Skeletal muscle model based bionic muscle and manufacturing method

A bionic muscle and muscle technology, applied in the field of bionics, to achieve the effect of large contraction and good contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

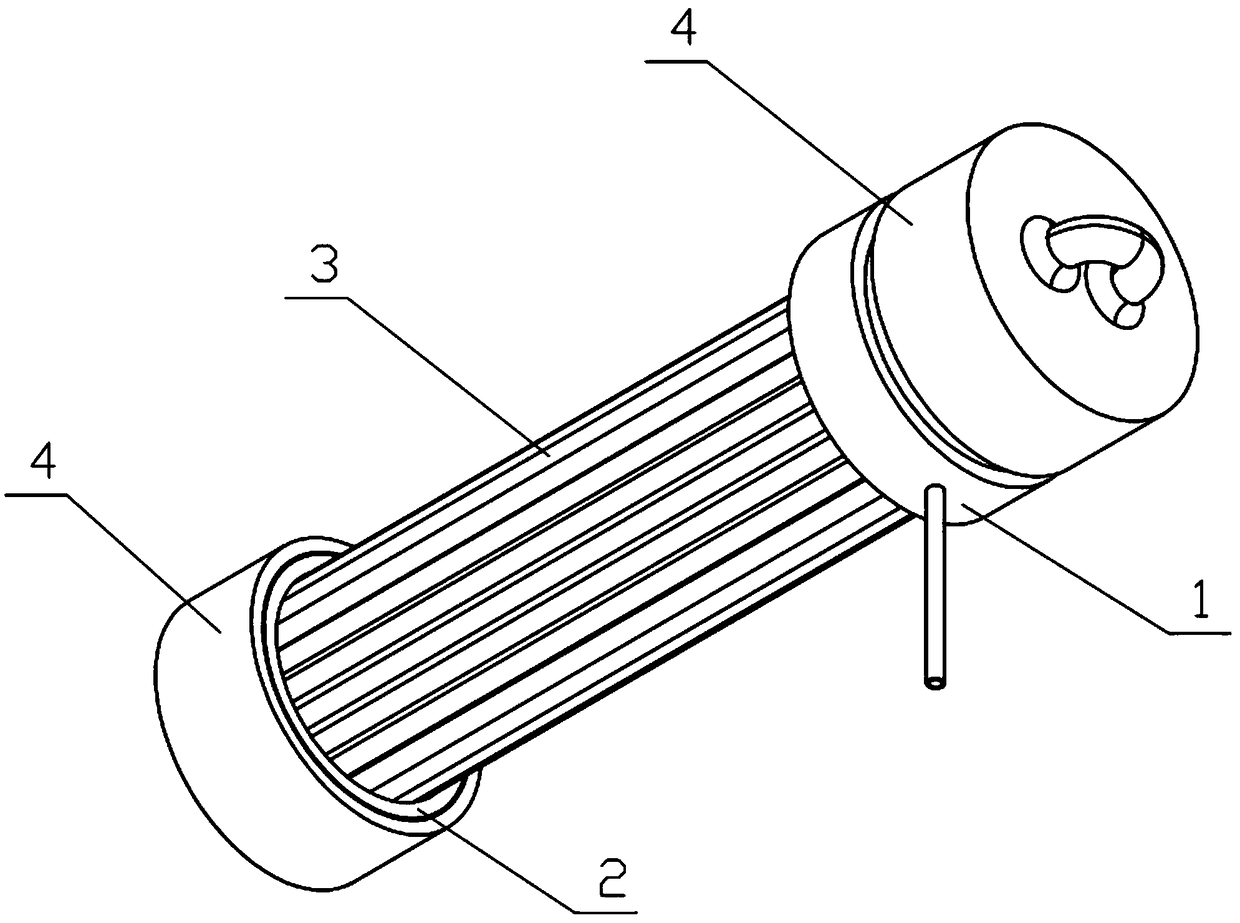

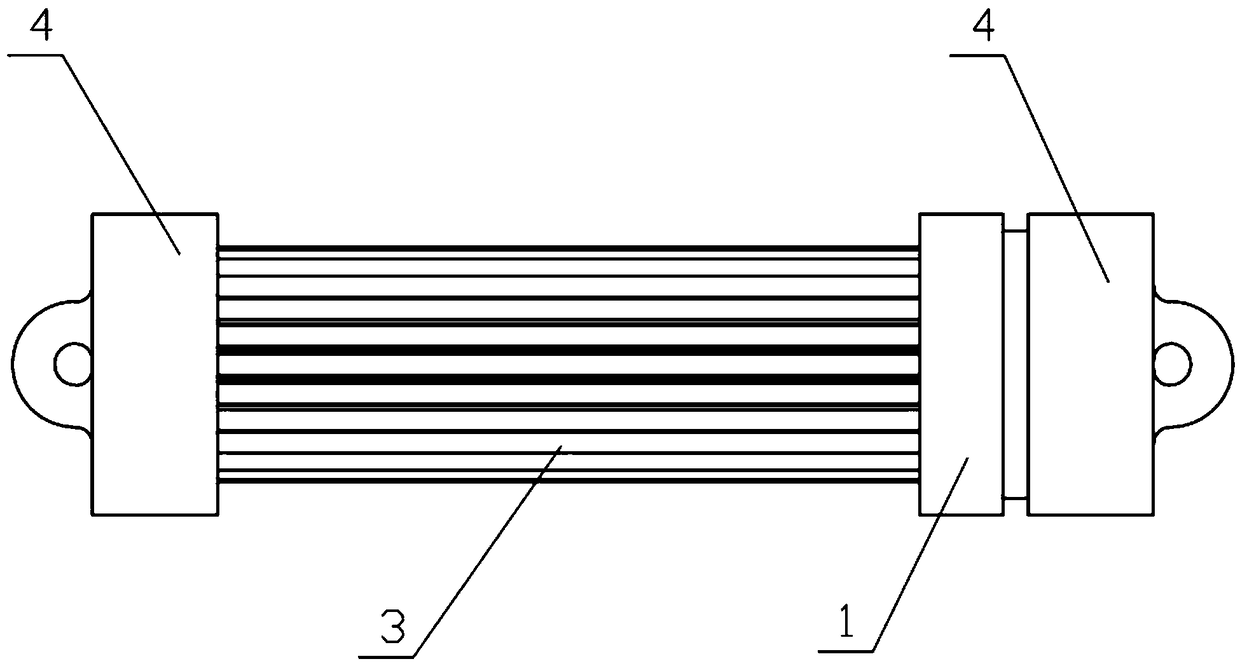

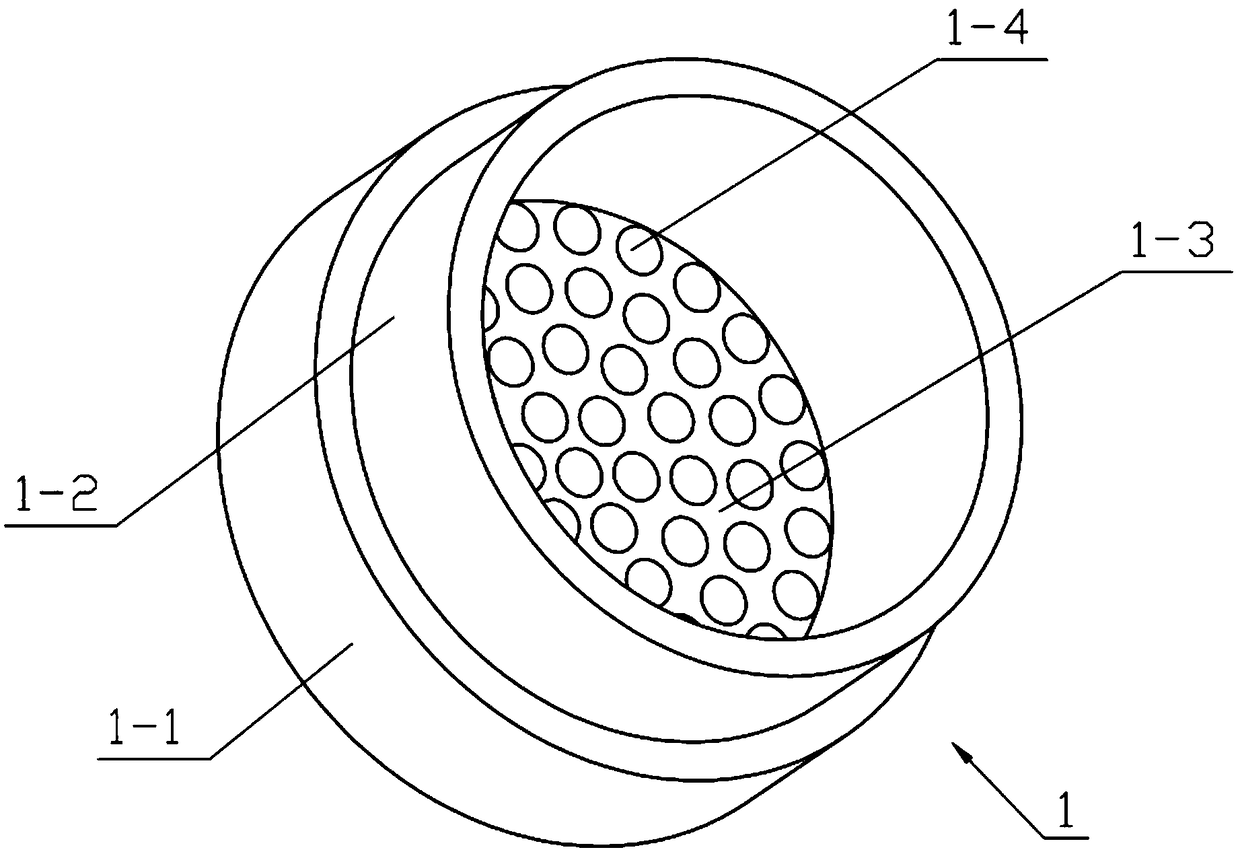

[0030] Combine below Figure 1-5 To illustrate this embodiment, a bionic muscle based on a skeletal muscle model includes an air intake cylinder 1, a fixed cylinder 2 and a pneumatic muscle monofilament 3, and the air intake cylinder 1 and the fixed cylinder 2 are fixedly connected with A plurality of pneumatic muscle monofilaments 3, the pneumatic muscle monofilaments 3 ventilate and expand laterally; the gas can be passed into the multiple pneumatic muscle monofilaments 3 through the air intake cylinder 1 fixedly connected to the air intake hose, and the inner silicone hose 3-1 Ventilation for lateral expansion shortens the relative distance between the fixed cylinder 1 and the intake cylinder 2 to simulate human muscles, multiple pneumatic muscle monofilaments 3 are relatively independent, and multiple pneumatic muscle monofilaments 3 are used to integrate muscles In the process of expanding and contracting, the pneumatic muscle monofilament 3 will squeeze each other, so as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com