Pressure cylinder for a drafting arrangement of a textile machine

A technology of pressure cylinder and textile machinery, which is applied to spinning machines, mechanical equipment, stretch spinning, etc., and can solve the problems that the stretching mechanism cannot be restarted, the circuit breaker is in an inaccurate operating state, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

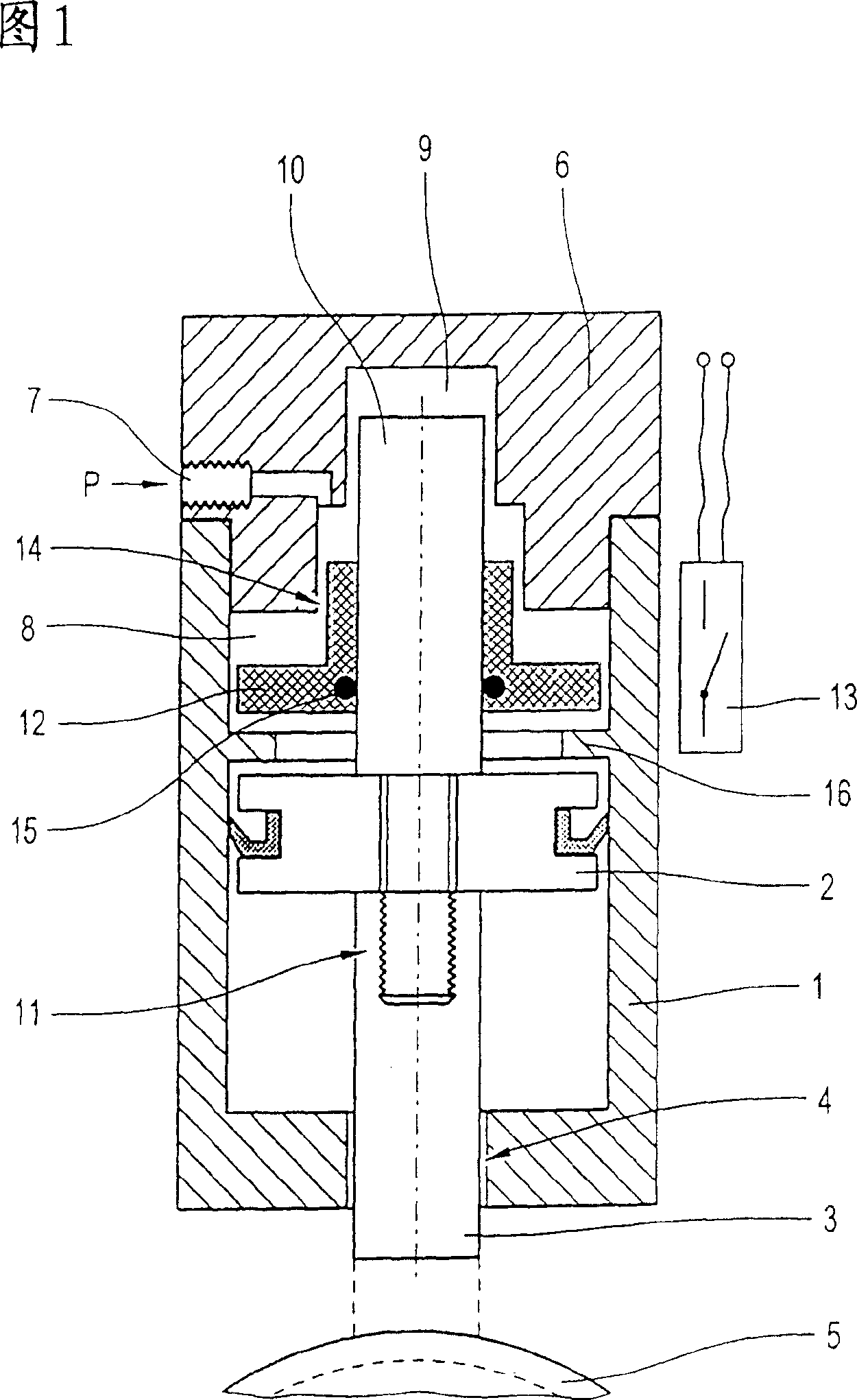

[0020] According to the figure, the compressed-air driven pressure cylinder has a cylinder housing 1 in which a piston 2 is movably mounted. A piston rod 3 protrudes from the piston 2 . The piston rod 3 protrudes from a bottom-side bore 4 of the pot-shaped cylinder housing 1 . The bore 4 also serves as the inner wall of the cylinder housing 1 that guides the piston 2 with the piston rod 3 . The piston rod 3 cooperates with an upper roller 5 of a stretching mechanism for the fiber material (for more detailed technical details of the stretching mechanism, refer to the prior art discussed at the outset). The pot-shaped cylinder housing 1 is closed at the end facing away from the bore 4 with a cylinder bottom 6 . The connection between the cylinder housing 1 and the cylinder bottom 6 is designed in this embodiment as a snap-fit connection. The cylinder base 6 has a pressure medium connection 7 for supplying the pressure chamber 8 of the pressure cylinder with air. A guide re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com