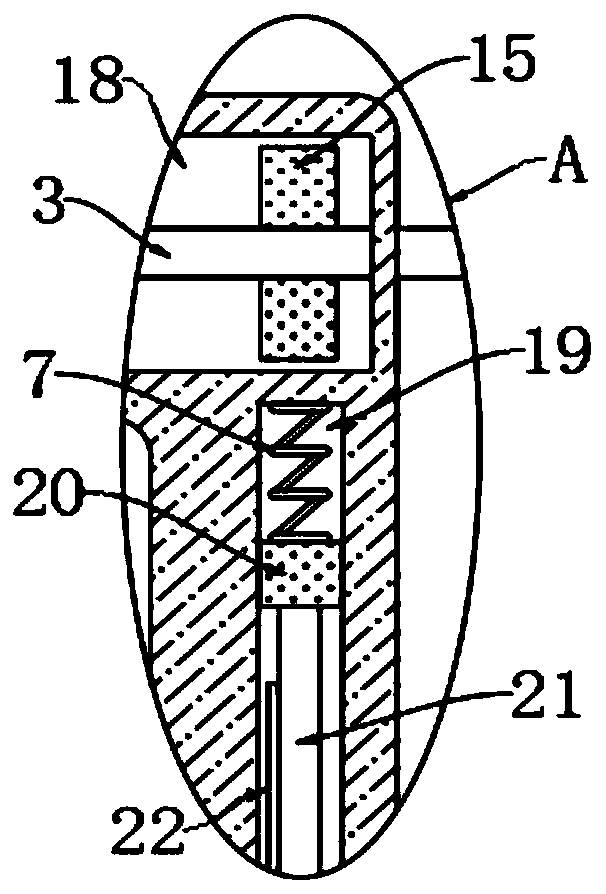

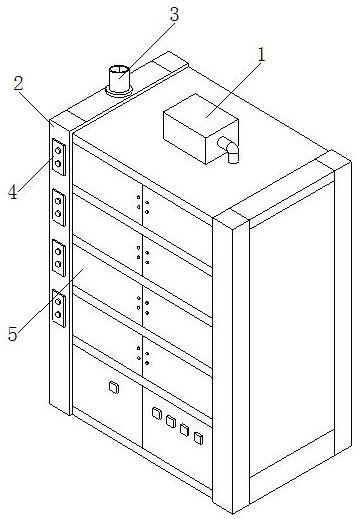

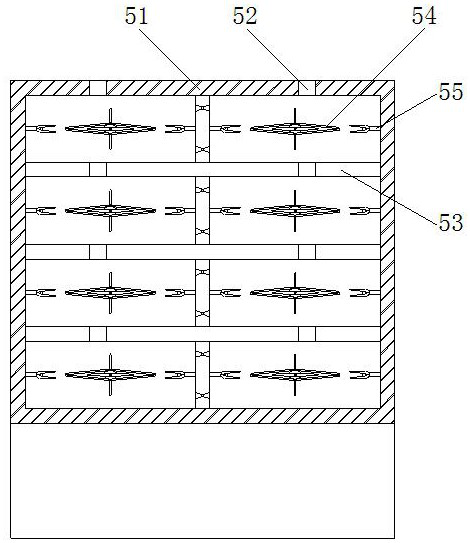

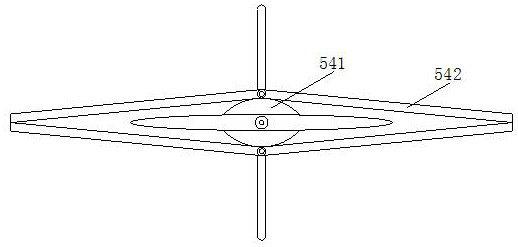

Active heat dissipation type box-type substation

ActiveCN111146721AShrink bigBig-amplitudeFouling preventionSubstation/switching arrangement cooling/ventilationThermodynamicsEngineering

The invention discloses an active heat dissipation type box-type substation, and the substation comprises a shell; a plurality of supporting blocks are fixedly connected to the lower end of the shell,and a mounting cavity is formed in the shell; transverse cavities are formed in the upper inner wall and the lower inner wall of the shell, and a vertical cavity is formed in the inner wall of the left side of the shell. A wind energy triggering mechanism comprises a rotating shaft which is horizontally and rotationally connected between the two inner walls of the transverse cavity, and the two ends of the rotating shaft penetrate through the inner walls of the two sides of the transverse cavity respectively, and fan blades are fixedly connected to the two ends of each rotating shaft; and anactive heat dissipation mechanism comprises a folding air bag vertically arranged in the vertical cavity, and first magnetic blocks are fixedly connected to the upper end and the lower end of the folding air bag. The substation dissipates heat through wind energy, does not need to use electric energy, is very convenient to use, can sweep dust on the heat dissipation net while dissipating heat, andavoids the situation that the heat dissipation efficiency is affected by too much dust.

Owner:易仁通电气集团股份有限公司

Low-temperature repairing material for high-speed rail base concrete in severe cold region and application of low-temperature repairing material

The invention belongs to the technical field of construction materials, and particularly relates to a low-temperature repairing material for a high-speed rail base concrete in a severe cold region and application of the concrete low-temperature repairing material. The low-temperature repairing material comprises the following components: 425 ordinary Portland cement, 425 sulphoaluminate cement, 725 sulphoaluminate cement, a waterproof admixture, rubber powder, an aggregate, a water reducer, a construction improver, a water-retaining agent, an early strength agent, a nano multifunctional water repellent agent, and PP (polypropylene) fiber. The low-temperature repairing material for the high-speed rail base concrete in the severe cold region, provided by the invention, has a repairing construction time meeting a skylight time requirement of a high-speed rail, has compression strength after completion of hydration matching with that of the base concrete, is high in tensile bond strength with the base concrete, is slightly expanded and strong in anti-freezing circulation capability at -40 DEG C, can avoid secondary detachment, and well meets requirements on the low-temperature repairing material for the high-speed rail base concrete in the severe cold region.

Owner:郑州筑邦建材有限公司 +1

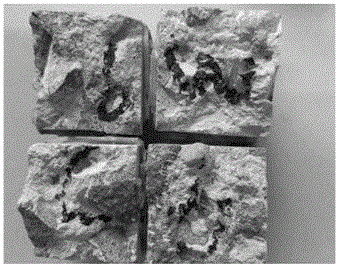

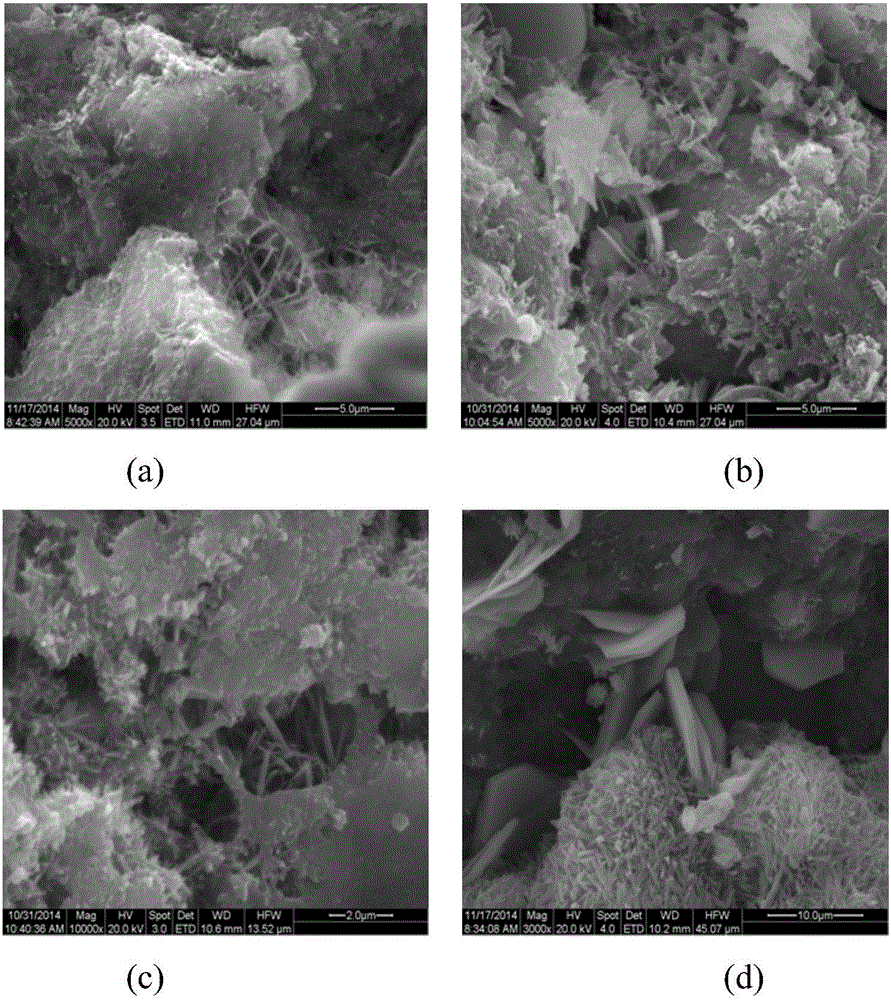

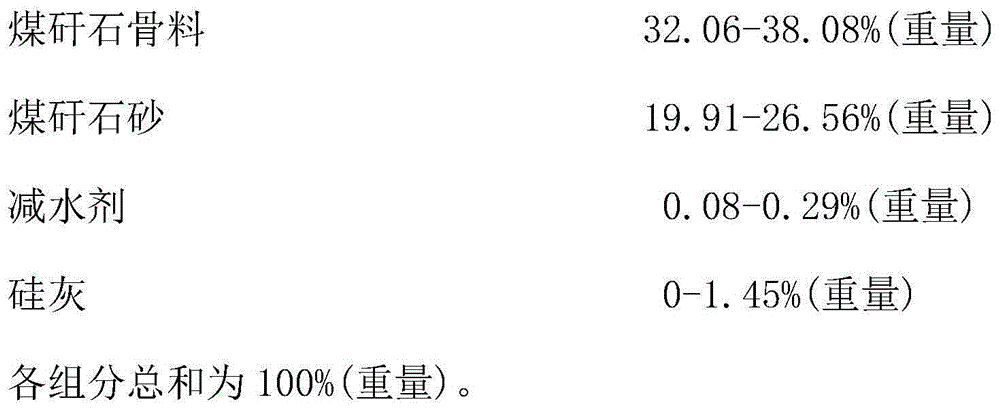

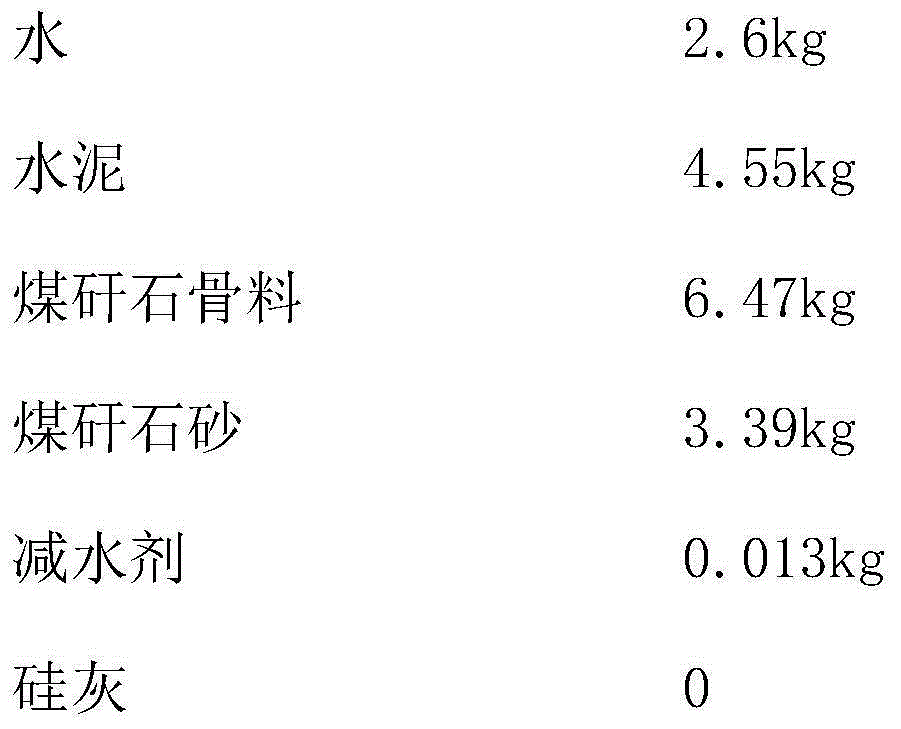

Coal-gangue lightweight aggregate concrete

Disclosed coal-gangue lightweight aggregate concrete is prepared by mixing water, cement, coal gangue aggregate, coal gangue sand, a water reducer and silica fume, the coal gangue aggregate is coal gangue large-particle-size composition, and the coal gangue sand is prepared coal gangue small-particle-size composition. The coal-gangue lightweight aggregate concrete possesses characteristics of being lightweight, high in strength, warm-keeping, fireproof and the like, is good in deformabiity, low in elastic modulus and relatively large in shrinkage and creep in an ordinary way, and is capable of reducing basic load, thereby reducing the whole building deadweight. According to the technical scheme, a large amount of coal gangue which is generated by coal mine and possesses pollution property is changed into valuables from waste, and is effectively applied to road paving and other municipal and building construction, and environment pollution is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

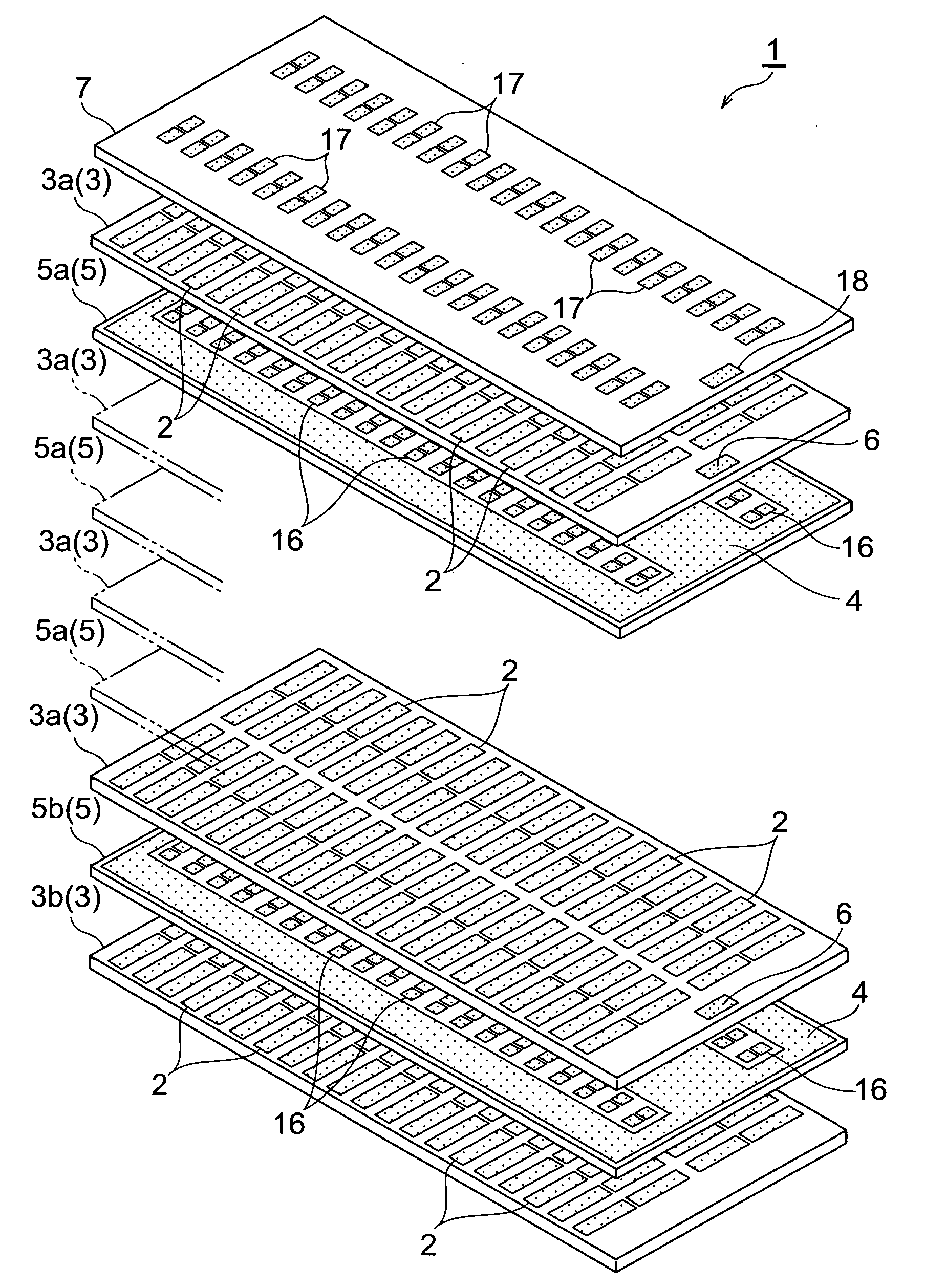

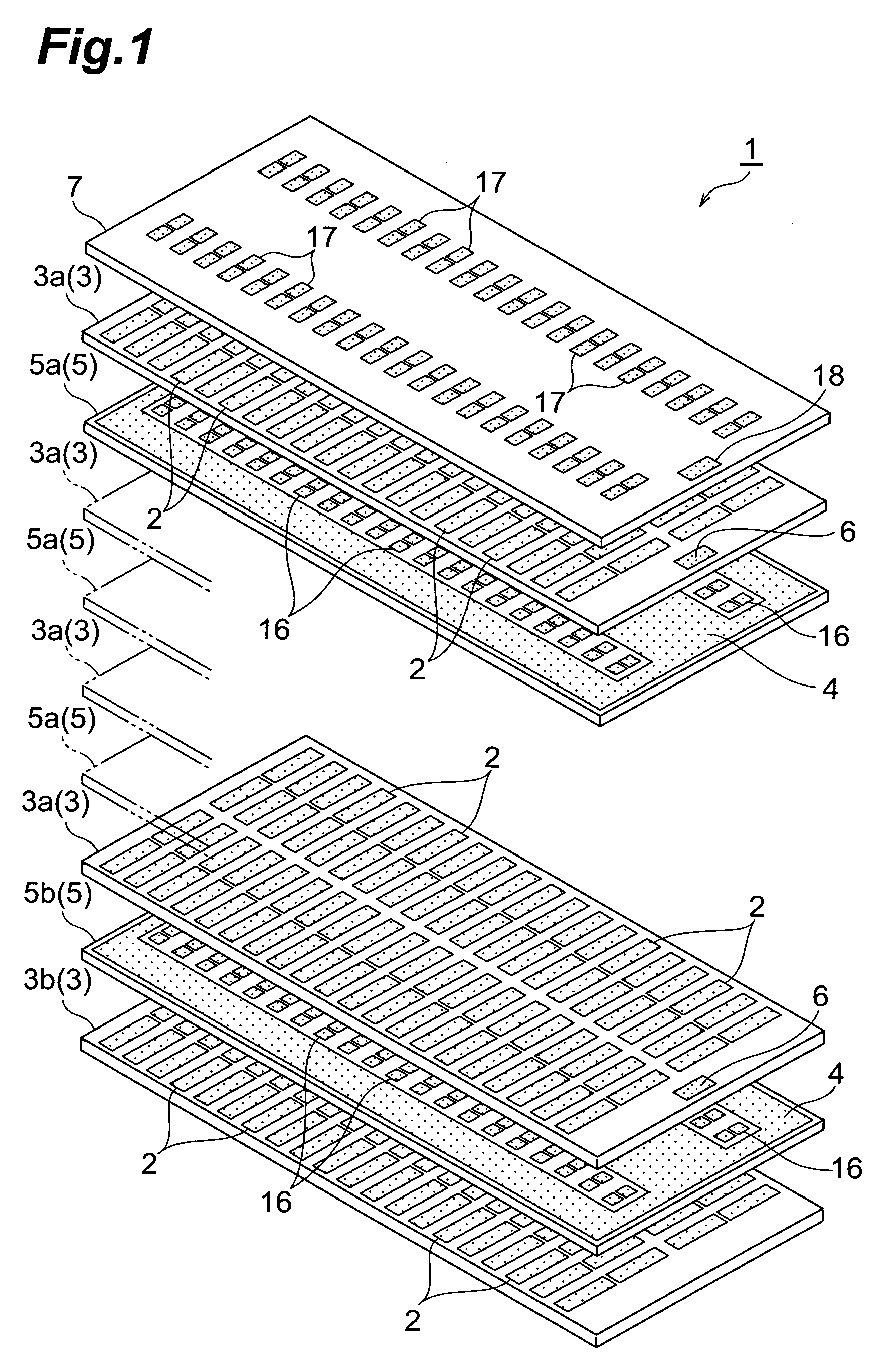

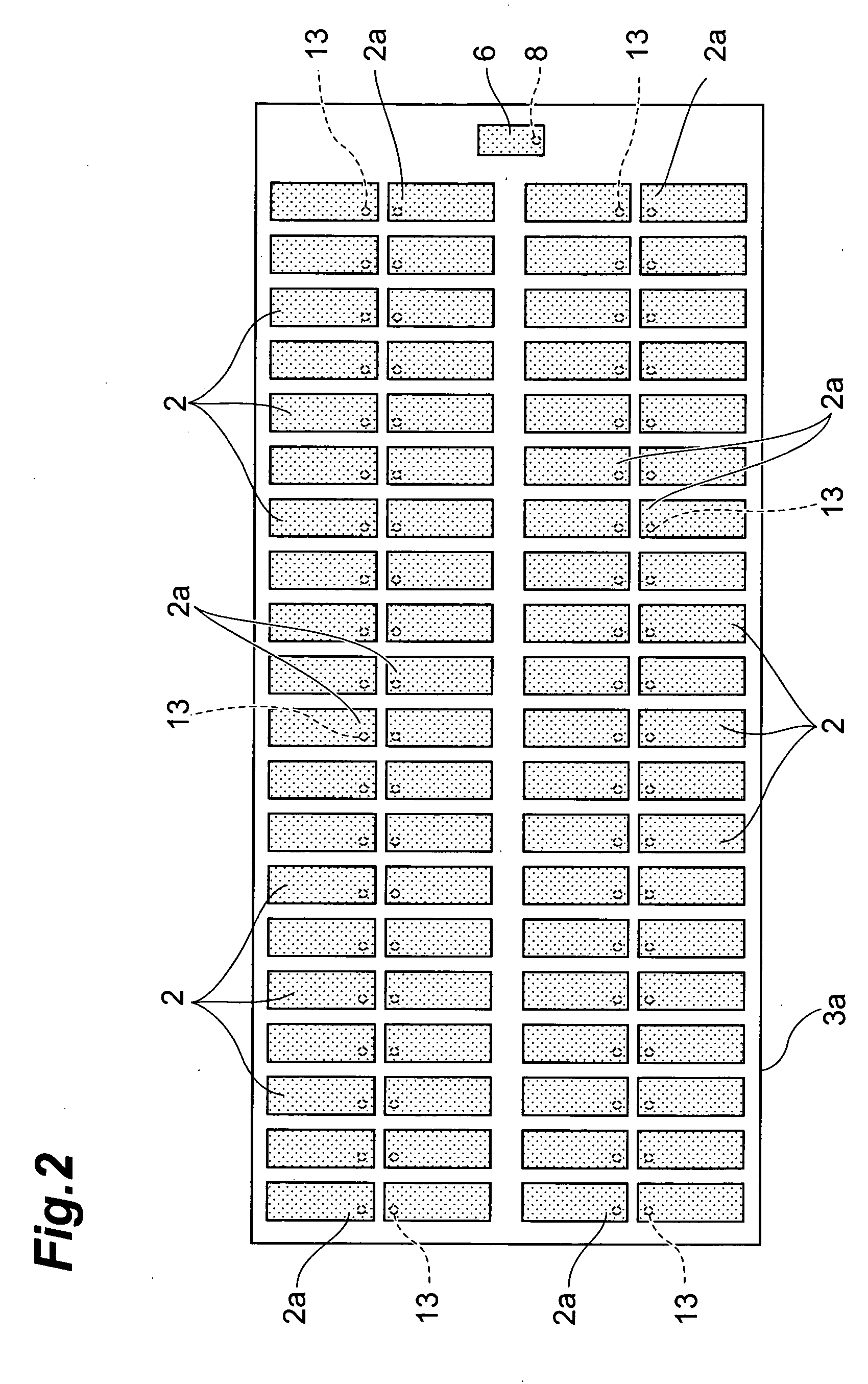

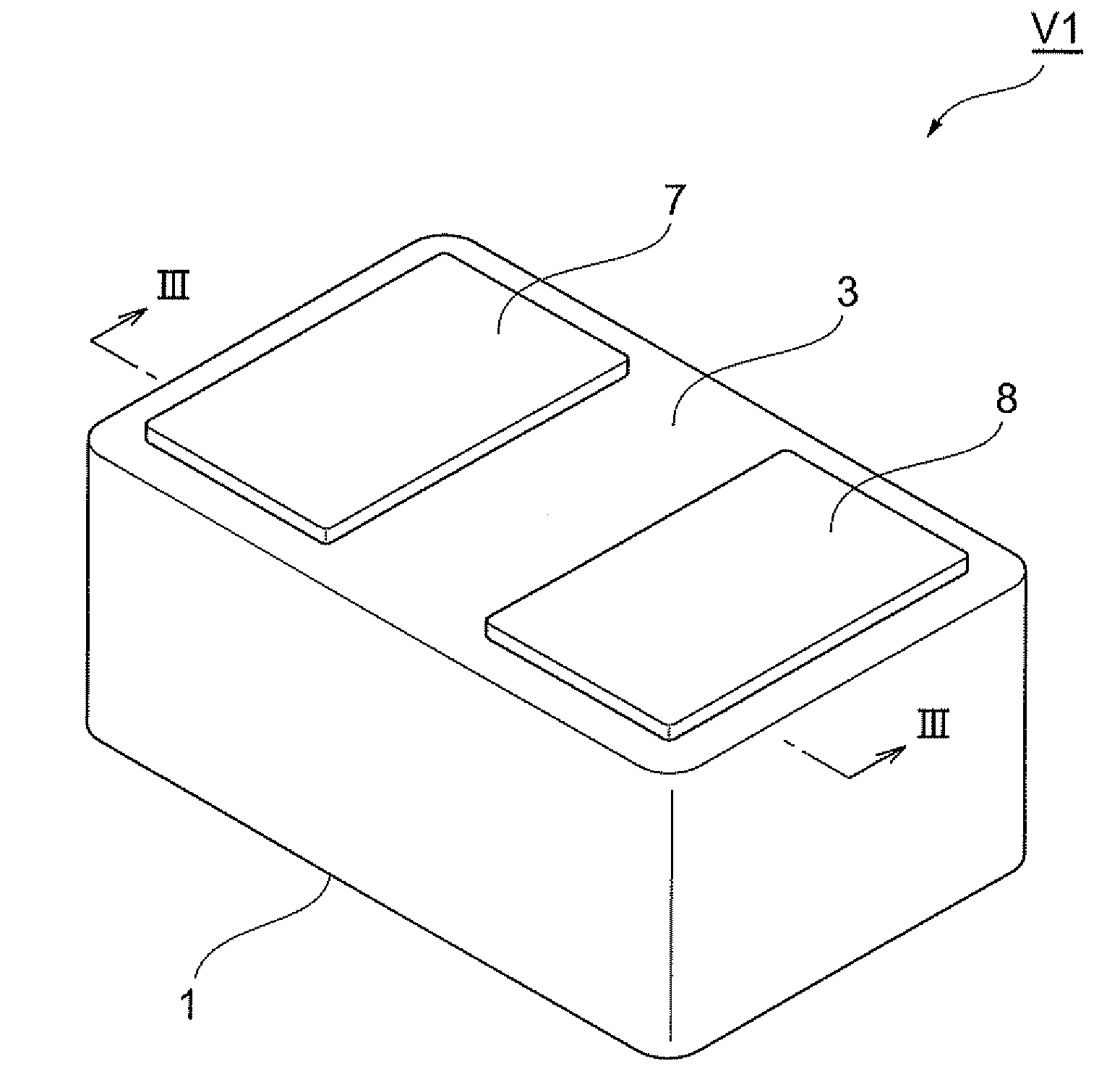

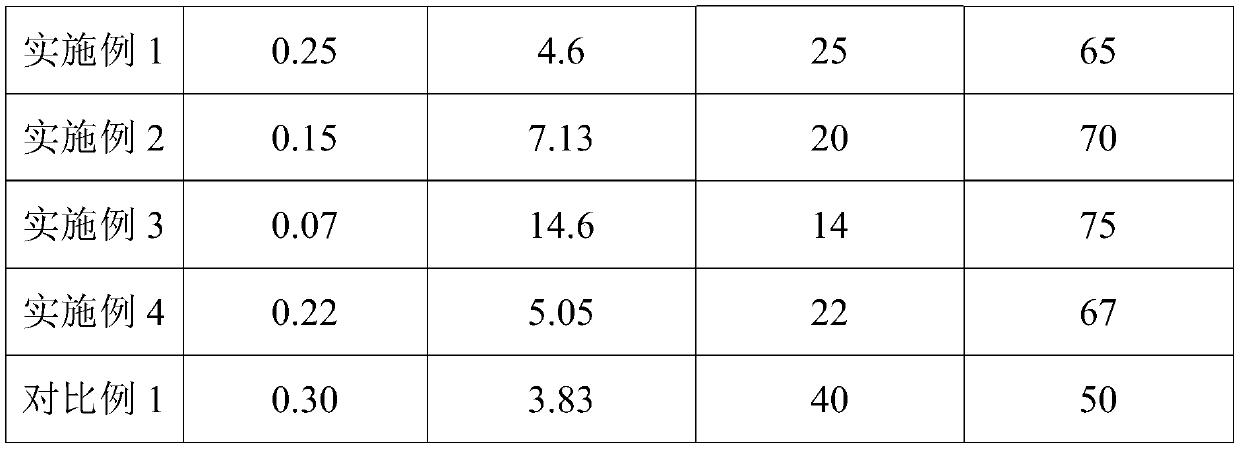

Multilayer ceramic device, method for manufacturing the same, and ceramic device

InactiveUS20060003151A1Constricting contractionAvoid breakingStacked capacitorsPiezoelectric/electrostrictive/magnetostrictive devicesCooking & bakingElectricity

There is provided a multilayer ceramic device enabling achievement of secure electric connection via electroconductive members in through holes and reduction in the thickness of internal electrodes during manufacturing. In multilayer piezoelectric device 1, a melting point of a material of the electroconductive members in the through holes is higher than a melting point of a material of the internal electrodes 2 and others. For this reason, the electroconductive members in the through holes have a contraction percentage in baking smaller than that of the internal electrodes 2 and others. Therefore, contraction of the electroconductive members is relatively constricted in baking, so as to decrease the difference of contraction percentages in baking between green sheets intended for piezoelectric layers 3 and others, and the electroconductive members in the through holes. This results in preventing breakage of the electrical connection via the electroconductive members in the through holes. On the other hand, contraction of the internal electrodes 2 and others is relatively promoted in baking, so as to make the internal electrodes 2 and others thinner by baking.

Owner:TDK CORPARATION

Preparation method of high-temperature-resistant aluminum oxide-silicon oxide aerogel composite material

PendingCN113831103AImprove mechanical propertiesEnhanced skeleton structureCeramicwareFiberOxide composite

The invention discloses a preparation method of a high-temperature-resistant aluminum oxide-silicon oxide aerogel composite material, wherein the preparation method comprises the following steps: (1) sufficiently dispersing and mixing nano aluminum oxide powder, micron aluminum oxide powder, an infrared opacifying agent and short fibers to obtain a mixture A; (2) performing compression molding on the mixture A to obtain an aluminum oxide composite material; (3) uniformly mixing a silicon source, ethanol and water to obtain silicon dioxide sol; (4) dipping the aluminum oxide composite material by adopting silicon dioxide sol; and (5) performing drying treatment to obtain the high-temperature-resistant aluminum oxide-silicon oxide aerogel composite material. According to the preparation method disclosed by the invention, compounding of aluminum oxide and silicon oxide aerogel is realized through impregnation, a complex preparation process is avoided, the preparation period is shortened, the silicon oxide aerogel is fixed in the aluminum oxide composite material, the compactness of the aluminum oxide composite material is further increased, the composite material has relatively good mechanical properties, and great shrinkage of the aluminum oxide composite material at high temperature is avoided.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

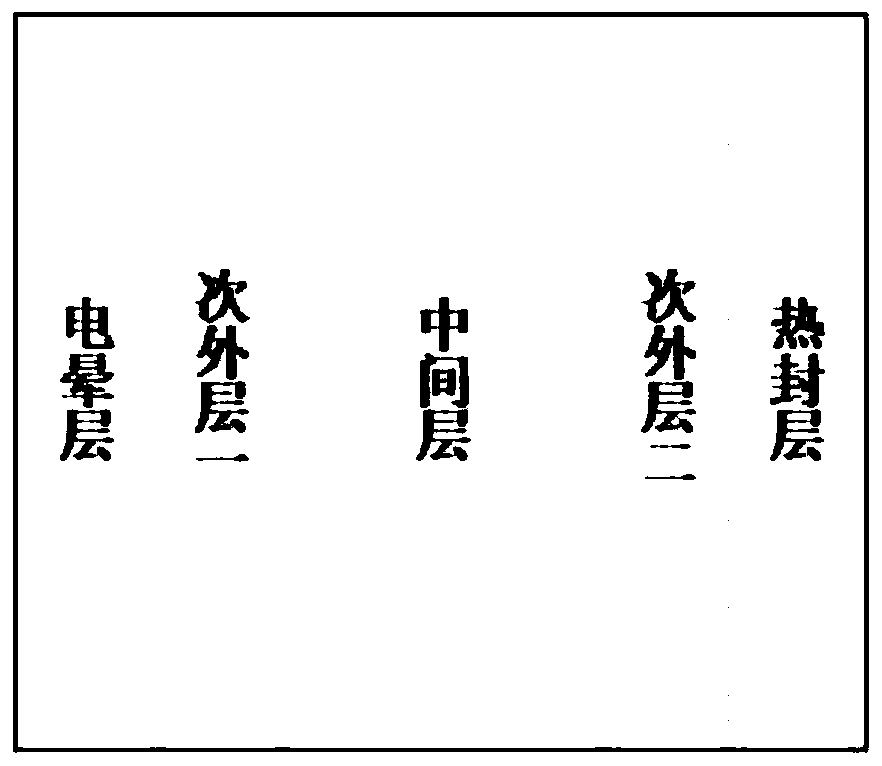

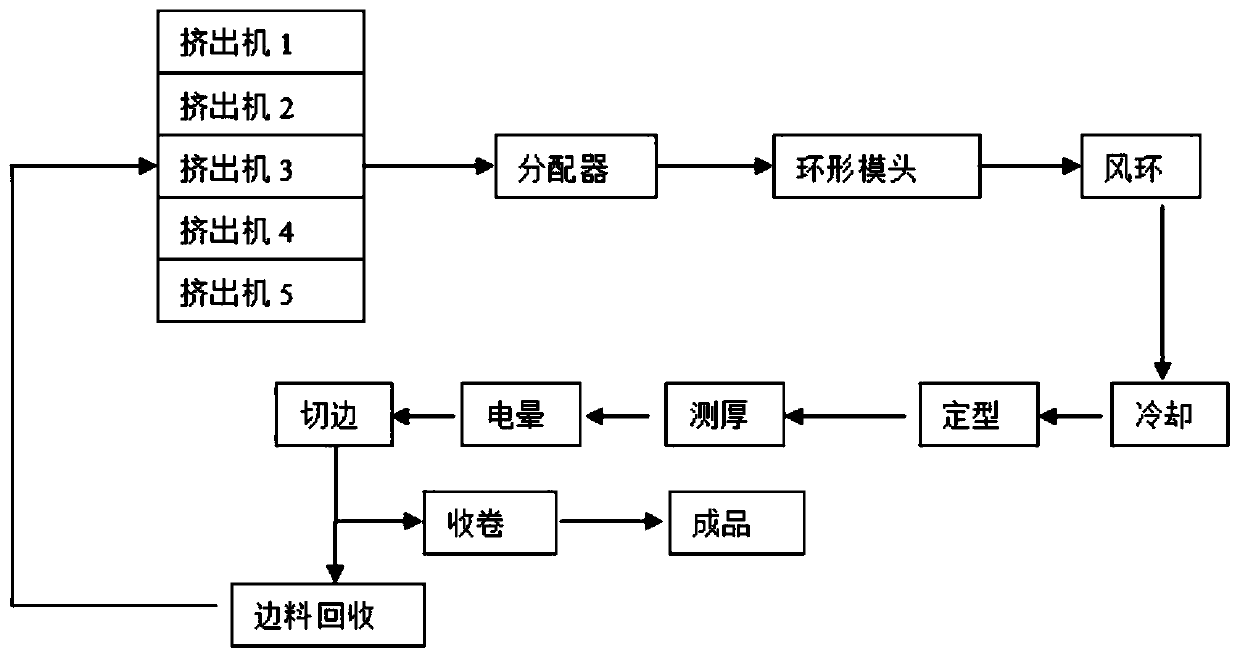

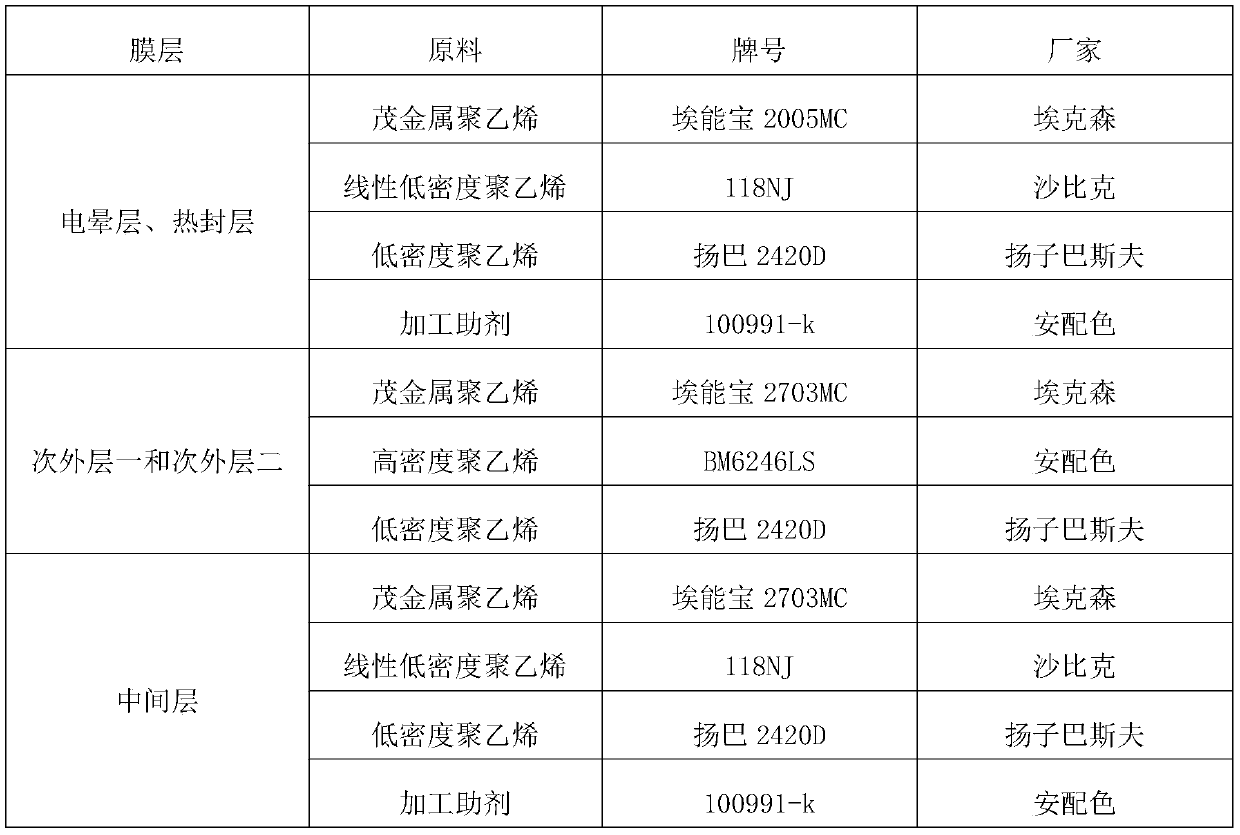

High-light low-haze PE heat shrinkable film and preparation method thereof

ActiveCN110216960AFlat forceIncrease productivitySynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

The invention relates to a high-light low-haze PE heat shrinkable film and a preparation method thereof. A film layer structure of the PE heat shrinkable film successively comprises a corona layer, afirst sub-outer layer, an intermediate layer, a second sub-outer layer and a heat sealing layer; the corona layer, the intermediate layer and the heat sealing layer separately comprise metallocene polyethylene, linear low-density polyethylene, low-density polyethylene and a processing aid in a mass ratio of (28-32):(8-12):(58-62):(0.1-0.3); and the first sub-outer layer and the second sub-outer layer separately comprise metallocene polyethylene, high-density polyethylene and low-density polyethylene in a mass ratio of (28-32):(28-32):(38-42). The PE heat shrinkable film has high shrinkage rate, powerful shrinkage memory function, large tensile strength, powerful puncture resistance and anisotropic tearing resistance, and has the characteristics of low haze, high transparency and high gloss, the friction coefficient is moderate and stable, thickness uniformity and flatness are good, and printing adaptability is good.

Owner:HUANGSHAN NOVEL

Electrical switchgear apparatus comprising an arc extinguishing chamber equipped with deionizing fins

InactiveUS20030201853A1Good energyStable and fastCircuit-breaking switches for excess currentsProtective switchesFree edgeEngineering

A circuit breaker comprises a pair of separable contacts arranged in an opening volume. A plurality of flat de-ionization fins are arranged inside an arc extinguishing chamber opening out onto the opening volume. The chamber is bounded by two opposite side walls, a rear wall located away from the opening volume, a bottom wall and a top wall. Each fin has a free attack edge exposed to the arc. The free edges of the fins laterally bound a longitudinal gulley extending in a heightwise direction from the bottom electrode to the top wall, and longitudinally from a first longitudinal end opening out onto the opening volume at a second longitudinal end tapering to form a stack near to the rear wall, passing via a narrow intermediate portion. A bottom longitudinal electrode partially covers the bottom wall and extends longitudinally facing the gulley at least from the second contact up to the stack.

Owner:SCHNEIDER ELECTRIC IND SAS

Process for Producing Intertwined Ultrafine Filament Sheet

ActiveUS20080095972A1Maintain good propertiesSoft touchShrinkingPattern makingPolyvinyl alcoholWater soluble

A method of producing an entangled sheet of microfine long fibers using long fibers for forming microfine fibers. The method includes a step of forming a long-fiber web made of long fibers for forming microfine fibers, at least one component of the long fibers being a water-soluble, thermoplastic polyvinyl alcohol resin; a step of entangling the long-fiber web to form a long-fiber entangled sheet; a step of shrinking the long-fiber entangled sheet to form a long-fiber shrunk sheet; and a step of converting the long fibers for forming microfine fibers in the long-fiber shrunk sheet to microfine long fibers, thereby producing the entangled sheet of microfine long fibers. The step of entangling is conducted so as to allow the long-fiber entangled sheet to have an interlaminar peel strength of 2 kg / 2.5 cm or more. The step of shrinking is conducted so as to shrink in an areal shrinkage of 35% or more.

Owner:KURARAY CO LTD

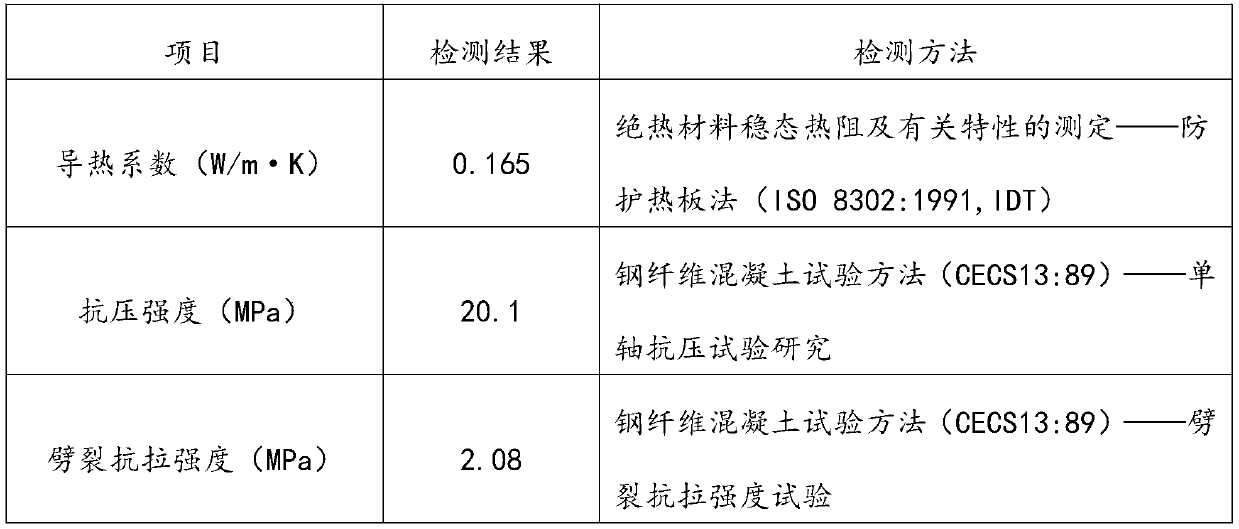

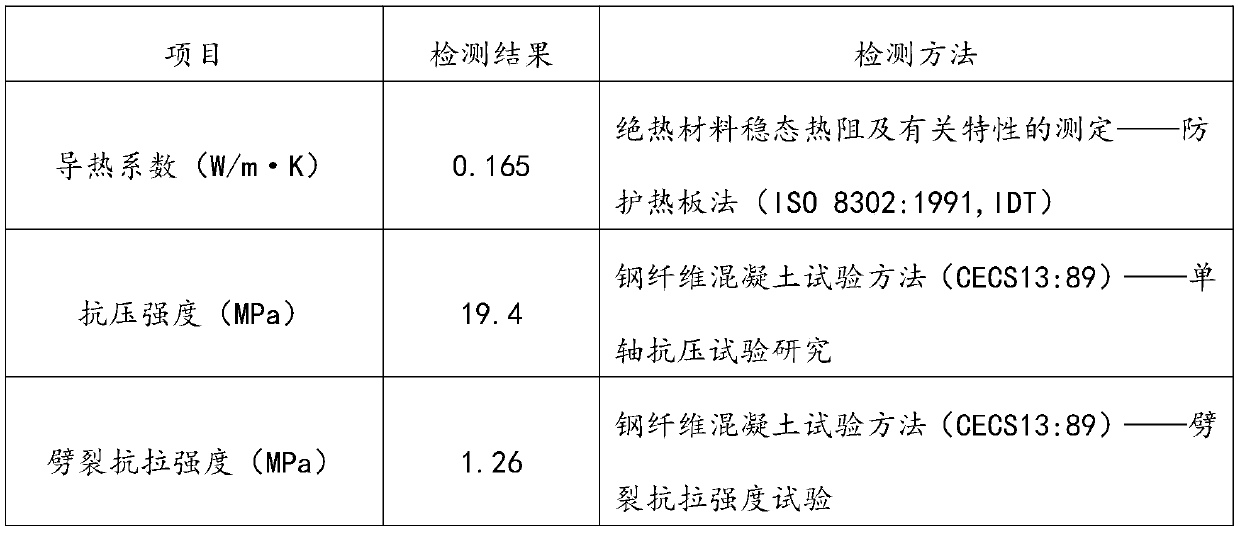

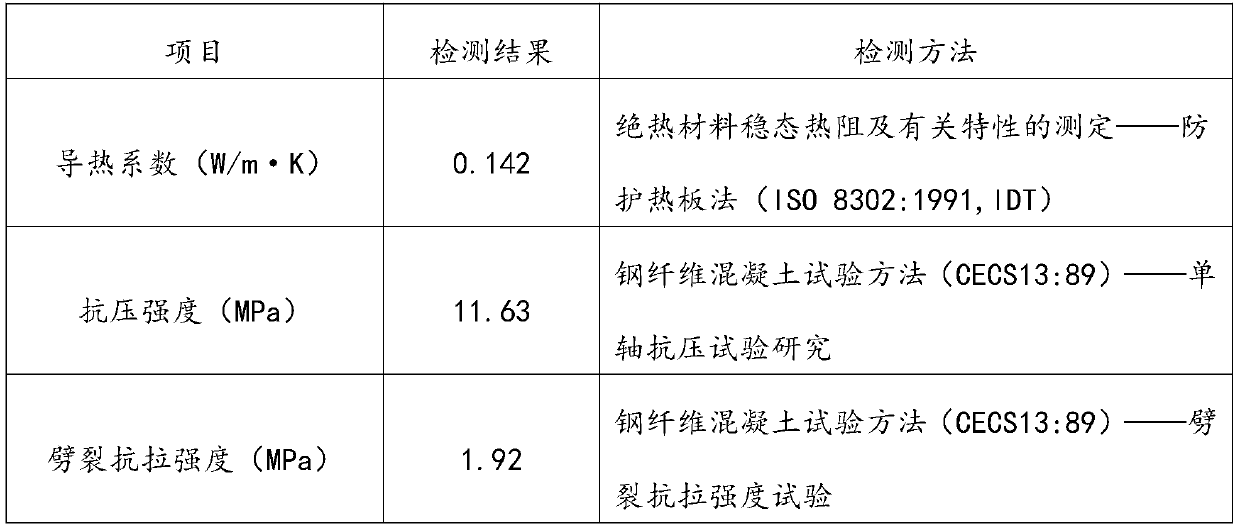

Steel-bamboo mixed fiber regenerated thermal insulation concrete and preparation method thereof

The invention discloses steel-bamboo mixed fiber regenerated thermal insulation concrete and a preparation method thereof, belonging to the technical field of building materials.The steel-bamboo mixedfiber regenerated thermal insulation concrete is prepared from the following raw materials in percentage by weight:15-22% of cement,10-15% of water, 29.75-36.65% of acidified regenerated fine aggregate, 29.75-36.65% of acidified regenerated coarse aggregate, 0.5 -1% of polypropylene composite bamboo fiber, 0.5-1% of steel fiber, 0.1-0.2% of hydroxypropyl methyl cellulose ether, 0.5-1% of polystyrene particles and 0.1-0.3% of resin rubber powder.The invention also discloses a preparation method of the steel-bamboo mixed fiber regenerated thermal insulation concrete.The steel-bamboo mixed fiberregenerated thermal insulation concrete has the advantages of tensile resistance, bending resistance, impact resistance, fatigue resistance and the like.

Owner:湖南湘科智测工程技术有限公司

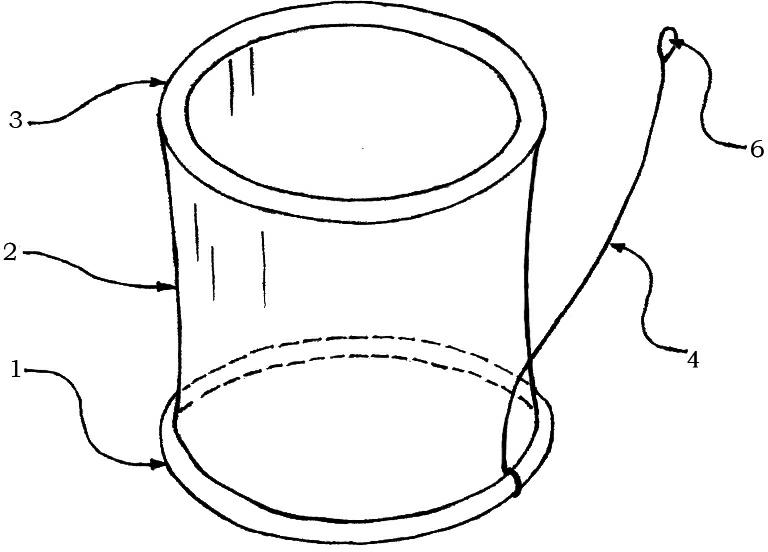

Operative incision traction and protection device

InactiveCN102429690AImprove antibacterial propertiesEasy to take outSurgeryCauchy elastic materialEngineering

The invention discloses an operative incision traction and protection device, which comprises an elastic inner ring made of an elastic material, a turnover traction outer ring and a soft bushing, wherein the elastic inner ring and the turnover traction outer ring are connected with two open ends of the soft bushing respectively; and the areas of the elastic inner ring and the turnover traction outer ring are larger than the size of an operative incision. The operative incision traction and protection device has the beneficial effects that: the operative incision can be effectively protected from being infected and can be uniformly dragged, and the size of the operative incision can be adjusted conveniently.

Owner:李志明

Slag adhesion preventing separant for stirring head and preparation method thereof

The invention discloses a slag adhesion preventing separant for a stirring head and a preparation method thereof and solves the problem of slag adhesion of the stirring head. The slag adhesion preventing separant for the stirring head is prepared from the following raw materials in parts by weight: 55 to 75 parts of quartz powder, 5 to 15 parts of amorphous graphite, 5 to 15 parts of silicon carbide, 3 to 8 parts of clay, 0.5 to 2 parts of sodium carboxymethylcellulose, 1 to 3.5 parts of paper fiber and 0.03 to 0.15 parts of organic fiber. The prepared separant disclosed by the invention has the characteristics of good adhesion under a normal temperature, high low-temperature bonding strength, reduction or loss of high-temperature bonding strength and benefit to automatic falling off; theseparant can generate larger volume expansion or contraction along with temperature rise and fall, so that the separant is favorable for self crack generating and has an automatic structure collapsingeffect. When being applied to the surface of a refractory material of the KR stirring head, the separant has an effect of preventing slag adhesion; thus, labor intensity is reduced, and service lifeof the stirring head is improved.

Owner:北京利尔高温材料股份有限公司

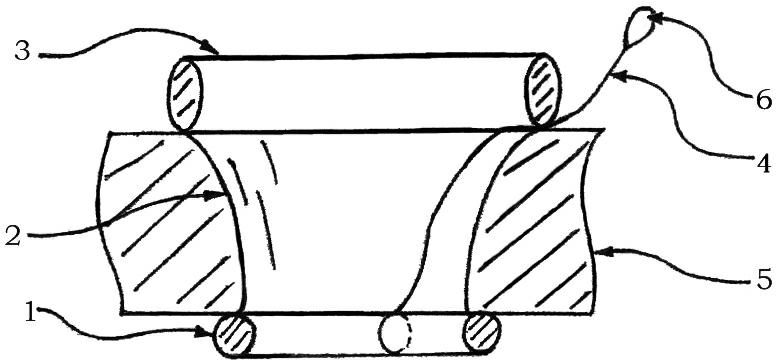

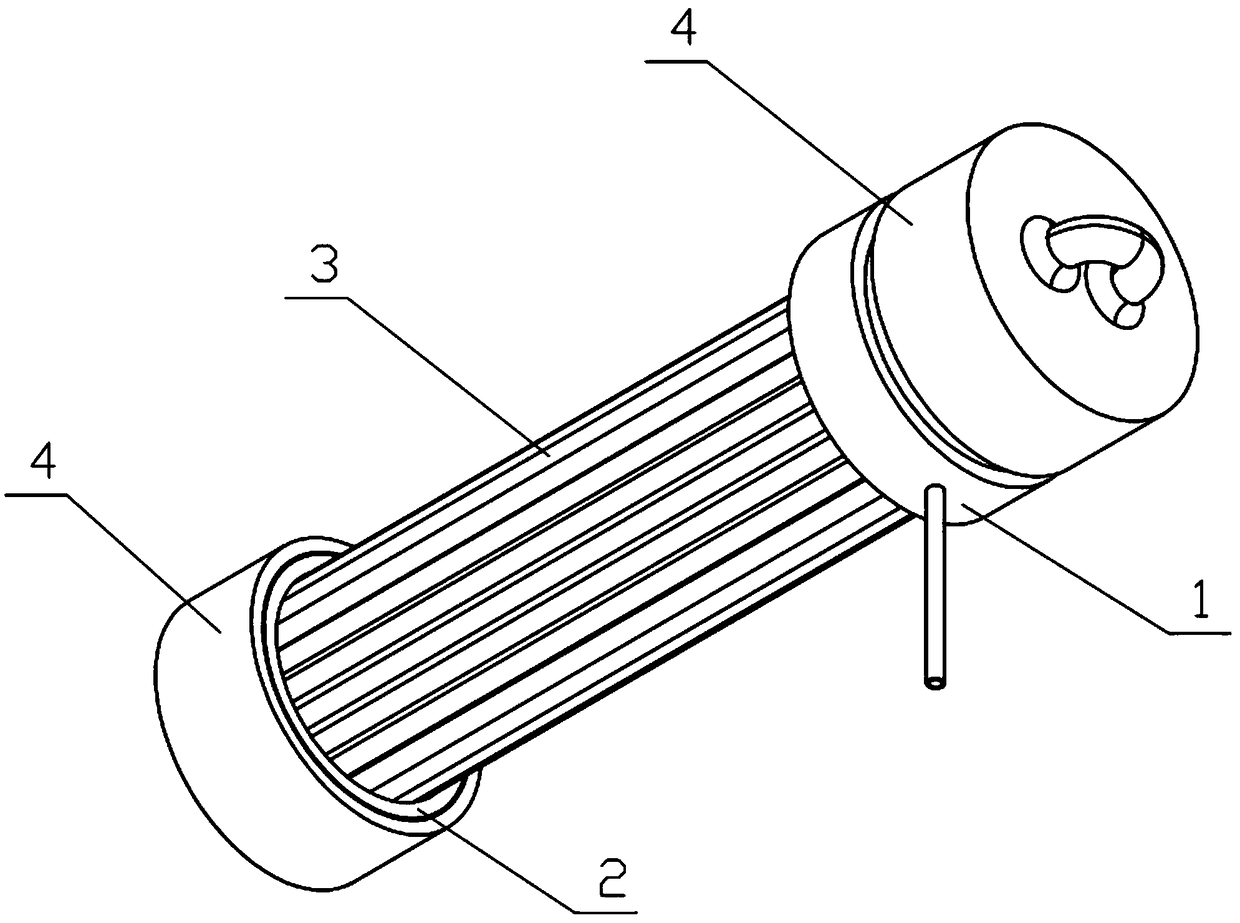

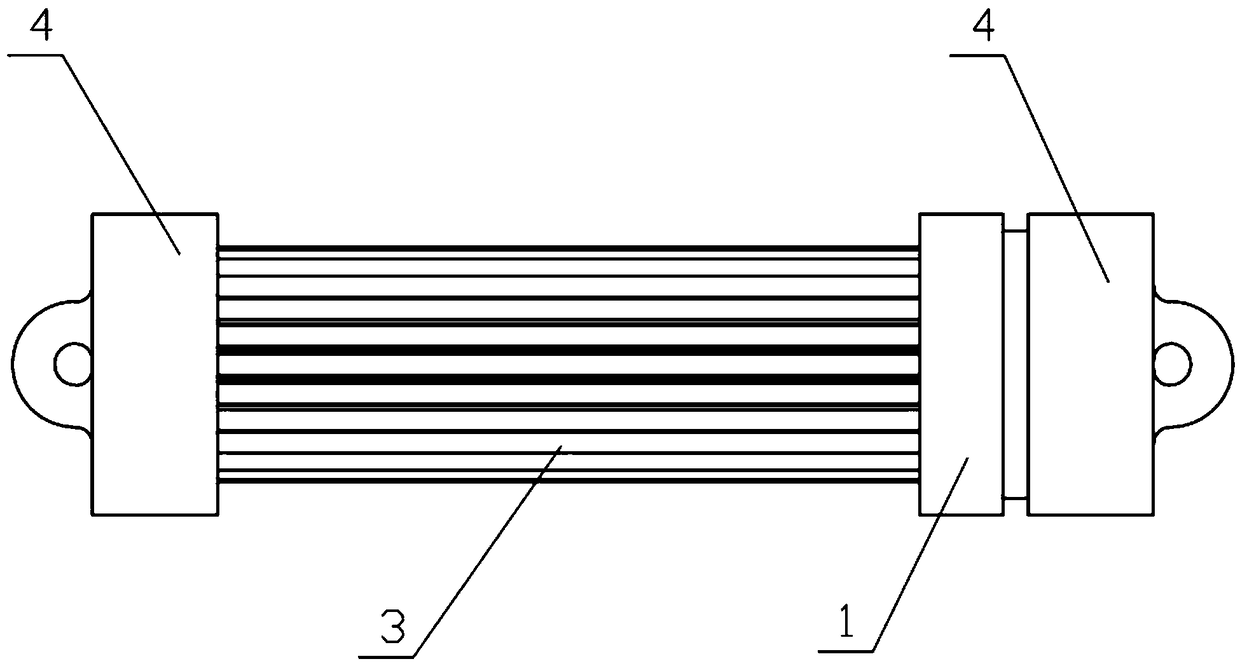

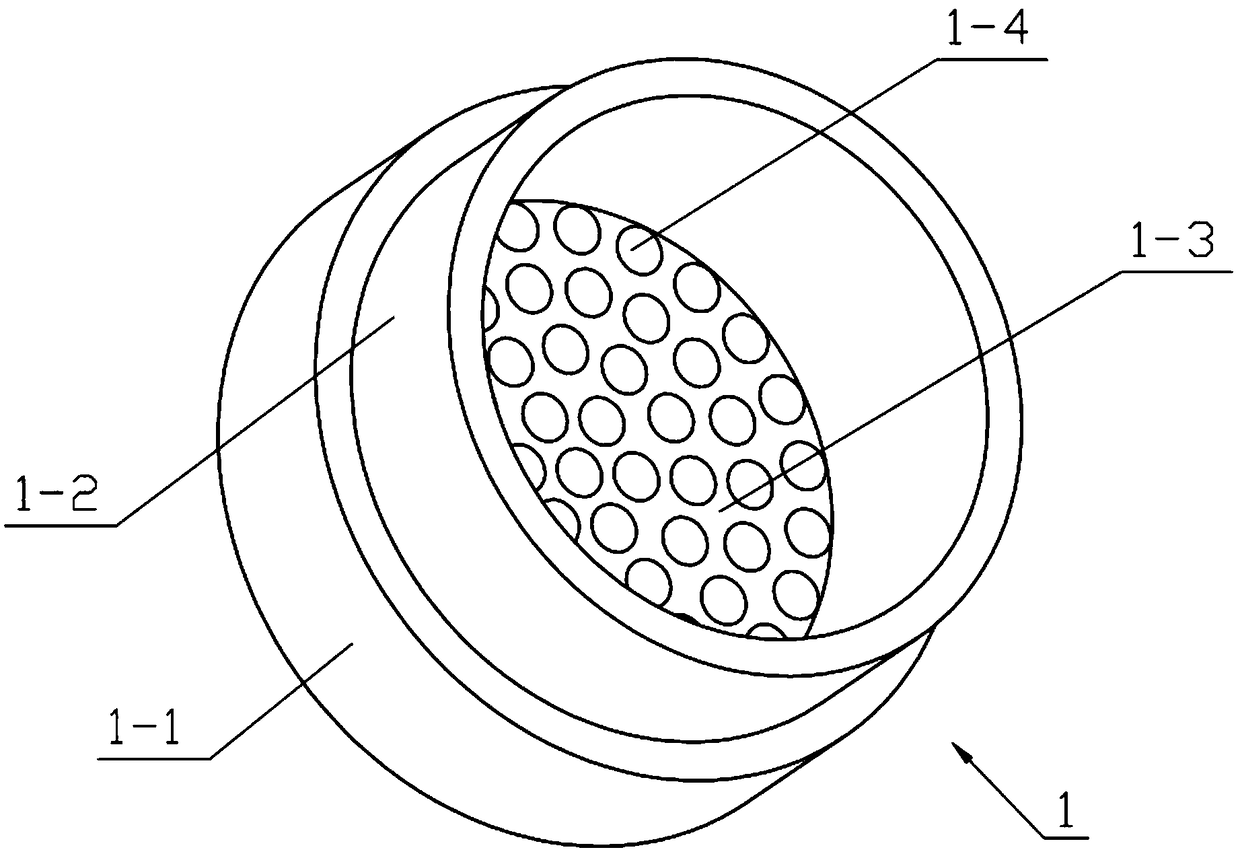

Skeletal muscle model based bionic muscle and manufacturing method

The invention relates to the bionic field, in particular to a skeletal muscle model based bionic muscle and a manufacturing method. The skeletal muscle model based bionic muscle comprises a gas inletcylinder, a fixed cylinder, pneumatic muscle monofilaments and a sealing cover, wherein a gas inlet hose is fixedly connected on the gas cylinder for introducing gas into the pneumatic muscle monofilaments; each pneumatic muscle monofilament is composed of an inner silica hose and an outer sleeve, is a woven net formed by knitting fiber monofilaments, wherein a knitting angle is 18 degrees, can beincreased to be 40 degrees to 50 degrees; the fiber monofilaments are pet monofilaments with diameters of 0.12 mm; the inner ring of an outer sleeve is in contact with the outer ring of the inner silica hose; when gas is charged into the inner silica gel hose, the pneumatic muscle monofilaments generate transverse expansion to cause radial shrinkage; and a relative distance between the fixed cylinder and the gas inlet cylinder is reduced to simulate body muscles by introducing gas through the inner silica gel.

Owner:黑龙江磐桓科技有限公司

Environment-friendly permeable ceramic brick and production method thereof

InactiveCN107793131ARealize resource reuseReduce consumptionCeramic materials productionClaywaresCompression moldingSurface layer

The invention provides an environment-friendly permeable ceramic brick and a production method thereof. The production method is characterized by comprising the following steps: taking particles of awaste unglazed ceramic product as a basic framework, taking waste brick particles with different sizes as bottom layer aggregate and surface layer aggregate according to certain proportions respectively and respectively adding proper amounts of ceramic binder, water and ceramic pigment; carrying out dosing, mixing, secondary cloth compression molding, firing, inspecting and other working procedures, thus obtaining the qualified environment-friendly permeable ceramic brick. The production method disclosed by the invention is suitable for large-batch industrial production of the permeable brick;the produced permeable brick has the characteristics of high permeability, high compressive strength, good skidproof performance, diversified varieties, convenience in maintenance and the like; in addition, waste bricks in a ceramic factory are used as raw materials, so that a novel path is provided for effectively utilizing ceramic waste products.

Owner:佛山绿顺透科技有限公司

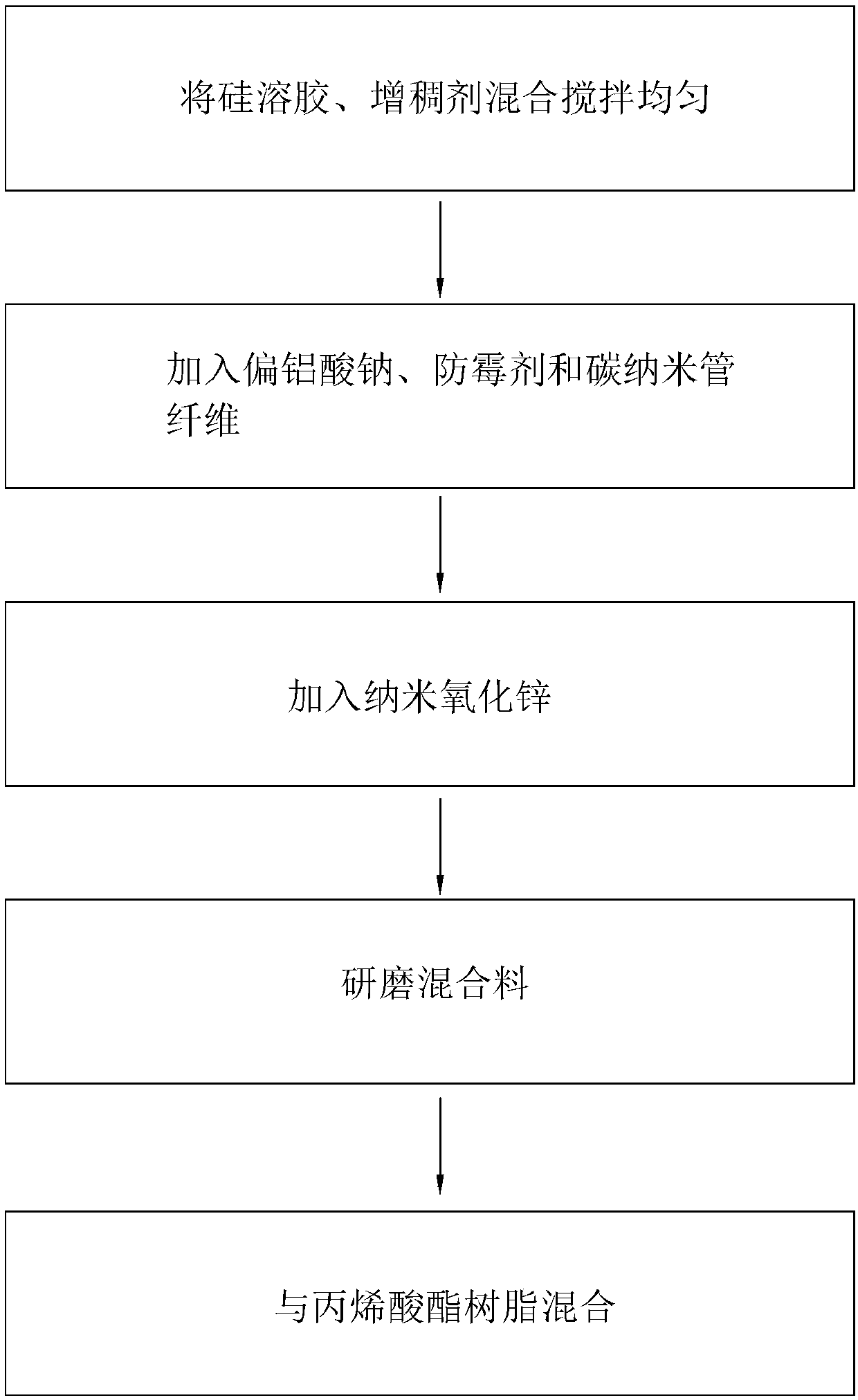

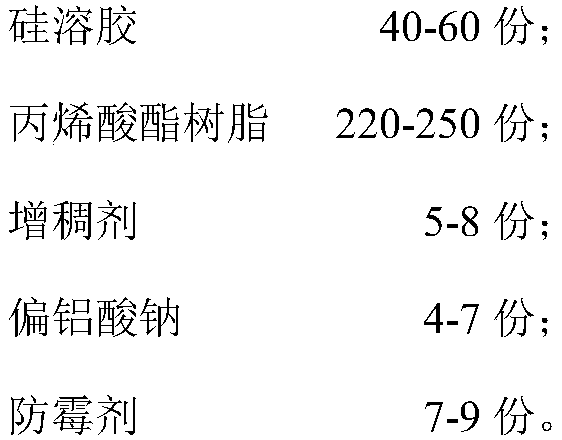

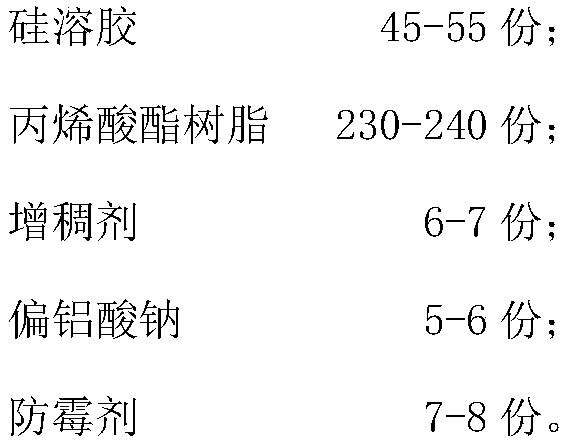

Coating method and preparation method of wall finish for underground space decoration

InactiveCN109679424AImprove adhesionImprove performanceAntifouling/underwater paintsPaints with biocidesCalcium silicateAcrylic resin

The invention discloses wall finish for underground space decoration. The wall finish is prepared from the following raw materials in parts by weight: 40-60 parts of silica sol, 220-250 parts of acrylate resin, 5-8 parts of a thickening agent, 4-7 parts of sodium metaaluminate and 7-9 parts of a mildewproof agent. Silica sol particles are ultrafine, can penetrate into a base layer through the capillary action of the wall surface and can react with calcium hydroxide in the concrete base layer to generate calcium silicate, and thus coating has high bonding force. When moisture in the silica solevaporates, colloidal ions firmly adhere to the surface of an object, and silica-oxygen bonded reticular membrane structures are formed between the particles. The silica sol can be mutually complemented with the characteristics of the acrylic resin, and thus the composite coating with excellent properties can be prepared. The sodium metaaluminate reacts with the silica sol in a silica sol system,thus a layer of zeolite film is formed on the surface of a paint film, the zeolite film is provided with a porous structure and has high catalytic activity, and the effect of the mildewproof agent oninhibiting and killing mold can be improved. The wall finish has the characteristic of good environmental protection while having a mildewproof effect.

Owner:温州市东日建筑装饰工程有限公司

Multilayer chip varistor

ActiveUS20100052841A1Inhibit productionAvoid connection failureResistor terminals/electrodesCurrent responsive resistorsElectrical conductorMetal

A multilayer chip varistor is provided as one capable of suppressing production of cracks and thereby preventing a connection failure between an internal electrode and a through-hole conductor. An internal electrode 21 is so configured as to be curved toward a direction of penetration of a through hole 10 in a connection portion 28 thereof to a through-hole conductor 27. By this configuration, a region T sandwiched between a curved surface 28a of the connection portion 28 and the through-hole conductor 27 is formed in a varistor layer 9 near the connection portion 28. In this region T, a metal concentration thereof becomes higher because of diffusion of metal of the internal electrode 21 and the through-hole conductor 27 into the varistor layer 9, and therefore, after completion of firing, the region T has an intermediate contraction percentage between that of the internal electrode 21 and through-hole conductor 27 and that of the other region of the varistor layer 9. This permits the region T to relax stress near the connection portion 28 where the internal electrode 21, through-hole conductor 27, and varistor layer 9 are congested so as to readily produce cracks.

Owner:TDK CORPARATION

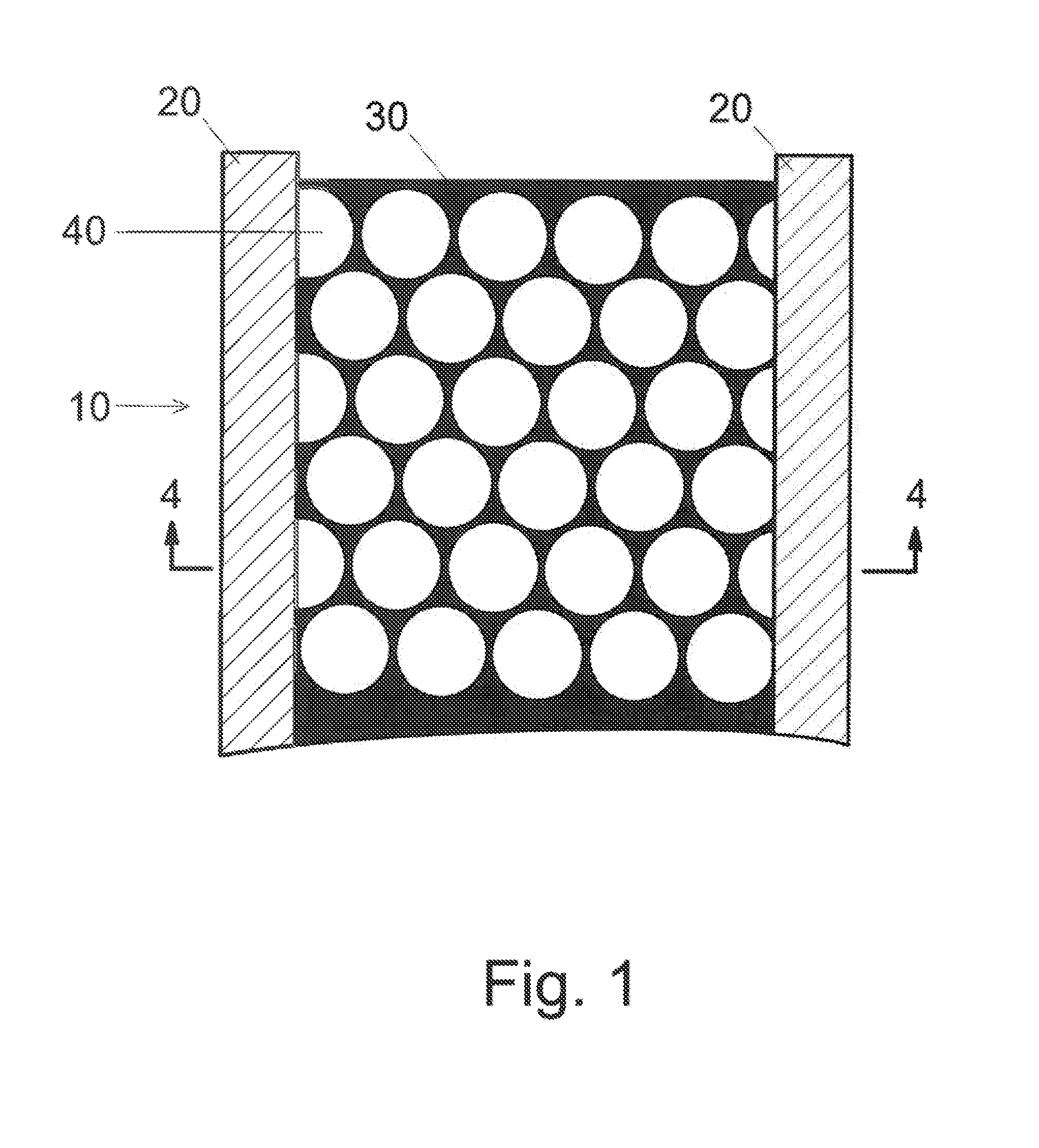

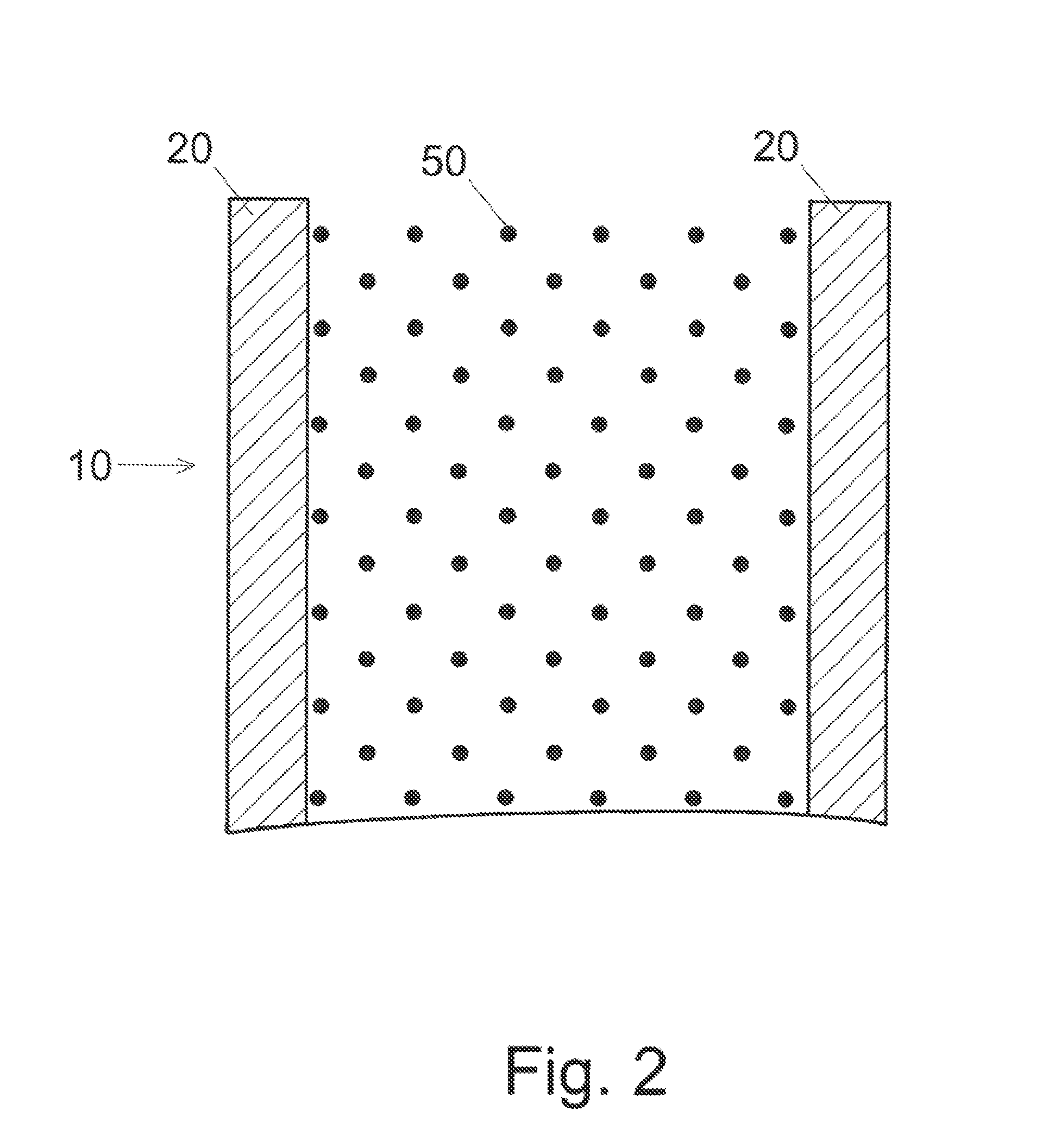

Package formed from pattern laminated double wall hot formable plastic webs with enhanced puncture resistance

ActiveUS20140295116A1Provide protectionLarge energyPackaging meatSynthetic resin layered productsAdhesiveSemi automatic

The present disclosure is concerned with packages formed from thermoformable webs with improved puncture resistance suitable for use in semi-automatic horizontal form fill and seal (HFFS) packaging machines and a process for packaging hard food items with sharp angular surfaces using such webs in such machines. The webs have a double wall partially laminated structure. The structure is conveniently formed by adhesively laminating two component films in a face to face configuration using a pattern of adhesive which leaves a substantial portion of the two facing surfaces unlaminated. The lamination just needs to be sufficient that the two component films will hot form together when they are vacuum drawn into a die to form a cavity for packaging the food items. The lamination pattern can vary from just edge strips to the edge strips and a honey comb pattern or a pattern of dots over the facing surfaces between the edge strips.

Owner:BEMIS COMPANY INC

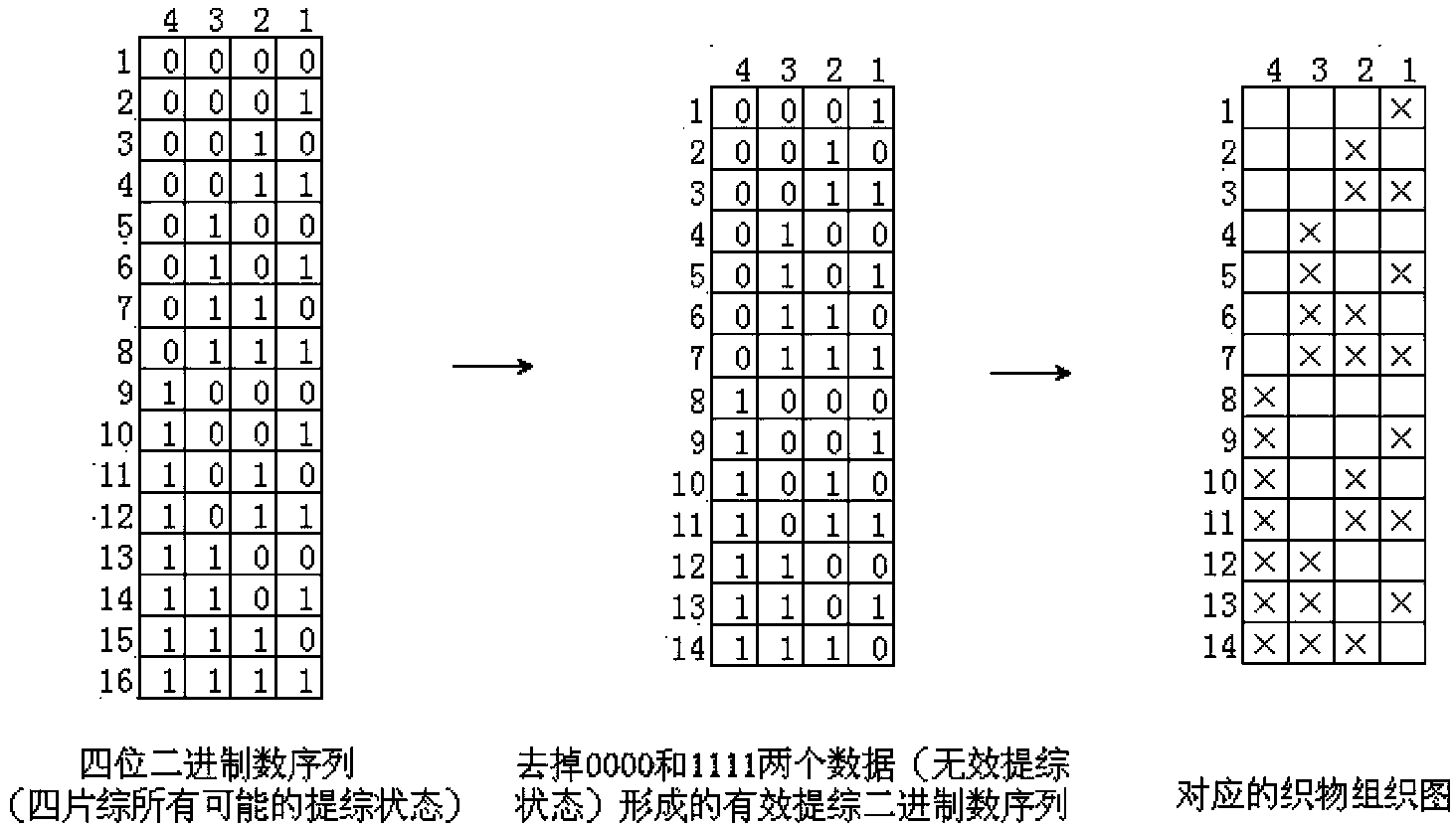

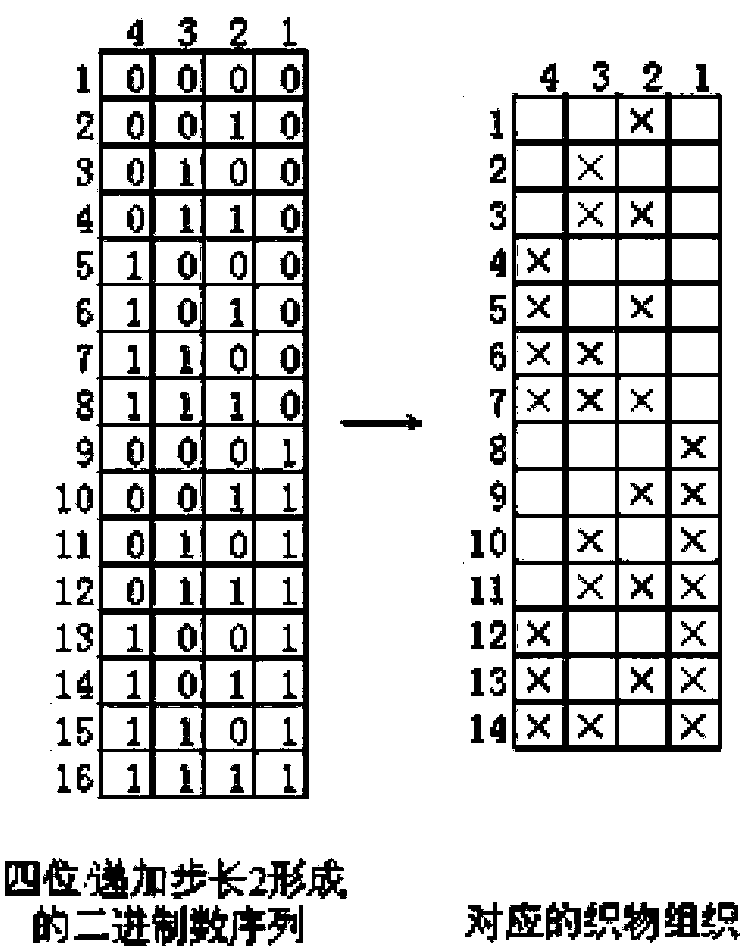

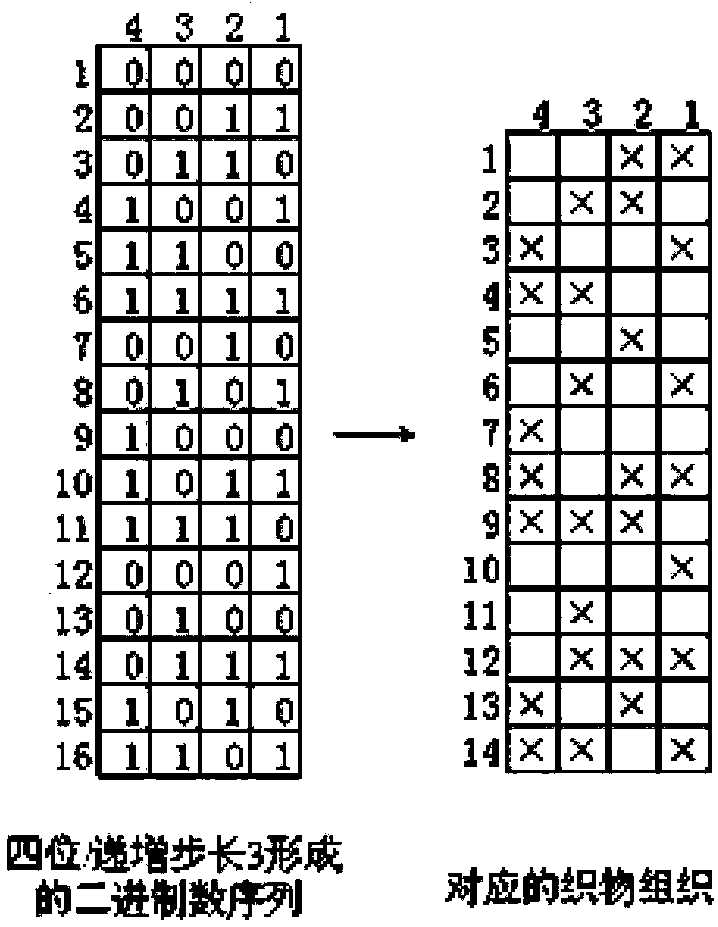

Construction method for interweaving regular pattern of woven fabric on basis of binary algorithm

InactiveCN103060992BWrinkling effectImprove breathabilityWoven fabricsRegular patternTear resistance

Owner:ZHEJIANG QIJIN TEXTILE

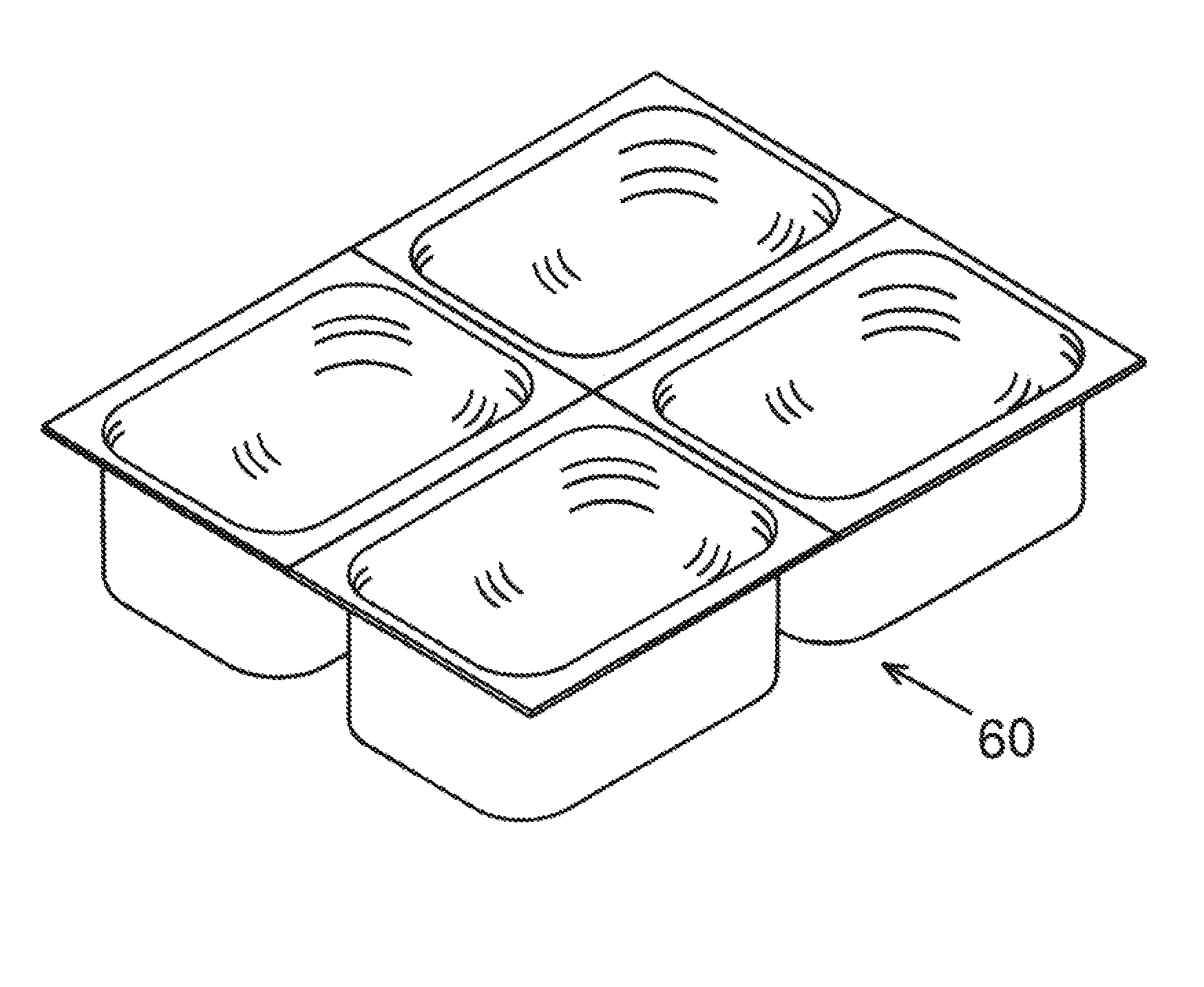

Preparation process of foaming product and foaming product

The invention discloses a preparation process of a foaming product. The preparation process comprises the following steps: first, preparing a solid foaming blank; and then, putting the solid foaming blank into a closed space, introducing supercritical fluid for dipping, and relieving pressure to foam the solid foaming blank until the solid foaming blank is completely attached to the inner side ofthe closed space to obtain a foaming product. The invention also discloses a foaming product prepared by the process. According to the invention, the solid foaming blank is foamed in a mold, and whenthe solid foaming blank expands to be in contact with the inner wall of the mold, the expansion is limited, and thermal pressure is formed between the solid foaming blank and the inner wall of the mold, so that the shape of the inner wall of the mold is formed on the surface of the solid foaming blank, and according to the characteristics of thermoplastic elastomers such as thermoplastic polyurethane, thermoplastic polyester and thermoplastic nylon elastomers, density increase and elastic performance reduction caused by shrinkage of the foaming material due to secondary mold pressing are avoided. The mold is used for controlling the surface structure of the foaming material, the size accuracy is improved, the surface structure of the foaming product is fine, and the problems of blurring and poor stability are solved.

Owner:SHINCELL NEW MATERIAL CO LTD

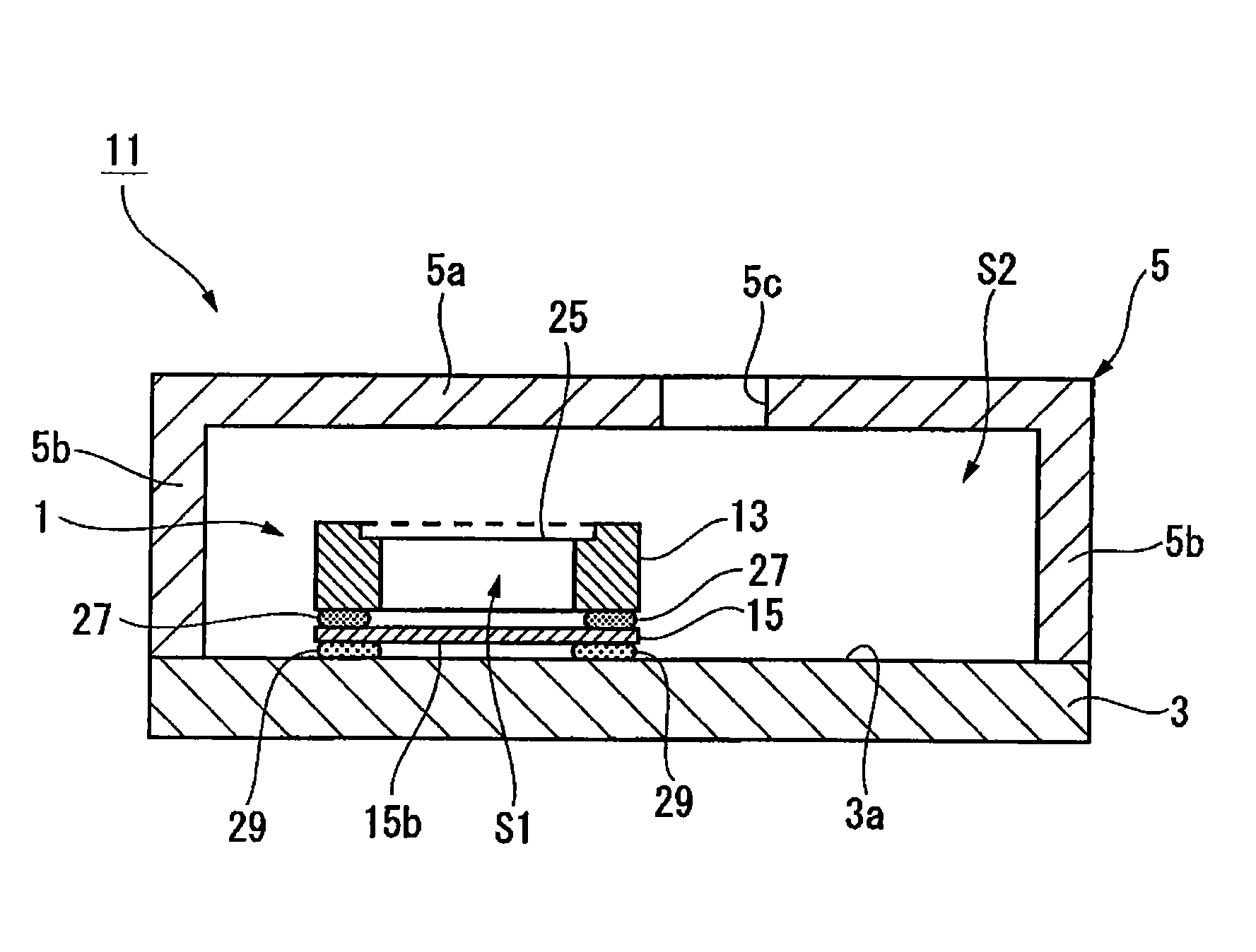

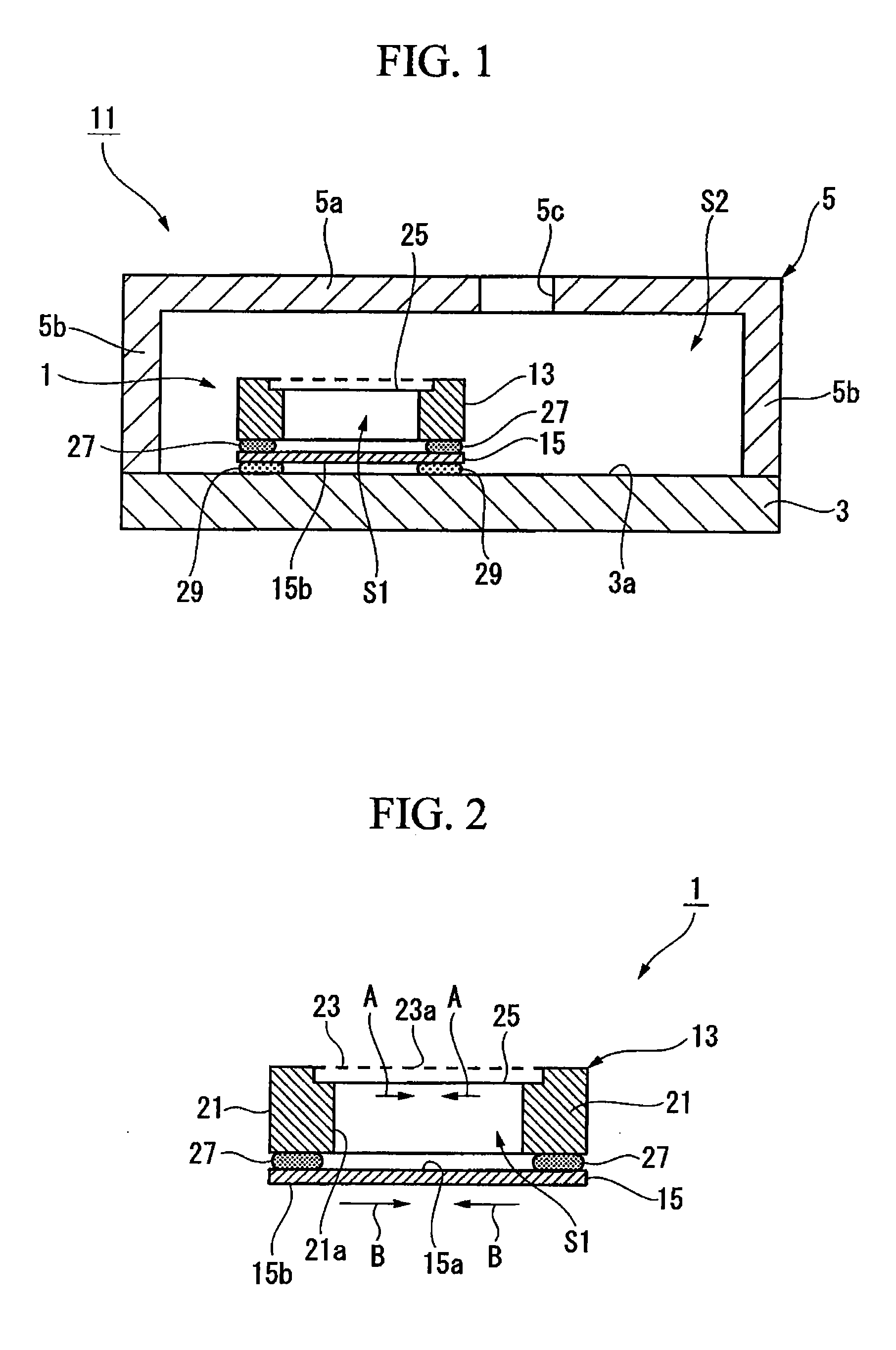

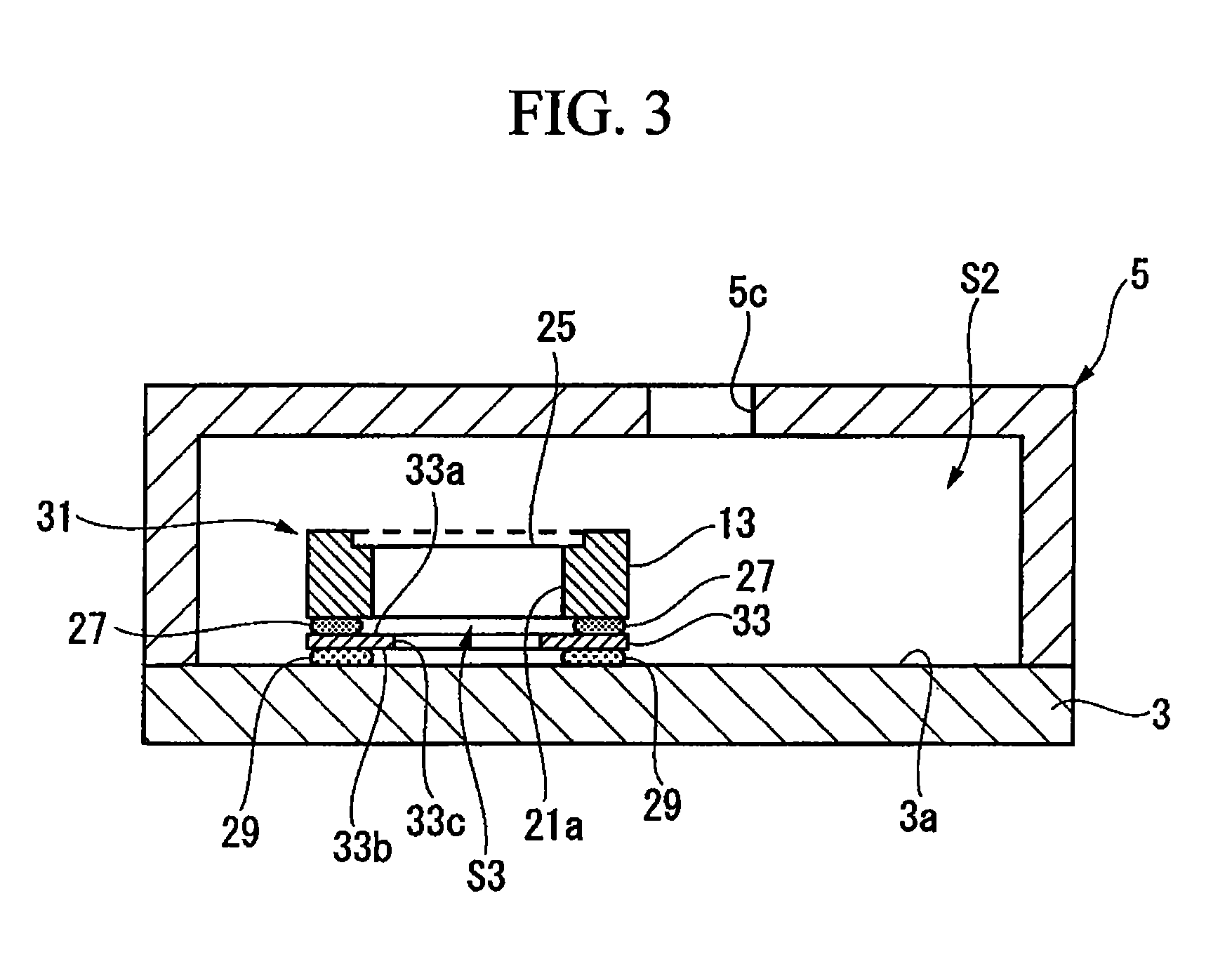

Semiconductor microphone unit

InactiveUS7579678B2Reduce tensile stressInhibition strengthPiezoelectric/electrostrictive microphonesSemiconductor/solid-state device detailsAdhesiveThermal expansion

A semiconductor microphone unit includes a semiconductor microphone chip having a diaphragm covering an inner hole of a support. The support is adhered onto the surface of a support substrate whose thermal expansion coefficient higher than the thermal expansion coefficient of the support via a thermosetting adhesive in such a way that the diaphragm is positioned opposite to the surface of the support substrate. The thermosetting adhesive has a tensile elastic modulus allowing a contraction of the support substrate to be transmitted to the support in a hardened state when the semiconductor microphone chip is cooled together with the support substrate. Thus, it is possible to reduce the tensile stress of the diaphragm, which occurs during the manufacturing of the semiconductor microphone chip, thus preventing the diaphragm from being unexpectedly reduced in strength; hence, it is possible to improve the sensitivity of the semiconductor microphone chip.

Owner:YAMAHA CORP

Hot air drying equipment for corrugated case printing machine

The invention discloses hot air drying equipment for a corrugated case printing machine. The hot air drying equipment structurally comprises a draught fan, side supporting plates, a dehumidification pipe, control panels and a drying box, wherein the draught fan is fixedly installed at the top of the drying box, the side supporting plates are welded to the side ends of the drying box, and the dehumidification pipe is fixedly installed at the upper ends of the side supporting plate in an embedded manner. In the drying process, hot air is guided into conduction pipes through air inlets in the front ends of connecting supporting plates, so expansion films expand and swell, at the moment, the angle between swinging plate bodies increases, the four outer sides of a corrugated plate are propped open, magnetic attraction is carried out through second magnetic blocks on laminating plates and first magnetic blocks, meanwhile the laminating plates rotate around positioning shafts, when the laminating plates are attached to the surfaces of the swinging plate bodies, collision plates and the surfaces of the swinging plate bodies maintain laminating strength, the traction on the outer side on the corrugated plate is improved, large shrinkage occurring to the corrugated plate in the drying process is prevented, and ink printing gelatinization of the corrugated plate during drying is avoided.

Owner:广州佳优华信息科技有限公司

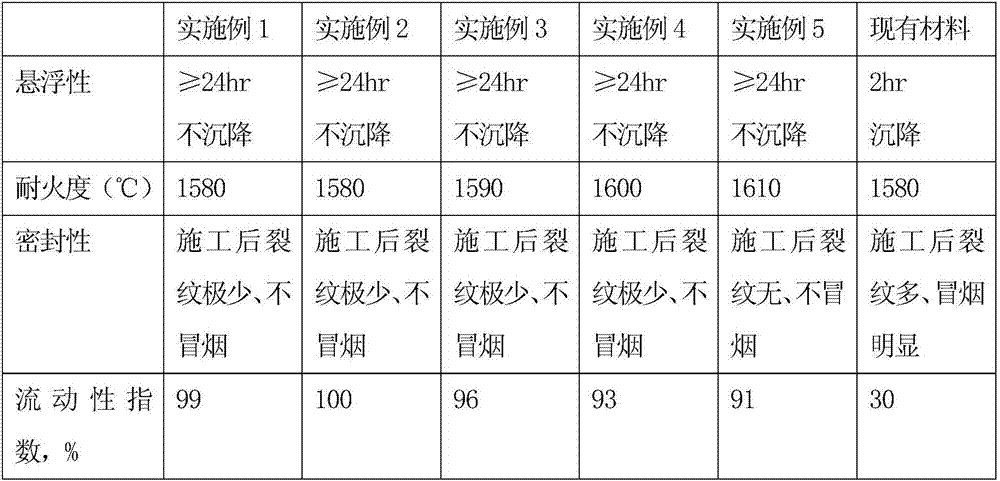

Automatic-casting material for coke oven coal loading holes

ActiveCN107312554AModerate high temperature resistanceGood application effectCoke oven doors/closuresFiberSodium Bentonite

The invention discloses an automatic-casting material for coke oven coal loading holes, wherein the automatic-casting material comprises, by weight, 82-92% of pyrophyllite, 3-10% of expanded vermiculite, 2-5% of bentonite, 1-4% of silicon micro-powder, and 0.5-1.5% of fireproof fiber. The automatic-casting material of the present invention has advantages of good construction performance, good application performance, good high-temperature resistance, easy uncovering, no corrosion on other equipment, no influence on the quality of coke after the falling of the material into the coke oven, and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

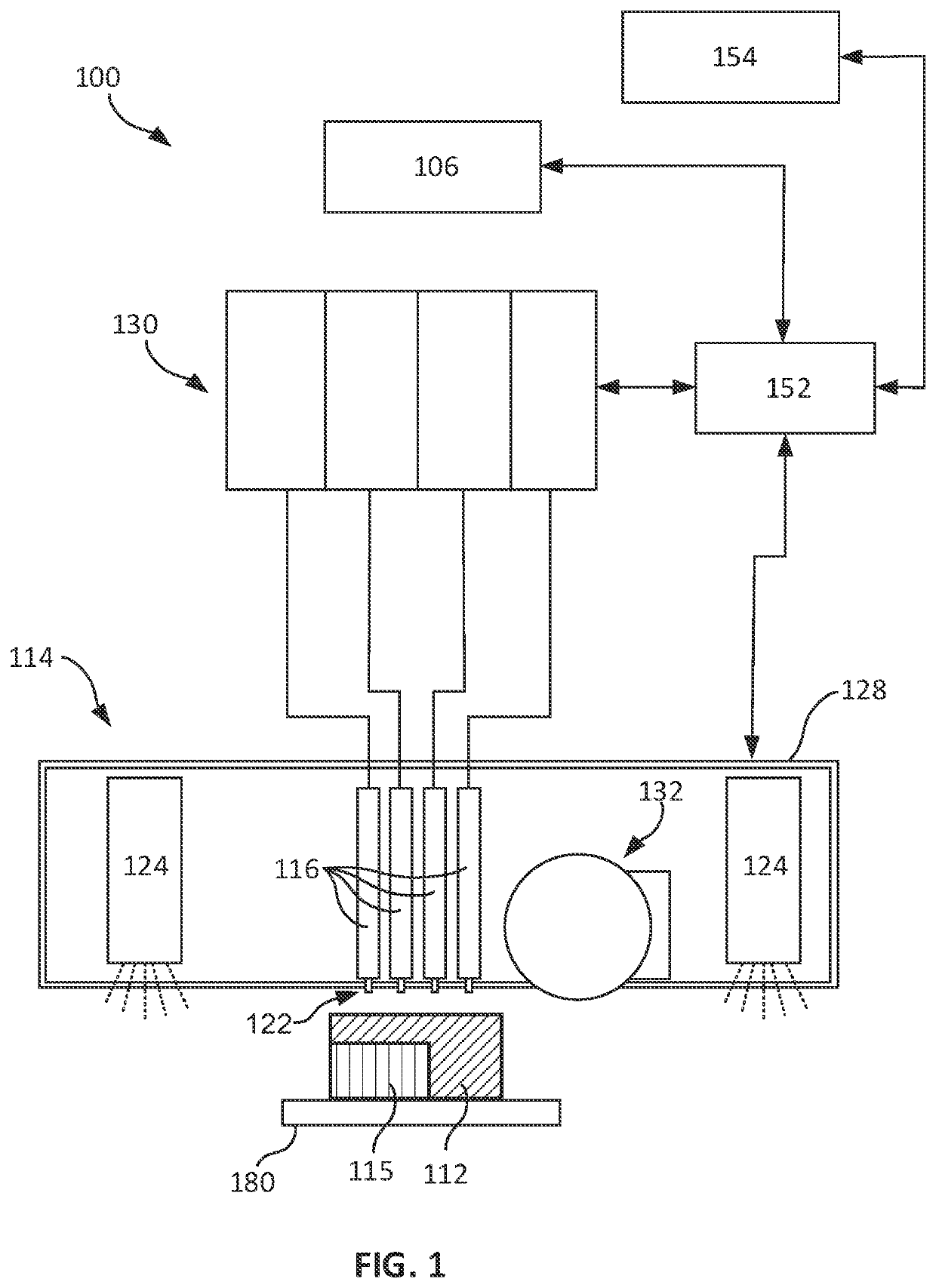

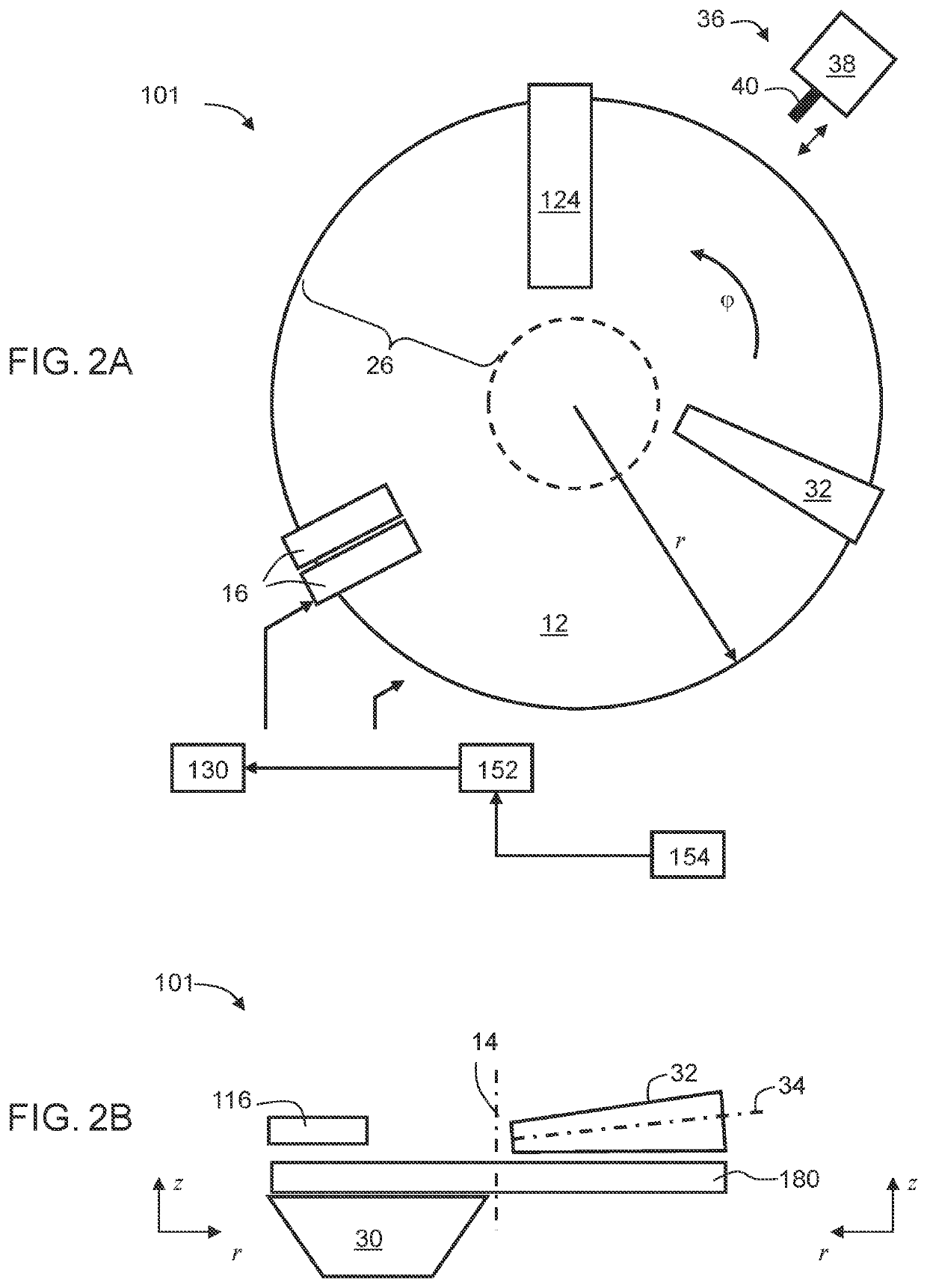

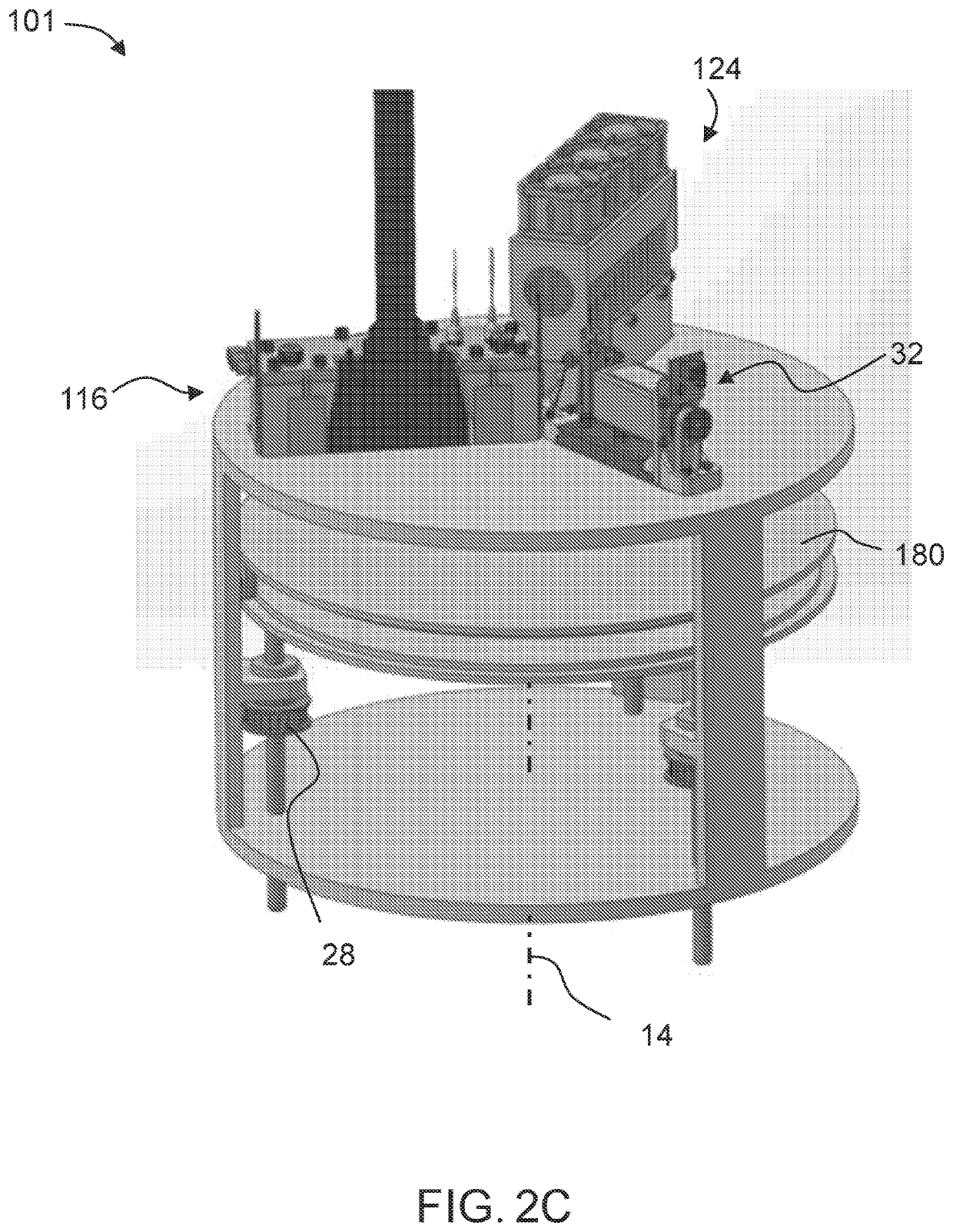

Method for additive manufacturing with partial curing

PendingUS20220324179A1Reduce distortionShrink bigAdditive manufacturing apparatusAdditive manufacturing with liquidsMechanical engineeringAdditive layer manufacturing

A method of additive manufacturing (AM) includes dispensing a first building material formulation to form an outer region, and dispensing a second building material formulation to form an inner region, the outer region surrounding the inner region, the inner and outer regions being shaped to form a layer of the object; exposing the layer to a first curing condition, repeating the dispensing and the exposing to sequentially form a plurality of layers of the object and collectively exposing the plurality of layers to a second curing condition. The selections are such that the first building material formulation is hardened to a higher degree than the second building formulation. The outer regions form a hardened coating that at least partially encapsulates the inner regions. The second curing condition is other than the first curing condition and is selected to increase the degree that the inner region is hardened.

Owner:STRATASYS LTD

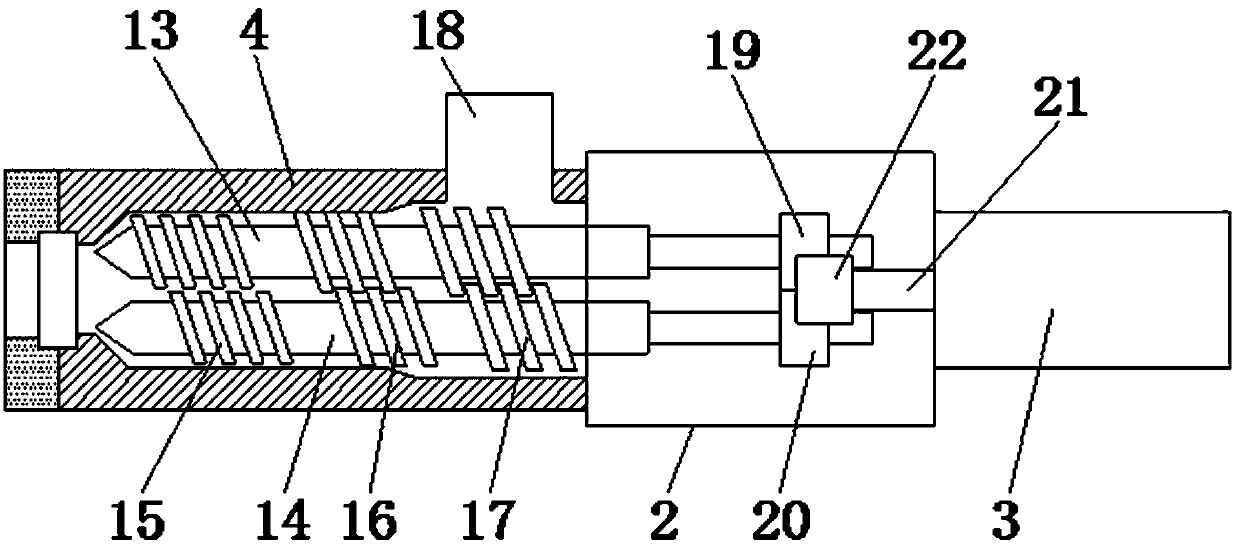

Modified PP and preparation method thereof

The invention discloses modified PP, a preparation method thereof and a twin-screw extruder used for preparing the modified PP. The modified PP is prepared from, by weight, 22-36 parts of PP resin, 25-37 parts of EPDM, 10-45 parts of talcum powder, 12-23 parts of polycarbonate, 11-19 parts of polyamide, 9-16 parts of modified polyphenylene ether, 13-22 parts of thermoplastic polyester, 1-7 parts of a stabilizer, 2-9 parts of a compatibilizer and 2-7 parts of an antioxidant. The modified PP and the preparation method thereof have the advantages that by adopting the PP resin, the EPDM, T15 and the polycarbonate, the advantages of high impact, weather resistance, high mobility and sprayability can be improved; by adopting the PP resin, the EPDM, T20 and the polyamide, the advantages of high rigidity, weather resistance, scratch resistance and low odor can be improved; by adopting the PP resin, the EPDM, T30 and the modified polyphenylene ether, the advantages of rigidity and toughness balance and low shrinkage can be improved; by adopting the PP resin, the EPDM, T40 and the thermoplastic polyester, the advantages of high melt value, low odor and rigidity and toughness balance can be improved; the rigidity of a system is improved, and the molding shrinkage rate is reduced, thereby obtaining the reinforced PP material with excellent comprehensive performance.

Owner:潮州市潮安区佳特塑料实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com