Hot air drying equipment for corrugated case printing machine

A technology for hot air drying and corrugated boxes, which is applied to printing machines, general parts of printing machinery, printing, etc. It can solve the problems of different drying strength, different shrinkage degrees, and different ink shrinkage degrees, so as to avoid gelatinization and improve The effect of traction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

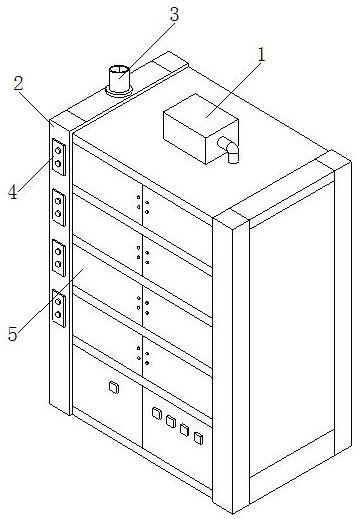

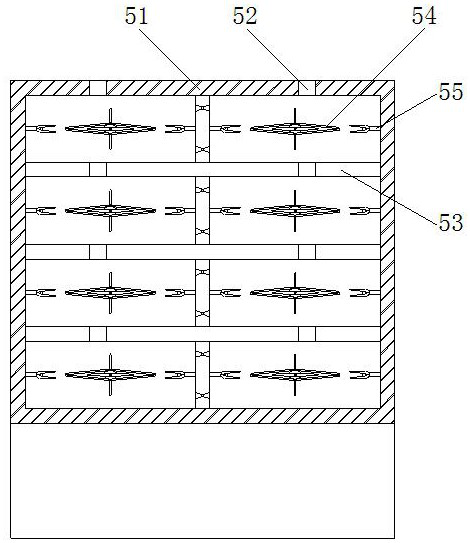

[0024] as attached figure 1 to attach Figure 5 Shown:

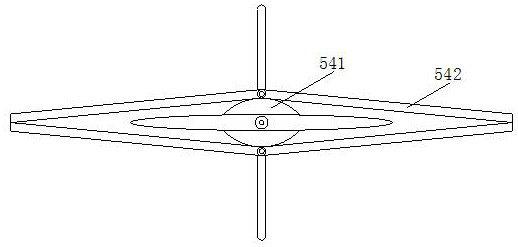

[0025] The invention relates to a corrugated box printing machine hot air drying equipment, the structure of which includes a fan 1, a side support plate 2, a moisture discharge pipe 3, a control panel 4, and a drying box 5. The fan 1 is fixedly installed on the top of the drying box 5, and the side The support plate 2 is welded to the side end of the drying box 5, the upper end of the side support plate 2 is embedded with a moisture discharge pipe 3, and the moisture discharge pipe 3 is connected with the interior of the drying box 5, and the control panel 4 is installed on the side support plate 2 front surface, and the control panel 4 is electrically connected with the fan 1, the drying box 5 includes a box body 51, a hot air inlet 52, a spacer 53, a clamping mechanism 54, and a welting mechanism 55. The top of the box body 51 is embedded There is a hot air inlet 52, and the hot air inlet 52 is connected with the fa...

Embodiment 2

[0032] as attached Figure 6 to attach Figure 8 Shown:

[0033] Wherein, the welt mechanism 55 includes a fixed sleeve 551, a telescopic hose 552, an outreach mechanism 553, a positioning shaft 554, a return spring 555, and a second magnetic block 556, and the right end of the fixed sleeve 551 is fixedly installed on the box. body 51 inside surface, the inside of the fixed sleeve 551 is provided with a telescopic hose 552, and the left end of the telescopic hose 552 is fixed to the right end of the abduction mechanism 553, and the middle part of the abduction mechanism 553 is provided with a positioning shaft 554. The inner side of the extension mechanism 553 is fixed with the return spring 555, and the inner surface of the left end of the extension mechanism 553 is welded with a second magnetic block 556. The telescopic hose 552 has a folded structure and is made of thermoplastic polyurethane elastomer rubber, with Certain ductility and high temperature resistance are bene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com