Steel-bamboo mixed fiber regenerated thermal insulation concrete and preparation method thereof

A technology of thermal insulation concrete and mixed fibers, which is applied in the field of building materials, can solve the problems of large porosity, reduce concrete density, and low strength, and achieve the effects of improving crack resistance, improving fluidity, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

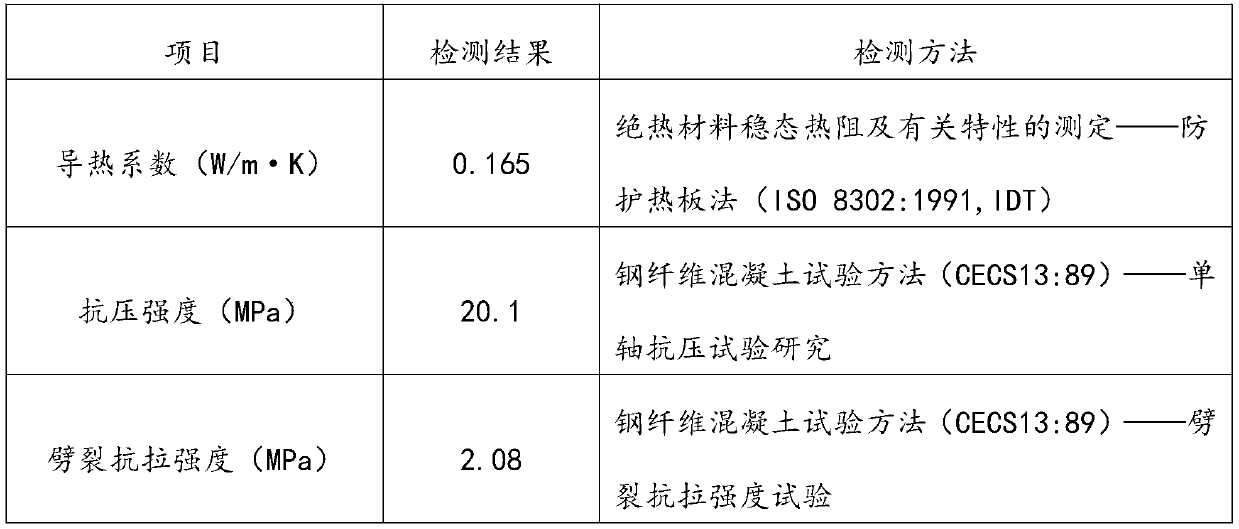

Embodiment 1

[0054] The steel-bamboo mixed fiber recycled thermal insulation concrete of this embodiment is made of the following raw materials according to the percentage of the total weight of raw materials: 16% of cement, 12% of water, 35.03% of acidified recycled fine aggregate, and 35% of acidified recycled coarse aggregate. %, polypropylene composite bamboo fiber 0.6%, steel fiber 0.5%, hydroxypropyl methyl cellulose ether 0.14%, polystyrene particles 0.6% and resin rubber powder 0.1%. Wherein, the strength grade of the cement is 42.5; the acidified regenerated coarse aggregate is obtained by taking waste concrete with a strength of 30MPa-50MPa, removing slag and steel bars, crushing, sieving, and soaking in acetic acid. diameter of 5mm-20mm fragments; the acidified regenerated fine aggregate is to take the waste concrete with a strength of 30MPa-50MPa, remove slag and steel bars, crush, sieve, and soak in acetic acid to obtain a particle size of Fragments of 0.1mm-5mm; the length of...

Embodiment 2

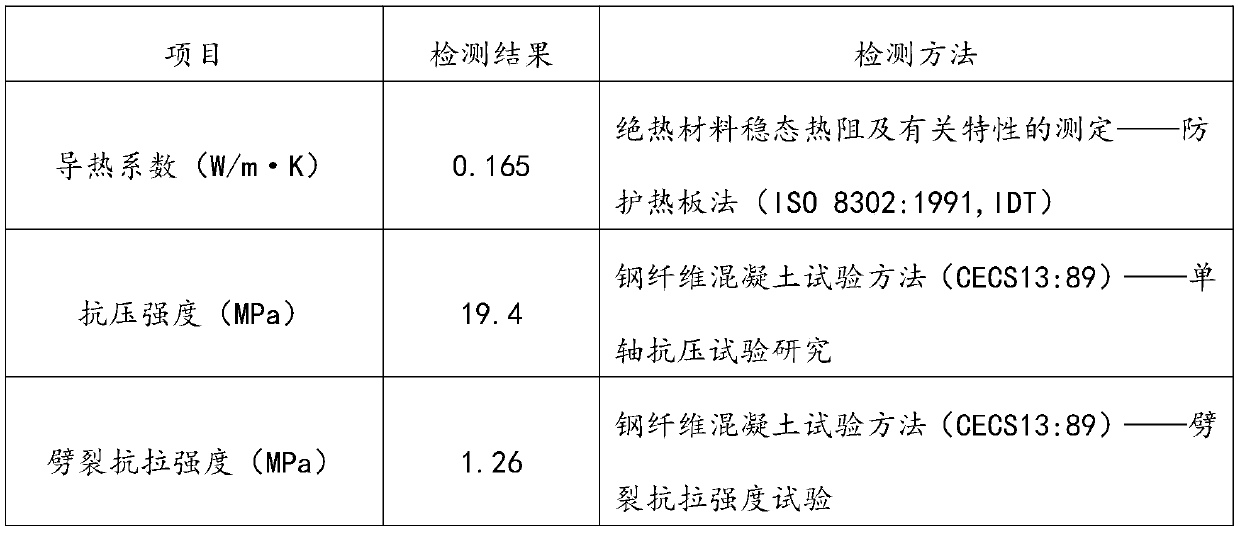

[0062] The steel-bamboo mixed fiber regenerated thermal insulation concrete of this embodiment is made of the following raw materials according to the percentage of the total weight of raw materials: 22% of cement, 15% of water, 29.75% of acidified regenerated fine aggregate, 29.75% of acidified regenerated coarse aggregate %, polypropylene composite bamboo fiber 1%, steel fiber 1%, hydroxypropyl methyl cellulose ether 0.2%, polystyrene particles 1% and resin powder 0.3%. Wherein, the strength grade of the cement is 42.5; the acidified regenerated coarse aggregate is obtained by taking waste concrete with a strength of 30MPa-50MPa, removing slag and steel bars, crushing, sieving, and soaking in acetic acid. diameter of 5mm-20mm fragments; the acidified regenerated fine aggregate is to take the waste concrete with a strength of 30MPa-50MPa, remove slag and steel bars, crush, sieve, and soak in acetic acid to obtain a particle size of Fragments of 0.1mm-5mm; the length of the st...

Embodiment 3

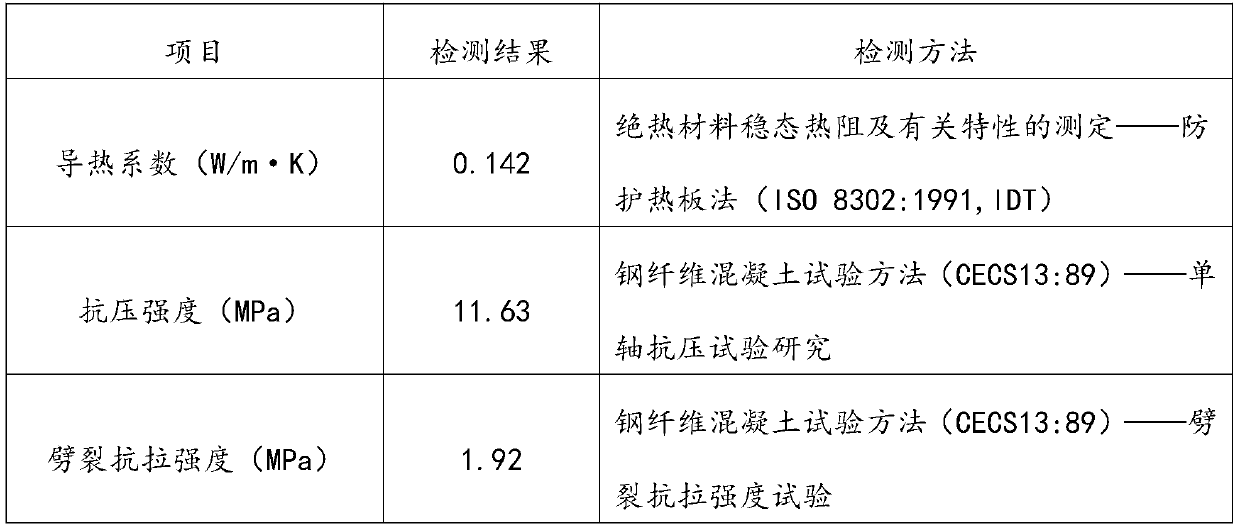

[0070] The steel-bamboo mixed fiber recycled thermal insulation concrete of this embodiment is made of the following raw materials according to the percentage of the total weight of raw materials: 15% cement, 10% water, 36.65% acidified recycled fine aggregate, 36.65% acidified recycled coarse aggregate %, polypropylene composite bamboo fiber 0.5%, steel fiber 0.5%, hydroxypropyl methylcellulose ether 0.1%, polystyrene particles 0.5% and resin rubber powder 0.1%. Wherein, the strength grade of the cement is 42.5; the acidified regenerated coarse aggregate is obtained by taking waste concrete with a strength of 30MPa-50MPa, removing slag and steel bars, crushing, sieving, and soaking in acetic acid. diameter of 5mm-20mm fragments; the acidified regenerated fine aggregate is to take the waste concrete with a strength of 30MPa-50MPa, remove slag and steel bars, crush, sieve, and soak in acetic acid to obtain a particle size of Fragments of 0.1mm-5mm; the length of the steel fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com