Patents

Literature

107results about "Material accumulating devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

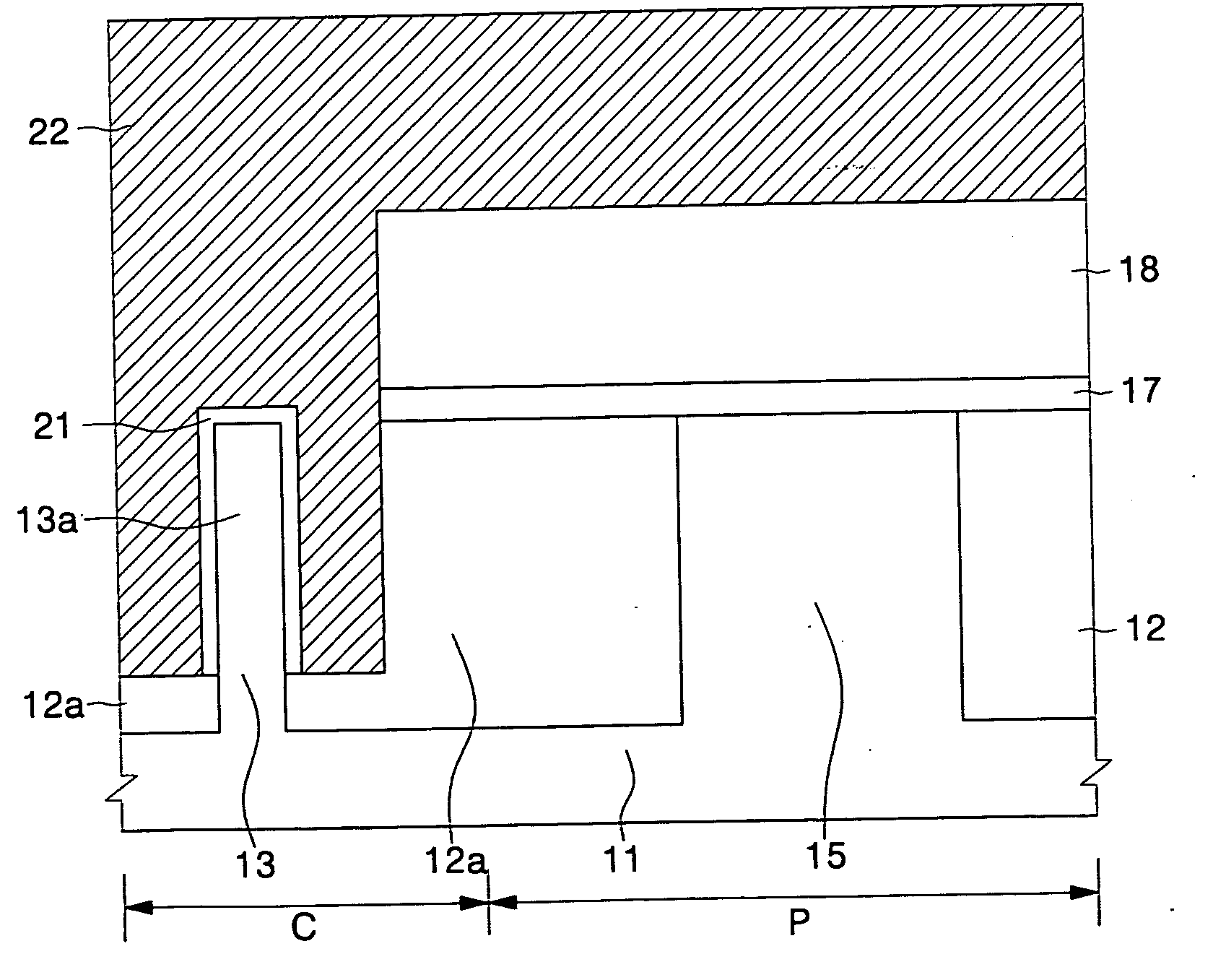

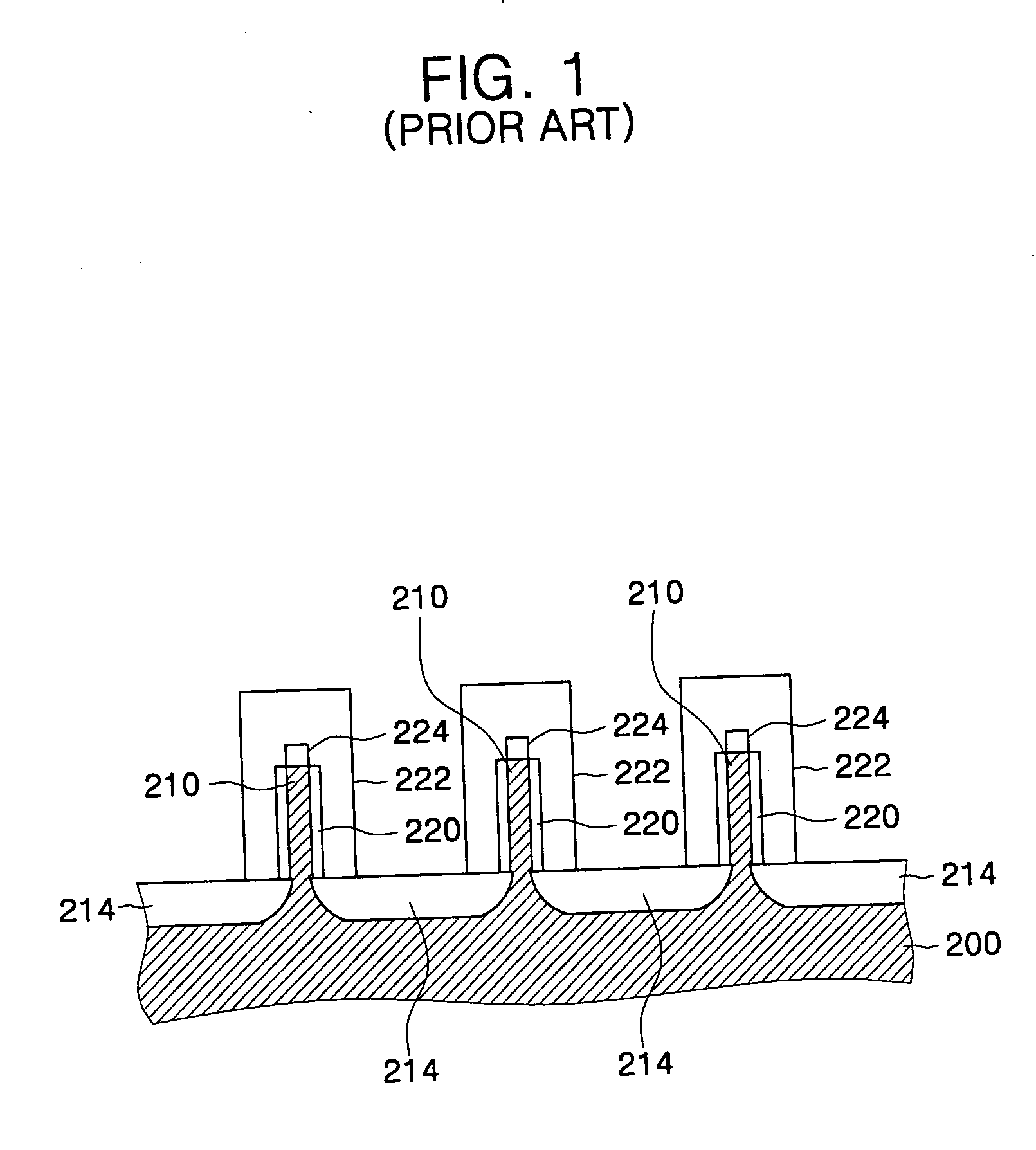

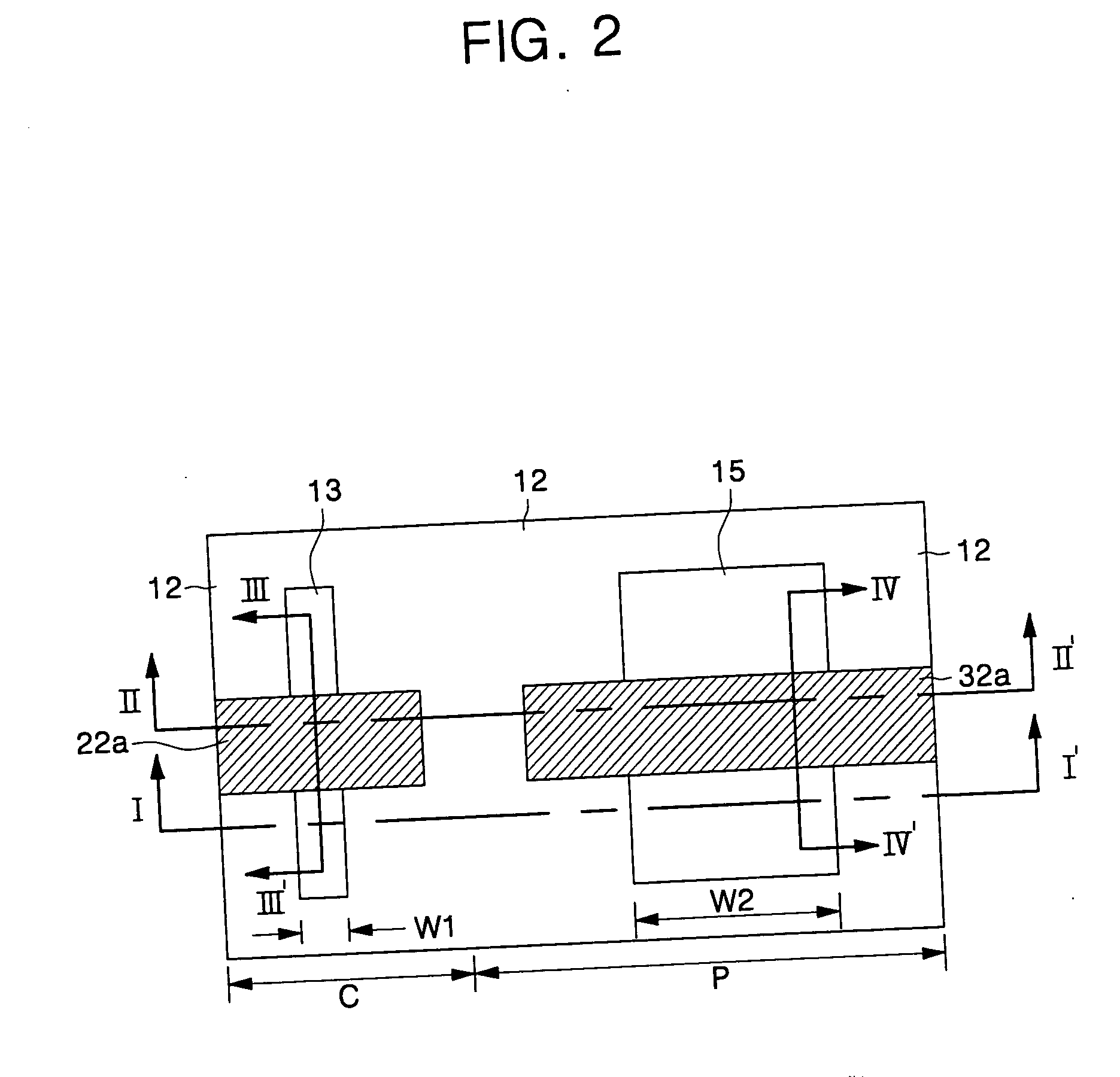

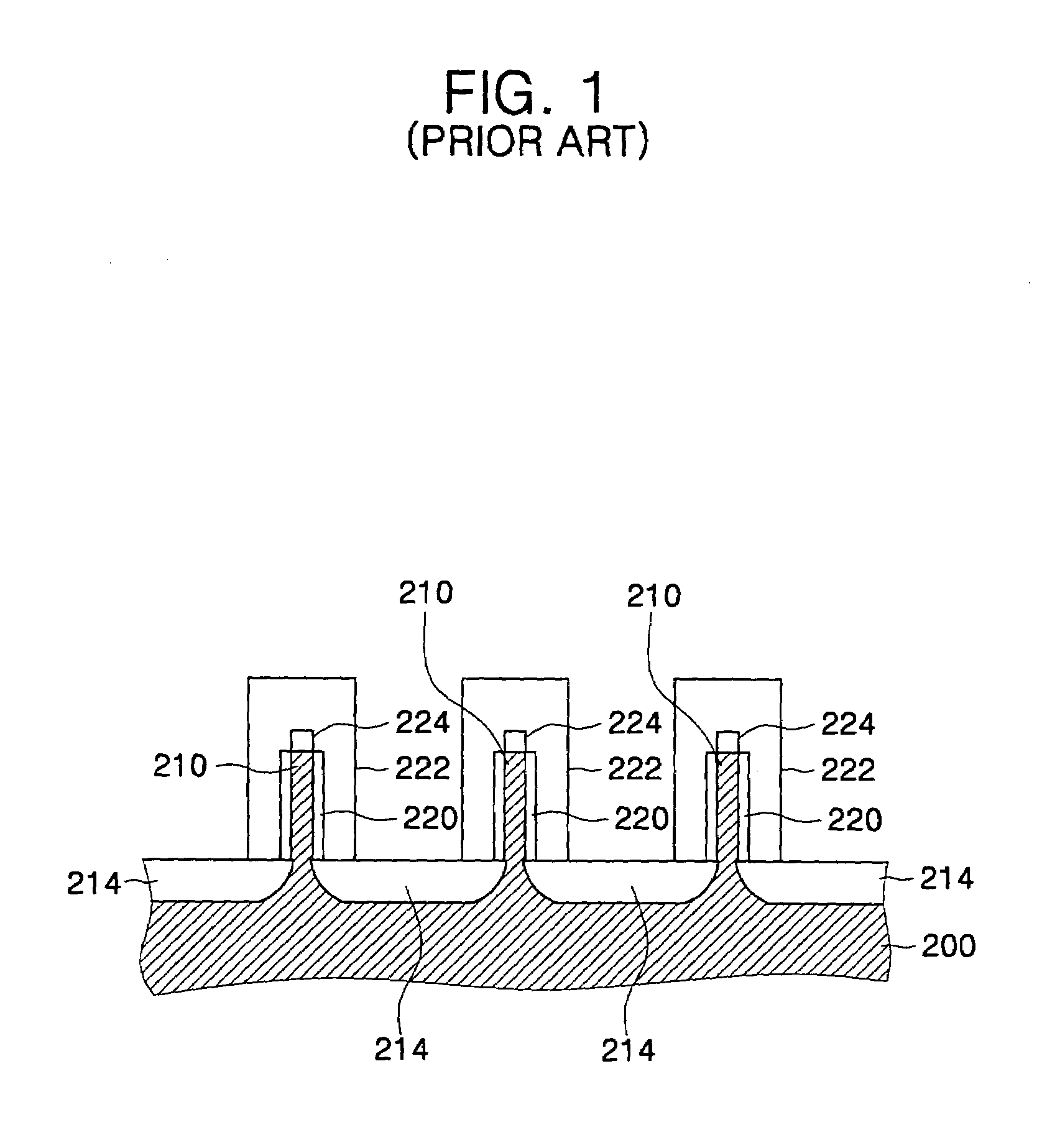

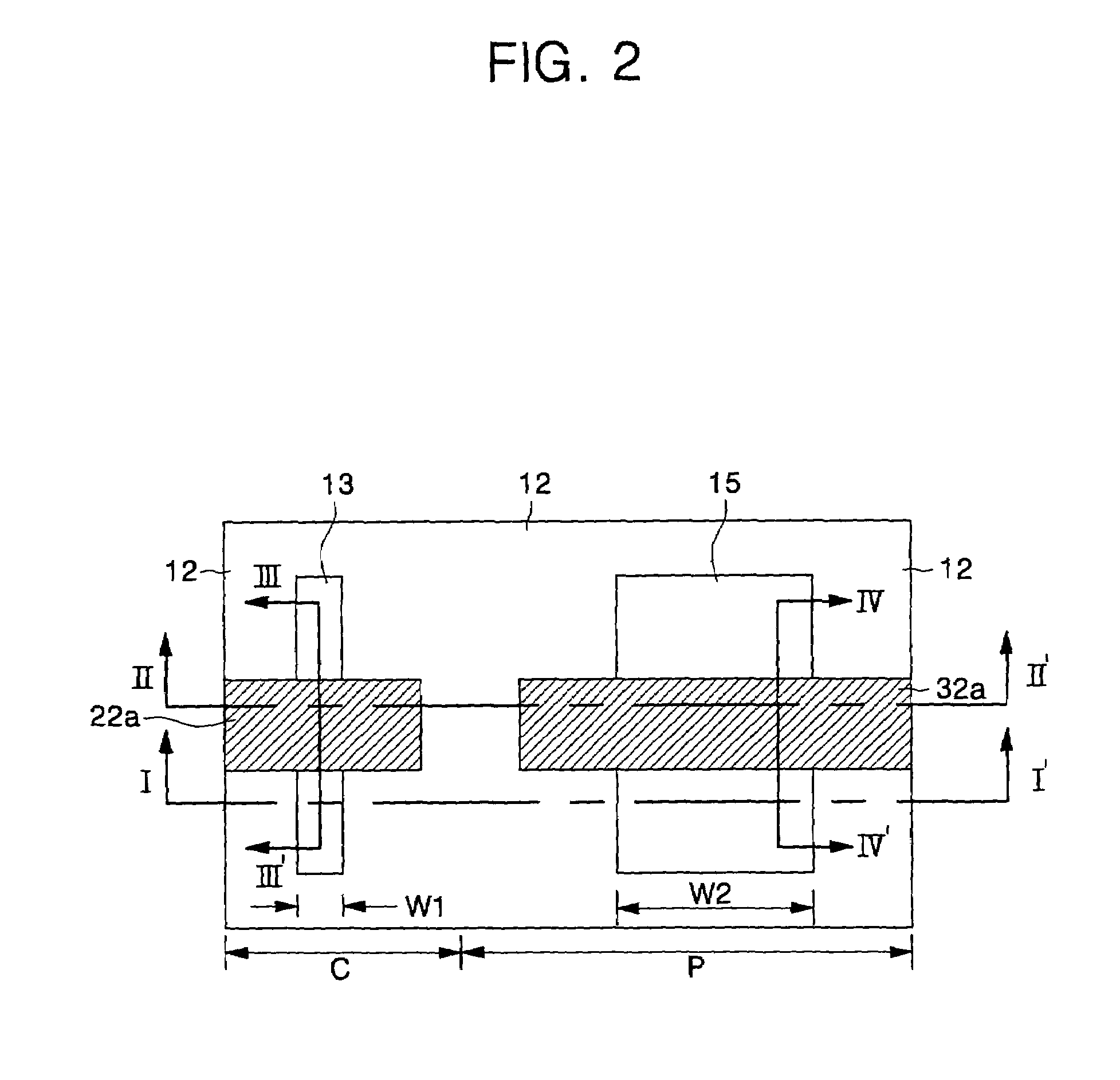

Methods of forming integrated circuit devices having field effect transistors of different types in different device regions

A method of forming an integrated circuit device includes forming a non-planar field-effect transistor in a cell array portion of a semiconductor substrate and forming a planar field-effect transistor in a peripheral circuit portion of the semiconductor substrate. The non-planar field-effect transistor may be selected from the group of a FinFET and a recessed gate FET. Dopants may be implanted into a channel region of the non-planar field-effect transistor, and a cell protection layer may be formed on the non-planar field-effect transistor. Then, dopants may be selectively implanted into a channel region of the planar field-effect transistor using the cell protection layer as a mask to block implanting of the dopants into the channel region of the non-planar field-effect transistor.

Owner:SAMSUNG ELECTRONICS CO LTD

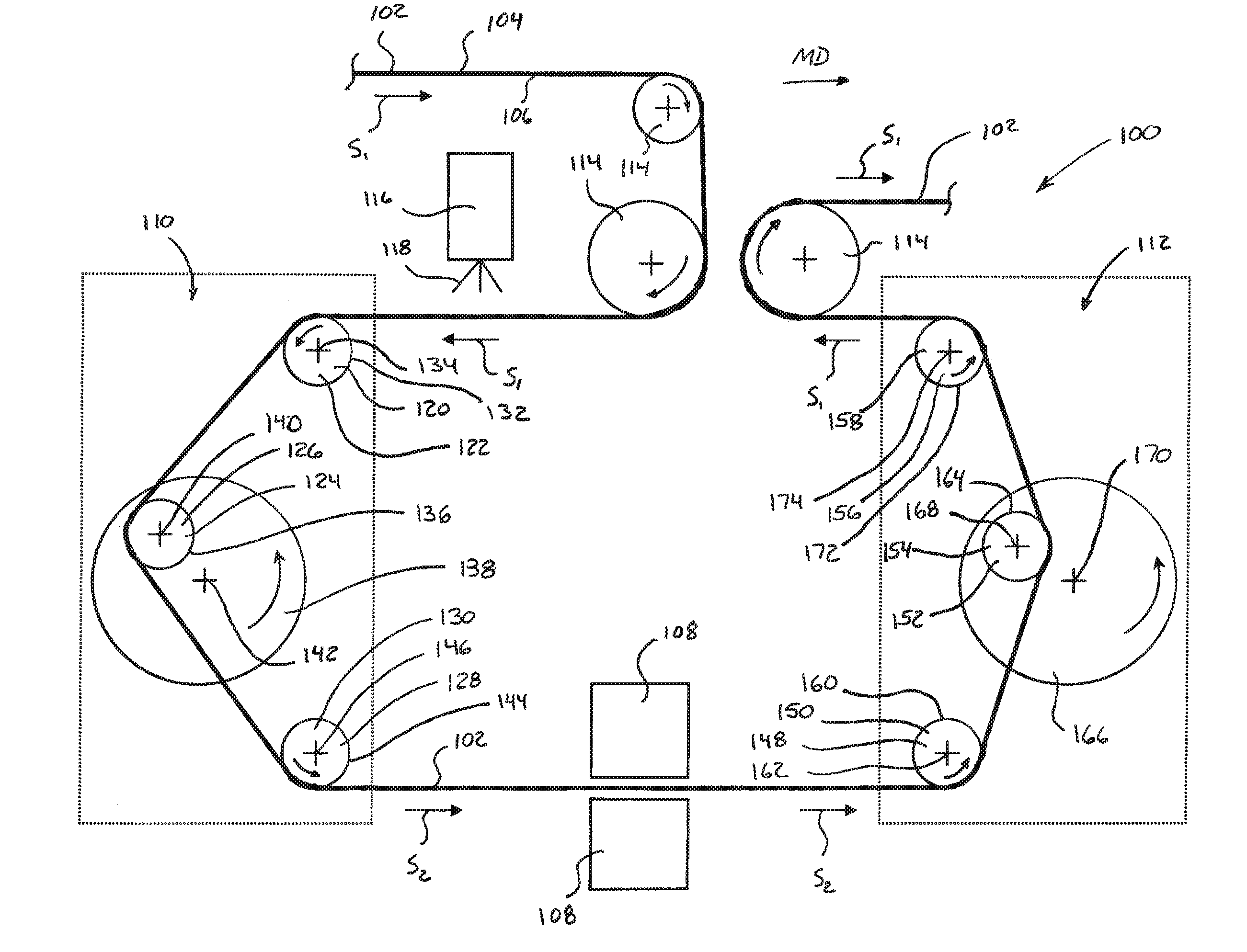

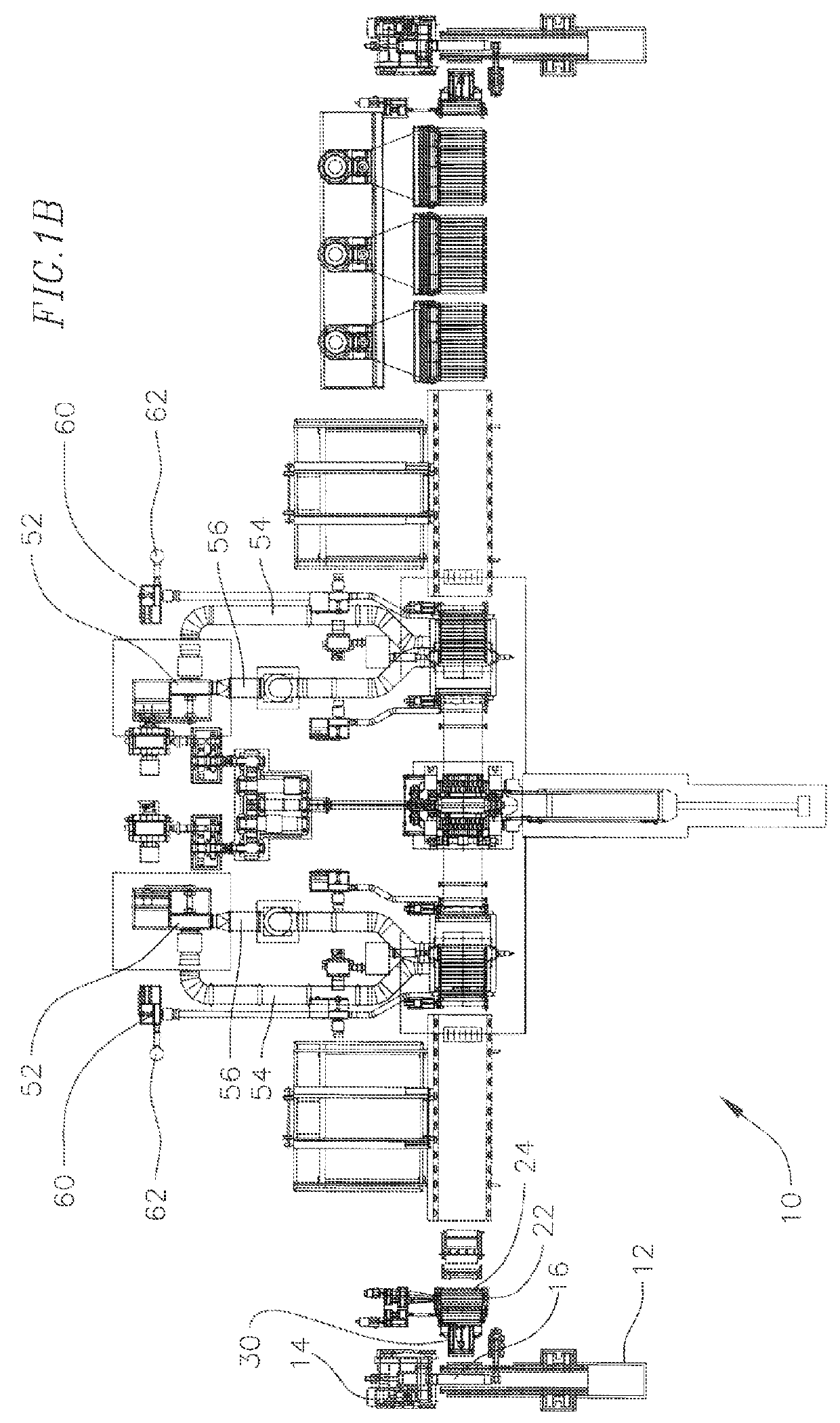

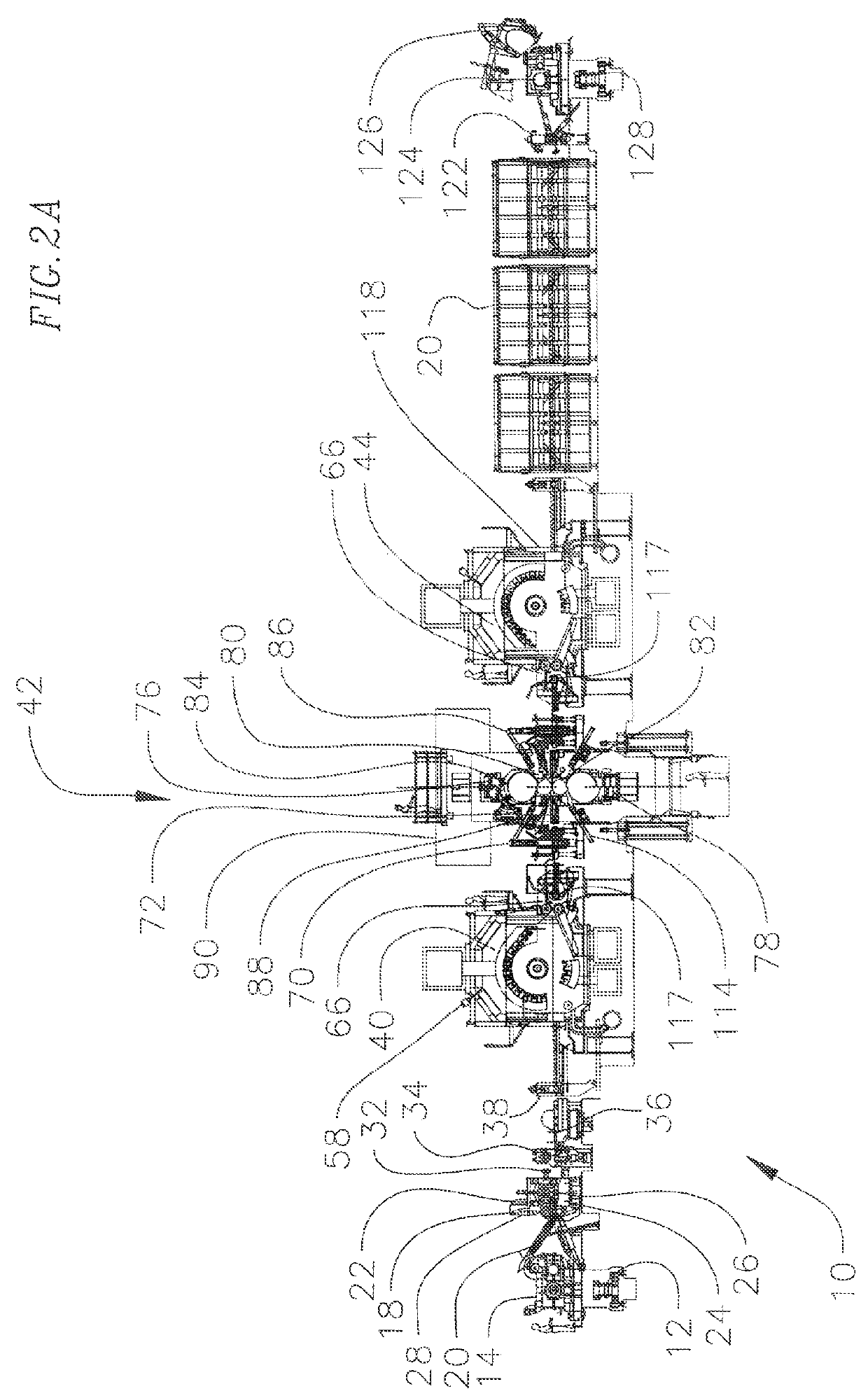

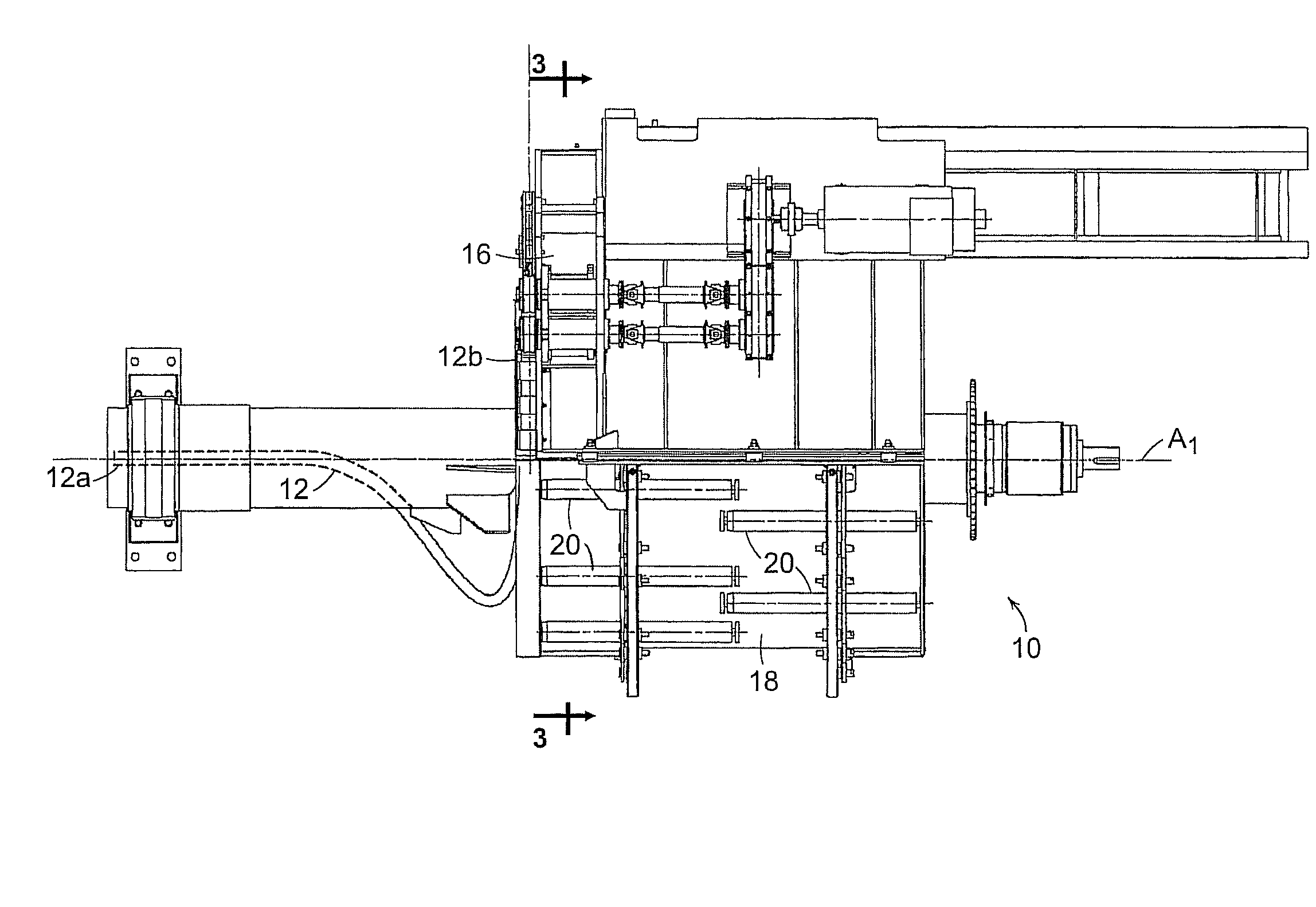

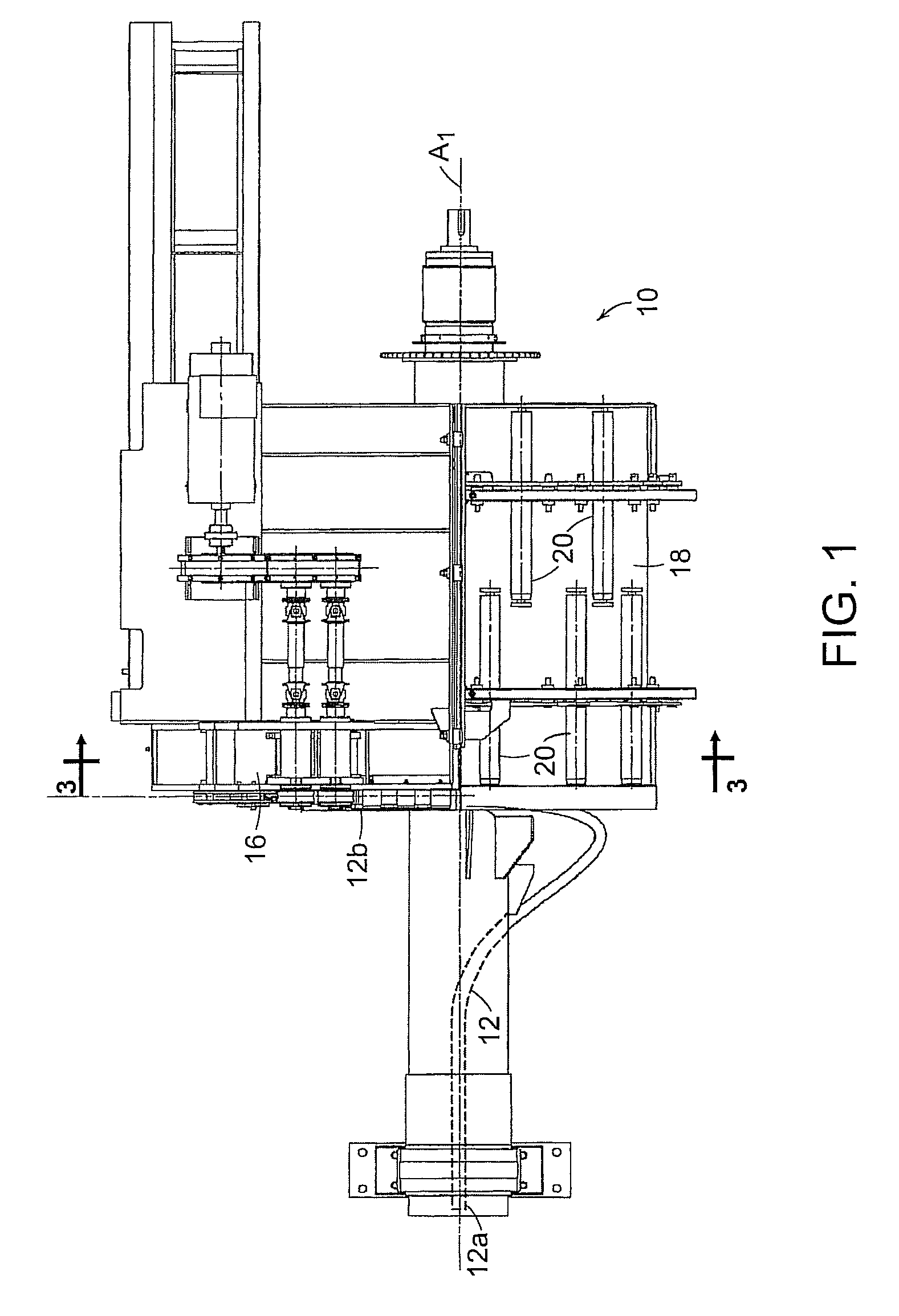

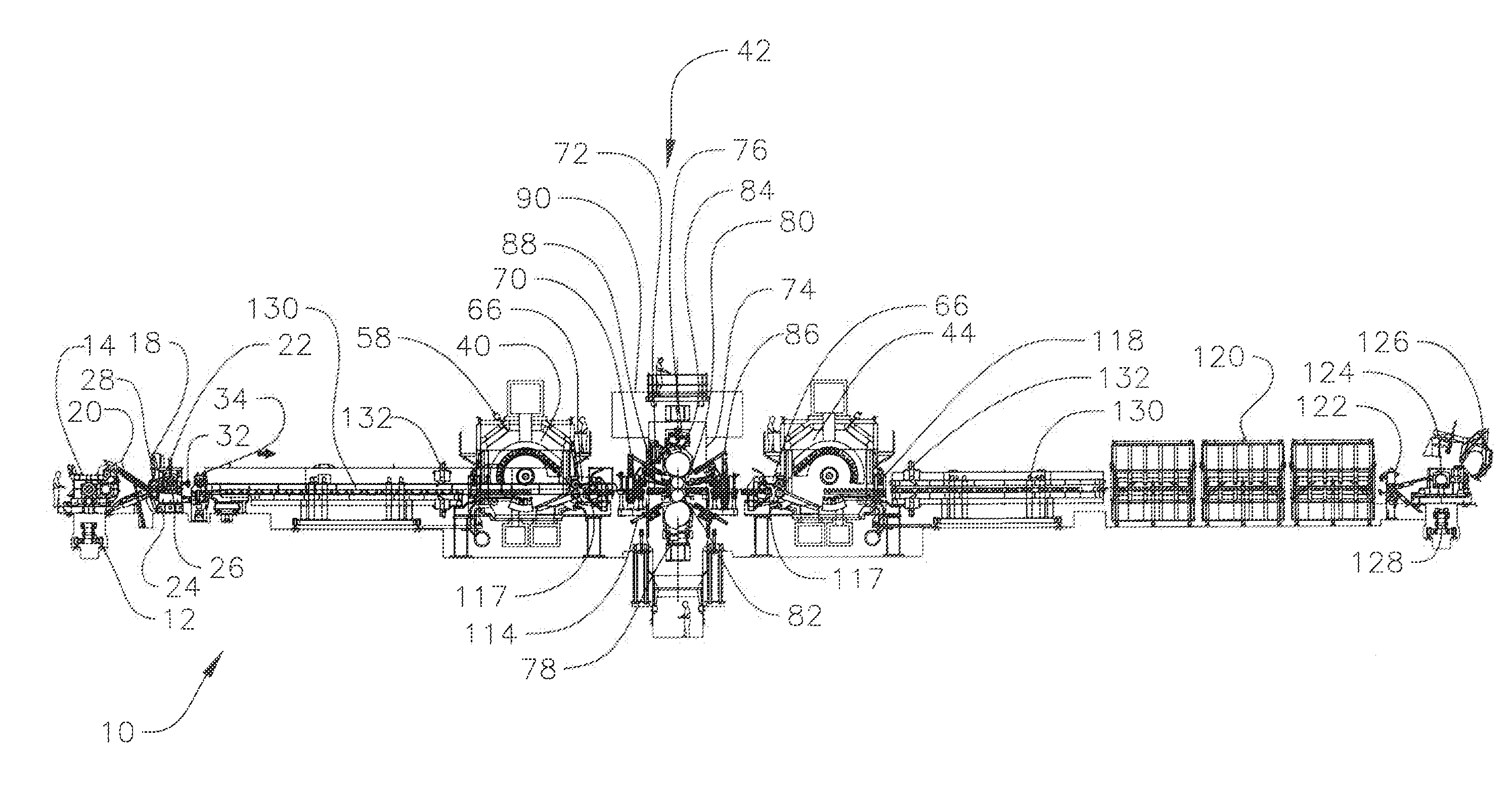

Appraratus and method for providing a localized speed variance of an advancing substrate

ActiveUS20100252603A1Adhesive processesLamination ancillary operationsElectrical and Electronics engineeringEngineering

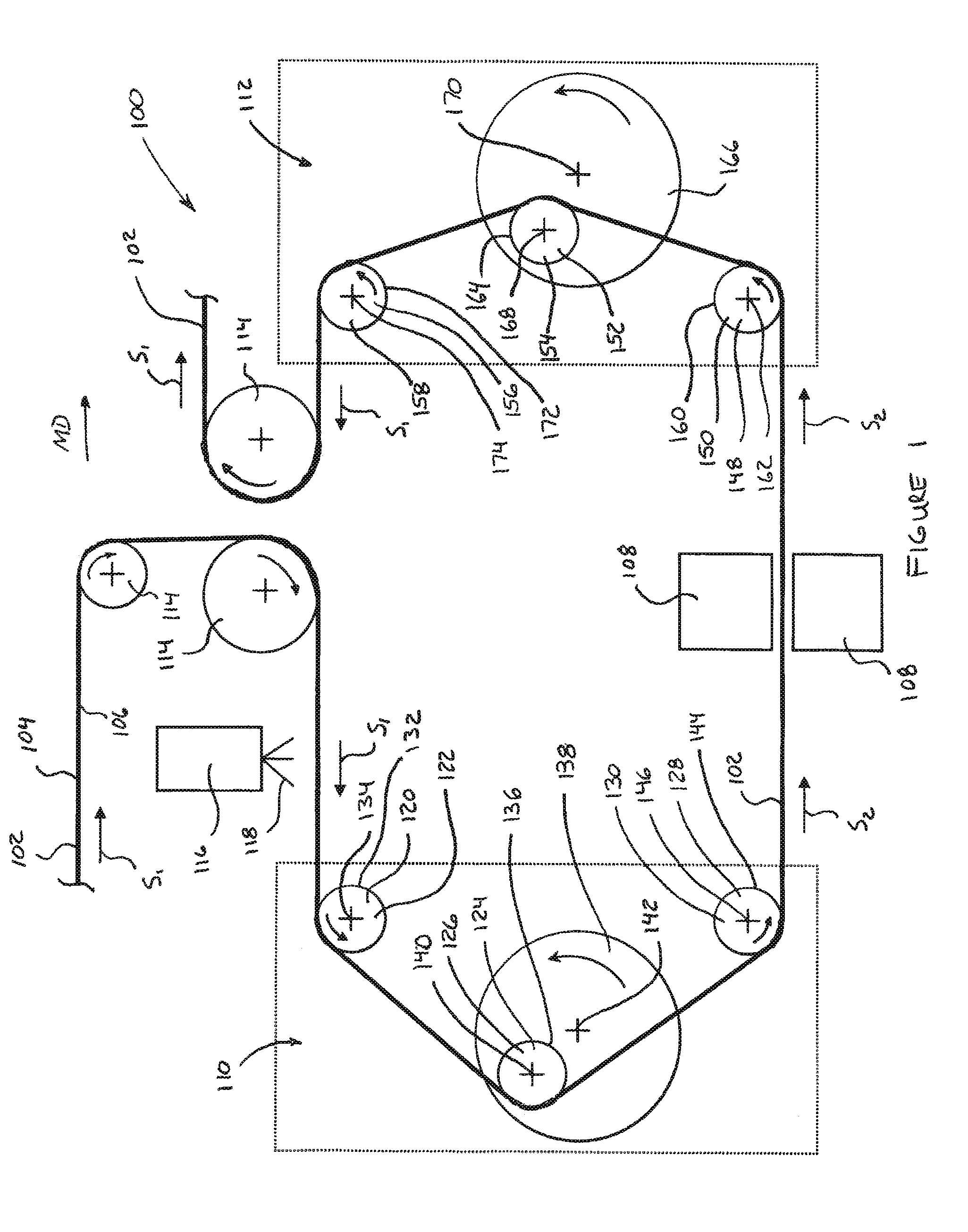

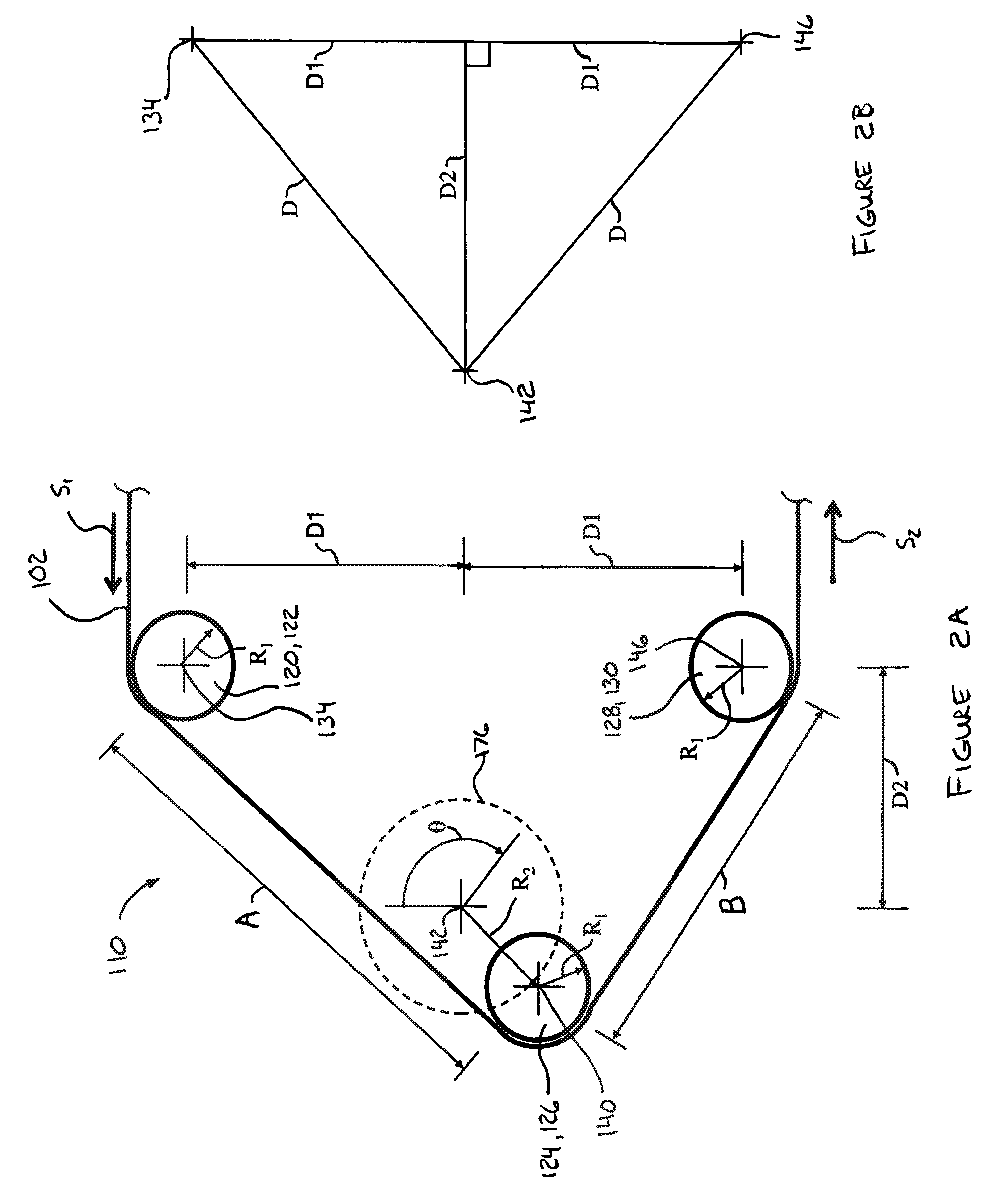

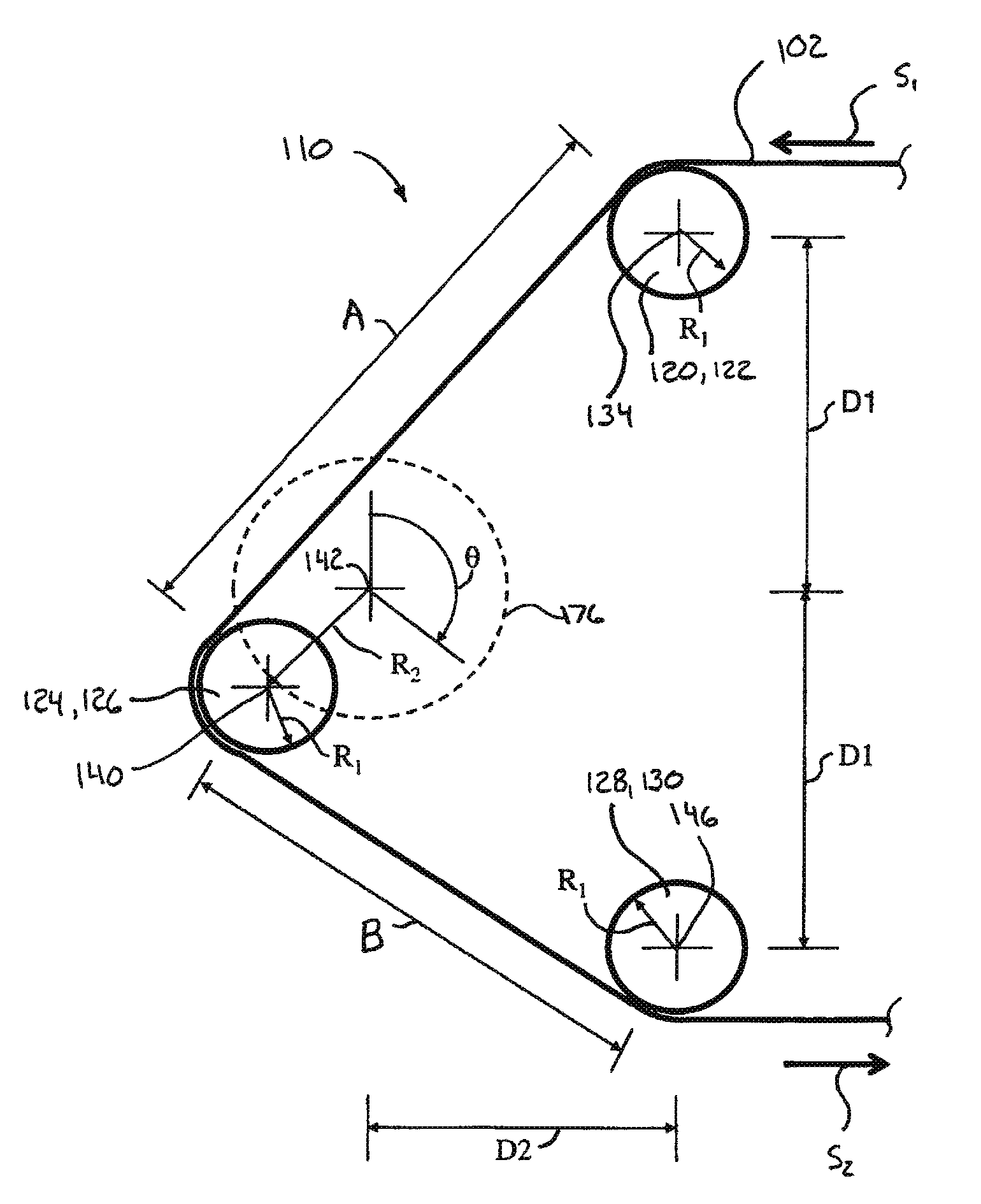

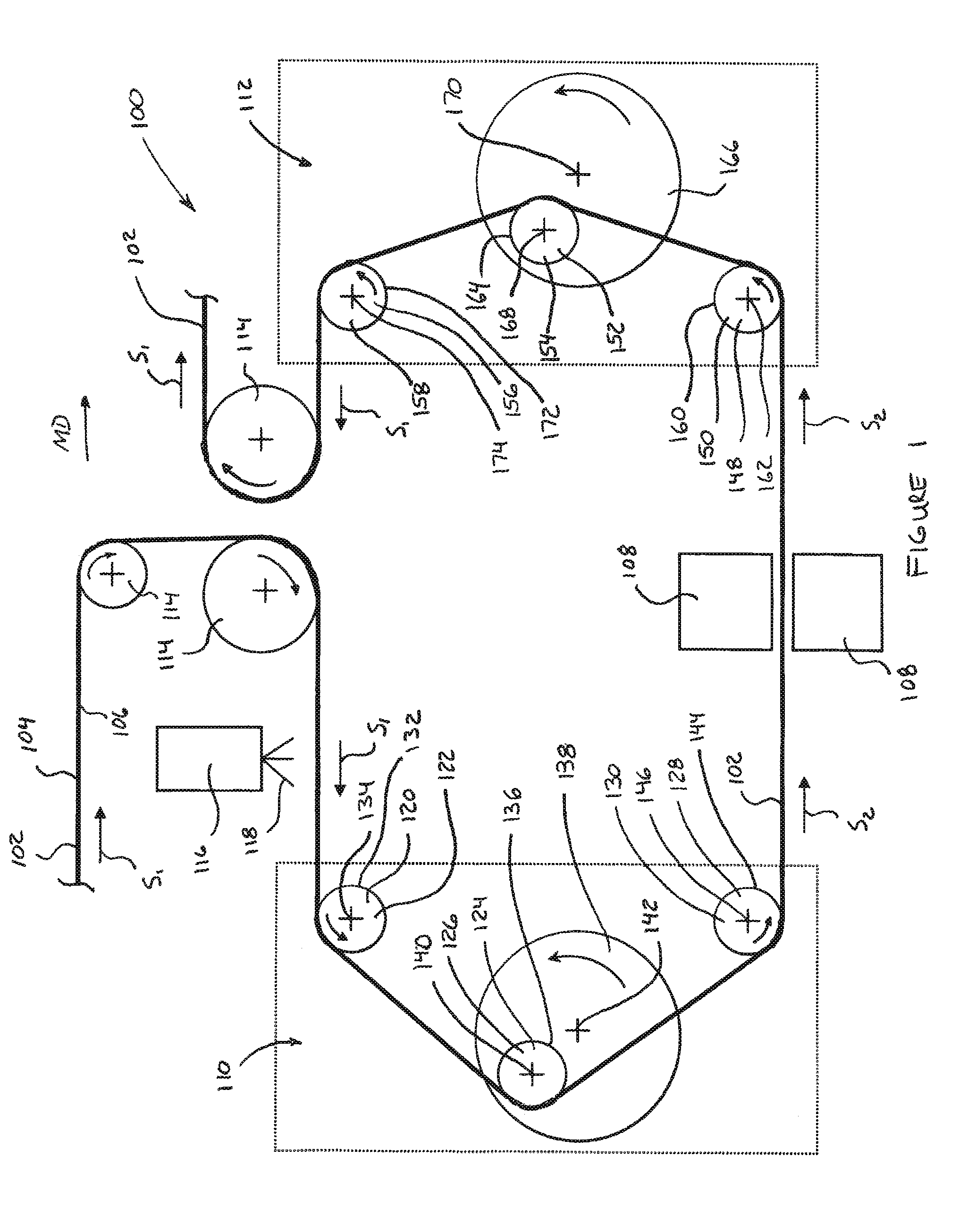

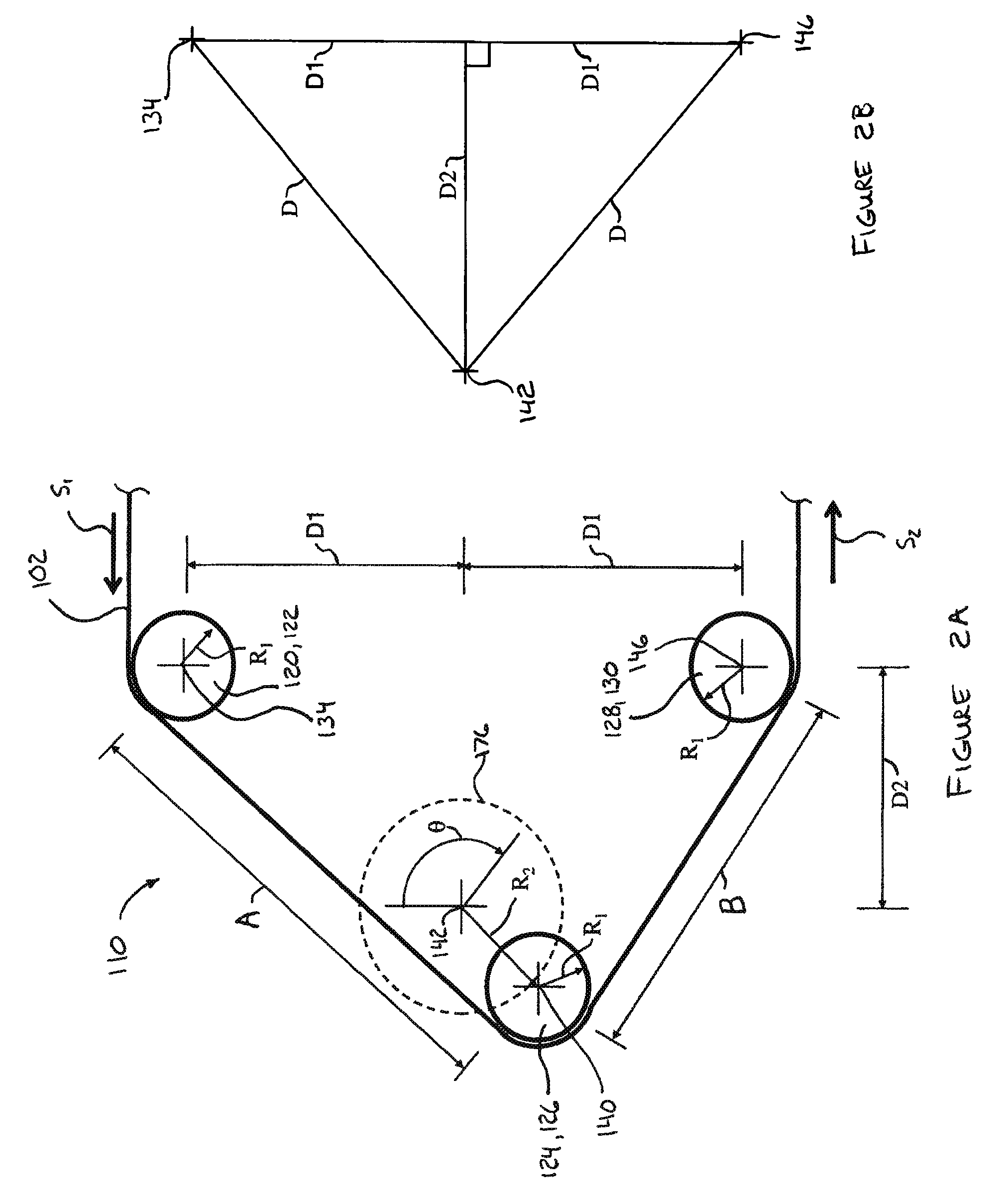

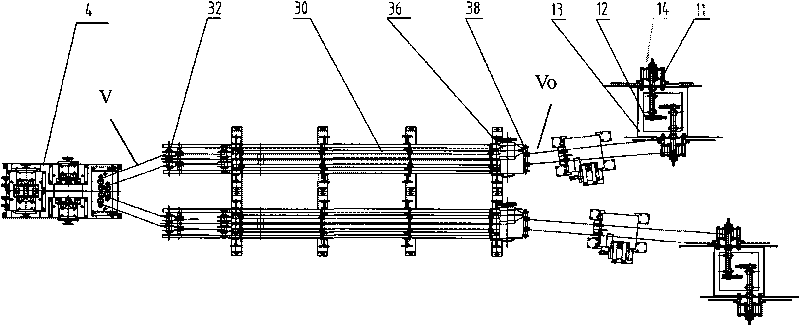

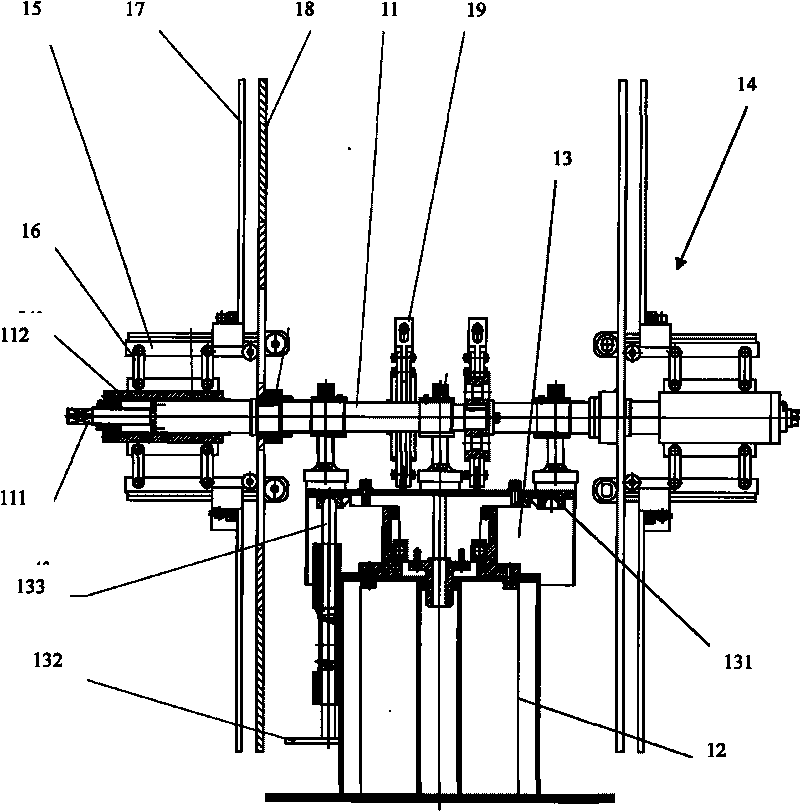

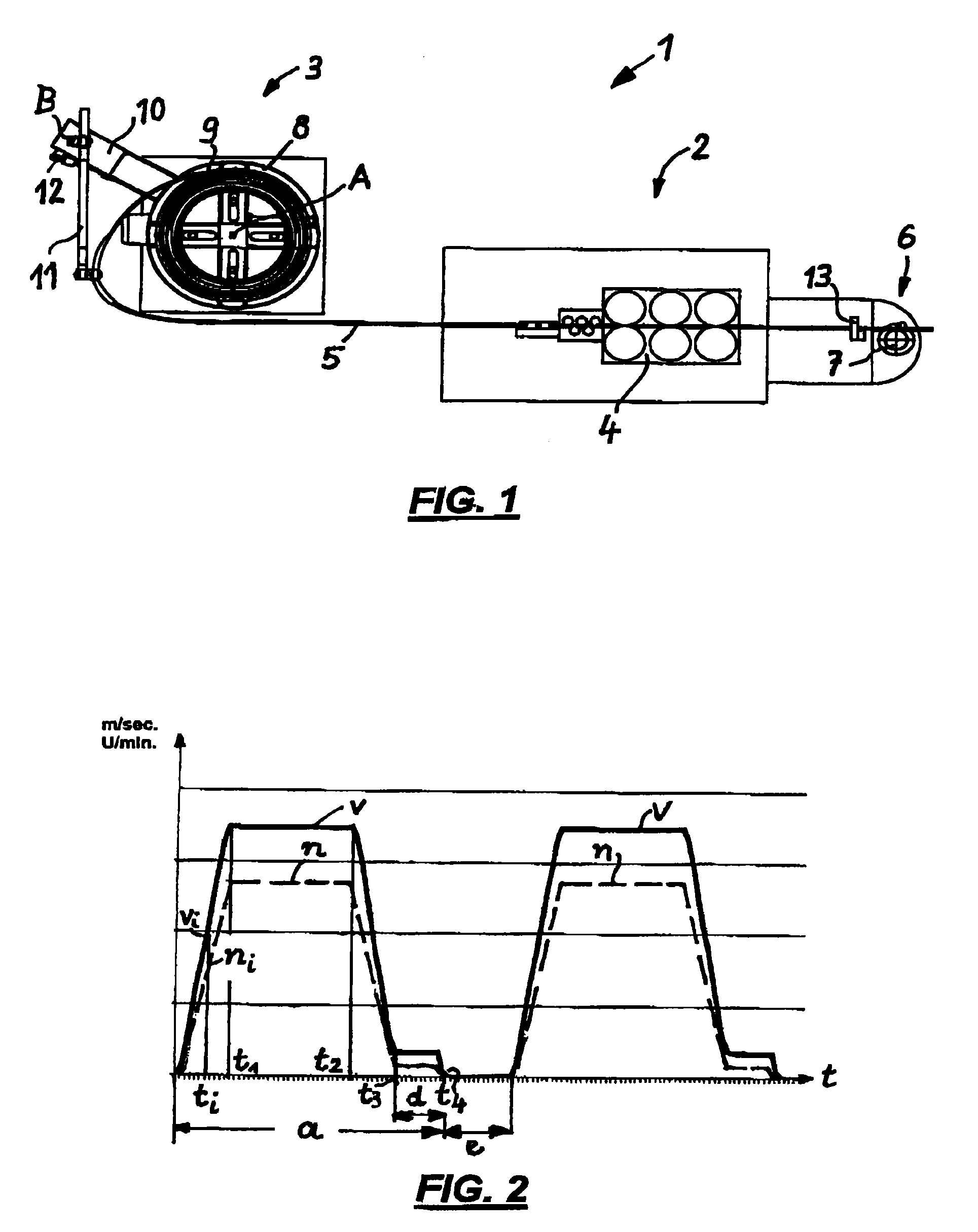

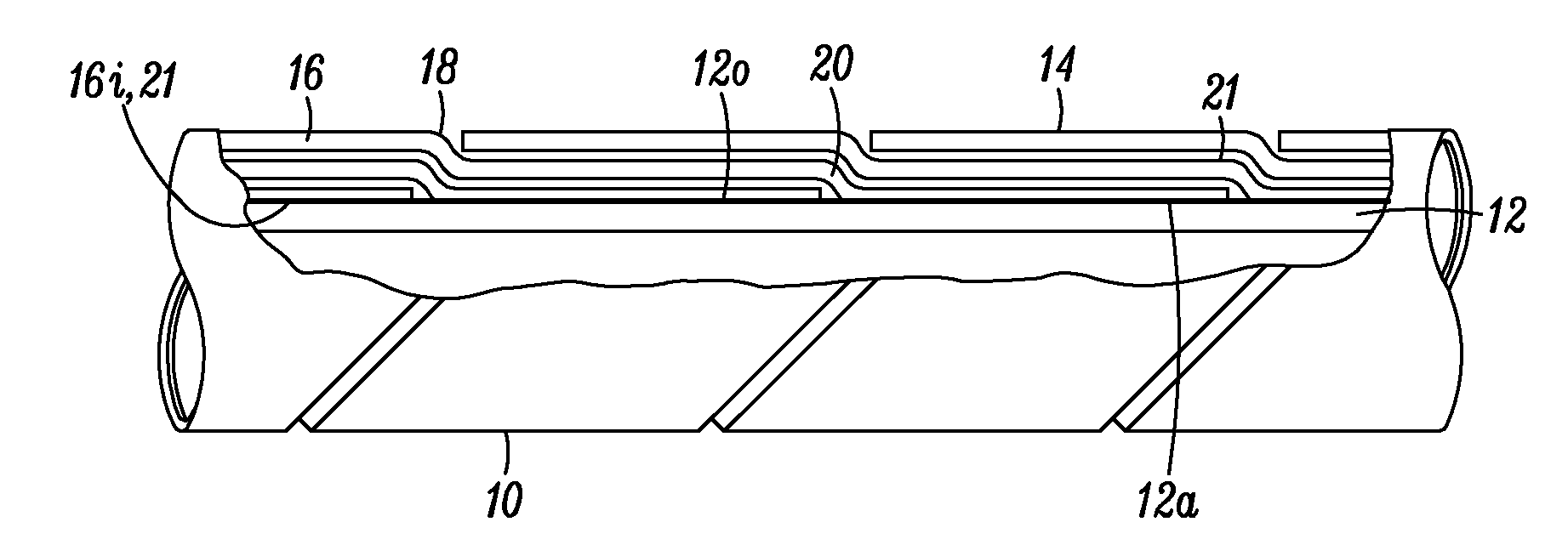

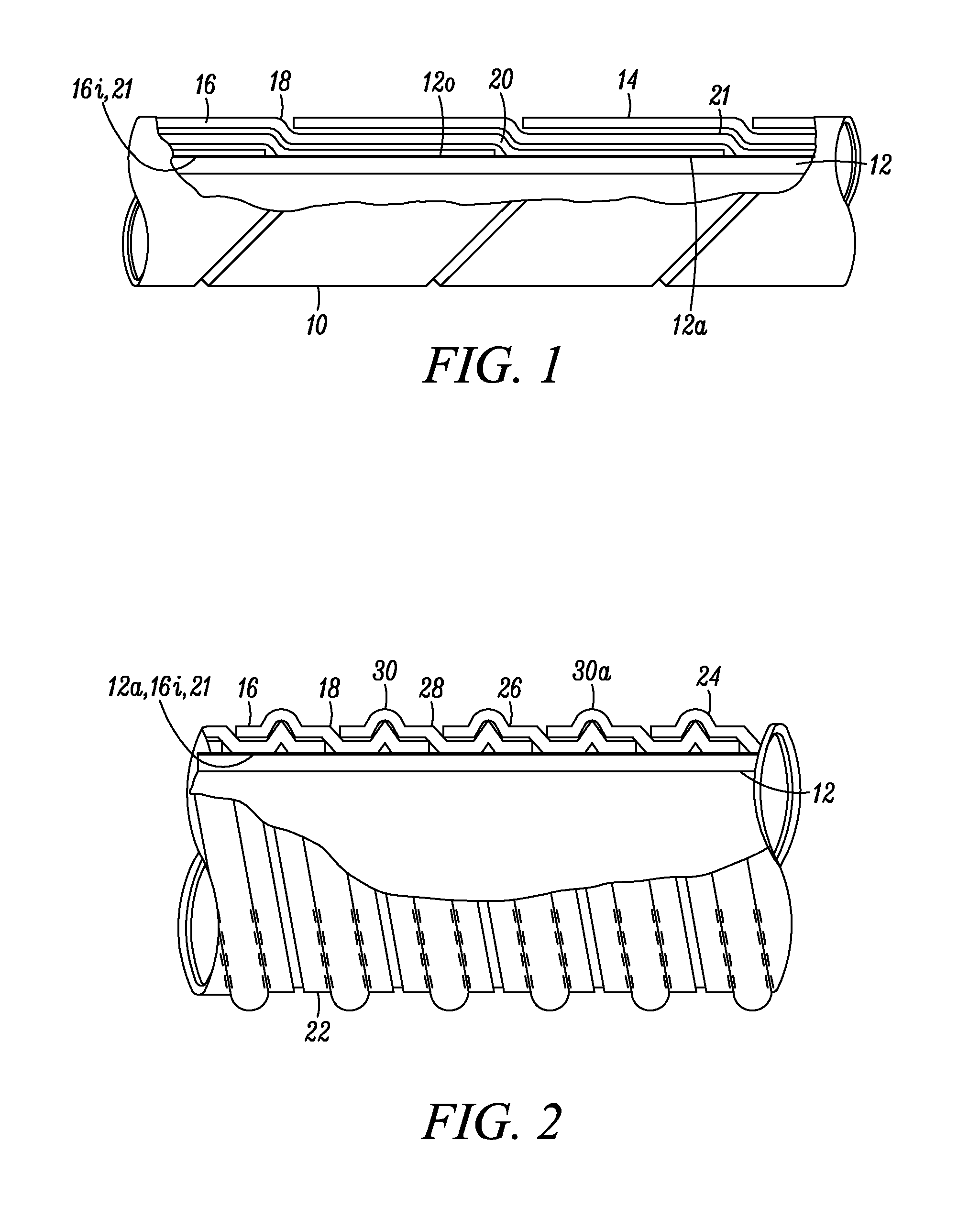

Methods and apparatuses discussed herein provide for localized speed changes of an advancing substrate. Embodiments of a localized speed varying apparatus may include first and second substrate guides positioned upstream and downstream of a processing station, respectively. The substrate guides may utilize orbital motion of guide members to change the length of the substrate within the substrate guides upstream and downstream of the processing station. The changes in substrate length within the substrate guides result in localized speed changes of the substrate between the substrate guides. Coordination between the substrate guides allows for localized speed changes of the substrate passing through the processing station without affecting the speed of the substrate upstream of the first substrate guide and downstream of the second substrate guide.

Owner:THE PROCTER & GAMBLE COMPANY

Appraratus and method for providing a localized speed variance of an advancing substrate

ActiveUS8377249B2Adhesive processesLamination ancillary operationsEngineeringElectrical and Electronics engineering

Methods and apparatuses discussed herein provide for localized speed changes of an advancing substrate. Embodiments of a localized speed varying apparatus may include first and second substrate guides positioned upstream and downstream of a processing station, respectively. The substrate guides may utilize orbital motion of guide members to change the length of the substrate within the substrate guides upstream and downstream of the processing station. The changes in substrate length within the substrate guides result in localized speed changes of the substrate between the substrate guides. Coordination between the substrate guides allows for localized speed changes of the substrate passing through the processing station without affecting the speed of the substrate upstream of the first substrate guide and downstream of the second substrate guide.

Owner:PROCTER & GAMBLE CO

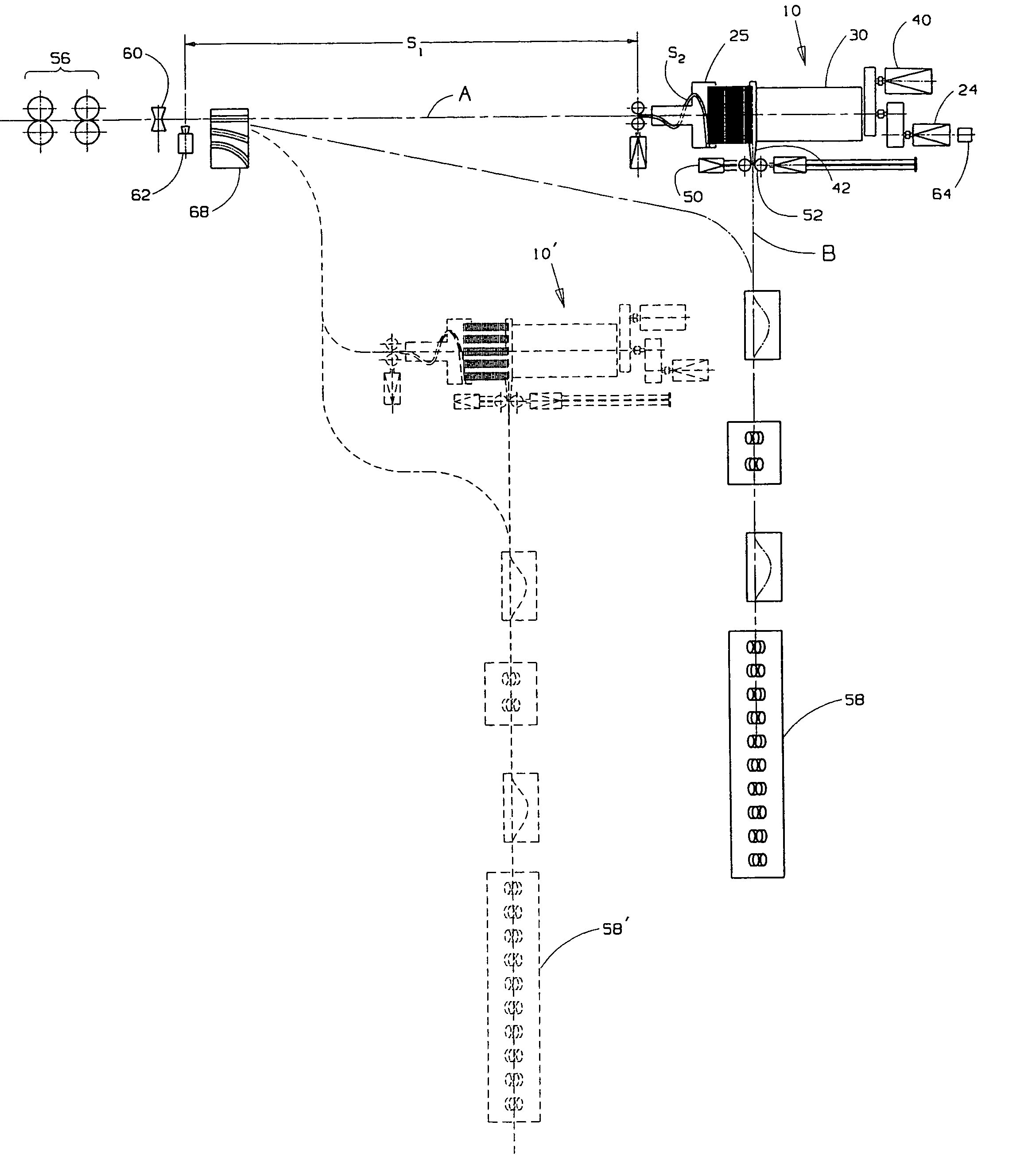

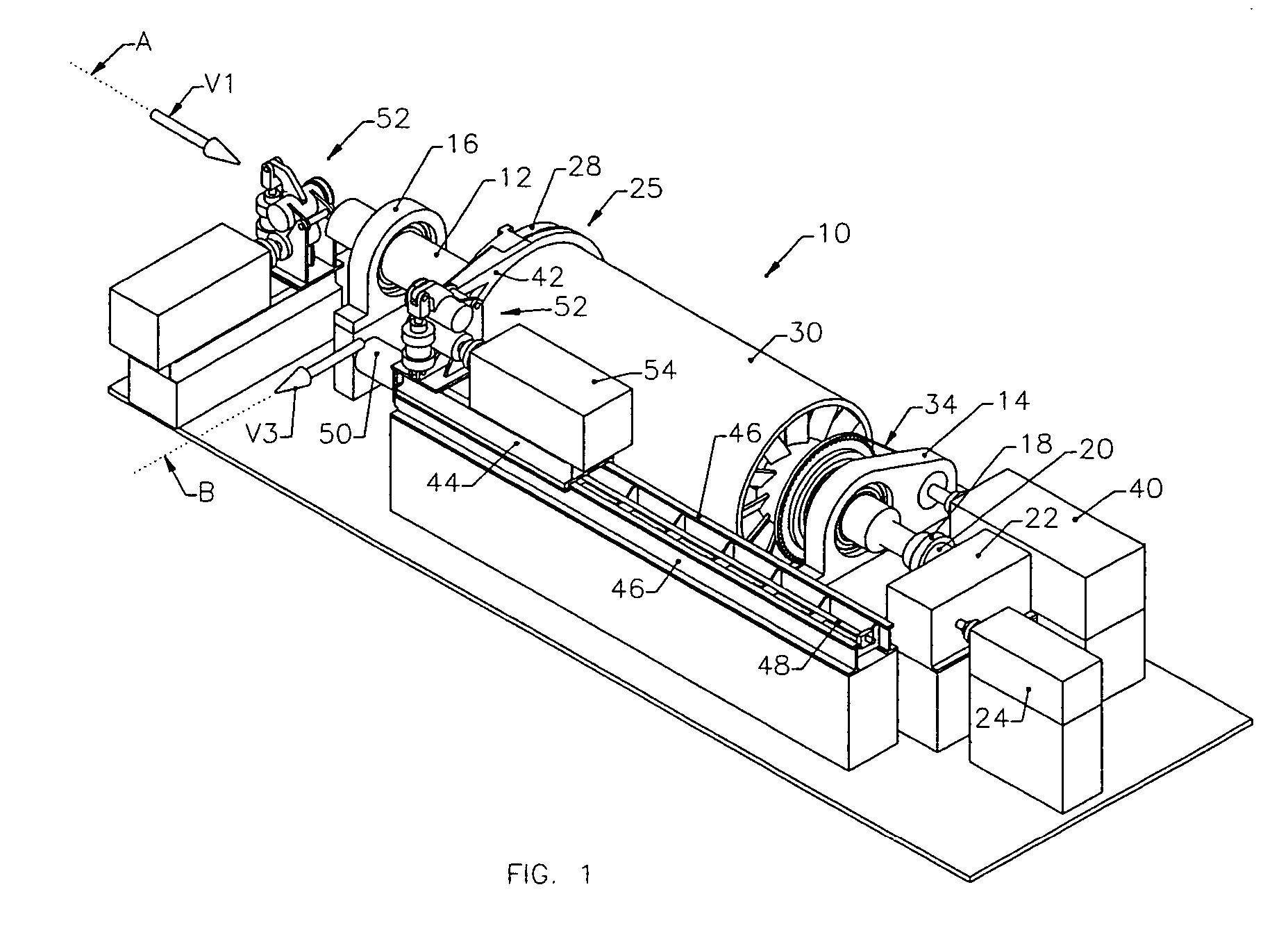

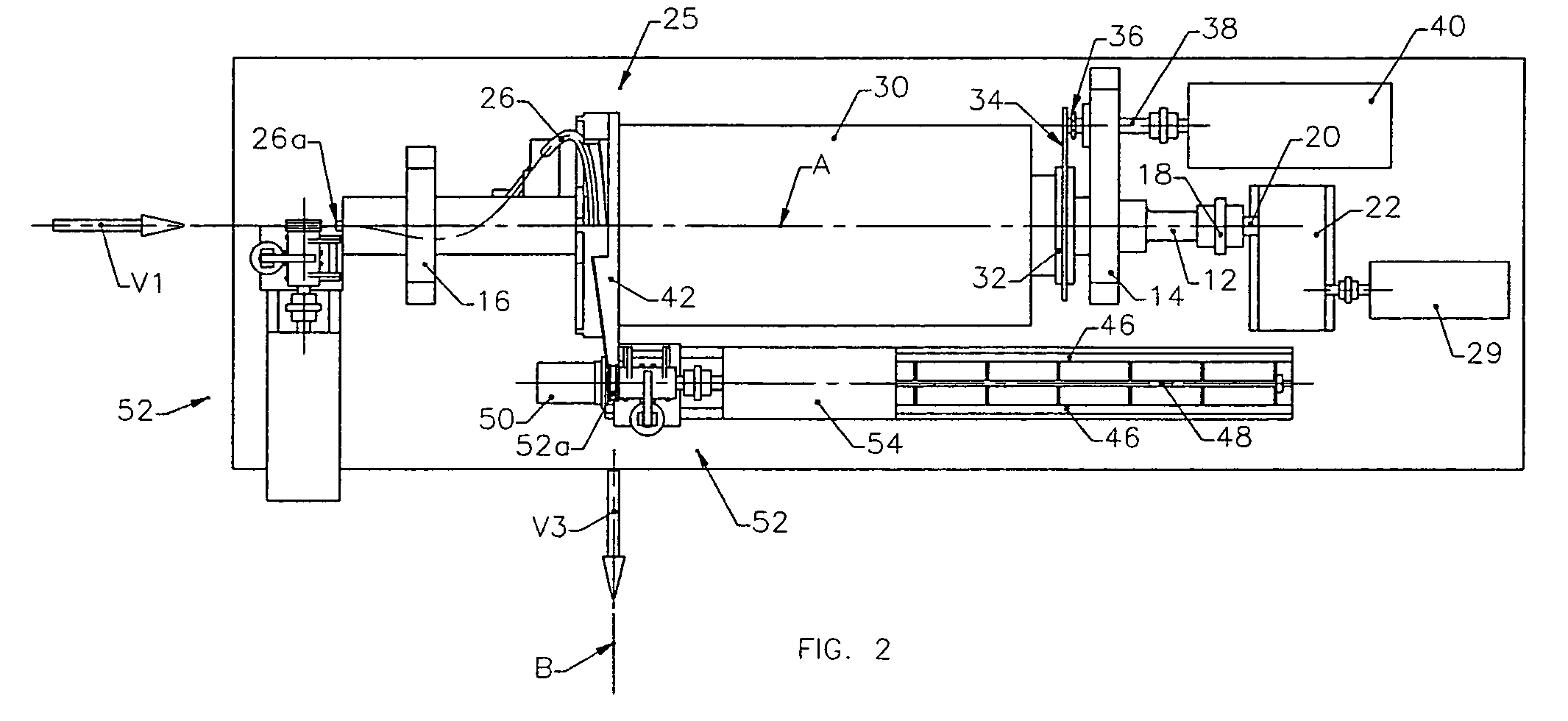

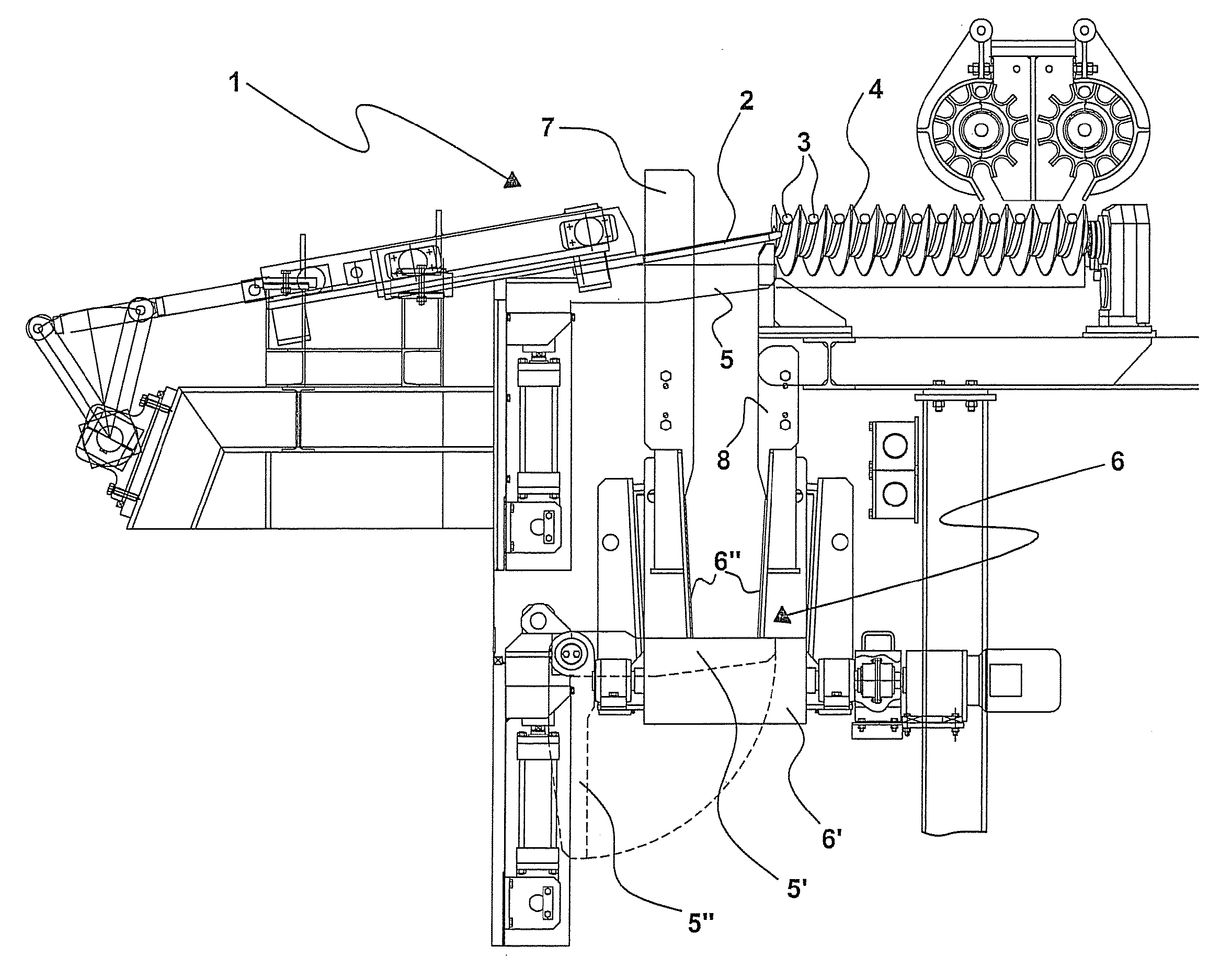

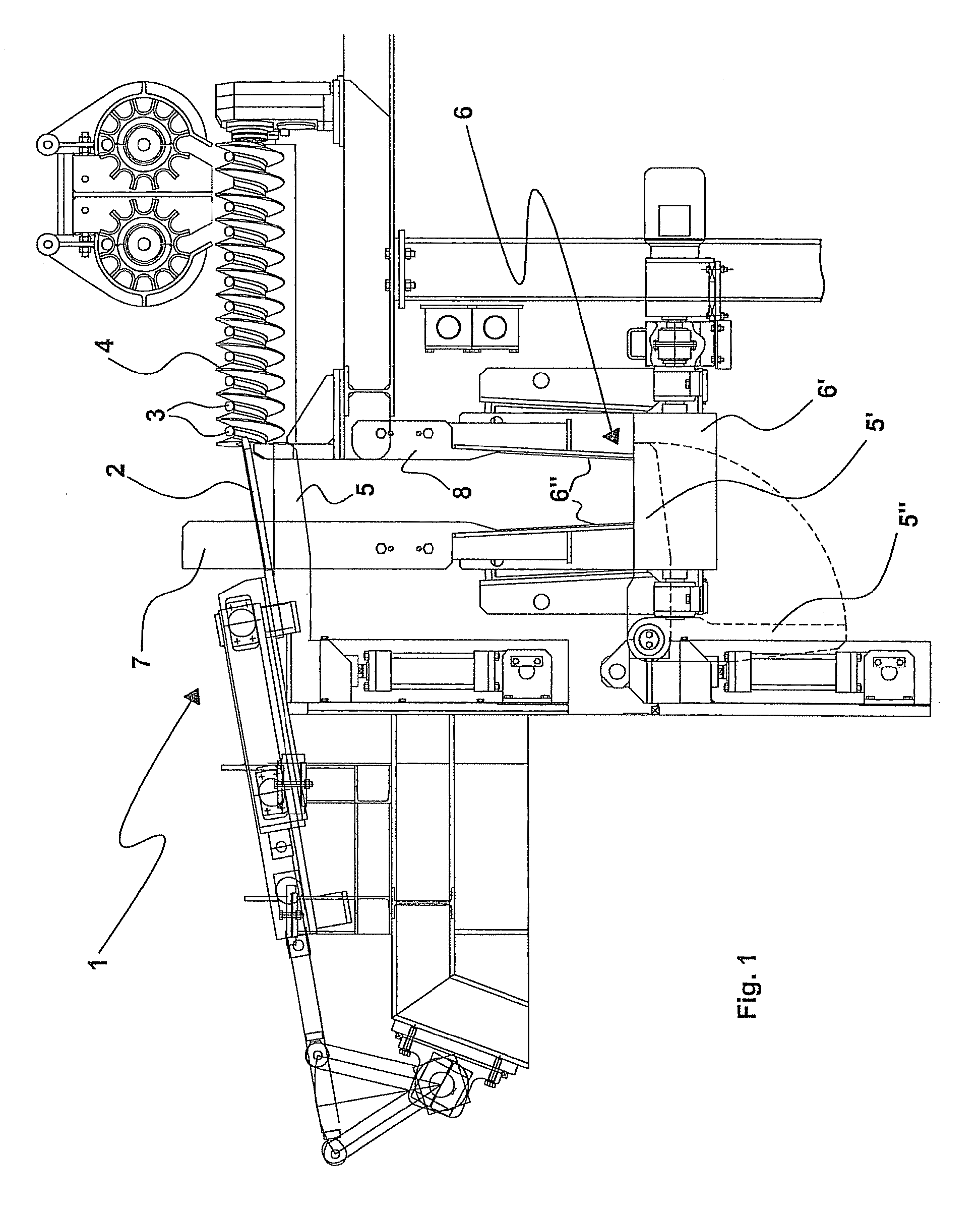

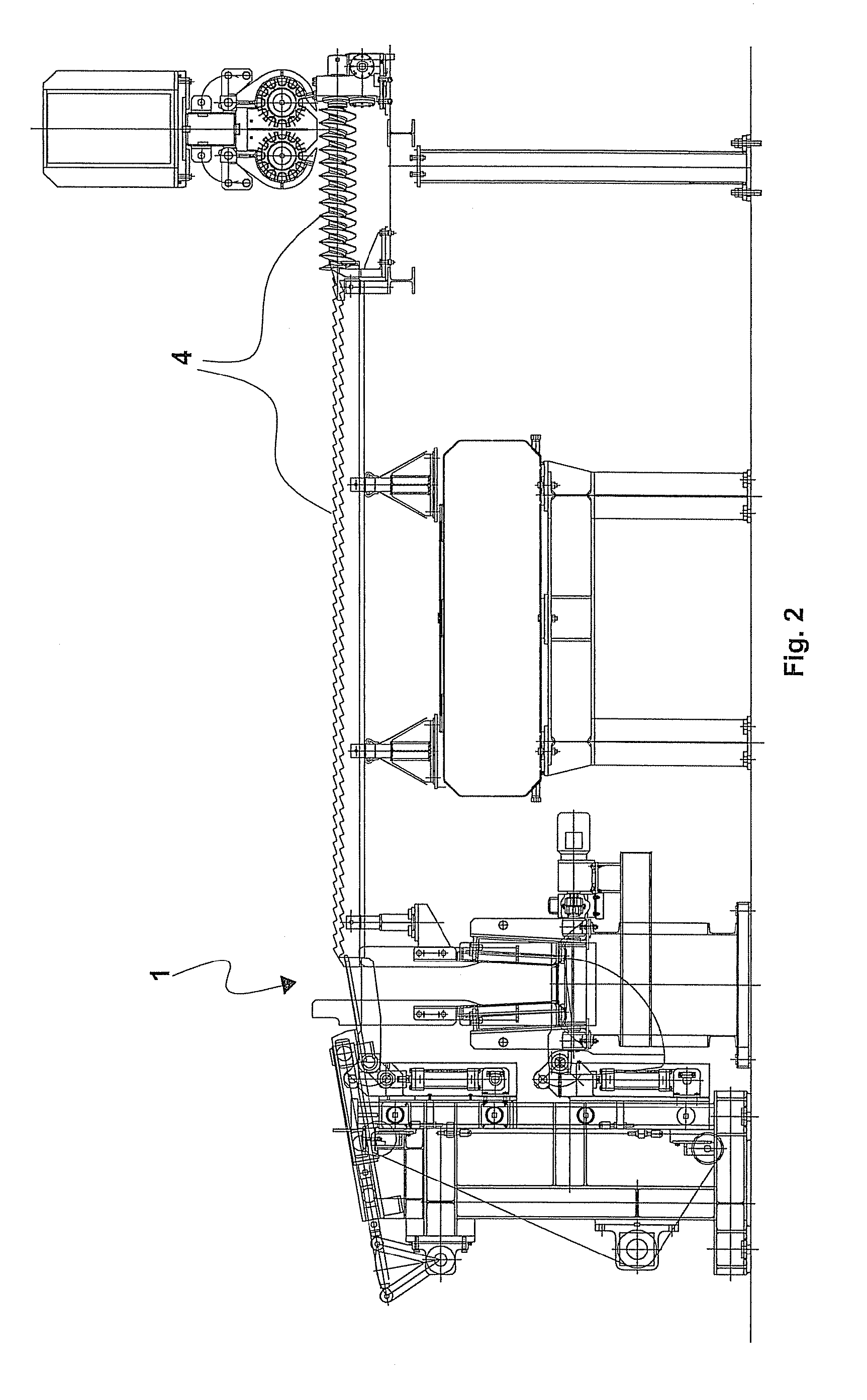

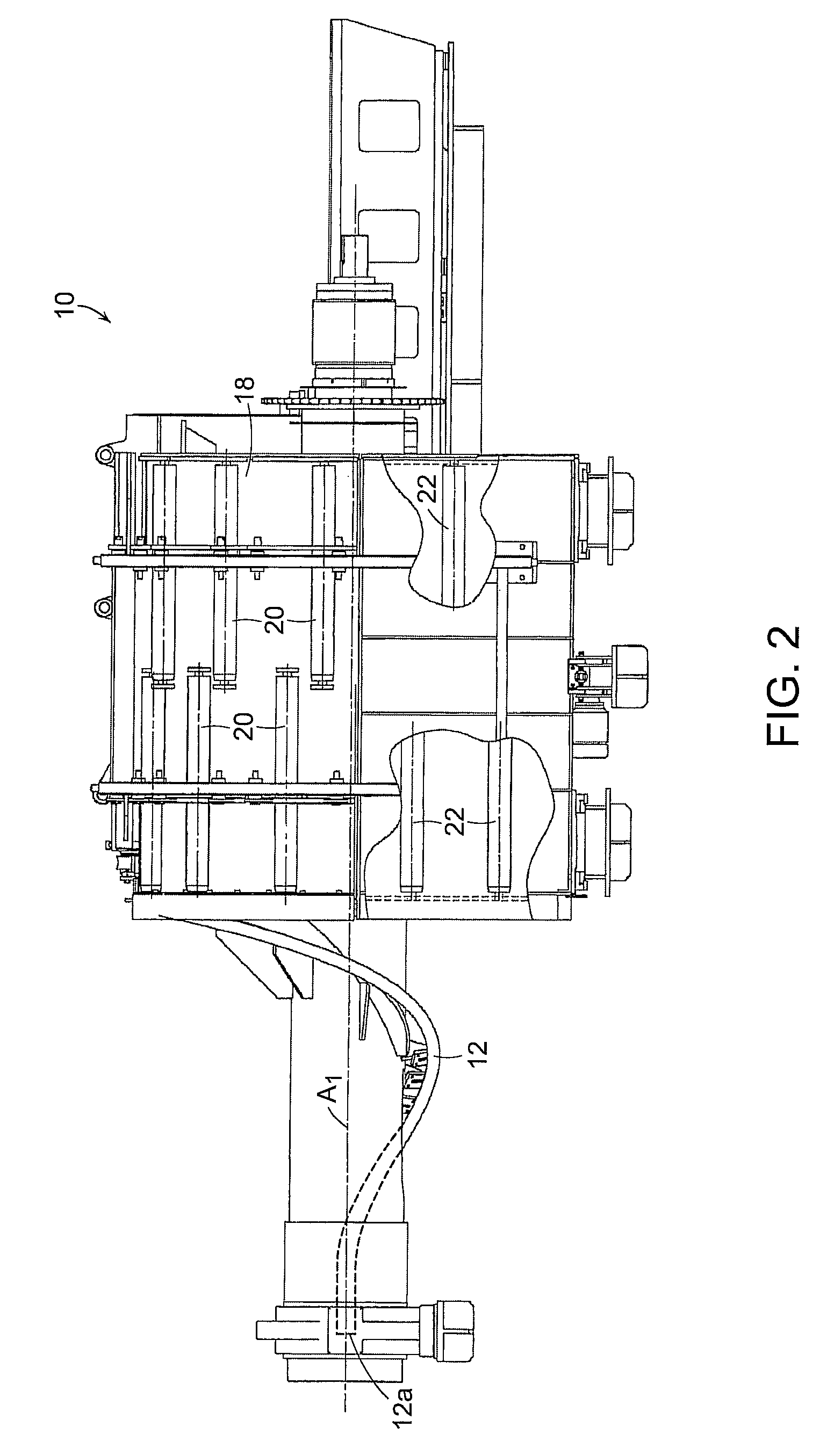

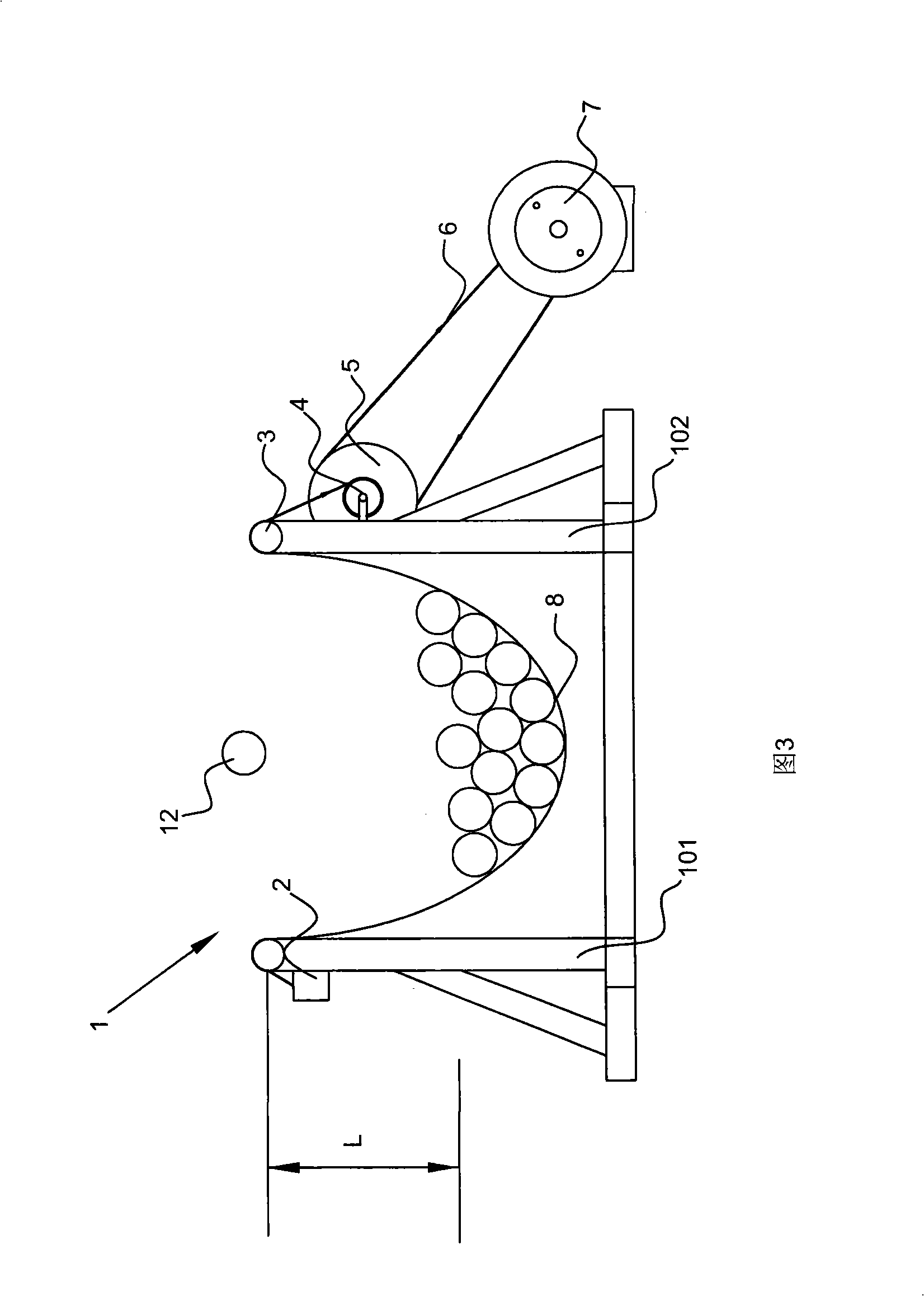

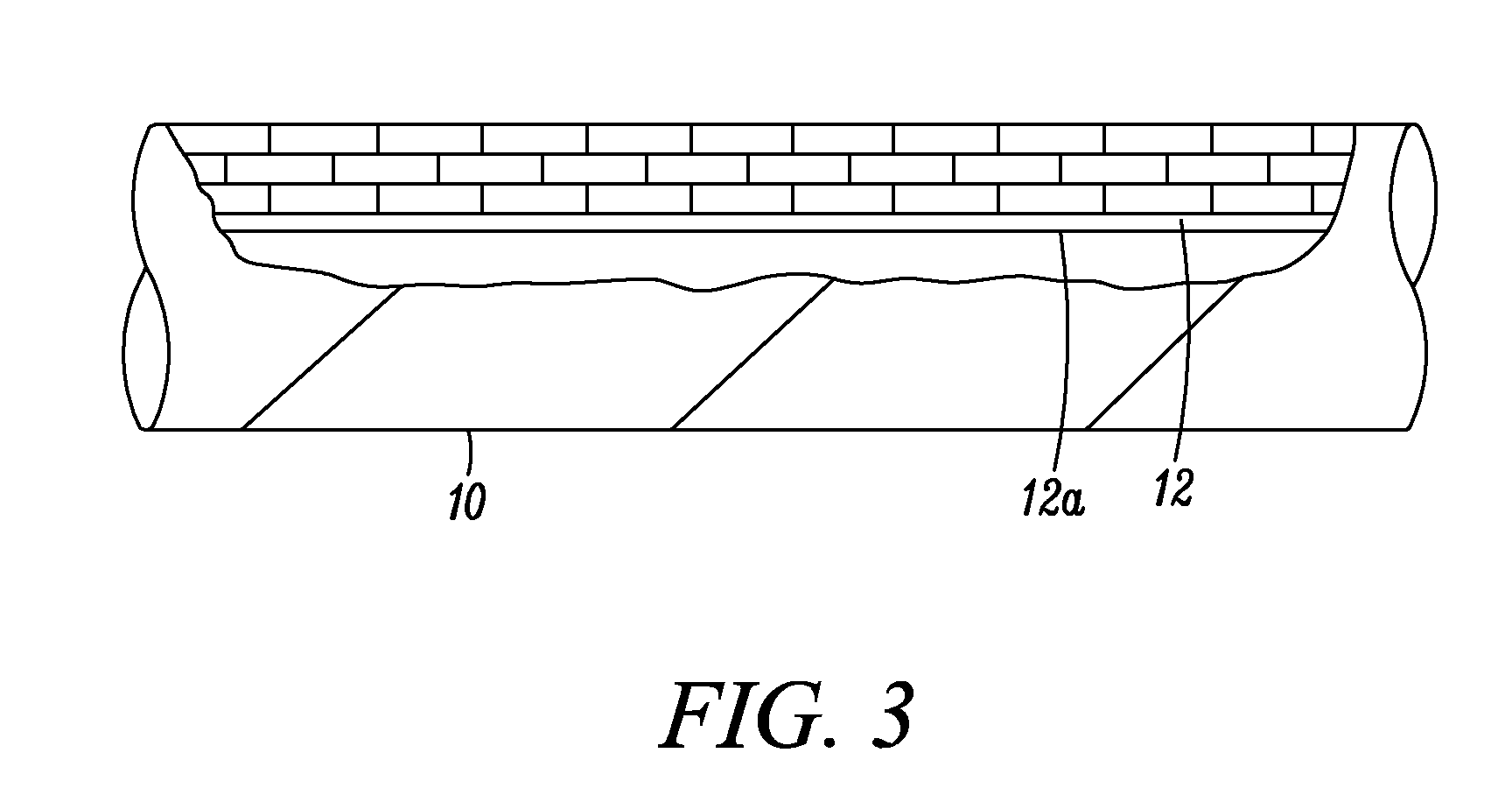

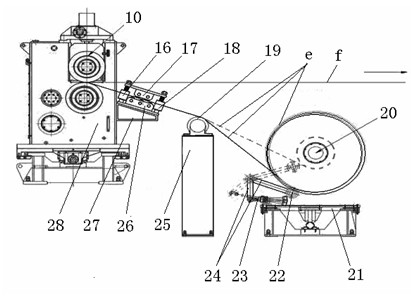

Method and apparatus for decelerating and temporarily accumulating a hot rolled product

InactiveUS7021103B2Guiding/positioning/aligning arrangementsFilament handlingEngineeringMechanical engineering

A method and apparatus is disclosed for decelerating and temporarily accumulating a hot rolled product moving longitudinally along a receiving axis at a first velocity V1. The product is directed through a curved guide having an entry end aligned with the receiving axis to receive the product, and an exit end spaced radially from the receiving axis and oriented to deliver the product in an exit direction transverse to the receiving axis. The curved guide is rotated about the receiving axis in a direction opposite to the exit direction of the product and at a speed at which the guide exit end has a velocity V2, thereby decelerating the product being delivered from the guide exit end to a reduced velocity V3 equal to V1−V2. The curvature of the guide and the orientation of its exit end is such as to form the delivered product into a helix deposited and temporarily accumulated on a cylindrical drum. The drum is rotated in a direction opposite to the direction of rotation of the curved guide to thereby unwind the product from the drum.

Owner:PRIMETALS TECH USA

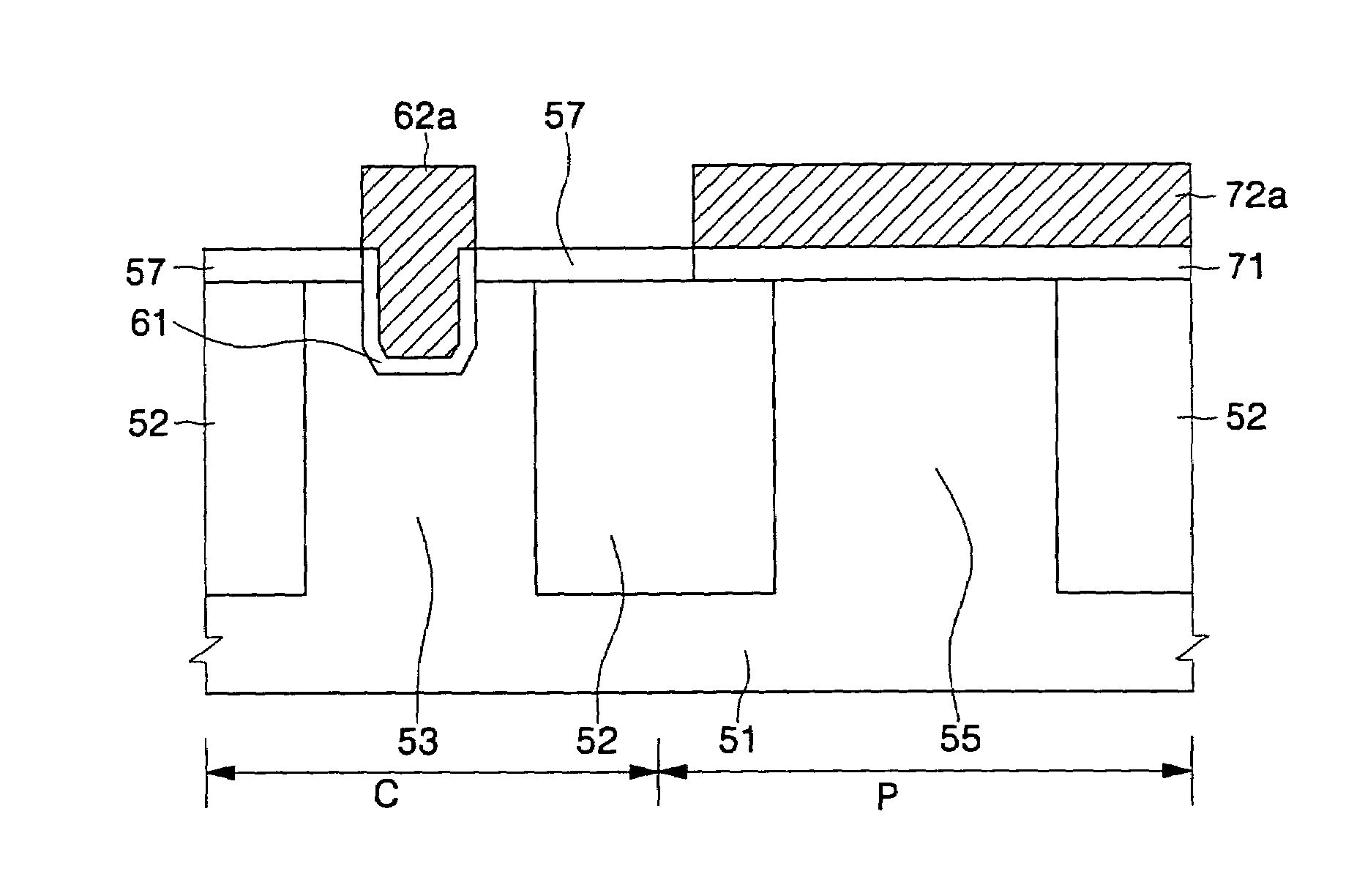

Methods of forming integrated circuit devices having field effect transistors of different types in different device regions

A method of forming an integrated circuit device includes forming a non-planar field-effect transistor in a cell array portion of a semiconductor substrate and forming a planar field-effect transistor in a peripheral circuit portion of the semiconductor substrate. The non-planar field-effect transistor may be selected from the group of a FinFET and a recessed gate FET. Dopants may be implanted into a channel region of the non-planar field-effect transistor, and a cell protection layer may be formed on the non-planar field-effect transistor. Then, dopants may be selectively implanted into a channel region of the planar field-effect transistor using the cell protection layer as a mask to block implanting of the dopants into the channel region of the non-planar field-effect transistor.

Owner:SAMSUNG ELECTRONICS CO LTD

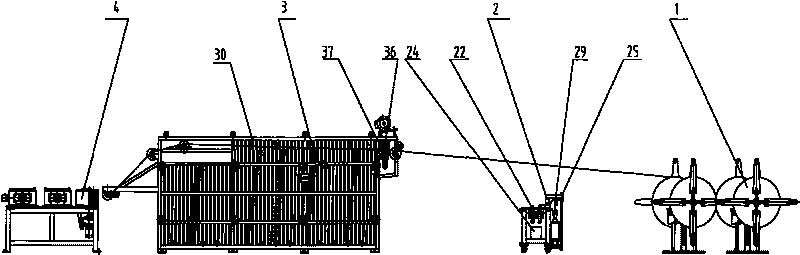

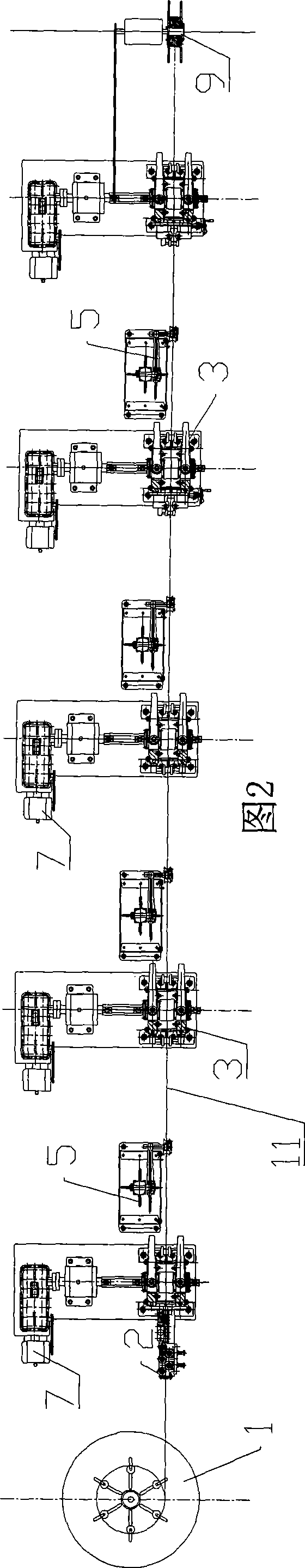

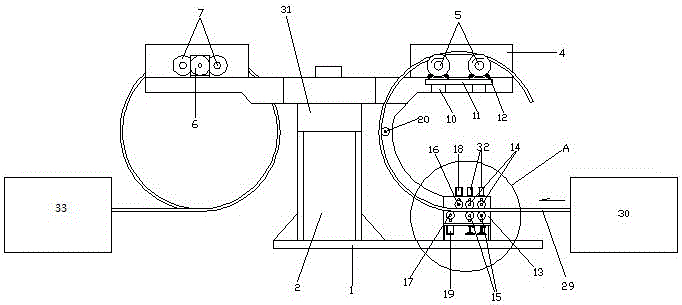

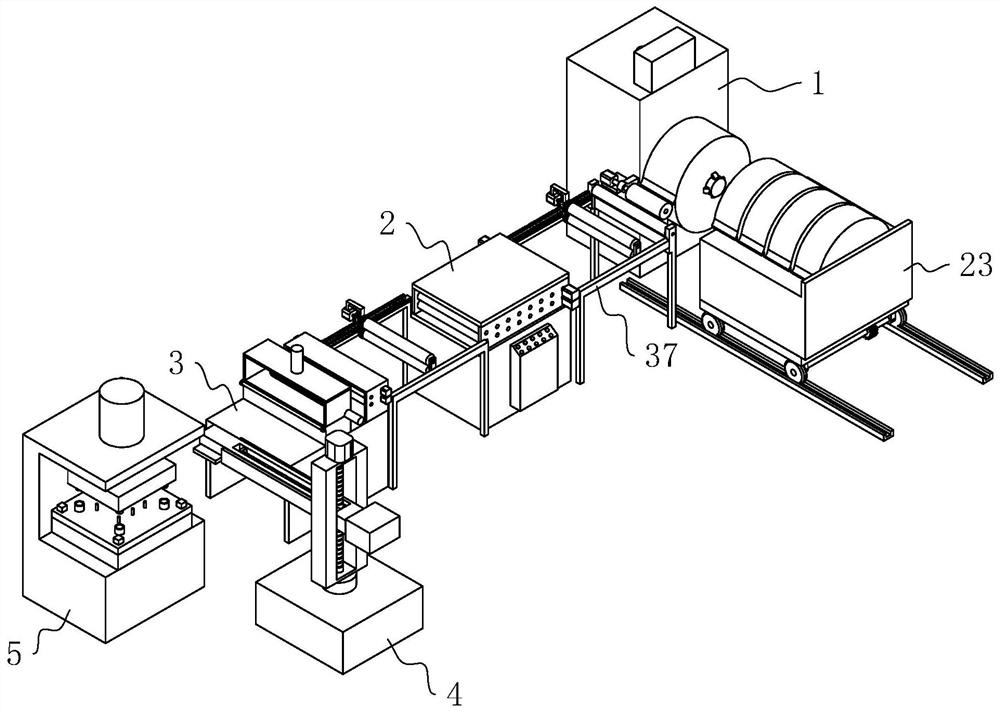

Device and method for continuously feeding strip coils

ActiveCN101734501AUninterrupted deliveryReduce wasteMaterial accumulating devicesWebs handlingContinuous productionEngineering

The invention relates to device and method for continuously feeding strip coils. A strip hanging machine of the device is provided with two or more than two sets of strip disc systems independent to each other, two or more than two sets of strip disc systems are fixed on a worktable capable of rotating at the same level and can be used for respectively hanging a coil of strips for alternate working, and the two sets of strip disc systems connect the strips between different strip disc systems through a splicing machine. The device also comprises a strip storing machine for storing the strips,and the strips outputted by the two or more than two sets of strip disc systems are alternatively inputted to the strip storing machine. The device and method can ensure the continuous production so as to enhance production efficiency and reduce waste.

Owner:HUAHAN SCI & TECH

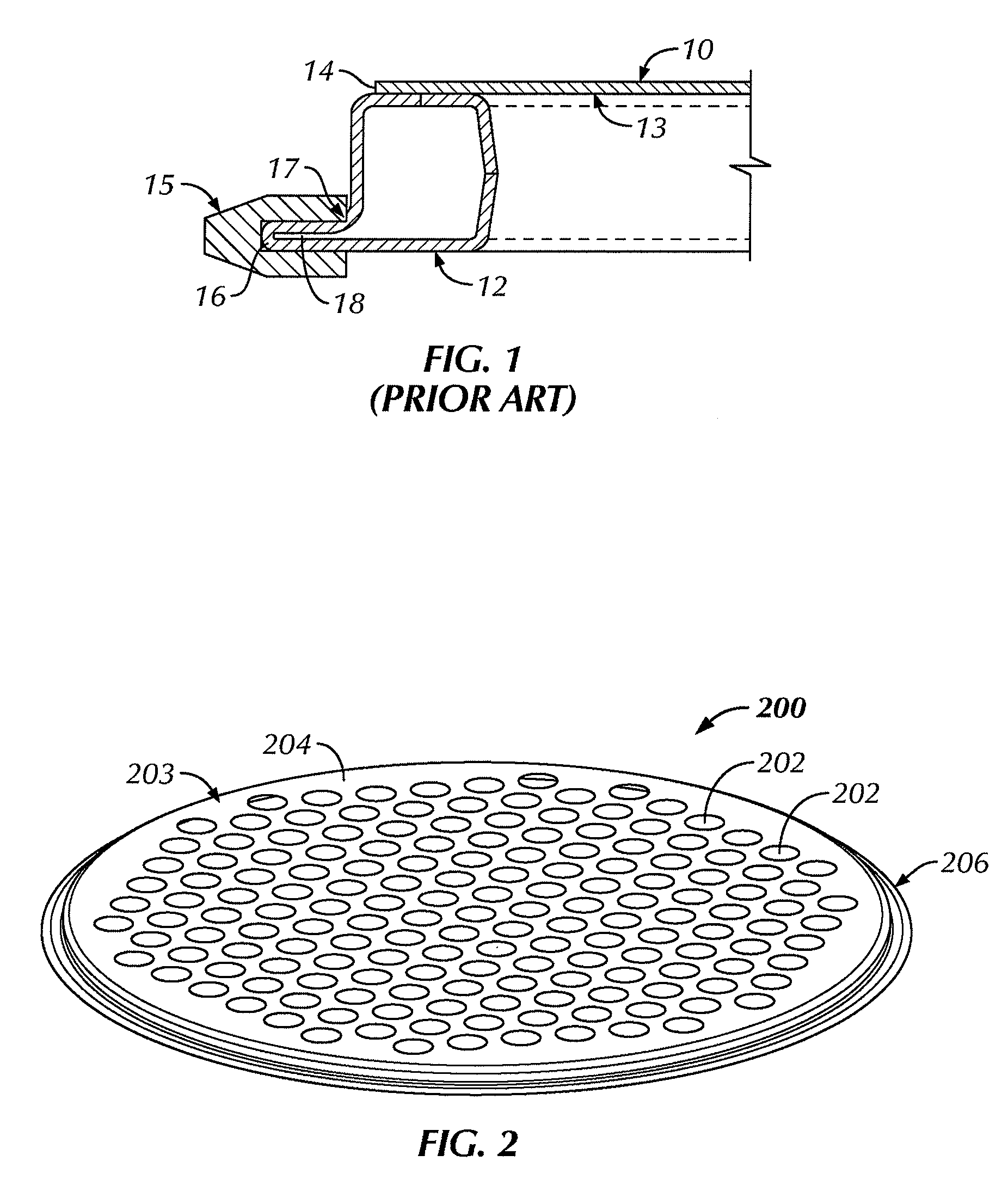

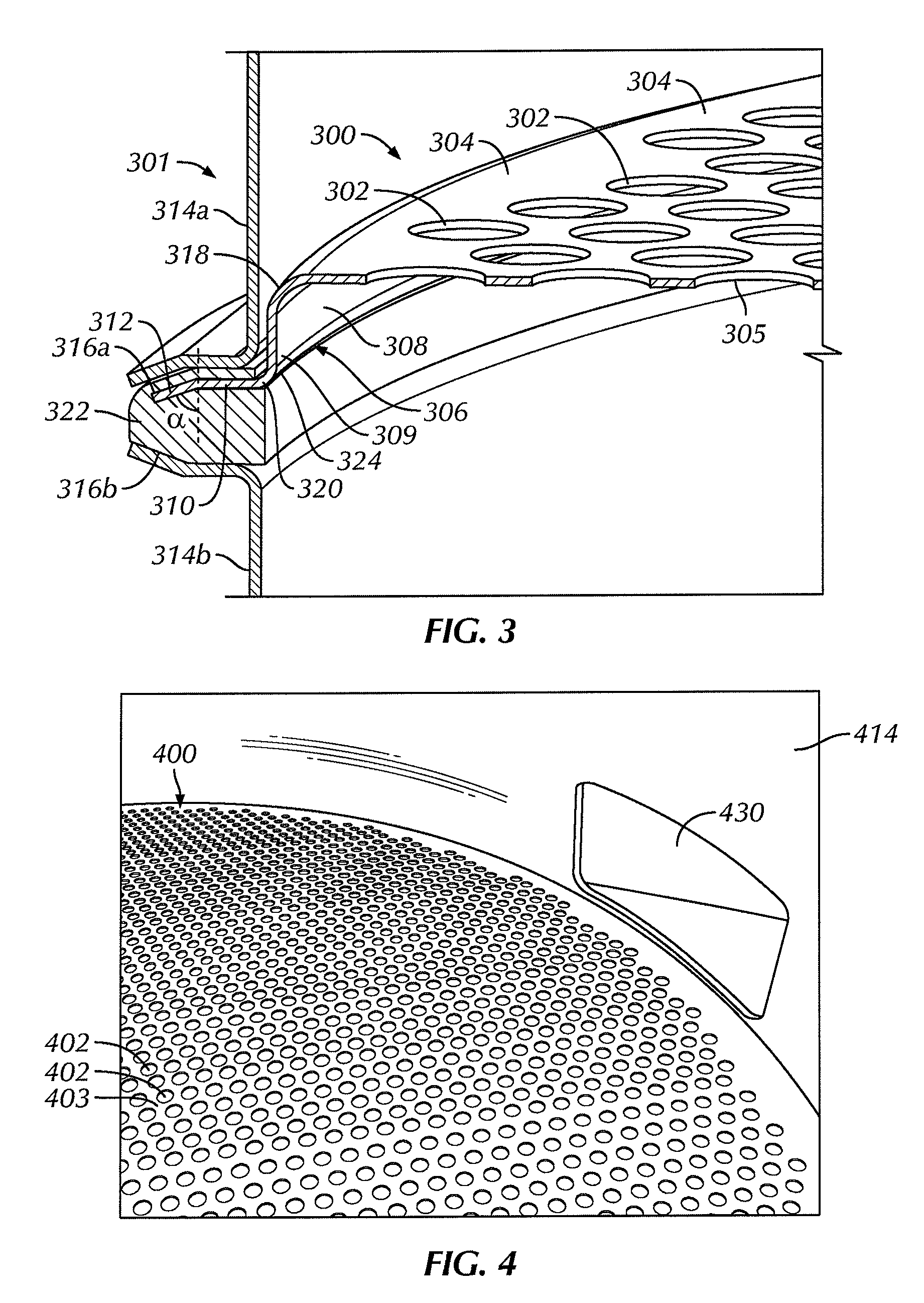

Flanged perforated metal plate for separation of pellets and particles

A perforated plate for a vibratory sifter, the perforated plate including a base plate comprising a plurality of openings formed therethrough, and a flange integrally formed with the base plate. A method of forming a screen assembly for a vibratory sifter, the method including forming a base plate, forming a plurality of openings extending from a top surface to a bottom surface of the base plate, and foaming an integral flange on the base plate.

Owner:MI

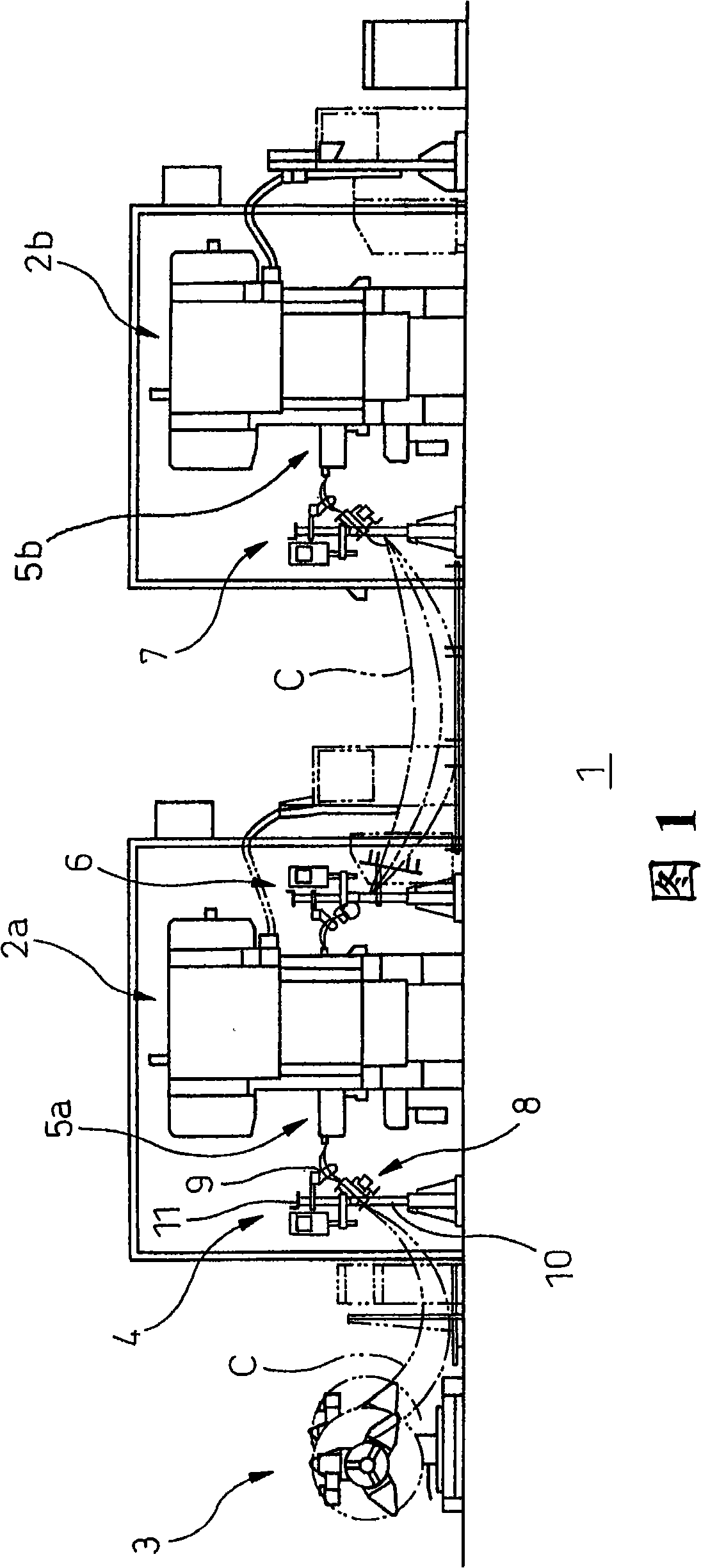

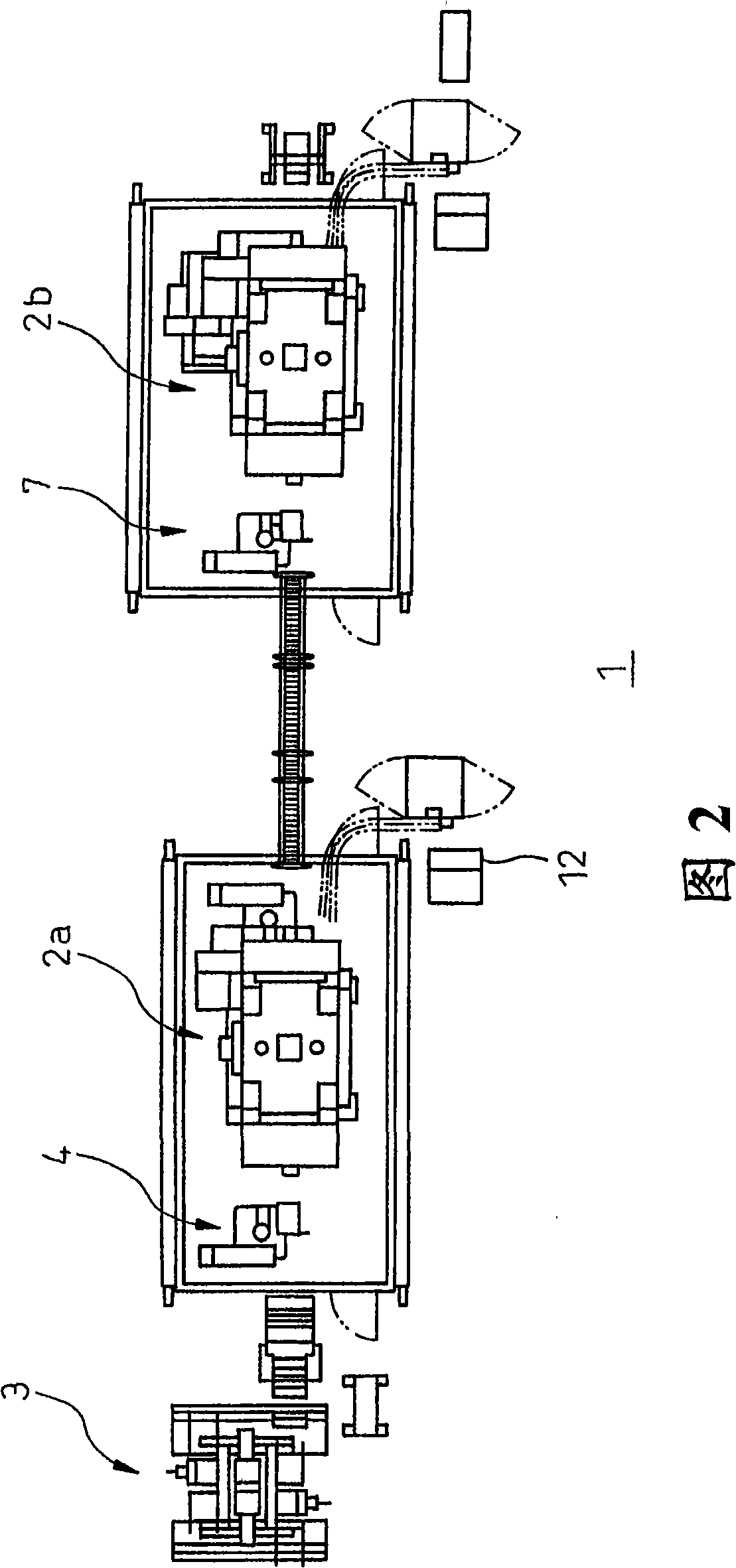

Plastic working method and plastic working system

ActiveCN101318365AReduce swing effectsMetal-working feeding devicesMaterial accumulating devicesEngineeringMachining system

Owner:DENSO CORP +1

Device for controlling the drive of a reel

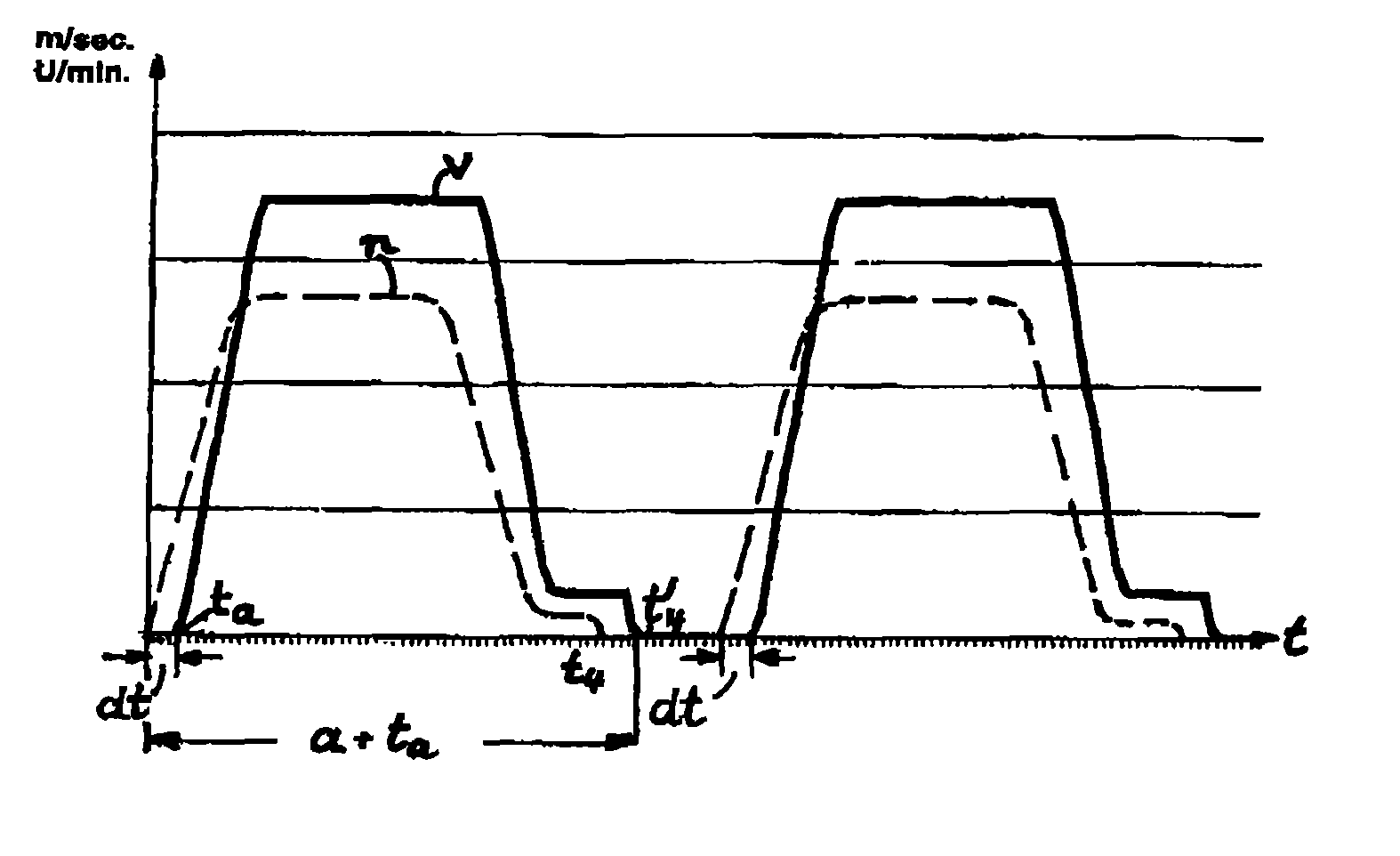

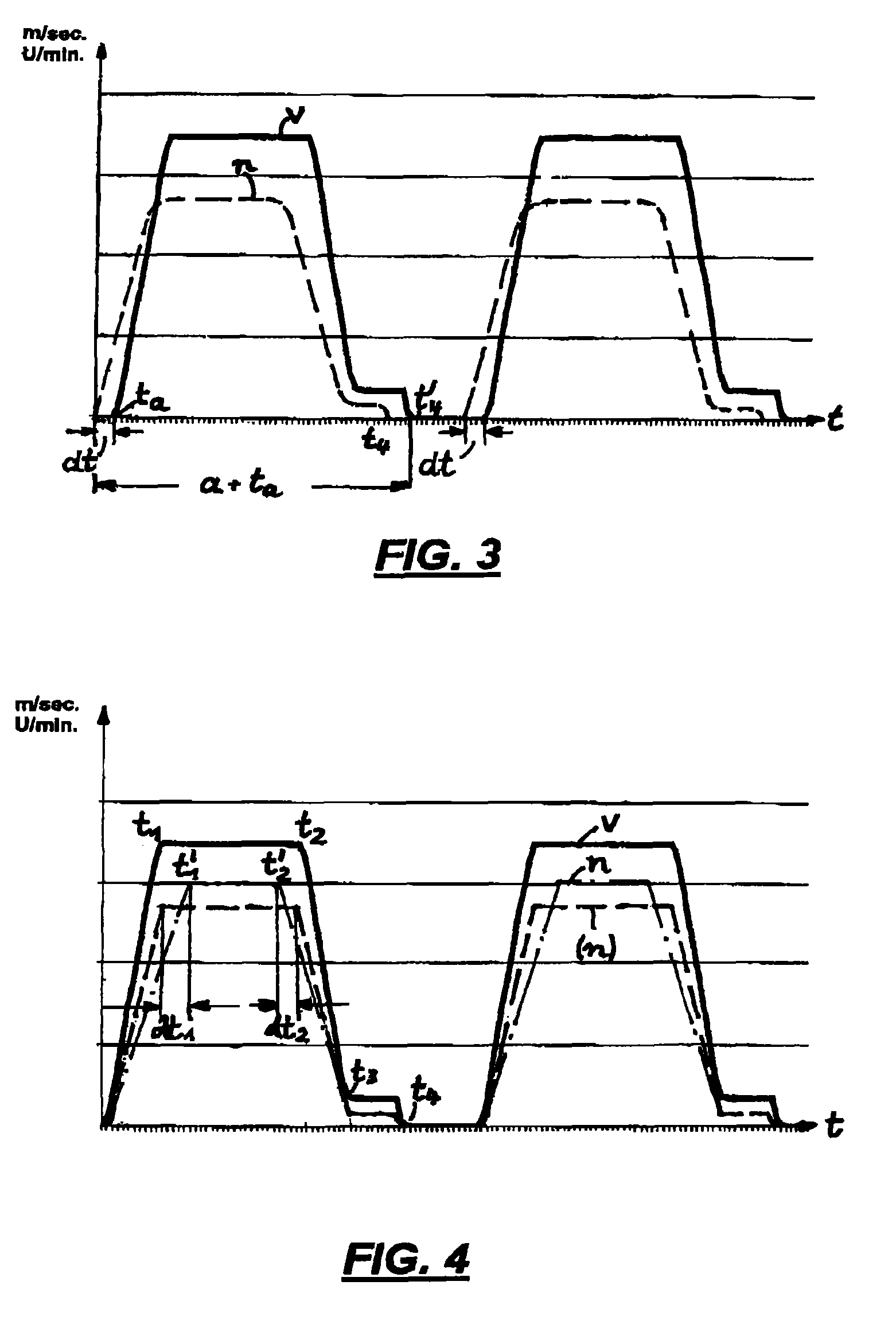

ActiveUS8382024B2Variable speedEasy to controlFilament handlingRecord information storageWire tensionTime profile

With a device for controlling the drive of a reel, with a wire supply in the form of a coil of said wire supply, from which the wire, through interposition of a tensioning device, which is spring-pretensioned in one deflection direction and effective up to a maximum deflection, for approximated stabilization of the wire tension of a feed installation of the wire infeed of a downstream positioned wire processing machine, the velocity curve of the feed rate of the wire infeed in accordance with a preset velocity-time profile is controlled by a control unit of the wire processing machine, and whereby the curve of the rotation speed of the reel in accordance with a preset rotation speed-time profile is controlled by the drive control of the reel, whereby the drive control of the reel sets the rotation speed-time profile of the reel, with regard to the velocity-time profile of the feed rate, forward by a preset time interval.

Owner:WAFIOS AKTIENGES

Magnesium roll mill

ActiveUS9248482B2Good molding effectFine surfaceMaterial accumulating devicesFurnace typesWork rollStrip mill

A magnesium hot rolling mill system including a rolling mill having at least two work rolls for rolling of magnesium sheet or plate, a hot coiler positioned on either side of the rolling mill for heating and maintaining a desired temperature of the magnesium sheet or plate, active thermal roller tables, a mill drive system for independently driving the work rolls for asymmetrical rolling of the magnesium sheet and a warm coil loading and payoff station.

Owner:DANIELI & CO

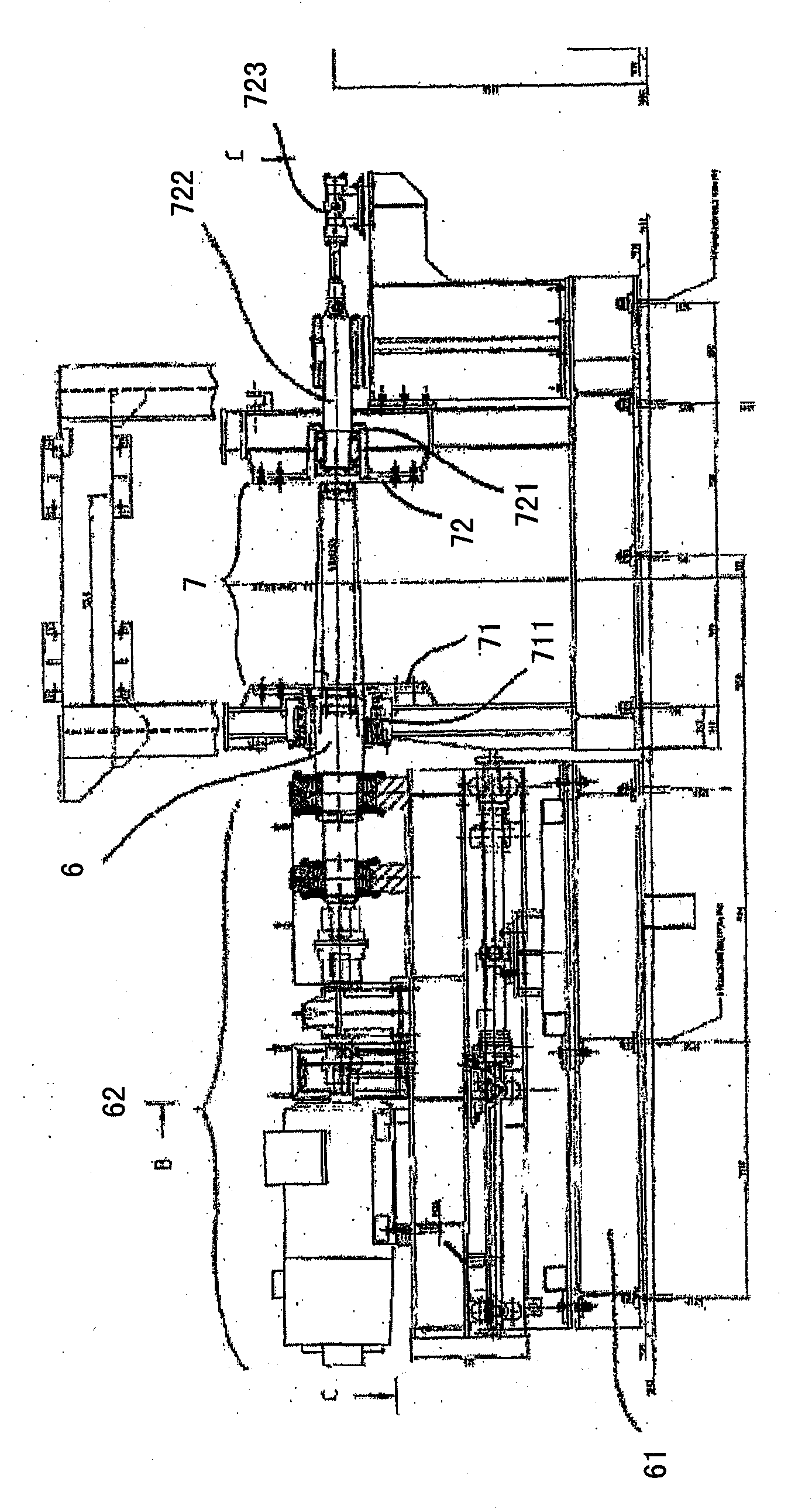

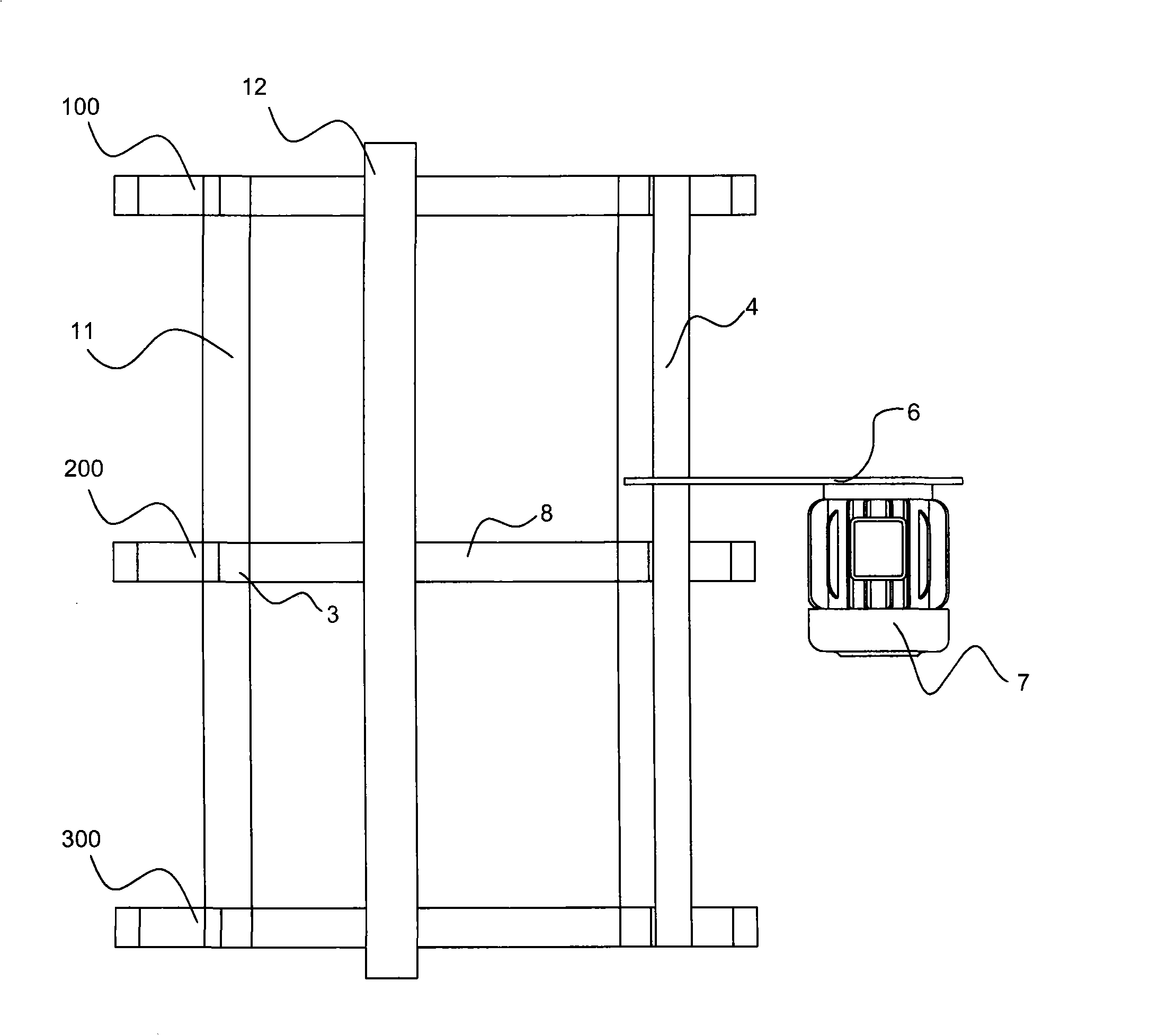

Device and process for forming rolled bar bundles

ActiveUS20110016940A1Excellently shapedExcellently regular appearanceMaterial accumulating devicesBiomedical engineering

Owner:DANIELI & C OFF MEC SPA

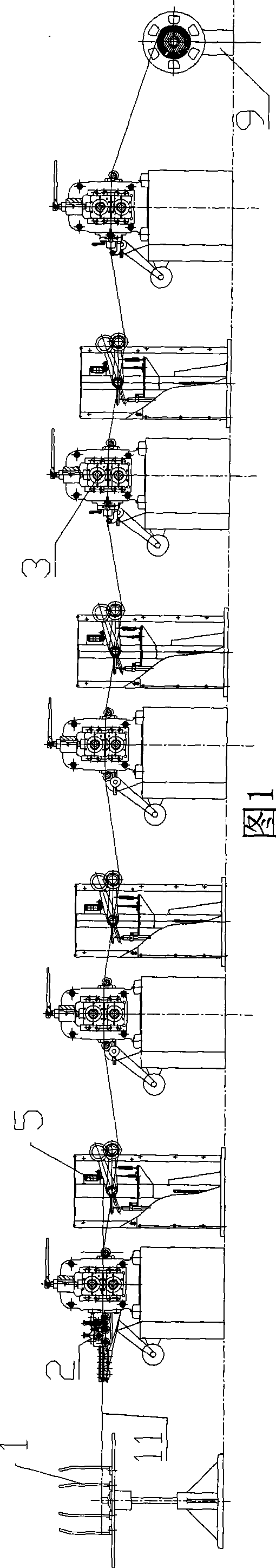

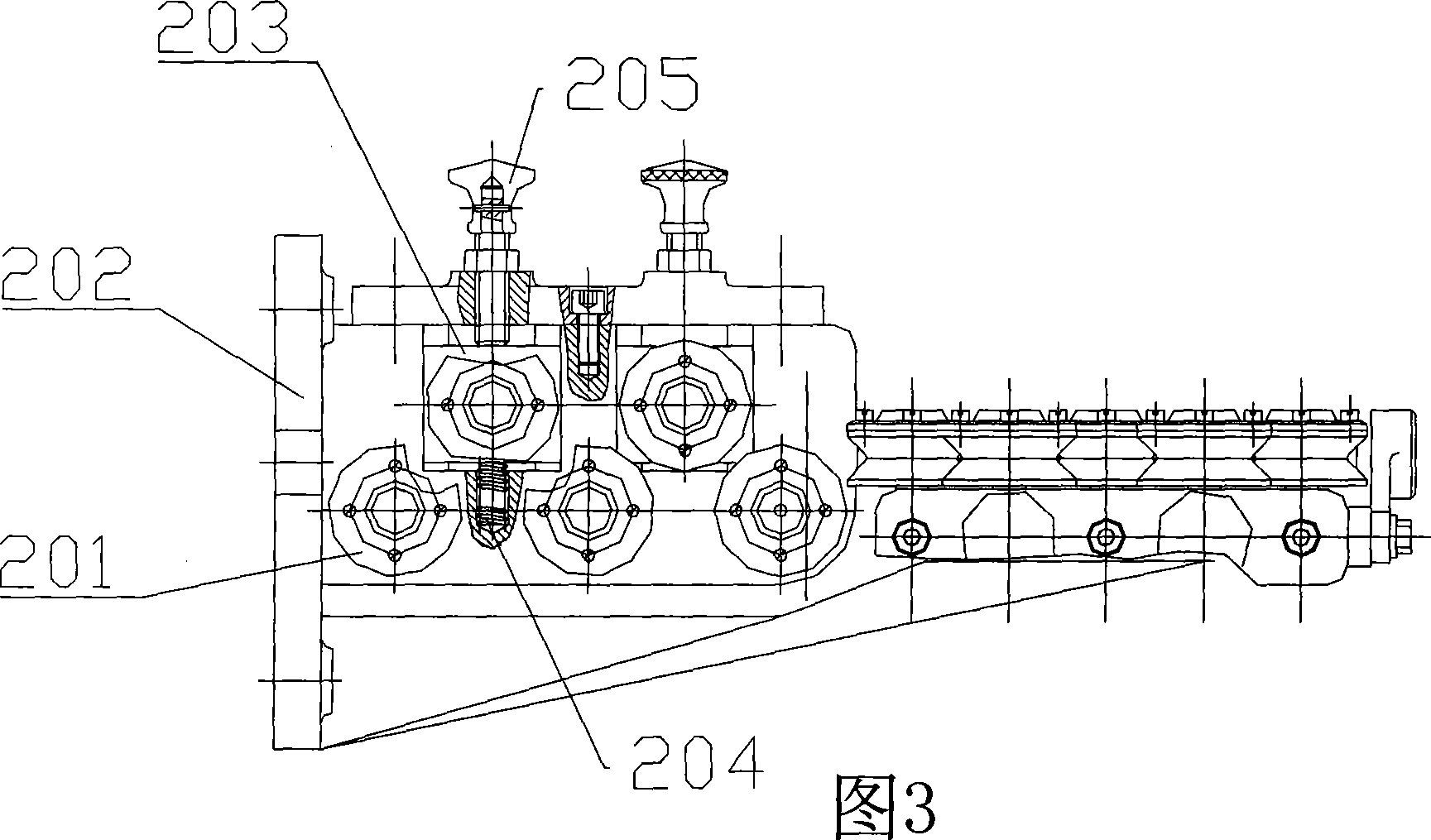

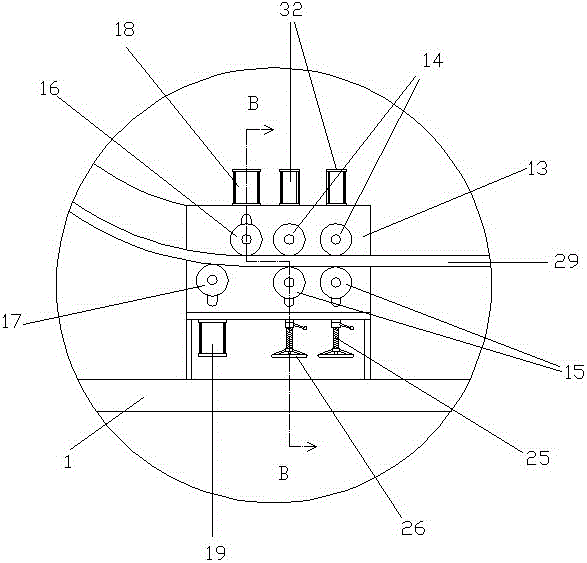

Equipment for rolling round thread into flat thread

InactiveCN101433909AResolve mutual coordinationSolve the real problemRoll mill control devicesMaterial accumulating devicesElectric machineryEngineering

The invention aims to provide a device for rolling circular wires into flat wires, which has high production efficiency and high material utilization rate. The device is as follows: the circular wires which are led out from an emptying rack are rolled by a plurality of tandem driving-roll rolling mills which are driven by speed regulation motors and enter a material receiving device; a flat wire storage amount control device which mainly comprises a rocker and a displacement sensor is arranged between two adjacent rolling mills; and the rocker is rotatably connected to the machine frame. The end part of the rocker is closely adhered to a flat wire between the two adjacent rolling mills under the action of dead weight; and the output end of the displacement sensor which senses the rotation angle of the rocker is connected with the speed regulation motor which controls the operation of the front rolling mill.

Owner:SUZHOU GLOBAL CHAIN TRANSMISSION CO LTD

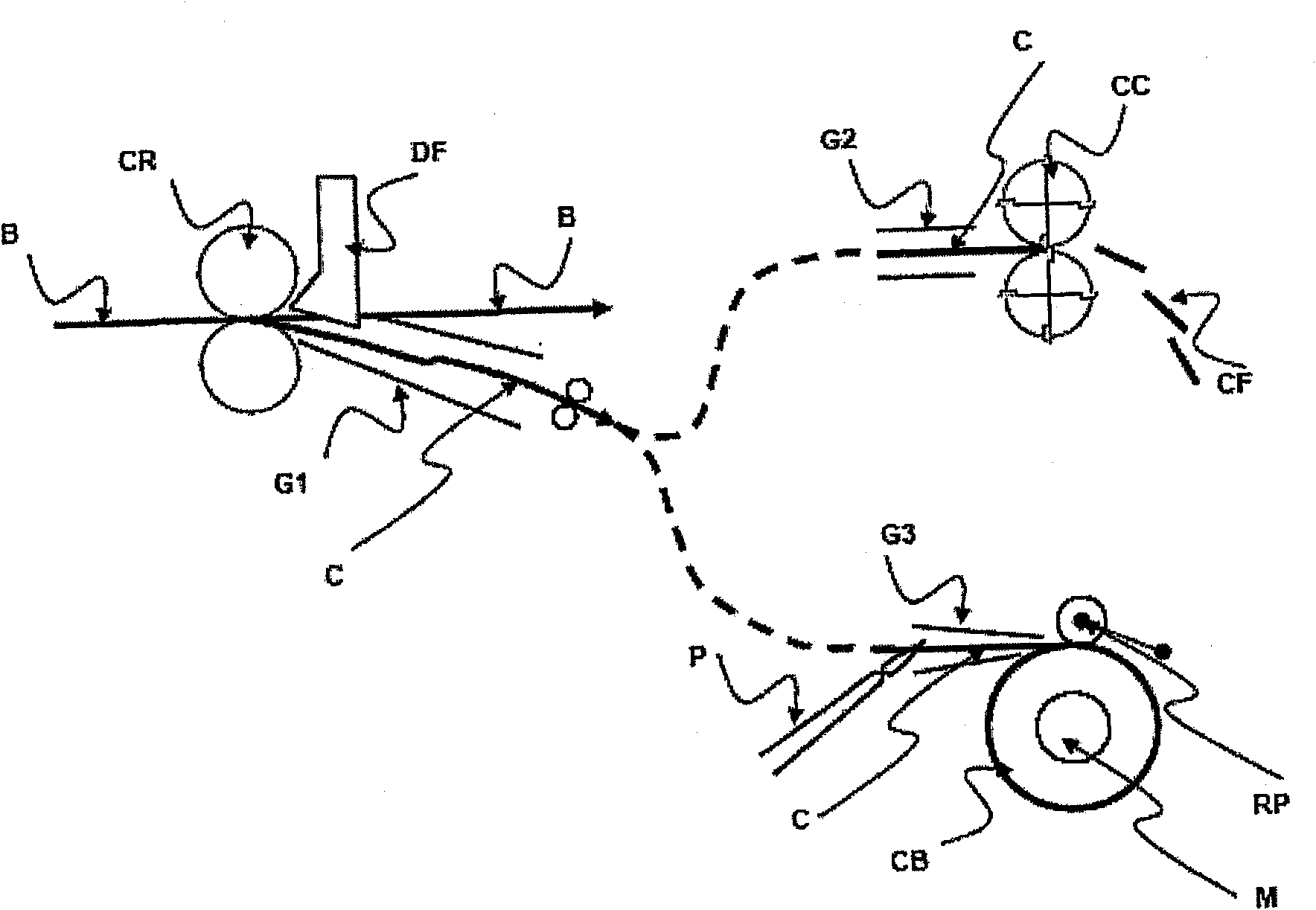

Device and method for winding sheared waste from steel band edges

InactiveCN102066017AGuaranteed Transition PositionFully automatedMaterial accumulating devicesWind shearCounter pressure

The invention relates to a device and method for winding sheared waste obtained from the edges of continuously moving steel bands, including: an edge shear (CR) which diverts the edges into a chute (G1) that conveys same to an accumulation chamber (2) in which the edge waste is stored in the form of a ball (1); a bundling drum (7) including a winding axis located between two side faces of said drum; and a handling means (4) designed to direct the end of the ball from the accumulation chamber to the winding axis in order to initiate the winding of the ball. According to the invention, the device also includes a winding mandrel (6) which can be inserted along the winding axis of the drum through a central opening in one of the side faces of the drum. In mandrel insertion mode, a counter pressure element (722, 723) engages coaxially with the mandrel and the end of the ball is clamped between said counter pressure element and mandrel.

Owner:CLECIM SAS

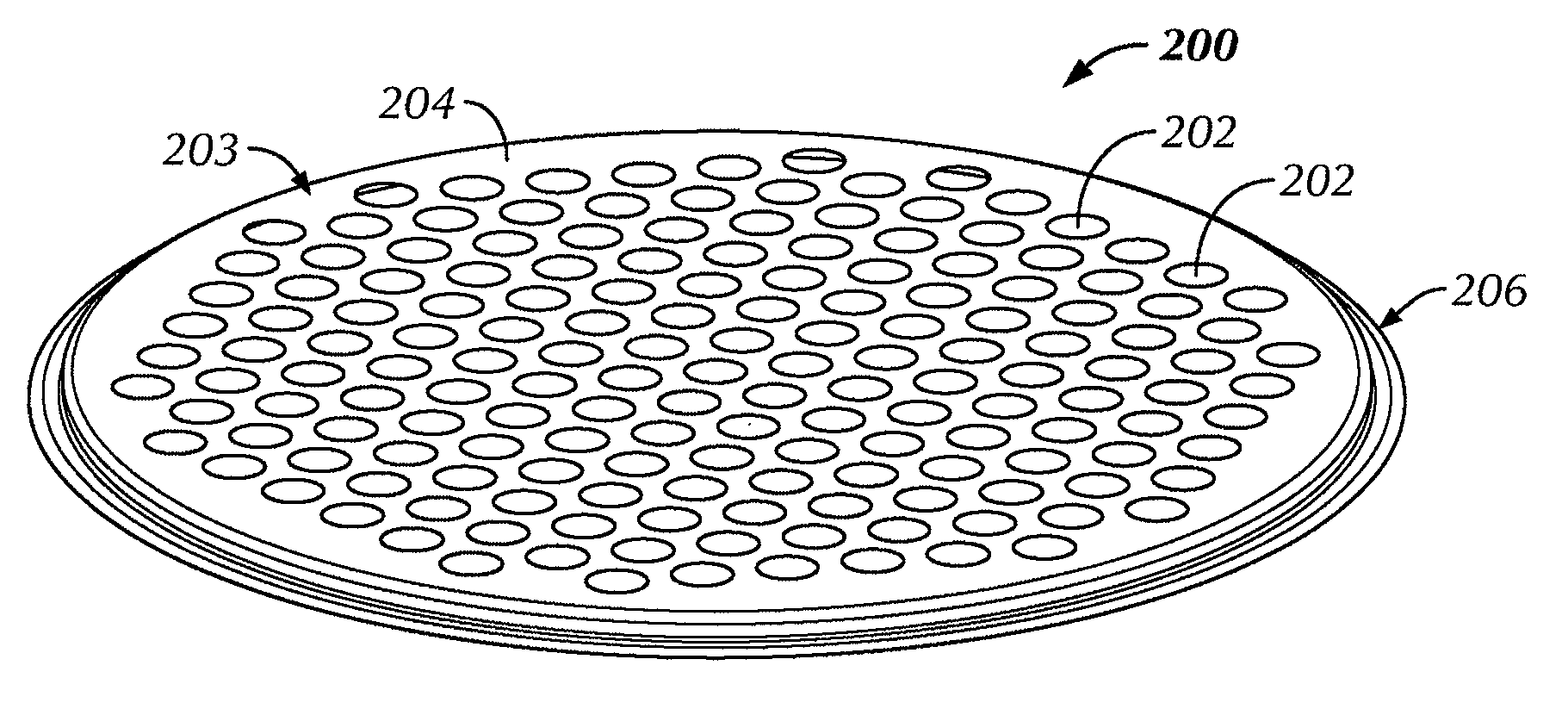

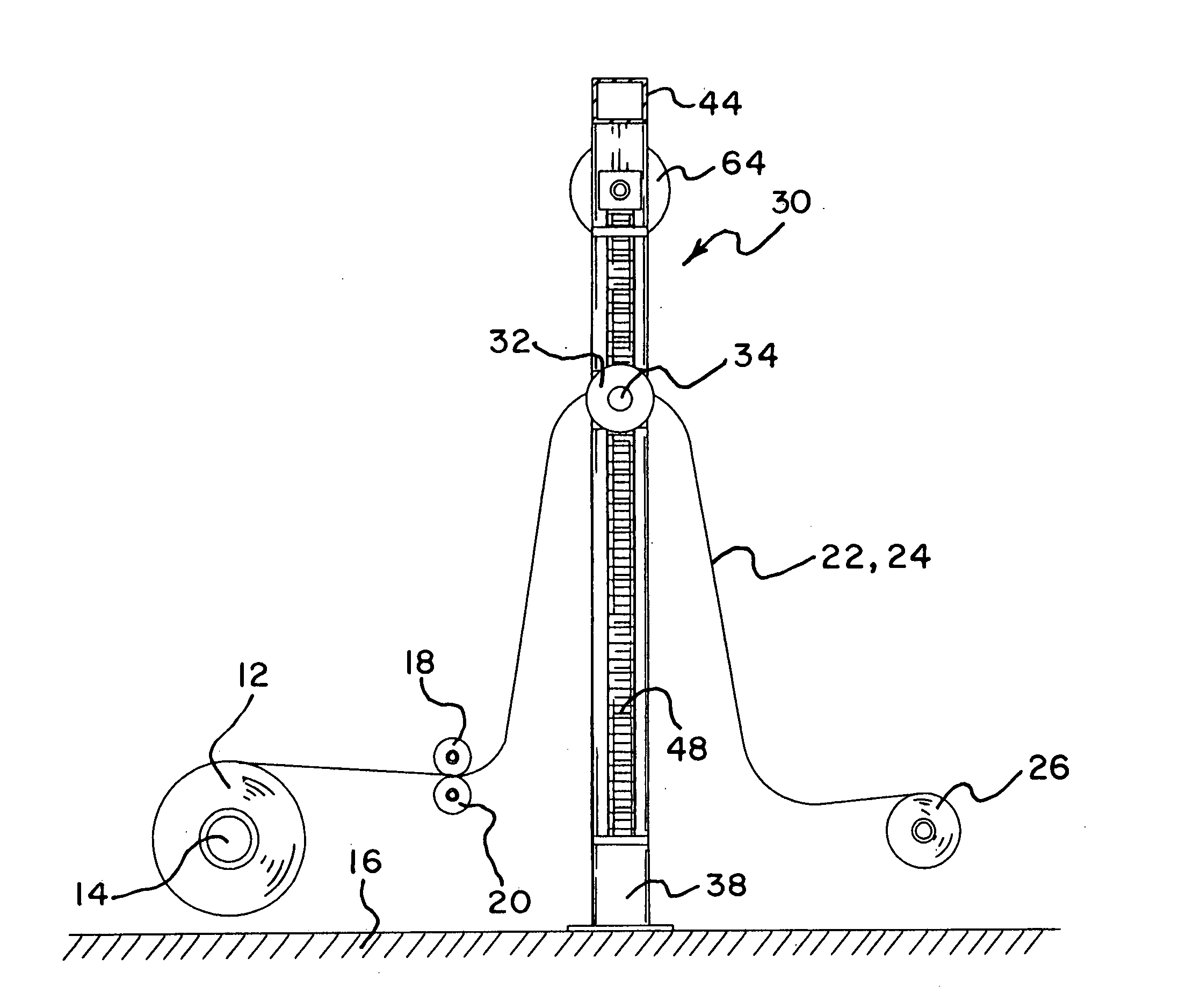

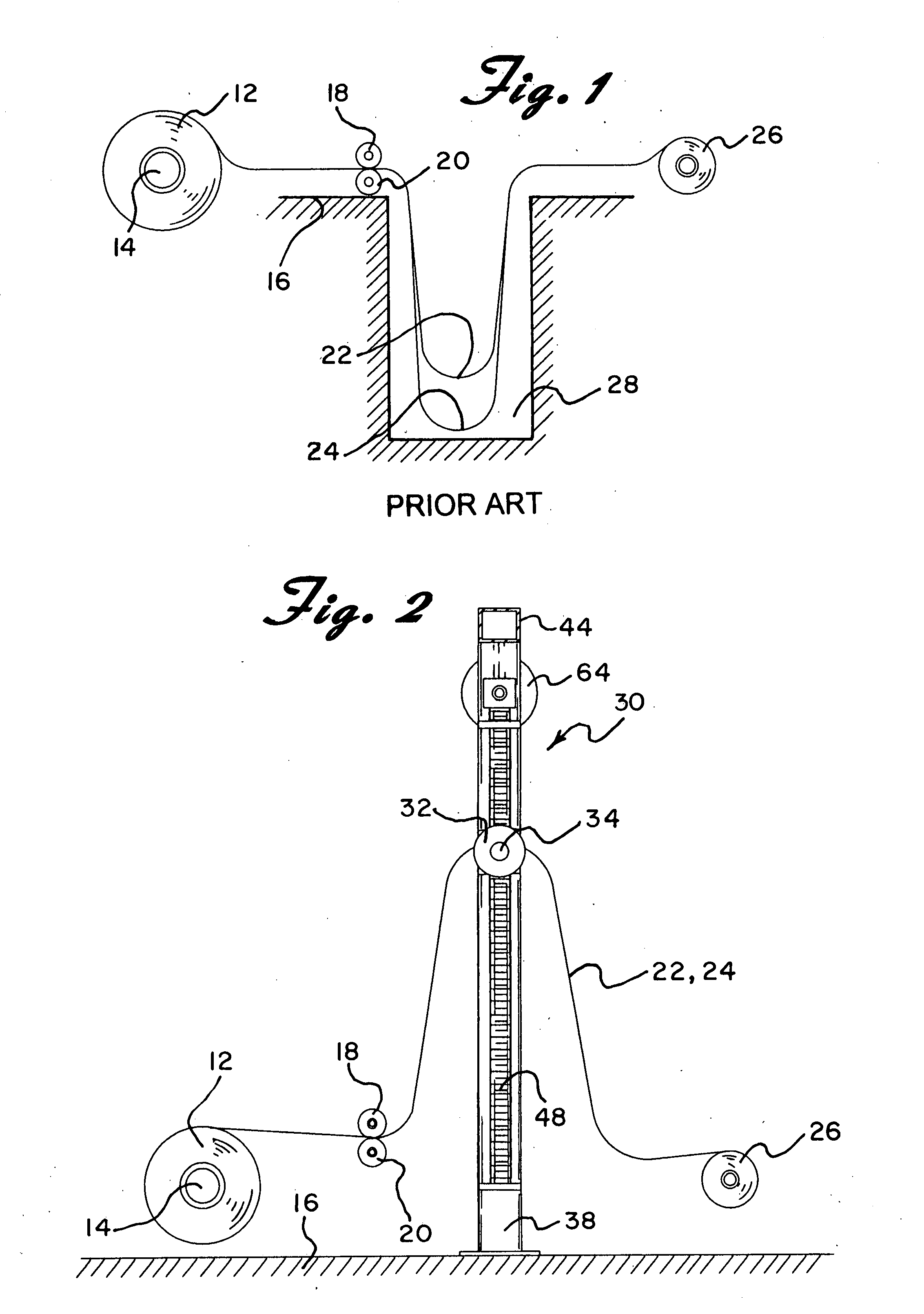

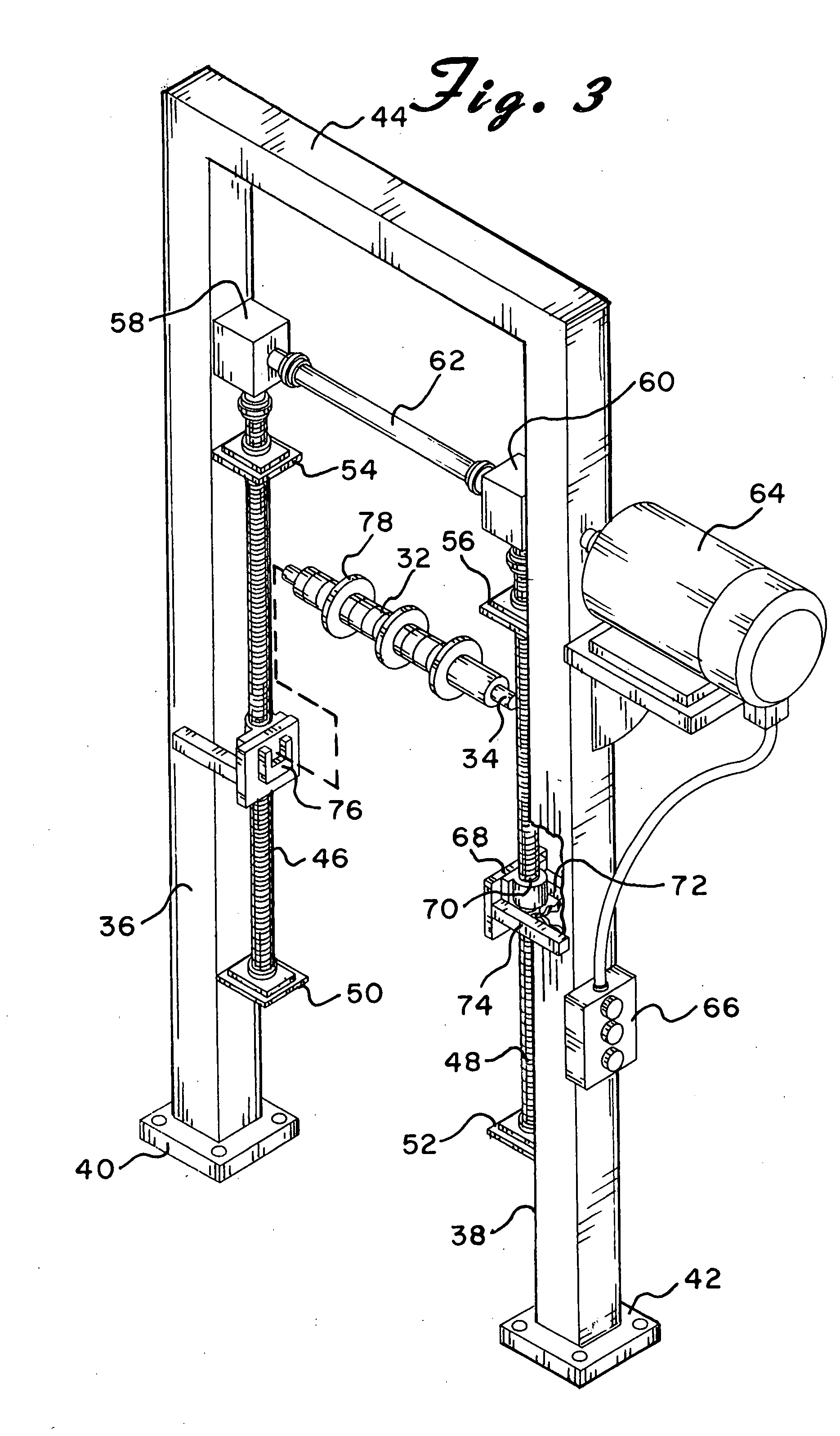

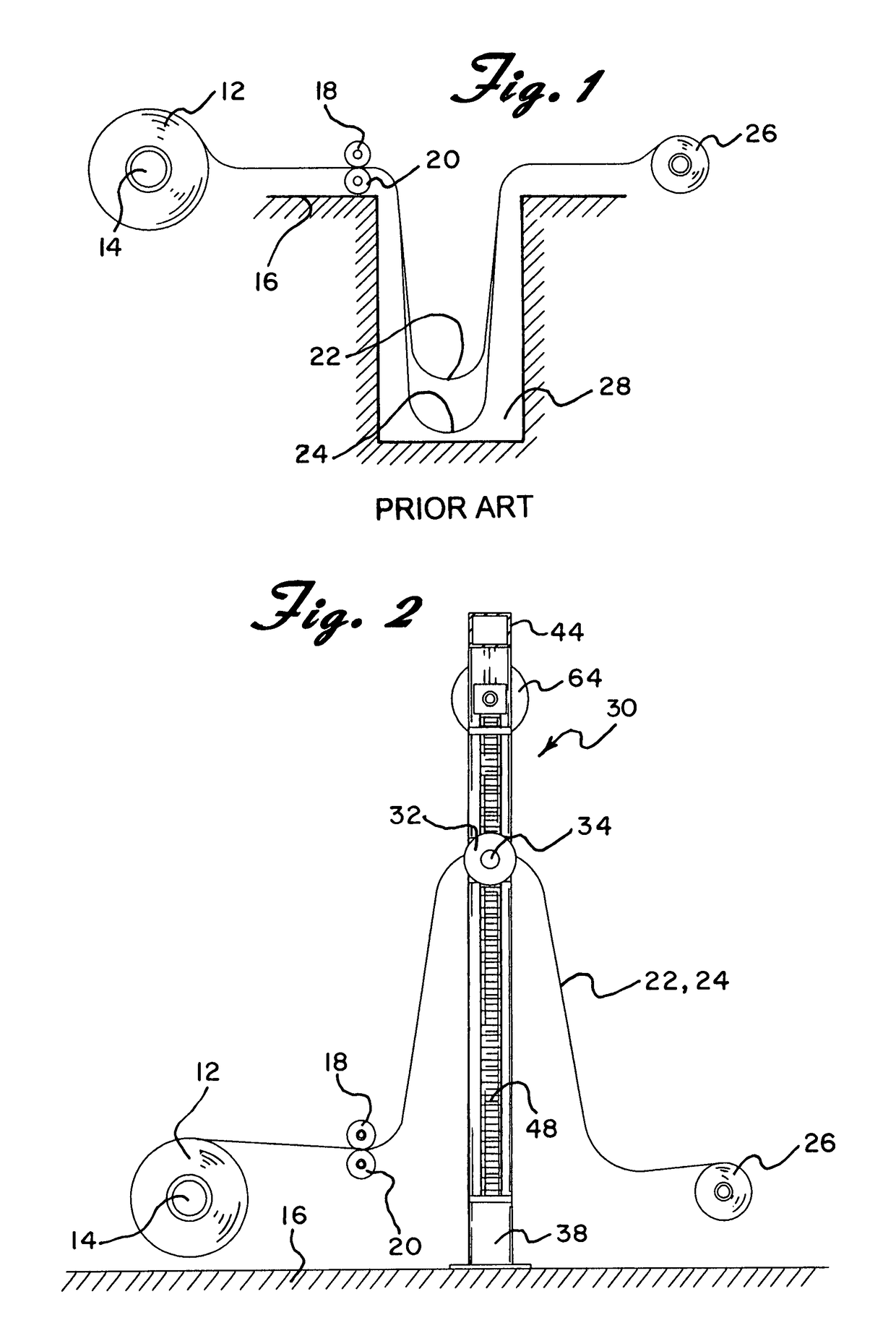

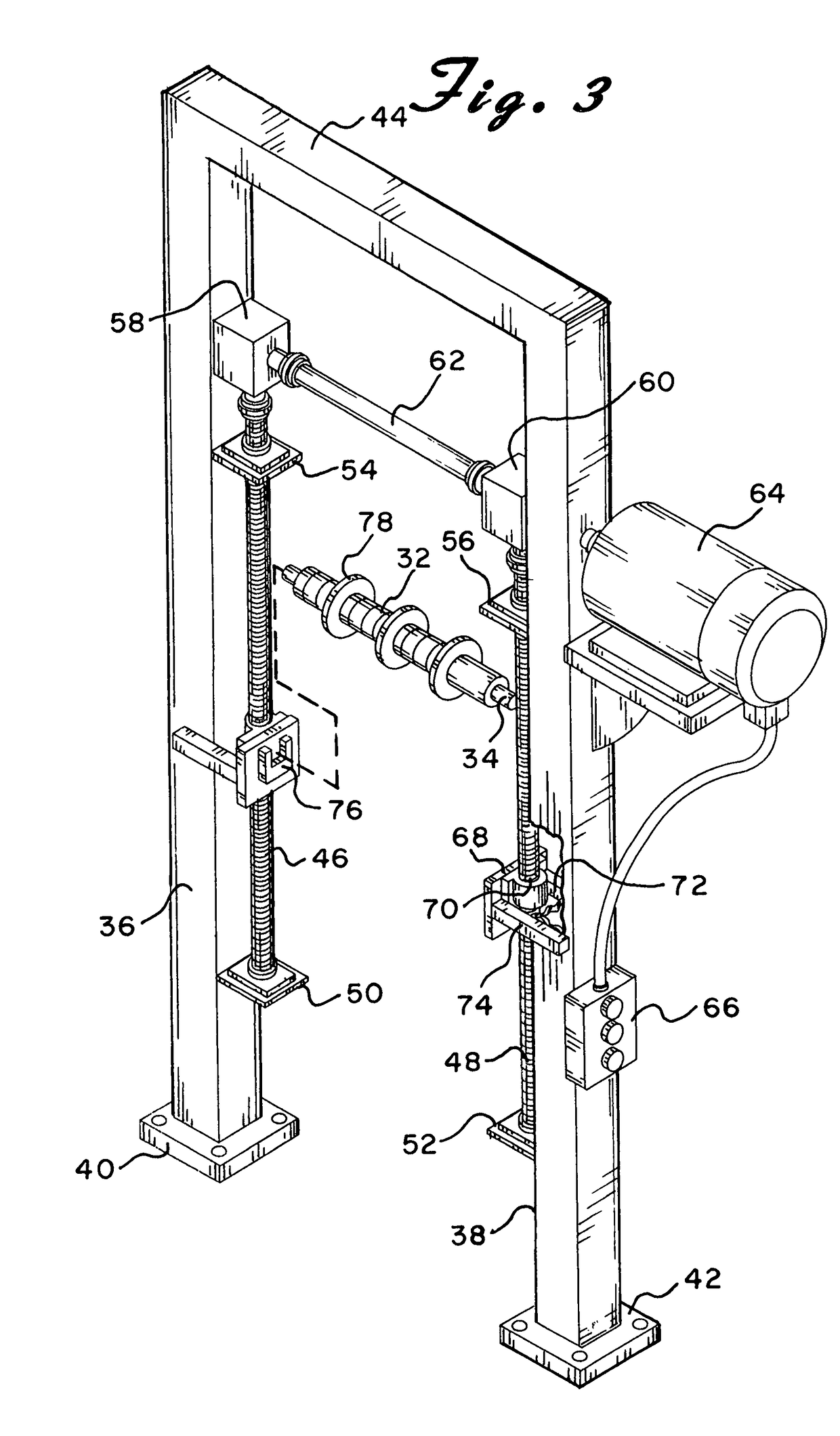

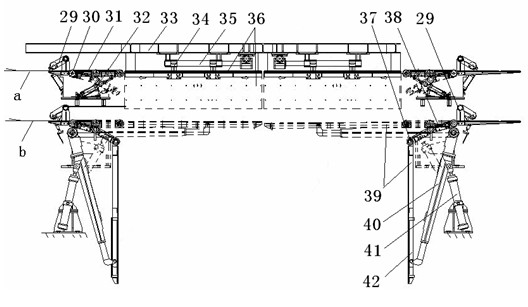

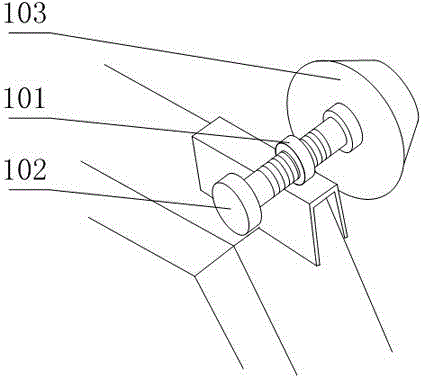

Adjustable vertical accumulator for slitting operation

InactiveUS20090108120A1Overcome deficienciesEliminate needRecord information storageMaterial accumulating devicesHorizontal axisEngineering

A vertical accumulator for use in a sheet metal unwinding, slitting and rewinding operation accumulates the slack created in the plurality of strips cut from an initial wide coil so that the proper tension can be maintained on the individual strips being rewound. The accumulator includes an elongated mandrel mounted for rotation about a horizontal axis parallel to the axis of the original sheet metal coil and is arranged such that all of the plurality of cut strips pass over the top of the mandrel. The mandrel is located above the height of the coil and above the height of the slitter and the rewound individual strips. A plurality of disks mounted on the mandrel separate the cut strips from each other. Upwardly extending threaded rotatable rods located on either side of the sheet metal strips carry holders that releasably support the mandrel. Rotation of the rods causes the holders to move up or down to thereby adjust the height of the mandrel.

Owner:PAPANIA JAMES F

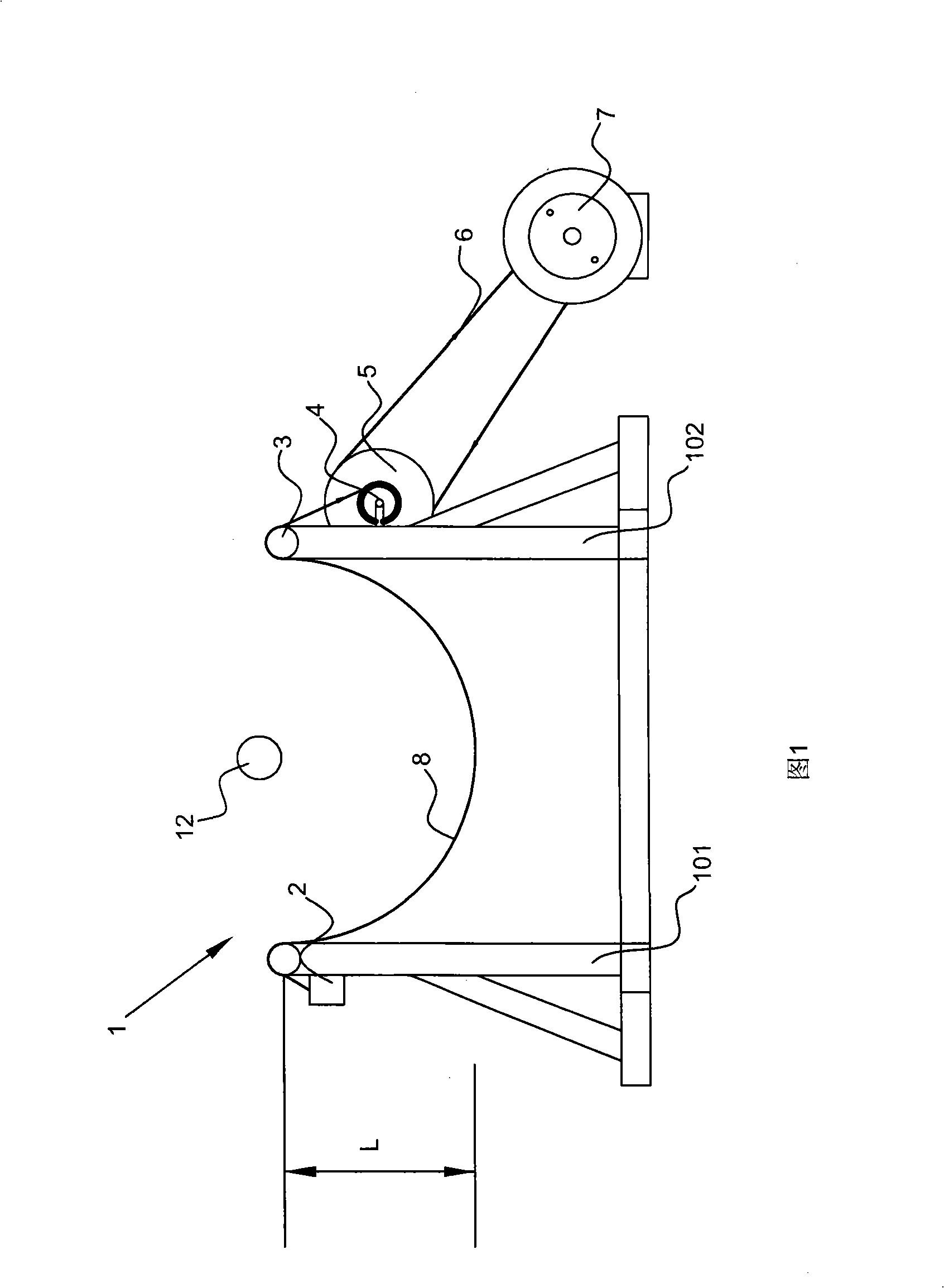

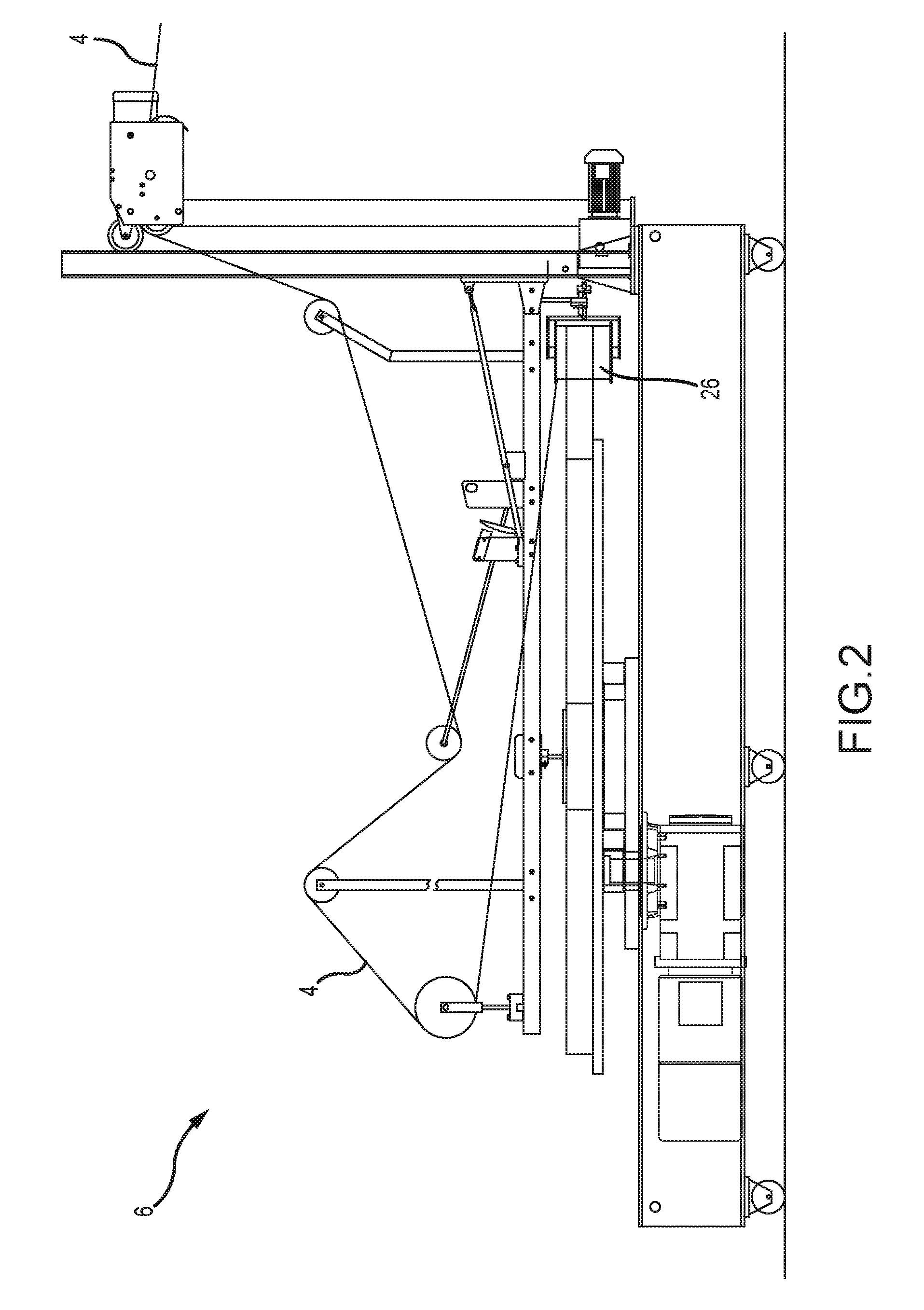

Apparatus for decelerating and temporarily accumulating hot rolled product

An apparatus is disclosed for decelerating and temporarily accumulating a hot rolled product moving longitudinally along a first axis at a first velocity V1. The apparatus comprises a curved guide with an entry end aligned with the first axis to receive the product, and with an exit end spaced radially from the first axis and orientated to deliver the product in an exit direction transverse to the first axis. The curved guide is rotatable about the first axis in a direction opposite to the exit direction of the product and at a speed at which its exit end has a second velocity V2 lower than V1 and such that the product is delivered from the exit end as a helical formation of rings and at a third velocity V3 equal to V1−V2. A cylindrical drum is arranged to axially receive the helical formation of rings and to rotate about the first axis in a direction opposite to the direction of rotation of the curved guide and at a speed such that the product is unwound from the drum at the third velocity V3. A receiver moves to and fro along a path parallel to the first axis to receive the product being unwound from the drum. A shroud is configured to partially encircle the drum, and rotatable interior rollers are circumferentially spaced around the interior of the shroud. The interior rollers are spaced radially from the surface of the drum and extend in parallel relationship with the first axis.

Owner:SIEMENS IND INC

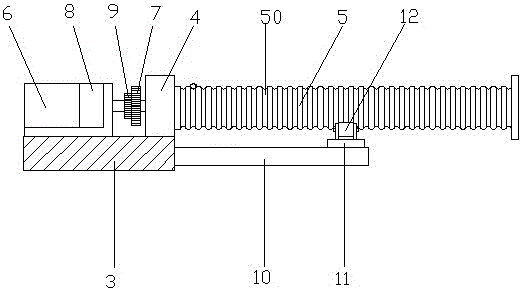

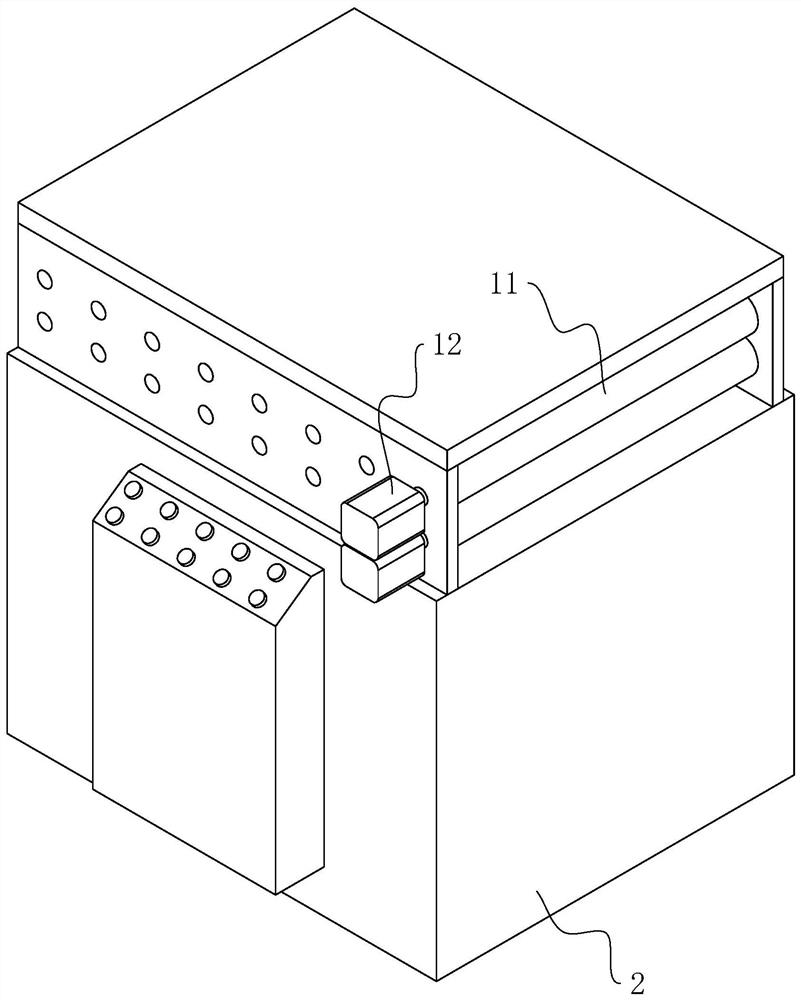

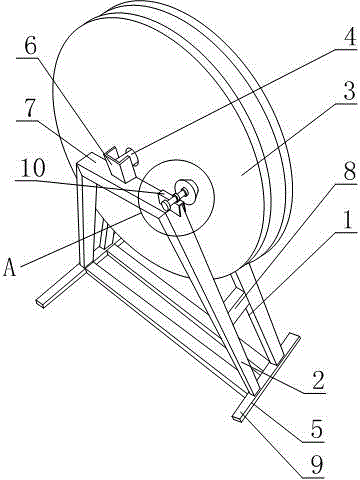

Rolled pipe blank winding and scheduling device

ActiveCN106825116AImplement bufferingImplement schedulingMaterial accumulating devicesCentre of rotationConductor Coil

The invention relates to the technical field of pipe blank stretching and machining, and discloses a rolled pipe blank winding and scheduling device. The device comprises a base, a supporting frame arranged at the left end of the base, a machine box and a beam. The center of the beam is rotationally connected with the top of the supporting frame. The side faces of the two ends of the beam are provided with pipe blank traction suspension mechanisms symmetrical about the rotating center of the beam. The front face of the machine box is provided with two upper positioning rollers and two lower positioning rollers. An upper movable roller is arranged on the front face of the machine box and located on the left side of the upper positioning rollers, and a lower movable roller is arranged on the front face of the machine box and located below the left portion of the upper movable roller. The top of the machine box is provided with an upper driving air cylinder for driving the upper movable roller to ascend and descend, and the bottom of the machine box is provided with a lower driving air cylinder for driving the lower movable roller to ascend and descend. The side faces of the upper positioning rollers, the lower positioning rollers, the upper movable roller and the lower movable roller are each provided with an annular limiting groove. By means of the rolled pipe blank winding and scheduling device, a pipe blank can be rapidly wound, and buffer and scheduling of the pipe blank material between a rolling machine and a combined drawing machine are achieved.

Owner:JIANGXI NAILE COPPER IND +1

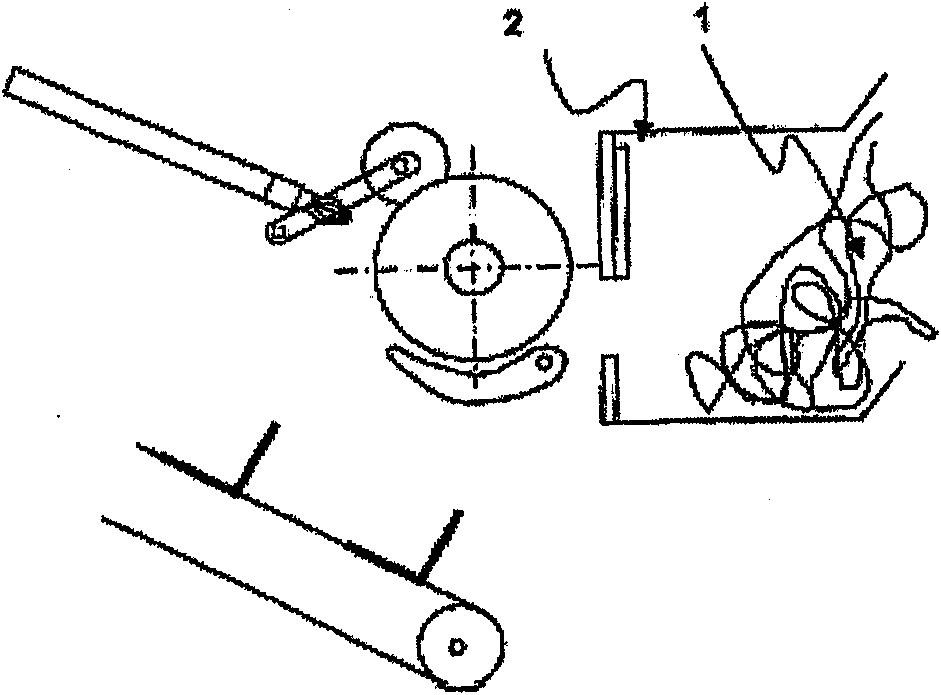

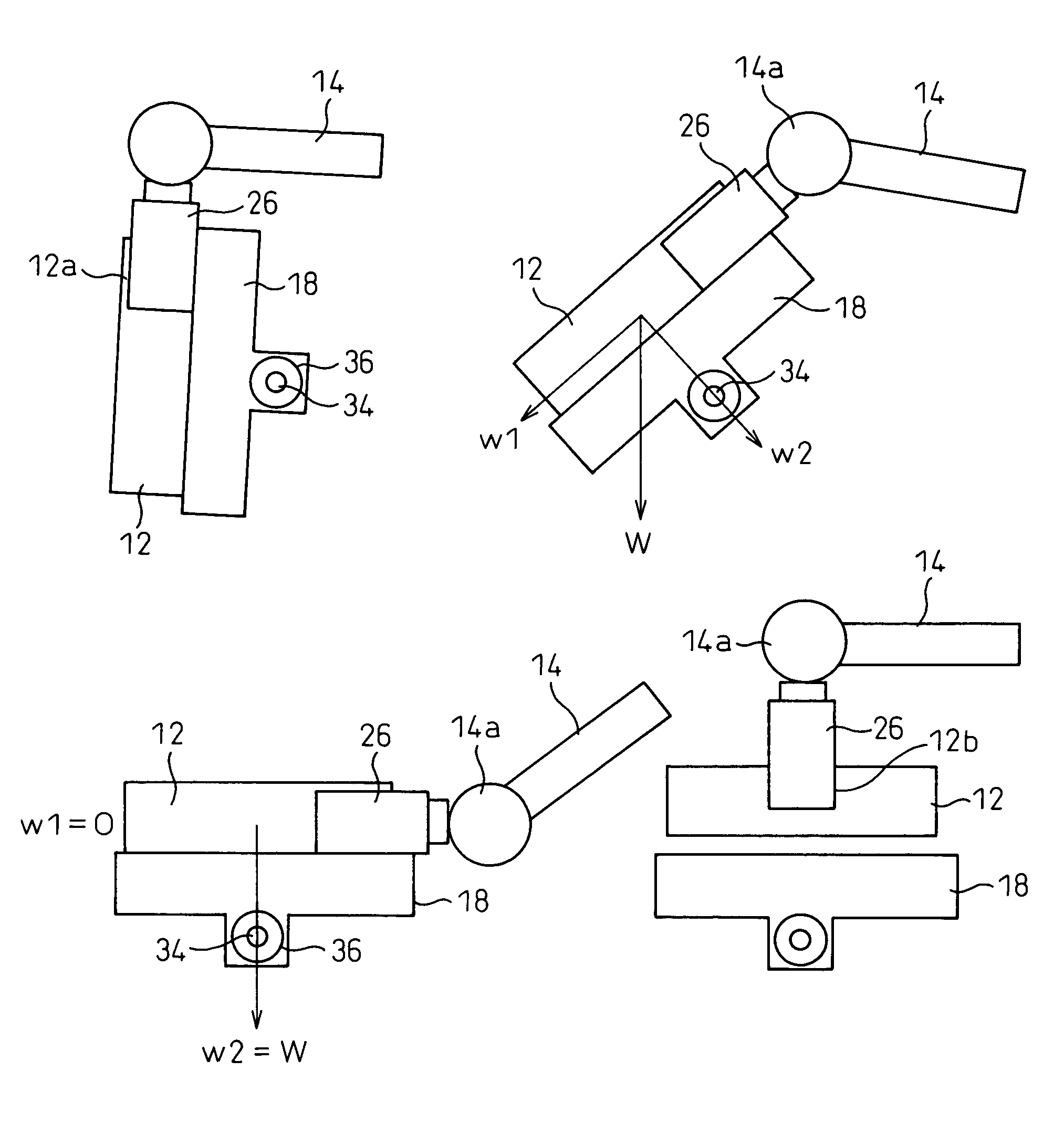

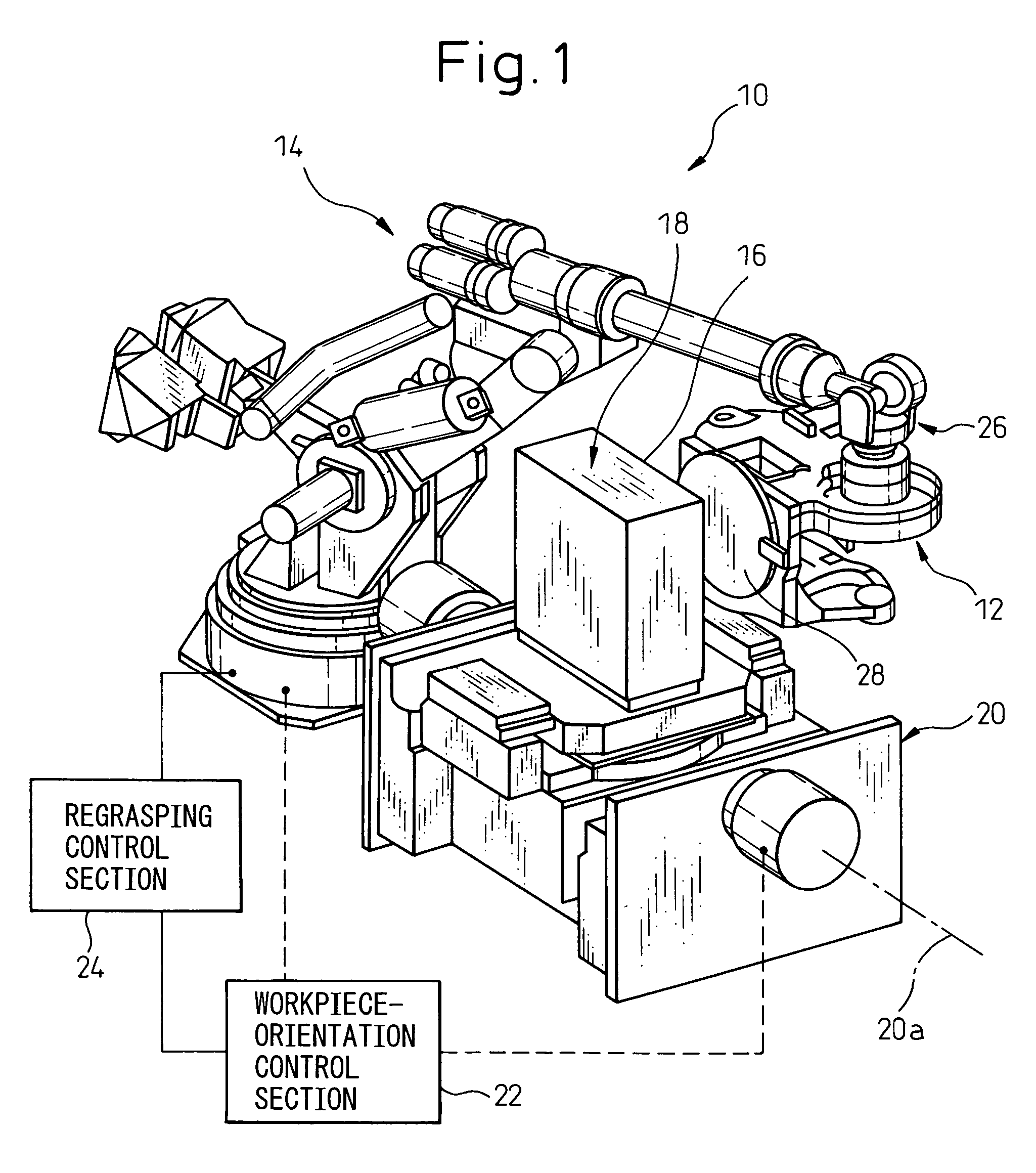

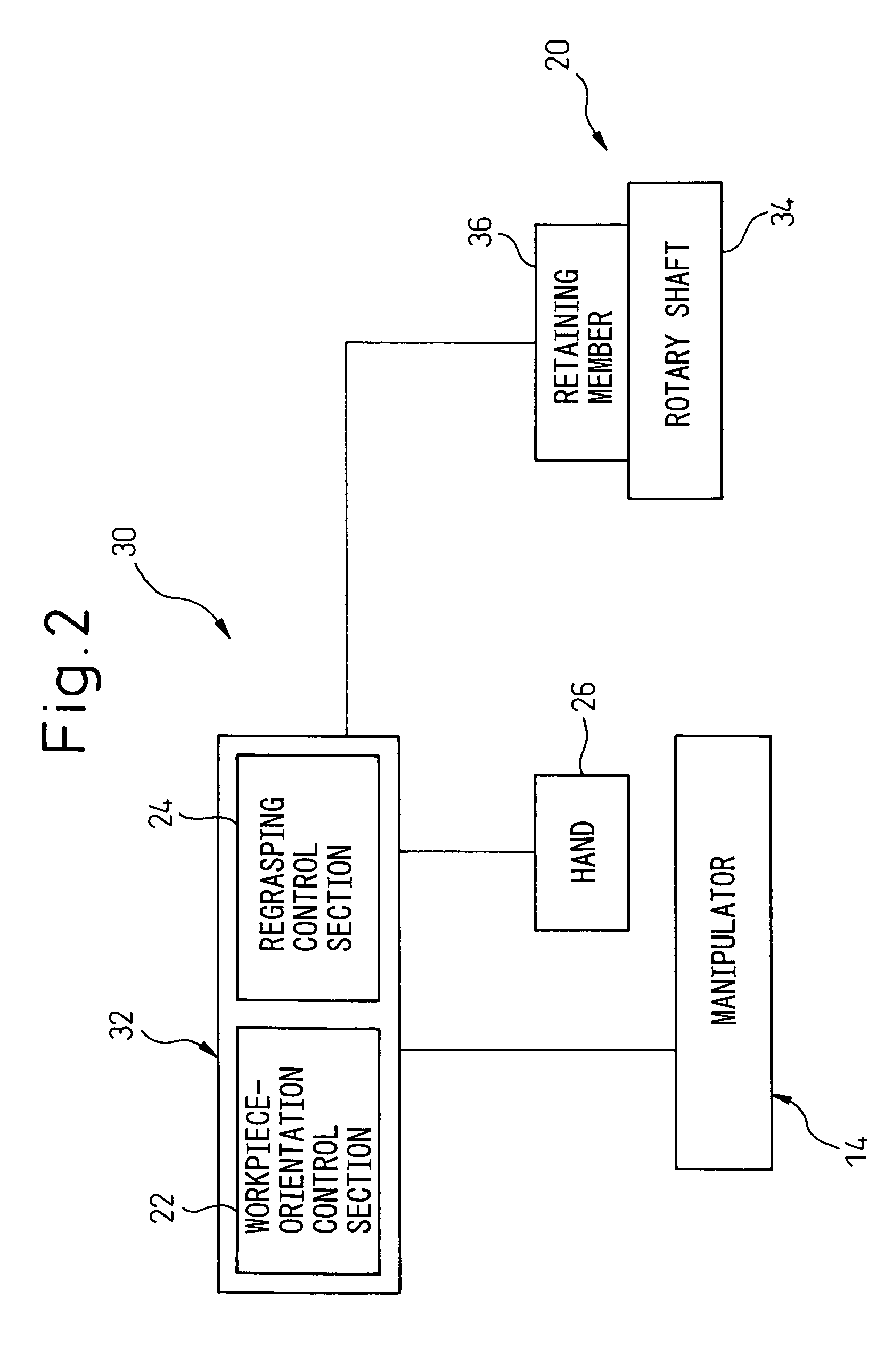

Workpiece regrasping system for robot

A workpiece regrasping system for a robot. The system includes a manipulator grippable a workpiece; a deck member having a deck surface on which a workpiece is placeable; a support mechanism rotatably supporting the deck member about an axis parallel to the deck surface; a workpiece-orientation control section for controlling the manipulator so as to grip a workpiece at a first point of the workpiece and to bring the workpiece into abutment with the deck surface of the deck member, and configured to displace the workpiece together with the deck member about the axis, while maintaining a mutually abutted condition, until the workpiece occupies a desired orientation, with at least a part of a weight of the workpiece being carried on the deck surface; and a regrasping control section for controlling the manipulator so as to temporarily release the workpiece placed on the deck surface in the desired orientation and to regrasp the workpiece at a second point different from the first point. The workpiece-orientation control section may control an operation of the manipulator, or control a rotational drive section for the deck member, while maintaining the workpiece in abutment with the deck surface, to displace the workpiece to the desired orientation.

Owner:FANUC LTD

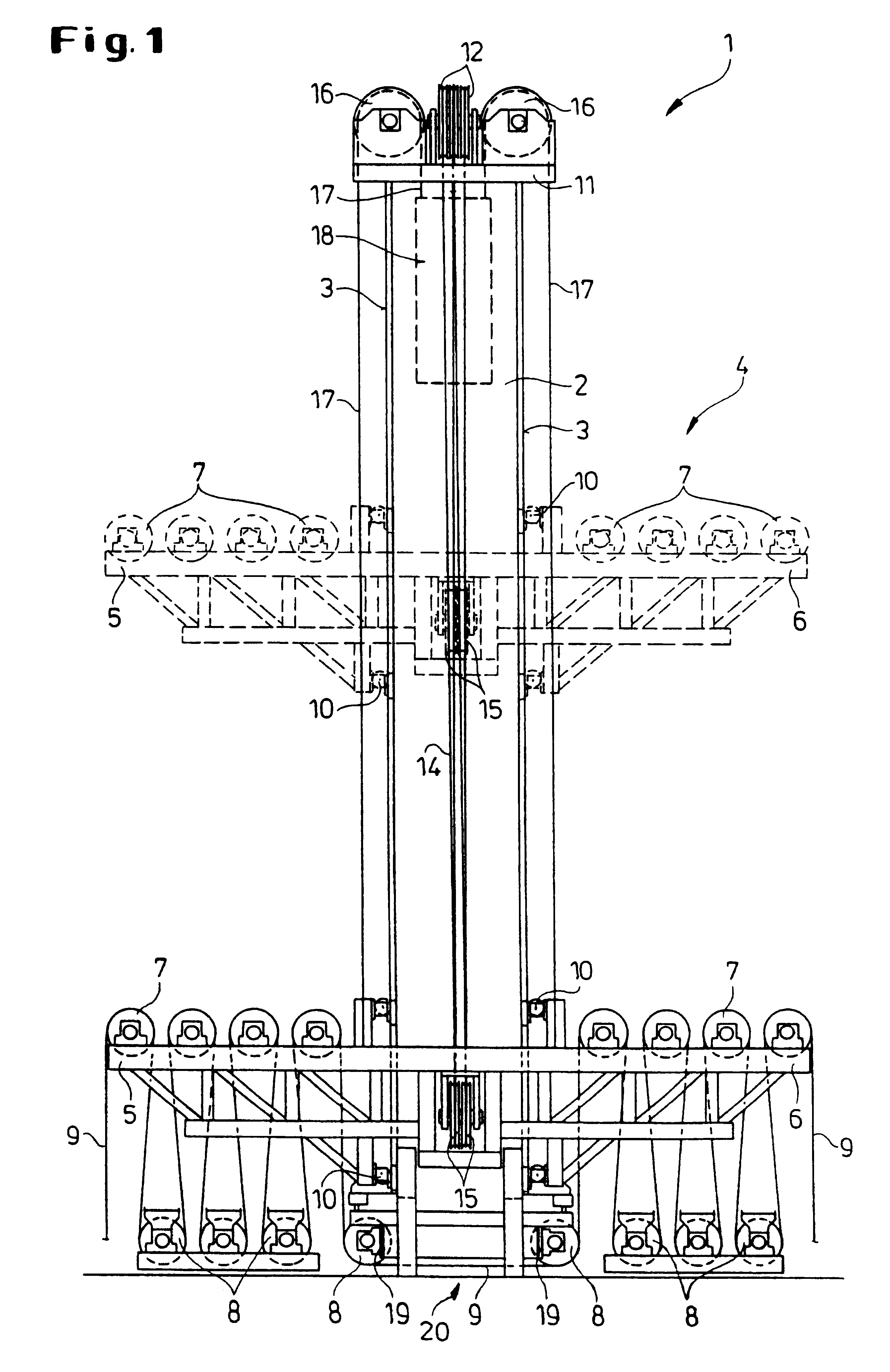

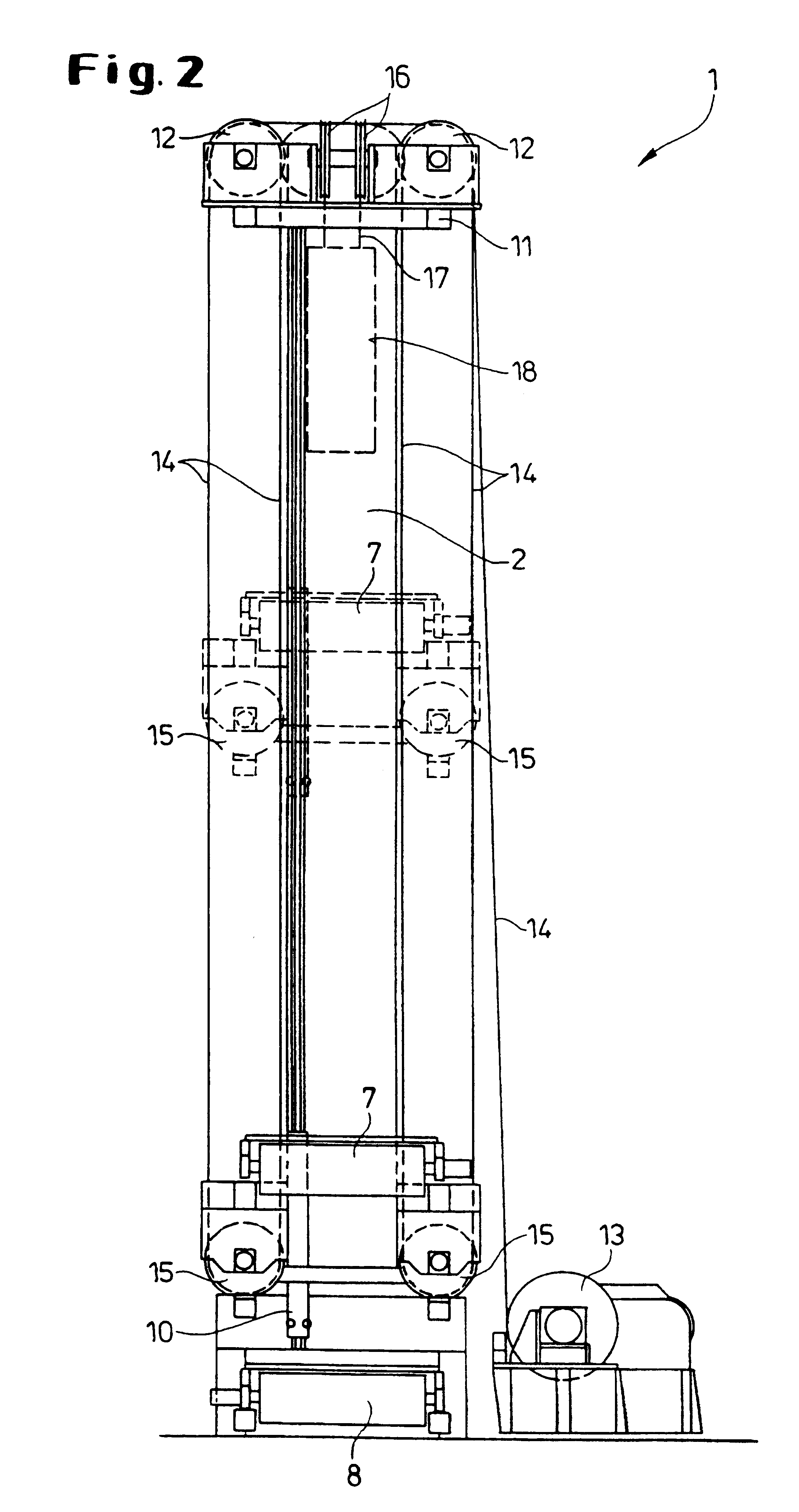

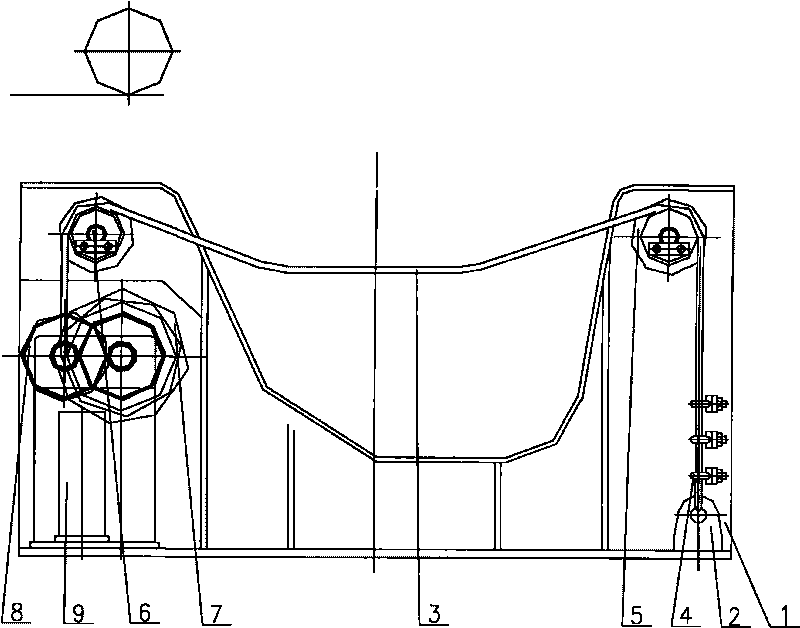

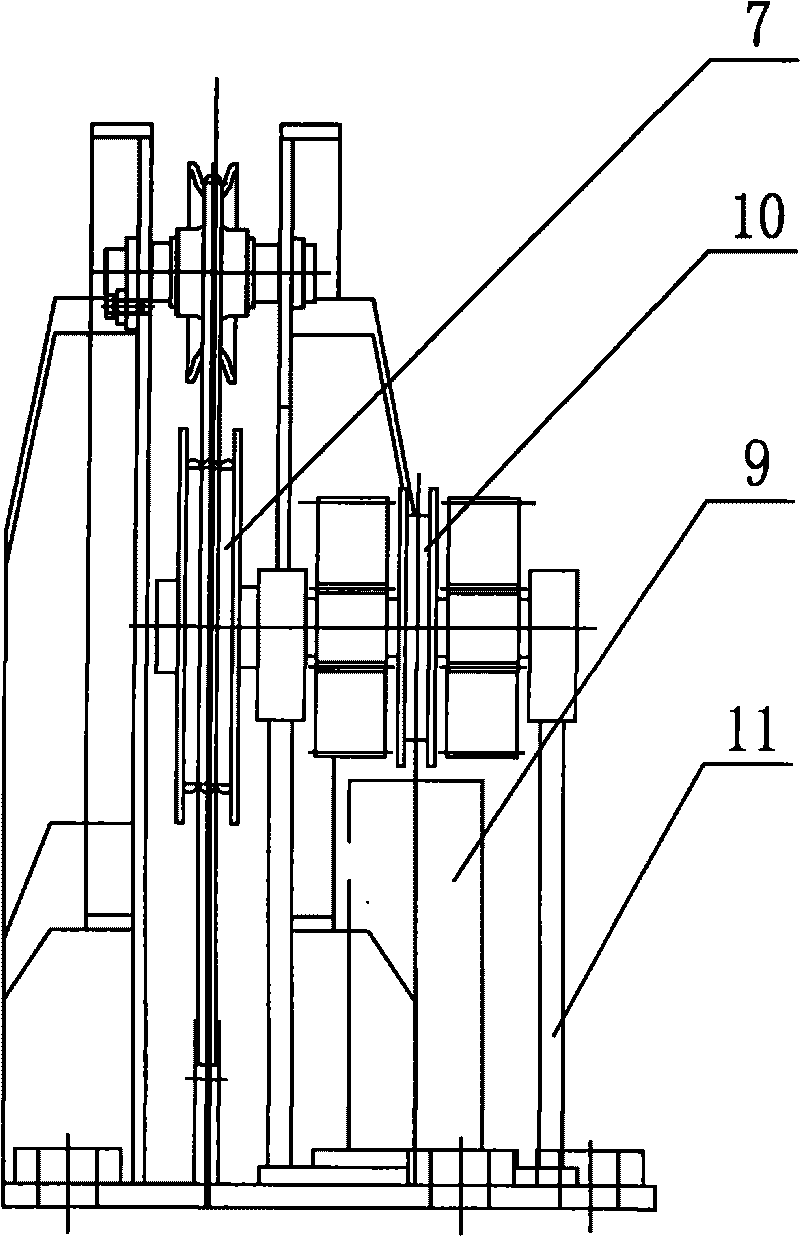

Vertical belt storage system

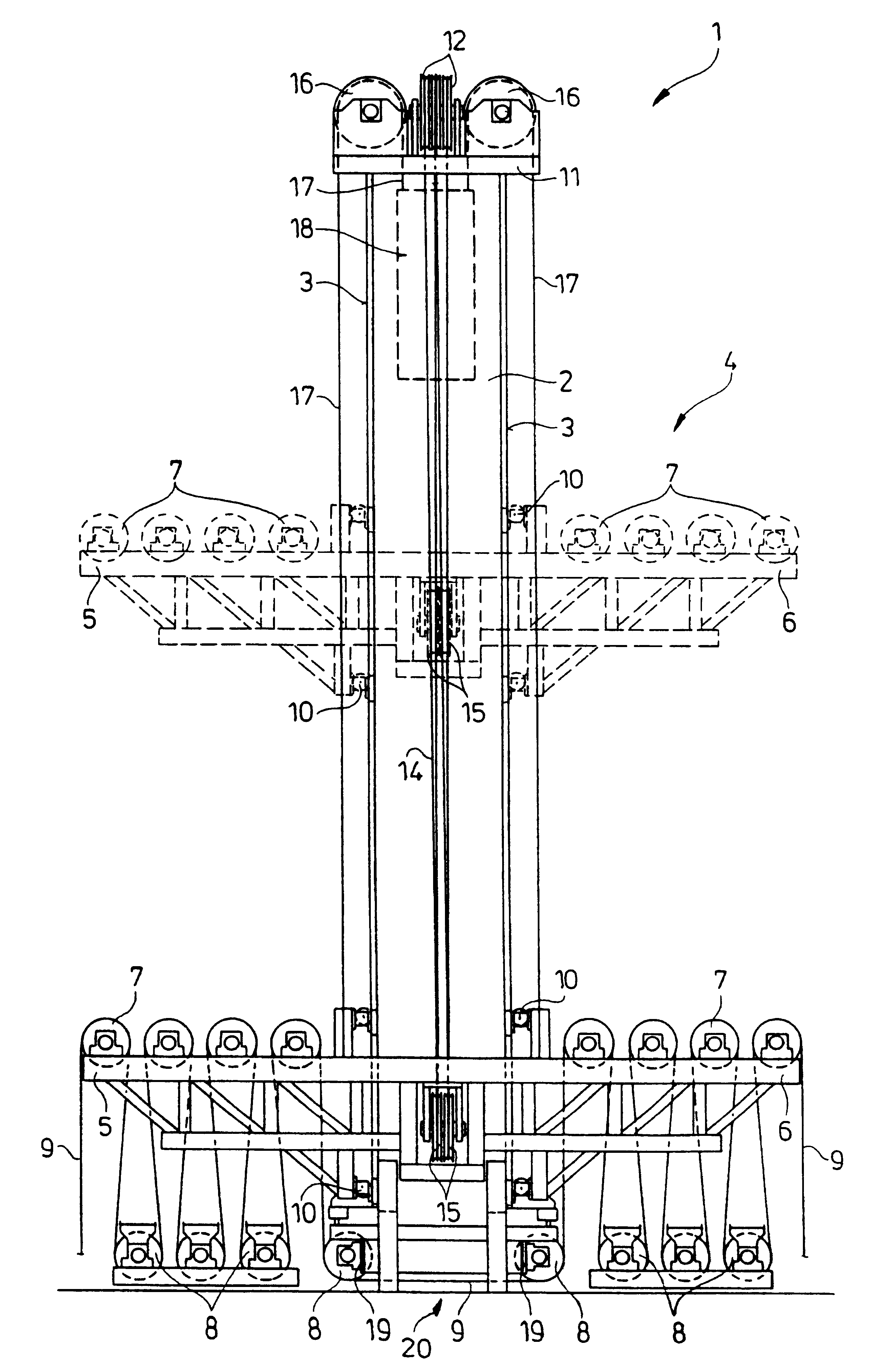

A vertical strip storage system has a support structure and a storage car connected to the support structure by cables in the fashion of a pulley block so as to be lifted and lowered relative to the support structure. The storage car is provided with a counterweight and with deflection pulleys which deflect and guide an incoming and / or outgoing strip in cooperation with stationary deflection pulleys on the ground. The support structure is a free-standing column without lateral supports and the storage car is a salient vehicle running on the outer surface of the column, wherein the column has an interior and the counterweight is guided in the interior of the column.

Owner:SMS SCHLOEMANN SIEMAG AG

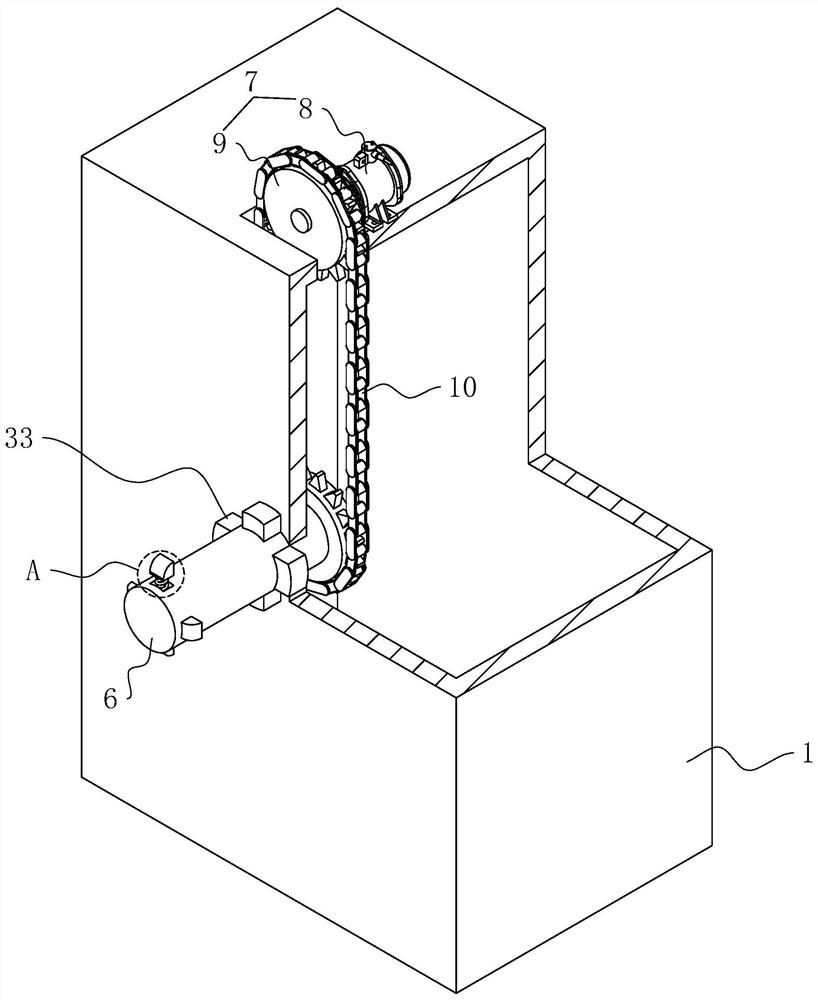

Steel pipe collecting device

ActiveCN101722212AAvoid collisionReduce frictionMetal-working feeding devicesMaterial accumulating devicesEngineeringConductor Coil

The invention relates to a steel pipe collecting device which comprises a material basket, a cushioning device, guide wheels, a retractable winding drum, a transmission mechanism and a spring box, wherein the material basket is fixed on the base by foundation bolts; the two guide wheels are respectively arranged on the side plate of the material basket by a stationary shaft; one side of the material basket is provided with the transmission mechanism, the retractable winding drum and the spring box; the transmission mechanism is respectively connected with the retractable winding drum and the spring box; the base plate at the other side of the material basket is provided with a lifting eye; and one end of the cushioning device is fixed on the lifting eye, and the other end passes by the retractable winding drum and is wound and fixed on the retractable winding drum. The steel pipe collecting device has reasonable structural design, effectively improves the surface quality of finished steel pipe products and greatly lightens the influence of noise to the bodies of operation staffs.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

Automatic lifting material rest

InactiveCN101513653ANot prone to scratchesImprove the phenomenon of bruisesMaterial accumulating devicesDrive wheelEngineering

Owner:TAICANG JINXIN COPPER TUBE CO LTD

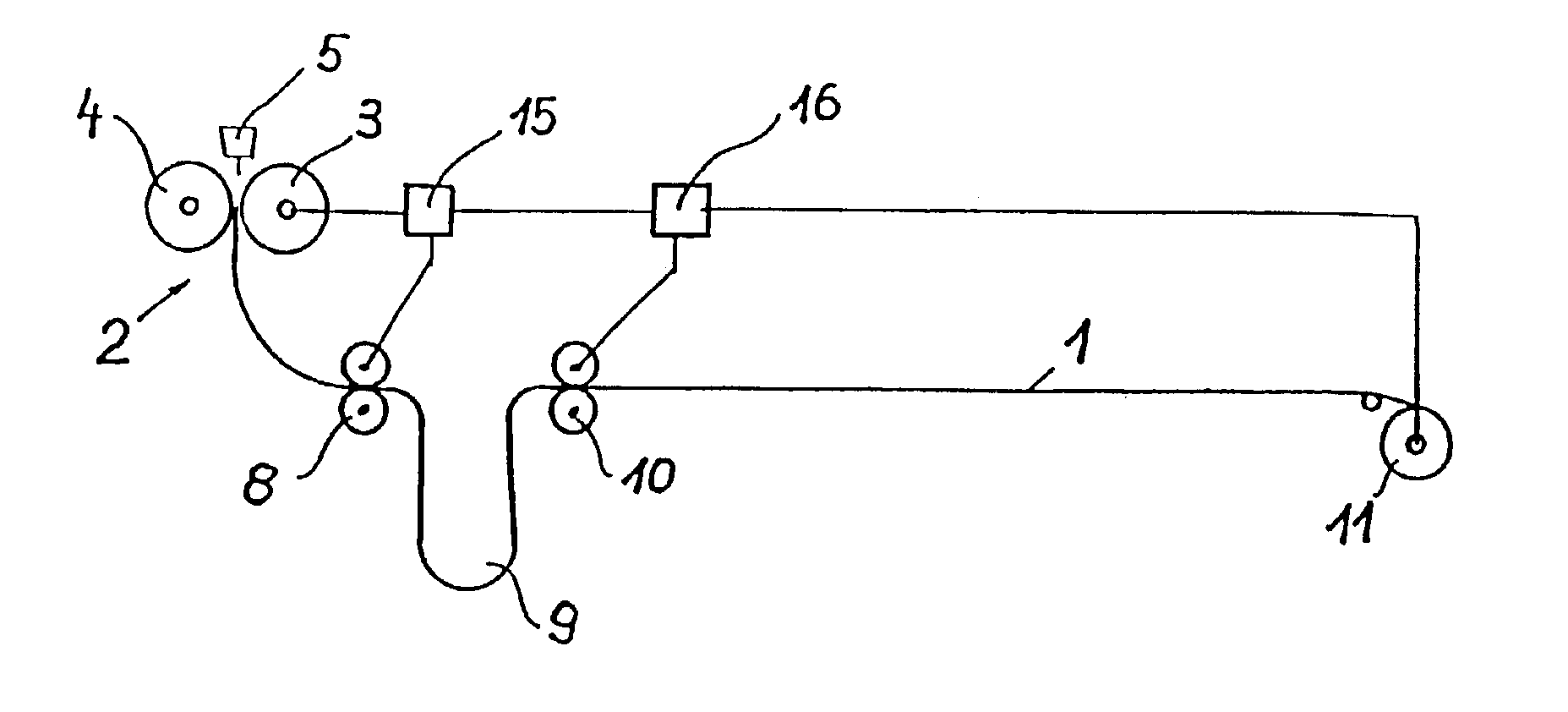

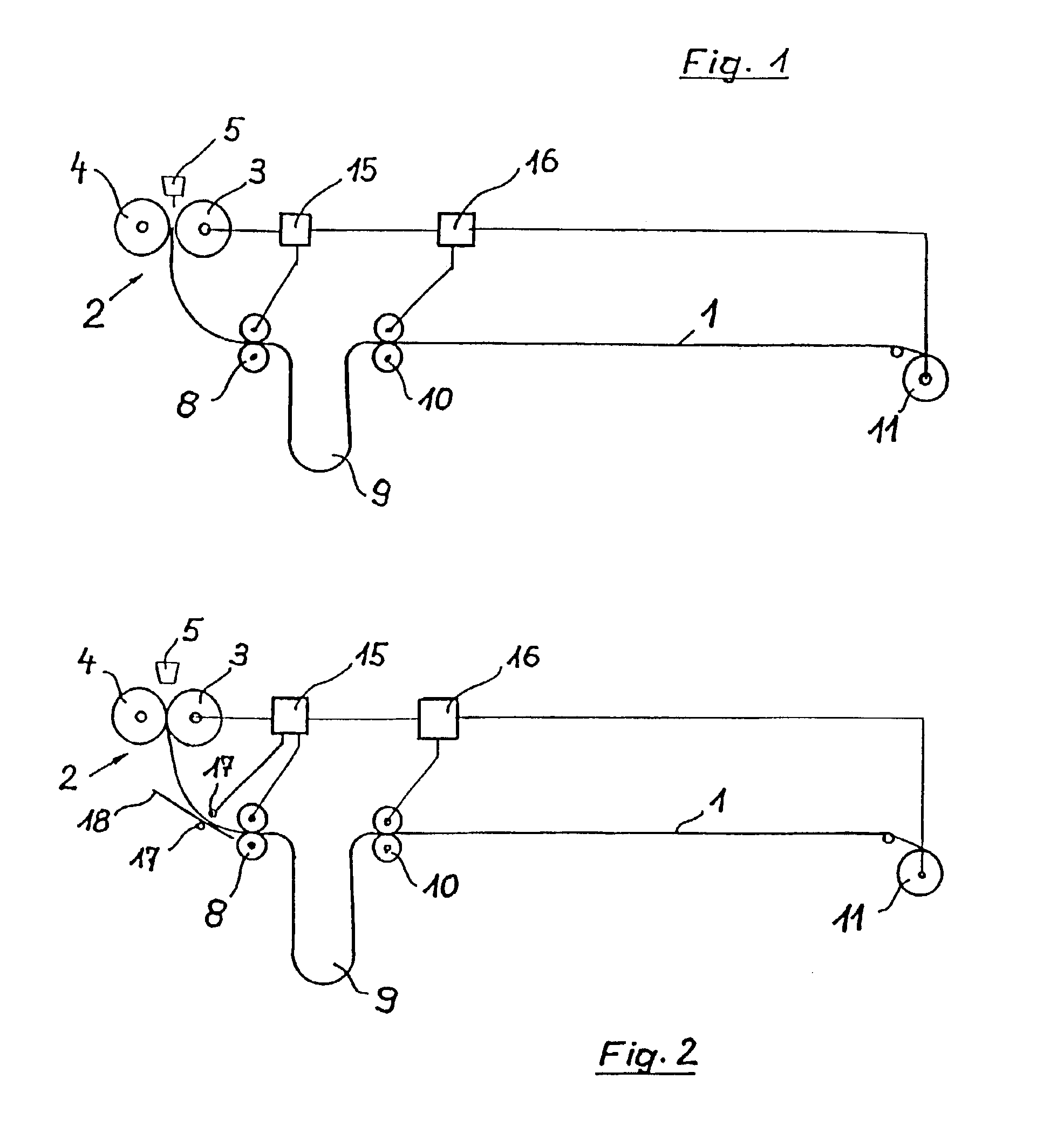

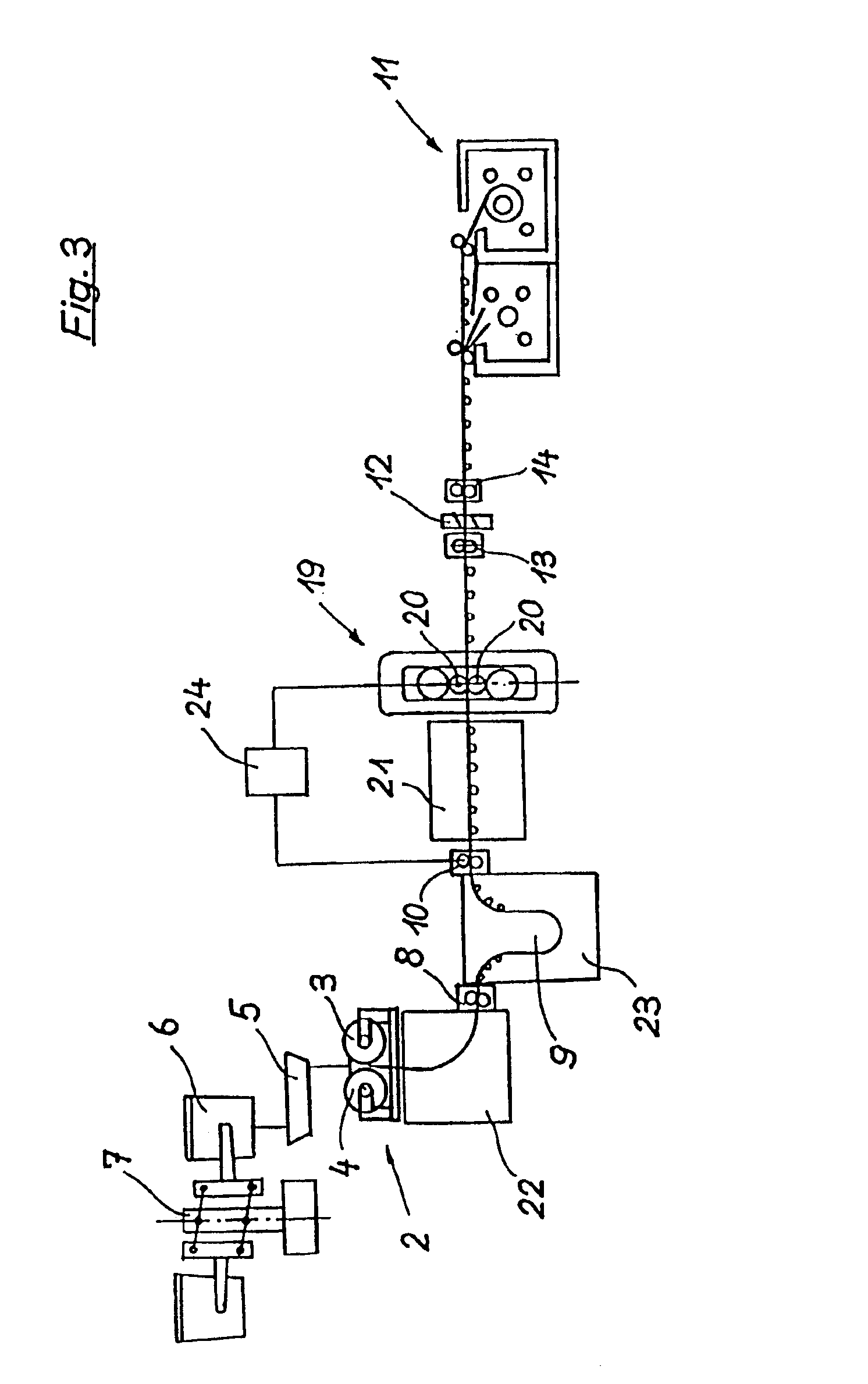

Method and installation for producing a metal strip

InactiveUS6907915B2High possible strip qualityAvoid disadvantagesWork treatment devicesMaterial accumulating devicesRotational axisControl manner

The invention relates to a method and to an installation for producing a metal strip. The aim of the invention is to make sure that the metal strip formed in the casting installation passes through the first cooling and grain texturing phase substantially without being subjected to stress and without effects on the subsequent installations. To this end, the molten bath is fed to a two-roll casting device and a cast metal strip is formed in the casting gap between two casting rolls whose rotational axes lie in a horizontal plane (two-roll casting method), the thickness of the cast strip ranging between 1.0 to 20 mm, preferably between 1.5 to 12 mm. The cast metal strip that freely emerges downwards from the two-roll casting installation is directly deflected from the vertical casting direction to a substantially horizontal transport direction. The metal strip is taken up and conveyed in a controlled manner by means of a first drive roll stand that operates at a first transport speed. The metal strip is then stored for a short time in a strip accumulator, and is then taken up and conveyed by means of a second drive roll stand that operates at a second transport speed. In a final step, the metal strip is coiled up to a bundle under pretension.

Owner:VOEST ALPINE AG

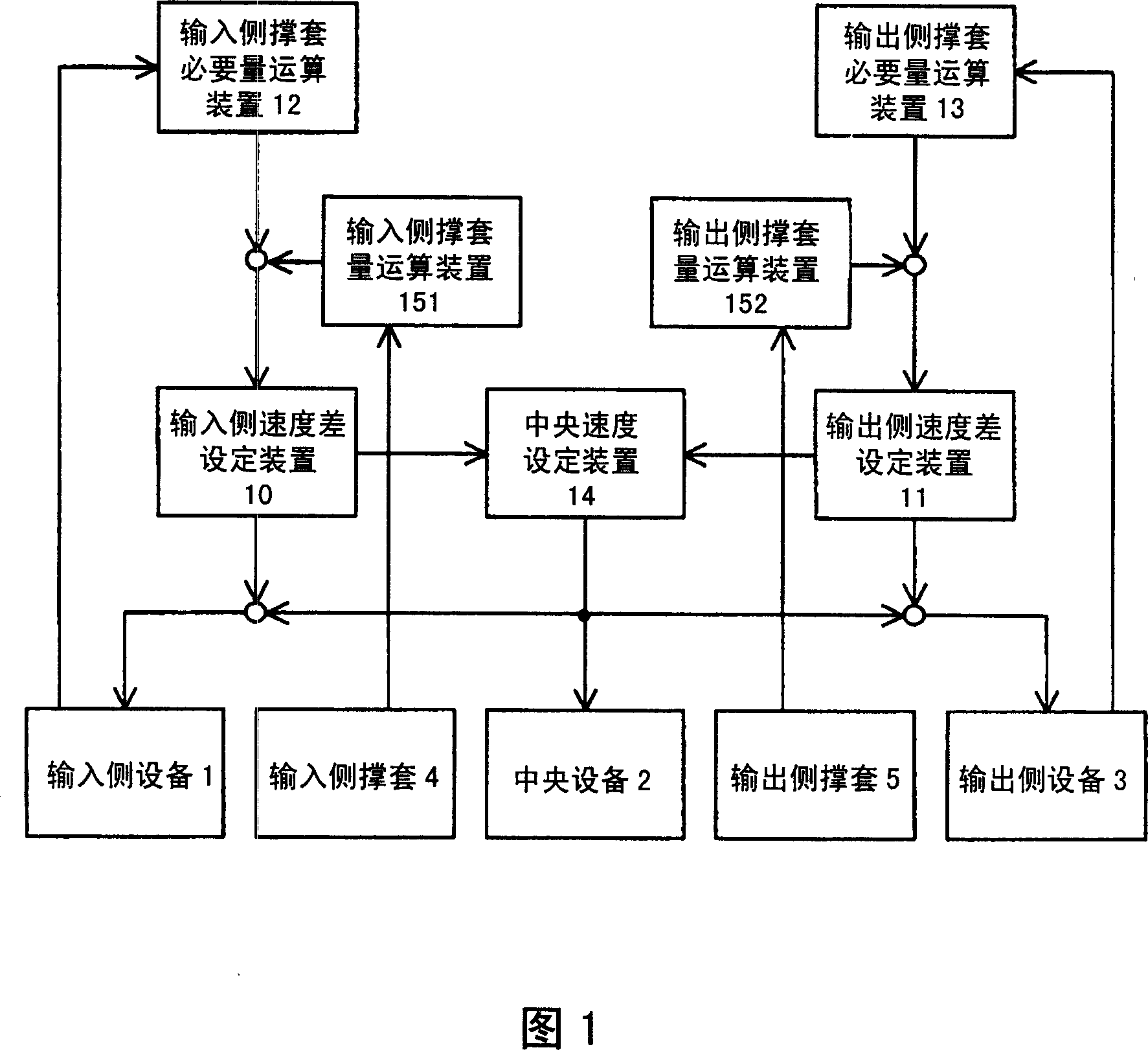

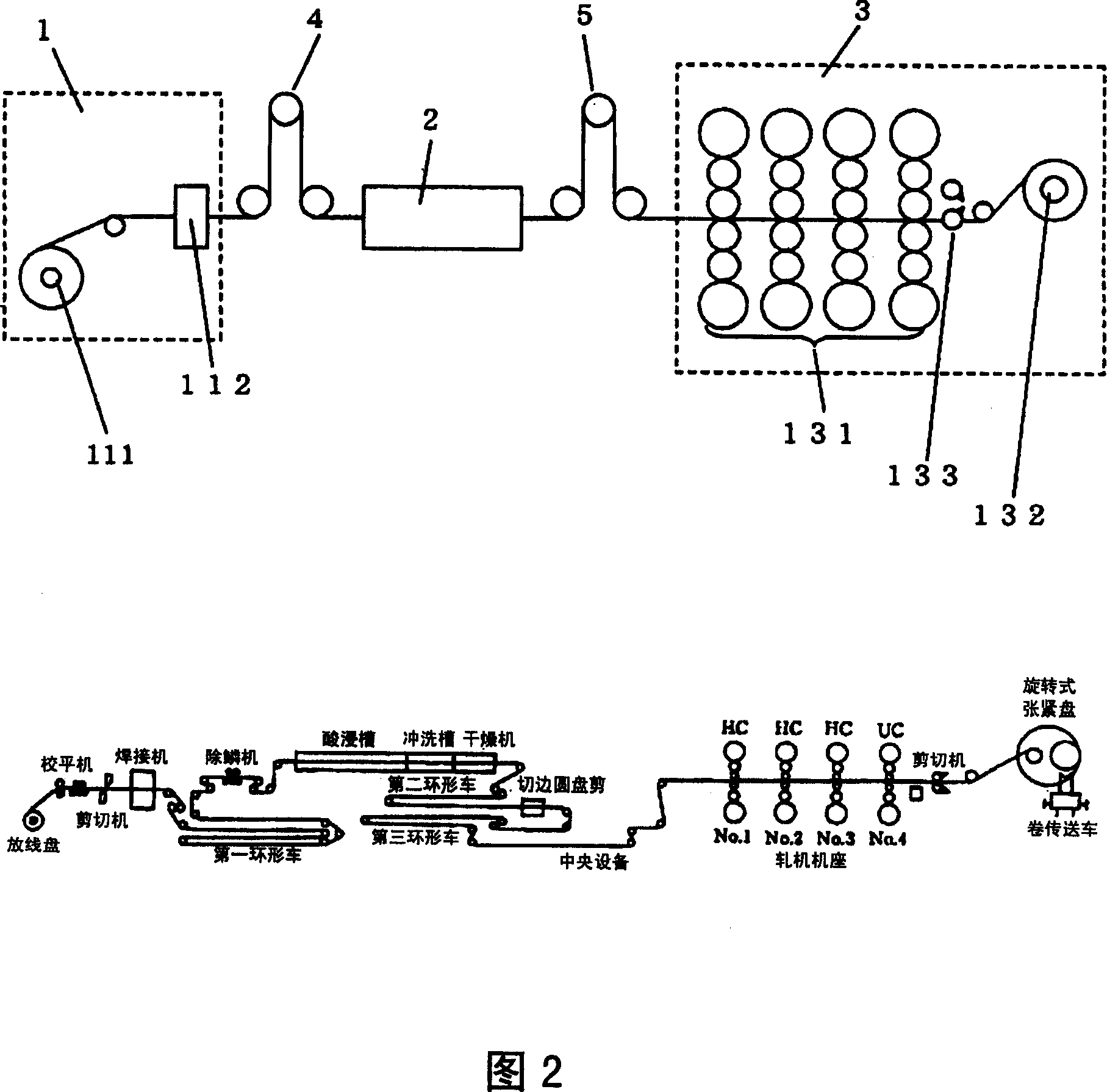

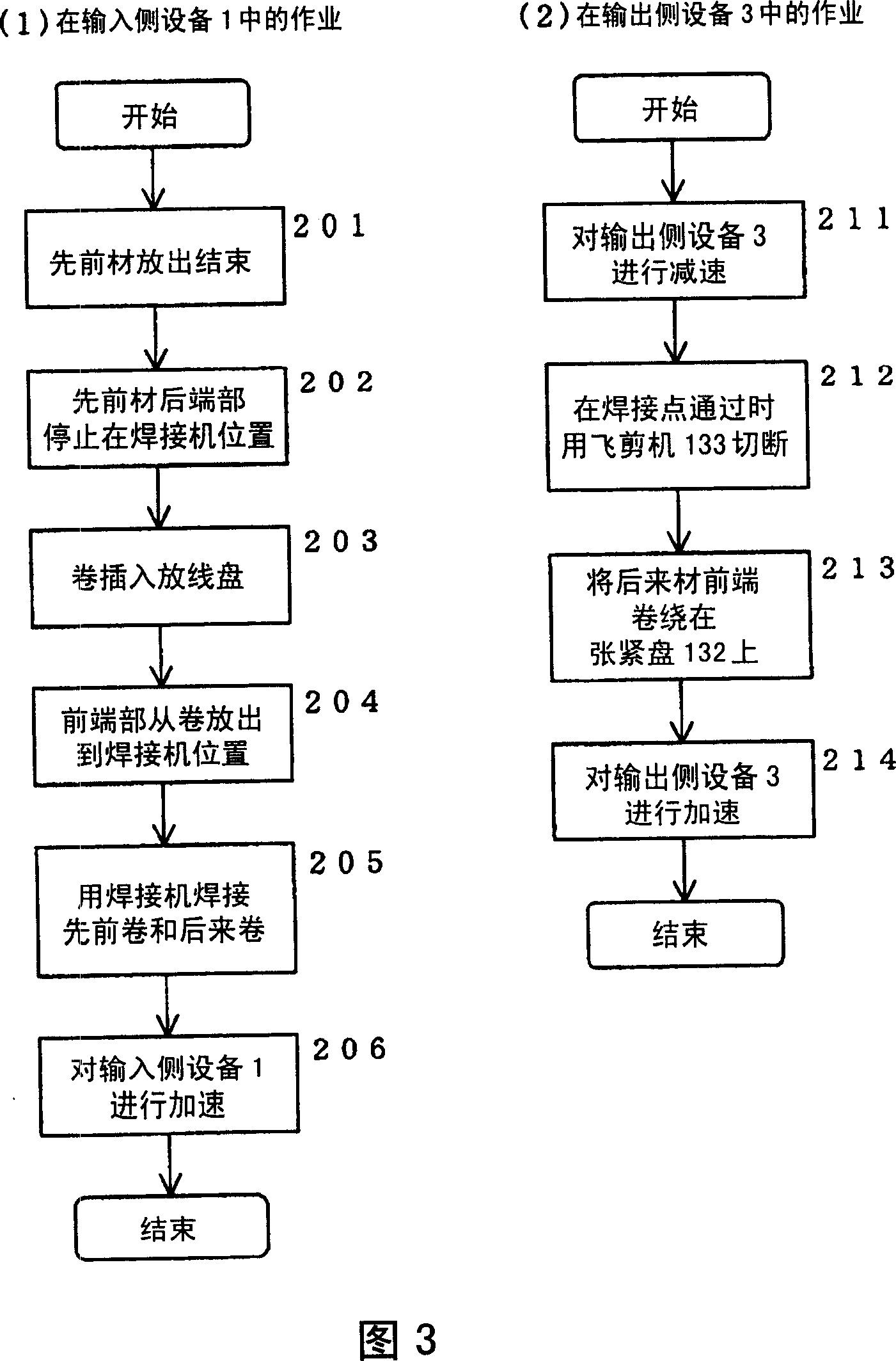

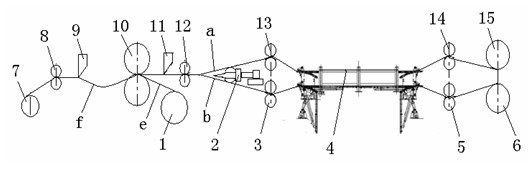

Speed control method of continuous processing apparatus

The invention provides a speed control method for continuous processing equipment capable of automatically arranging the transfer speed of the processing material. A continuous rolling apparatus has an input support sleeve 4 between an input device 1 and a central device 2, and an output support sleeve 5 between the central device 2 and an output device 3, wherein according to the operation state of the input device 1 and the output device 3, the necessary value of the input support sleeve 4 and that of the output support sleeve 5 can be obtained, and the speed difference between the input device 1 and the central device 2 and that between the central device 2 and the output device 3 are arranged, then the speed of each part can be controlled and the cumulating value of each support sleeve is converted to a necessary value.

Owner:HITACHI LTD

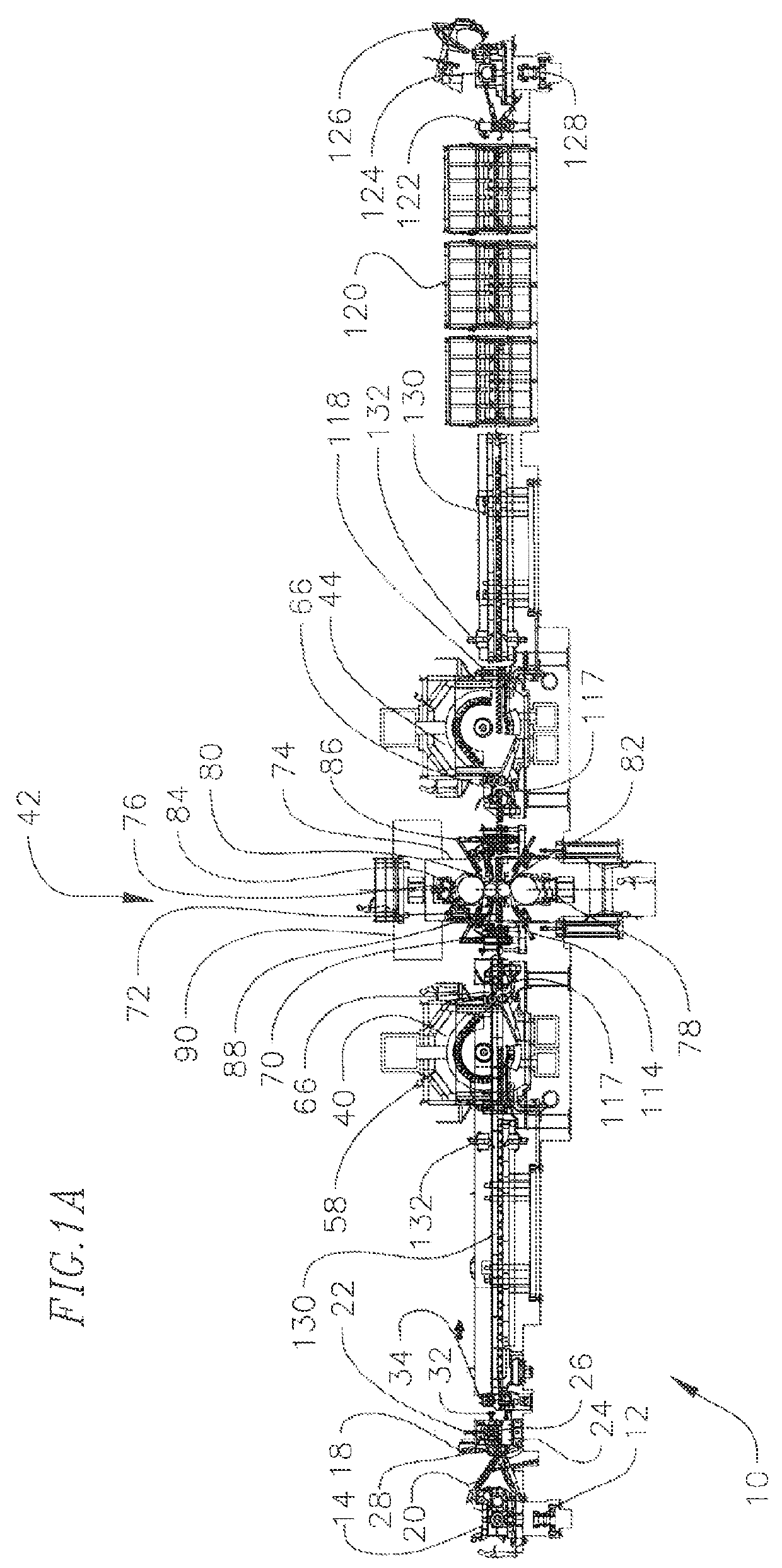

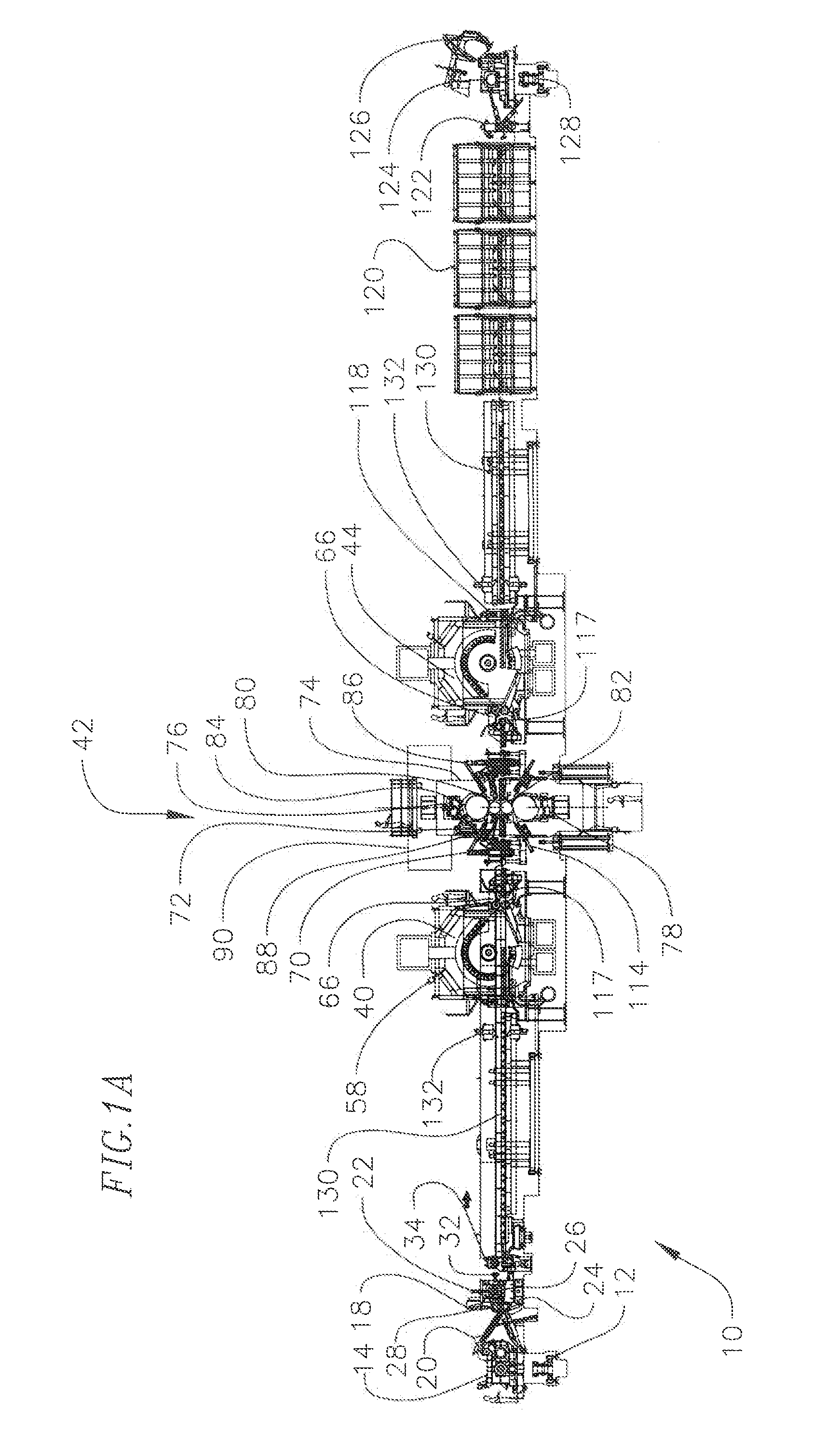

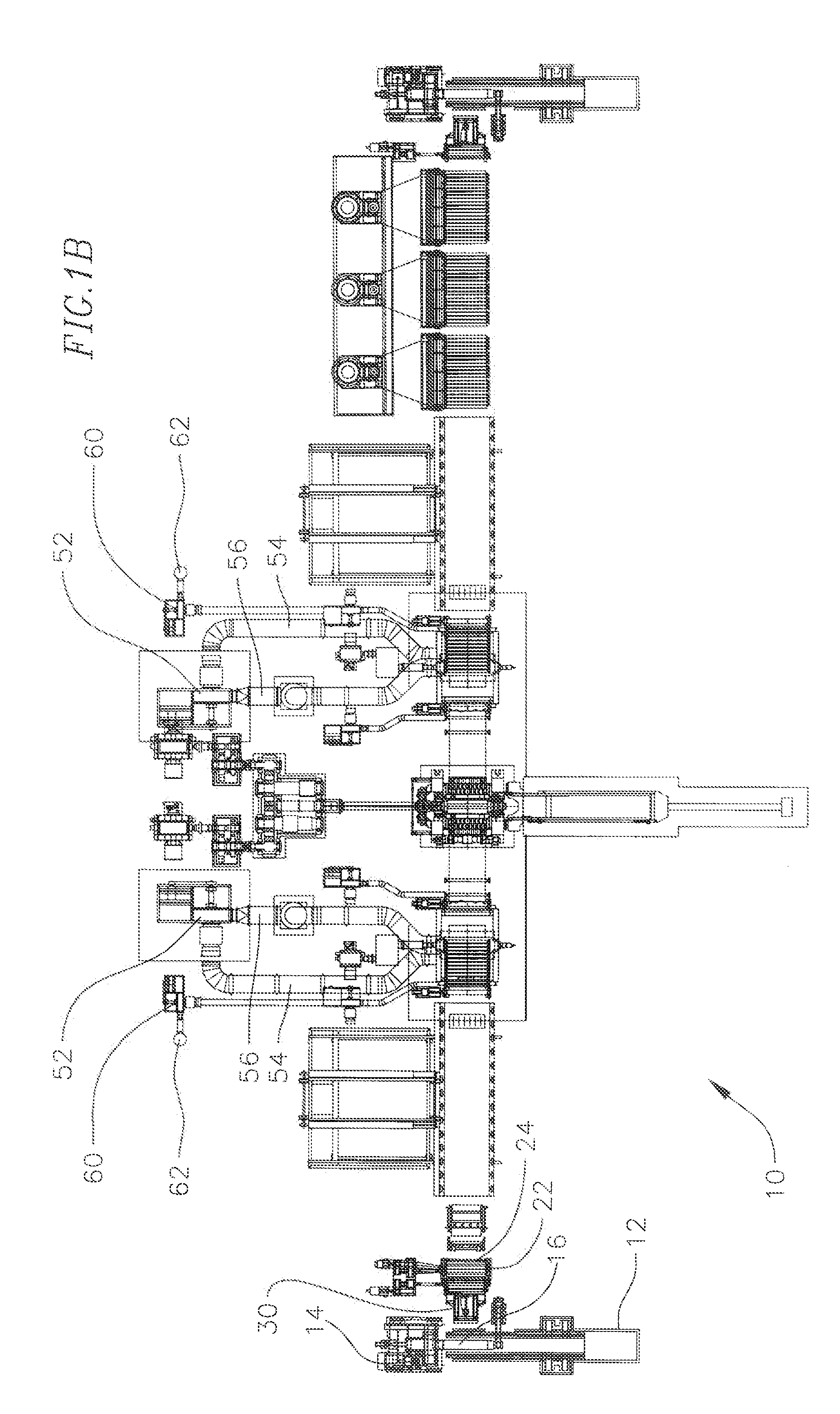

Apparatus for and method of manufacturing a helically wound tubular structure

InactiveUS20110277525A1Improve uniformityReduction or even elimination of downtime for reloadingMaterial accumulating devicesMetal rolling arrangementsMechanical engineeringSurface plate

An apparatus (50) for and method of manufacturing structures (116) includes coaxial rotating faceplates (74, 89, 97), capable of rotation at different angular speeds. A plurality of forming rollers (76) and diameter defining rollers (78) are mounted on the inner faceplate (74, 89), which, in operation, cause a strip material (80) to be plastically deformed into a helical winding which may be lain down in abutting or self-overlapping relationship to form said tubular structure (116). A plurality of support rollers are mounted in a circle on the inner faceplate (74, 89) at a distance from the axis exceeding that of the outermost forming roller and serve to support the stock of strip material.

Owner:ITI SCOTLAND

Adjustable vertical accumulator for slitting operation

InactiveUS7905443B2Overcome deficienciesEliminate needRecord information storageMaterial accumulating devicesMetal stripsHorizontal axis

A vertical accumulator for use in a sheet metal unwinding, slitting and rewinding operation accumulates the slack created in the plurality of strips cut from an initial wide coil so that the proper tension can be maintained on the individual strips being rewound. The accumulator includes an elongated mandrel mounted for rotation about a horizontal axis parallel to the axis of the original sheet metal coil and is arranged such that all of the plurality of cut strips pass over the top of the mandrel. The mandrel is located above the height of the coil and above the height of the slitter and the rewound individual strips. A plurality of disks mounted on the mandrel separate the cut strips from each other. Upwardly extending threaded rotatable rods located on either side of the sheet metal strips carry holders that releasably support the mandrel. Rotation of the rods causes the holders to move up or down to thereby adjust the height of the mandrel.

Owner:PAPANIA JAMES F

Device for trimming, shoveling and then coiling composite material plate

ActiveCN102581047AAvoid random scratchesAvoid wear and tearMaterial accumulating devicesAuxillary arrangementsCircular discScrap

The invention provides a device for trimming, shoveling and then coiling a composite material plate, including a decoiler, a straightener, an end shear, a disc shear, an accident treatment shear, a front pinch roller, a shoveling mechanism, a rear pinch roller, a tensioner and a coiler, characterized by further including a waste edge coiling mechanism and double layers of loops. At the same time of shearing the composite material plate, the shorn waste scraps are coiled; during the shoveling separation, the threading of an upper composite material plate and a lower composite material plate is smoothly completed, the surfaces of the upper and lower materials are effectively prevented from being scratched or worn, the quality of products is guaranteed, simultaneously, the adhered part between the upper material plate and the lower material plate is shoveled and cut via a flat head; during the individual coiling, the amount of loop is adjusted according to the actual demands in order to store the composite material plate temporarily, so that the stacking of steel is avoided effectively, the respective micro-tension adjustment is achieved, and asynchronous decoiling and asynchronous operating of different coilers are achieved, the equipment is effectively protected, and the coiling quality of products is improved.

Owner:YUNNAN HEAVY EQUIP MFG GRP +1

Sheet metal part production process facilitating feeding

InactiveCN112058944ANo manual operationSave human effortMaterial accumulating devicesOther manufacturing equipments/toolsPunchingIndustrial engineering

The invention relates to a sheet metal part production process facilitating feeding. The sheet metal part production process comprises the following steps that 1, a thin steel sheet coil is leveled, specifically, a leveling process is conducted, a thin steel sheet coil on an unwinding machine is pulled and conveyed into a shaping machine to be leveled; 2, the leveled thin steel sheet is cut, specifically, a cutting process is conducted, the leveled thin steel sheet coil is conveyed into a feeding machine to be cut; and 3, the cut thin steel sheet is conveyed into a pneumatic punching machine through a mechanical arm for punch forming; and in the above steps, a rotating roller is rotationally connected to the unwinding machine, a temporary storage table used for storing the thin steel sheetcoil is arranged beside the unwinding machine in a sliding mode, the temporary storage table slides towards the unwinding machine so as to sleeve the thin steel sheet coil on the rotating roller, conveying frames are fixedly connected between the unwinding machine and the shaping machine and between the shaping machine and the feeding machine, conveying mechanisms are arranged on the conveying frames. and guide mechanisms are arranged on the conveying frame close to the feeding machine. The sheet metal part production process facilitating the feeding has the effect of improving the thin steelsheet feeding condition.

Owner:湖南泰川宏业有限公司

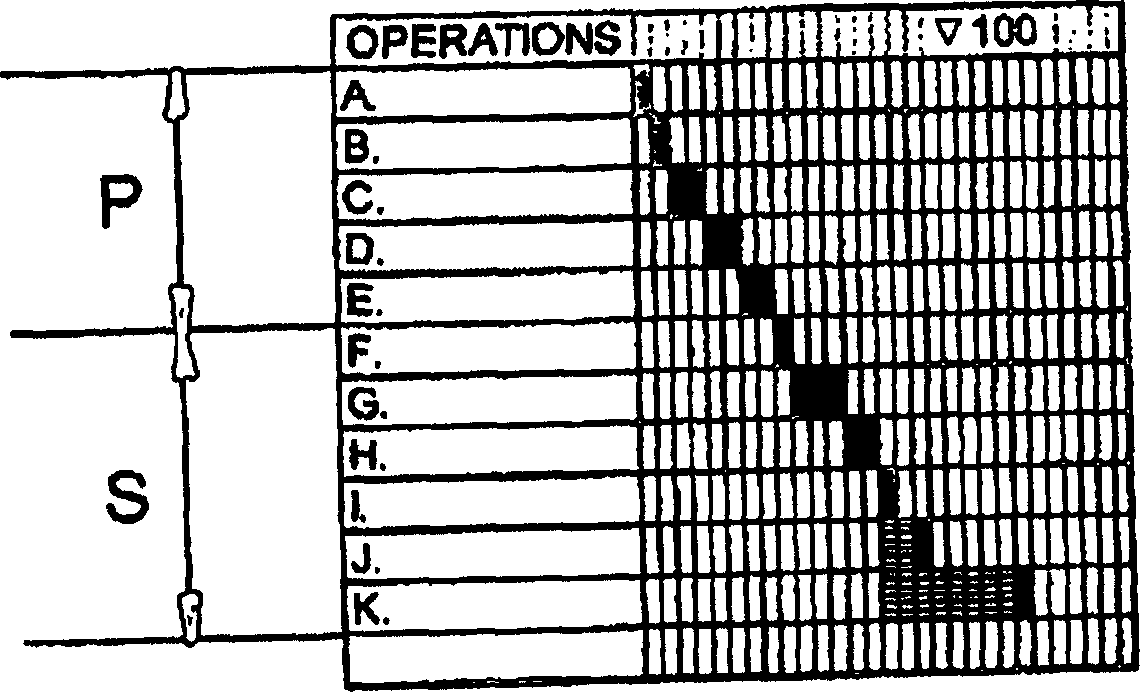

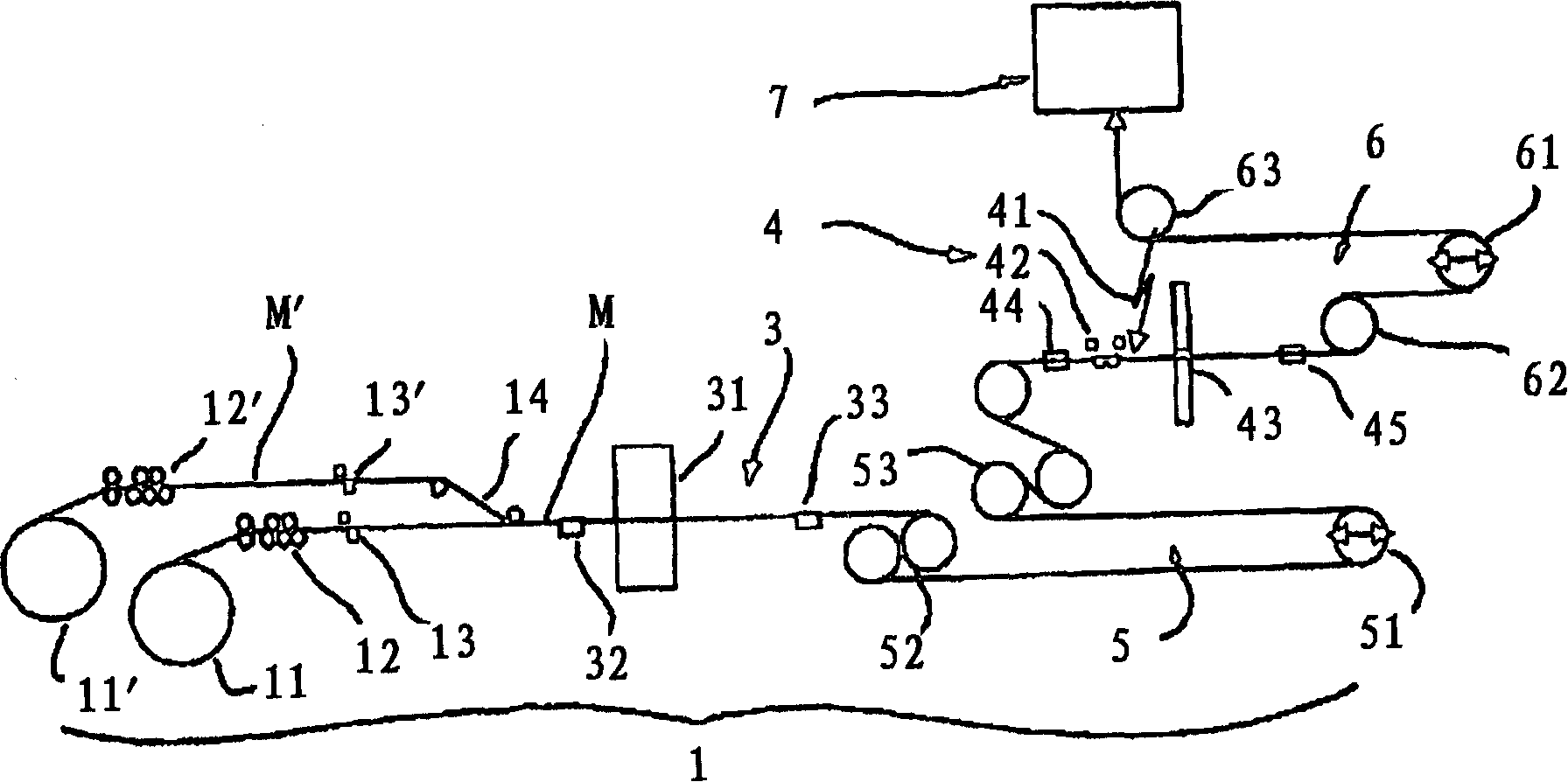

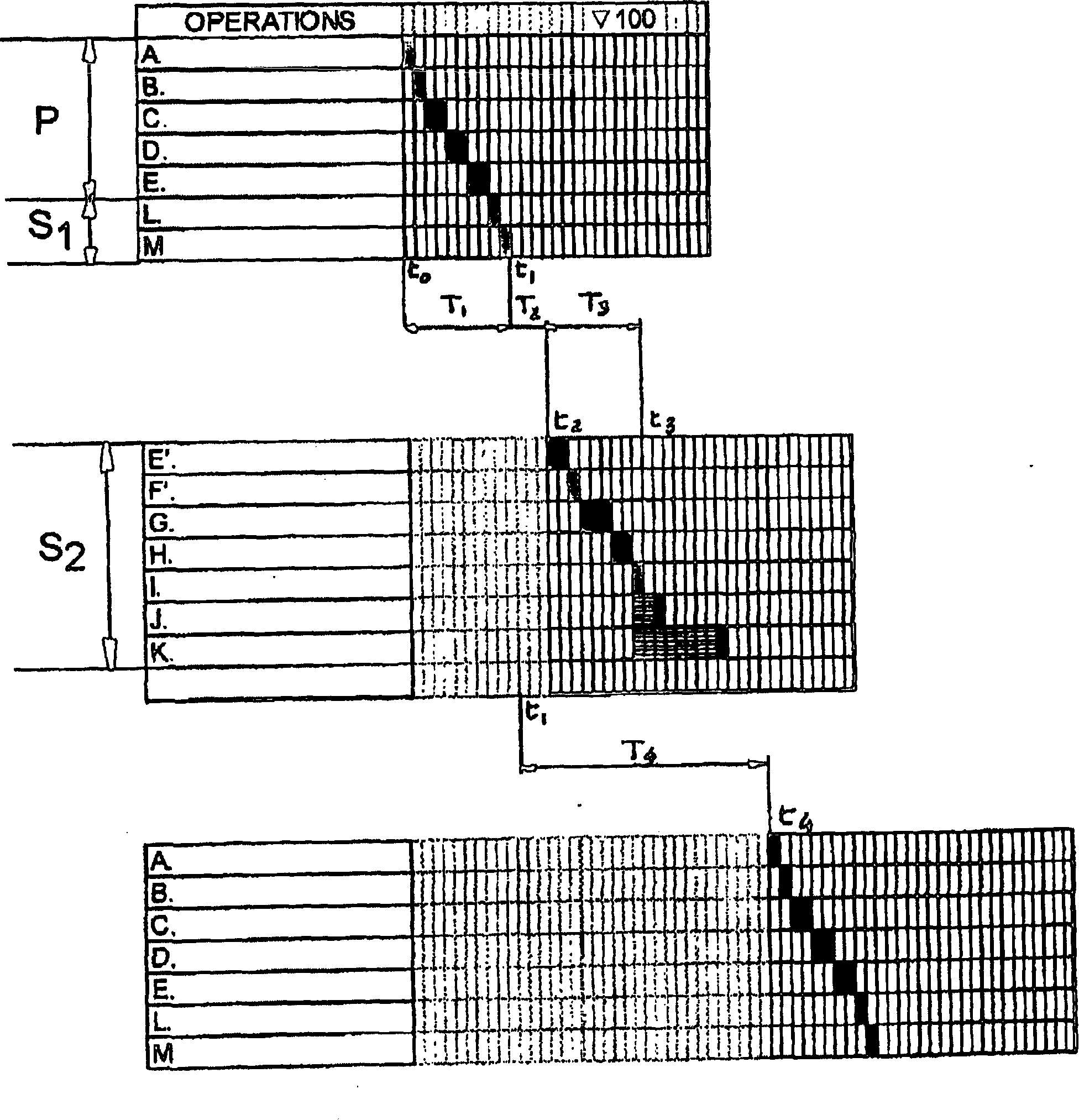

Management of the entry of a new coil in an installation for the continuous treatment of metal strip, specially applicable for pickling lines

InactiveCN101242915AReduce downtimeImprove productivityMaterial accumulating devicesFurnace typesProduction lineEngineering

The invention relates to a novel method for managing the entry of a new reel (11') in a continuous in-line installation for processing a strip-shaped product, in particular, for passing though the line of short reels. According to the invention, the overall time for carrying out the general method of connecting a new reel (11') is divided into at least two periods (T1, T3) realized in at least two successive portions (3, 4) of the entry section (1) of the installation, and the connection cycle is split into two separate phases (S1, S2) between which a variable length of strip is kept in at least one intermediate accumulator (5) in order to provide a time interval (T2) of a variable duration between these periods of the connecting method. The invention is used, in particular, in continuous steel strip pickling lines.

Owner:SIEMENS VAI METALS TECHNOLOGIES GMBH & CO

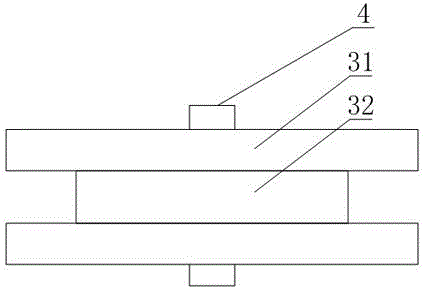

Aluminium strip enwinding device

InactiveCN104801568AAchieve stopQuality improvementMetal-working feeding devicesMaterial accumulating devicesEngineeringHot plate

The invention discloses an aluminium strip enwinding device. The device is used to accommodate aluminium strips of the edge covers of an electric hot plate and feed a curling machine. An electric hot plate edge cover aluminium strip shelf comprises a bracket and a belt wheel fixed on the bracket; the belt wheel comprises two side plates and a central plate arranged between the side plates; the side plates and the central plate all adopt round plates; the axes of the two side plates and the central plate are collinear; the diameter of the central plate is smaller than those of the side plates; a rotation shaft is fixed on the belt wheel as well; a shaft seat used to clamp the rotation shaft is arranged on the bracket; a pre-tightening part is fixedly connected with the bracket; a flexible part is arranged between the pre-tightening part and the belt wheel. The device is simple in structure and convenient for regulating the tensile force of aluminium strips and can improve the assembly quality and assembly efficiency of the electric hot plate.

Owner:CHENGDU YANGZHONG NEW ENERGY TECH

Magnesium roll mill

ActiveUS20120227455A1Good molding effectGood quality surfaceMaterial accumulating devicesFurnace typesWork rollMagnesium

A magnesium hot rolling mill system including a rolling mill having at least two work rolls for rolling of magnesium sheet or plate, a hot coiler positioned on either side of the rolling mill for heating and maintaining a desired temperature of the magnesium sheet or plate, active thermal roller tables, a mill drive system for independently driving the work rolls for asymmetrical rolling of the magnesium sheet and a warm coil loading and payoff station.

Owner:DANIELI & CO

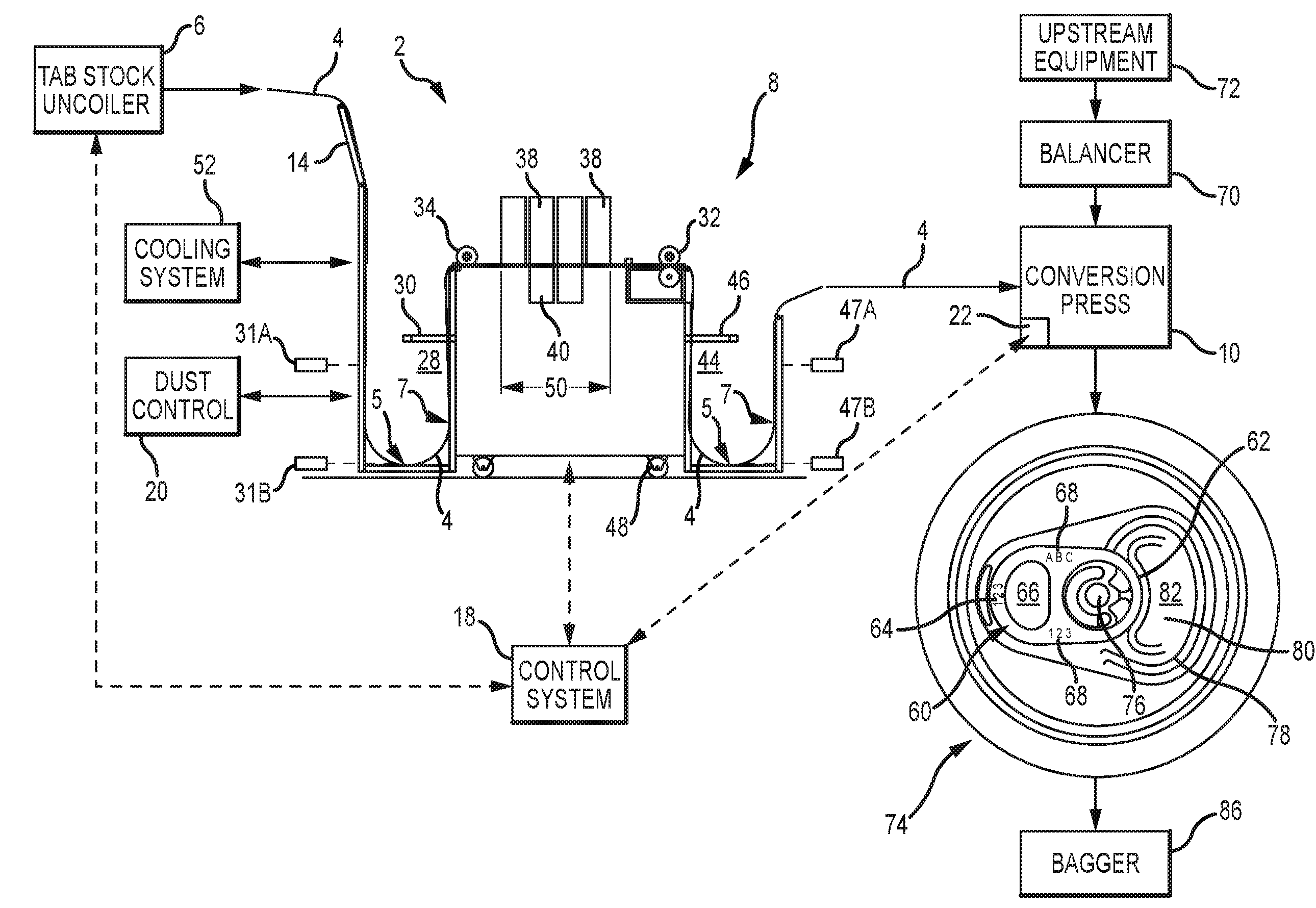

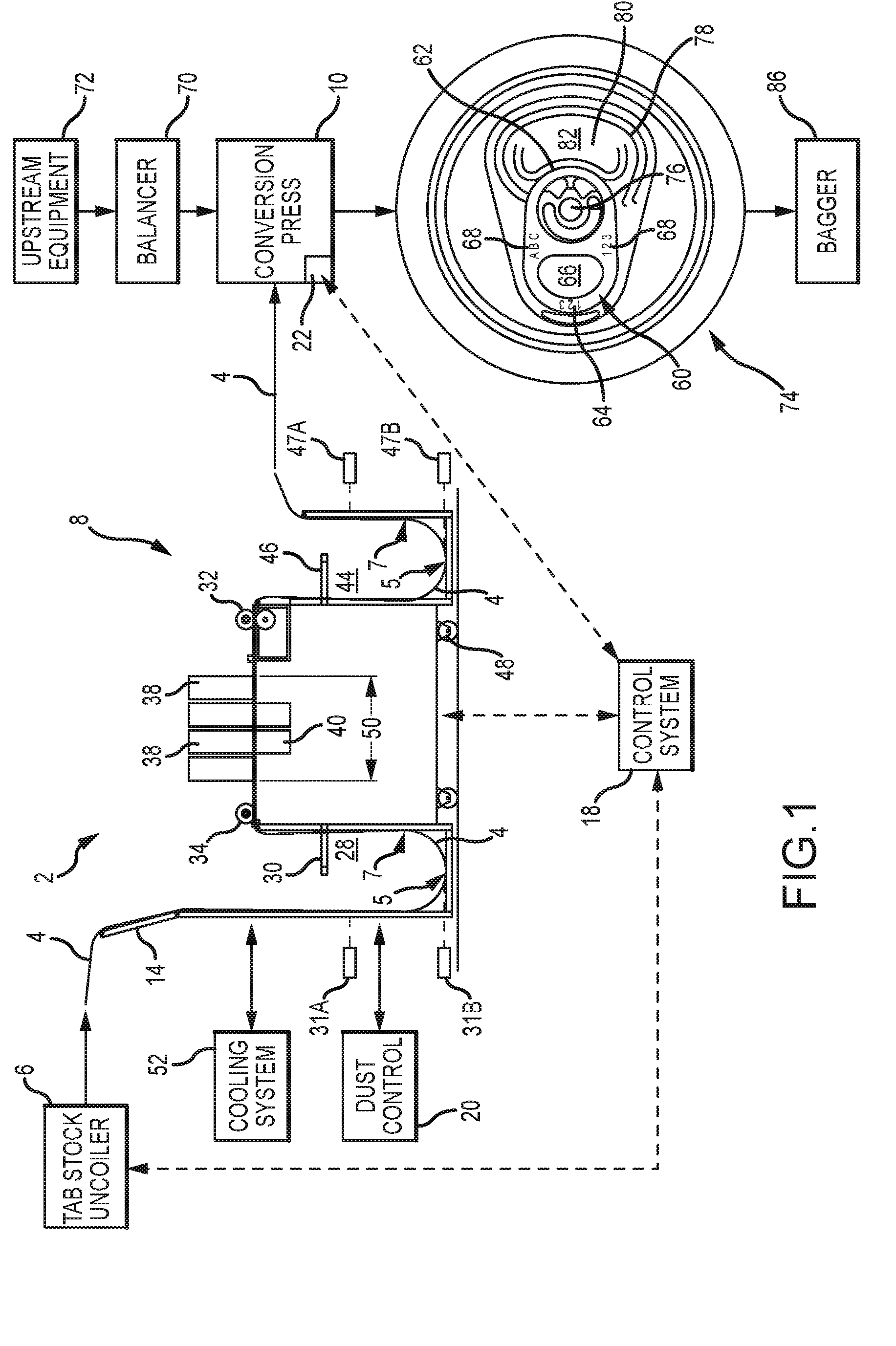

Method and Apparatus for Controlling the Speed of a Continuous Sheet of Material

ActiveUS20160306347A1Cost-effective and fast and reliableExtended availabilityMetal-working feeding devicesFunction indicatorsManufacturing systemsSheet material

A system and method of controlling the input and output speed of a continuous sheet of stock material is provided. More specifically, the present invention relates to a system and method used to perform an operation on a continuous sheet of stock material in a high speed manufacturing system. The continuous sheet of stock material may subsequently be received by a second system that performs a different operation on the stock material. In one embodiment, the second system forms the stock material into tabs for container end closures. The system includes an infeed accumulation device and an outfeed accumulation device. The infeed and outfeed accumulation devices enable the system to operate at a variable rate and out of phase with a high speed, coil fed manufacturing system to which the system may be removably integrated.

Owner:BALL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com