Management of the entry of a new coil in an installation for the continuous treatment of metal strip, specially applicable for pickling lines

A control method and strip technology, applied in heat treatment furnaces, heat treatment equipment, metal processing equipment, etc., can solve the problems of aggravated filler shortage and frequent strip size changes, so as to improve productivity, increase actual processing speed, and facilitate The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

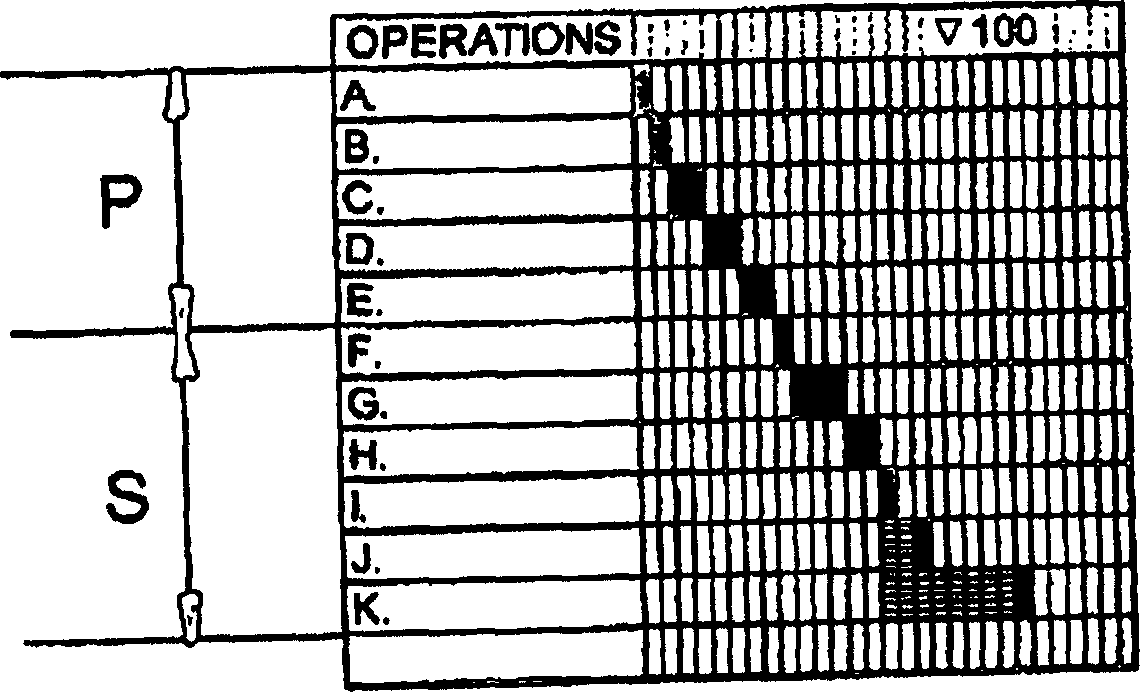

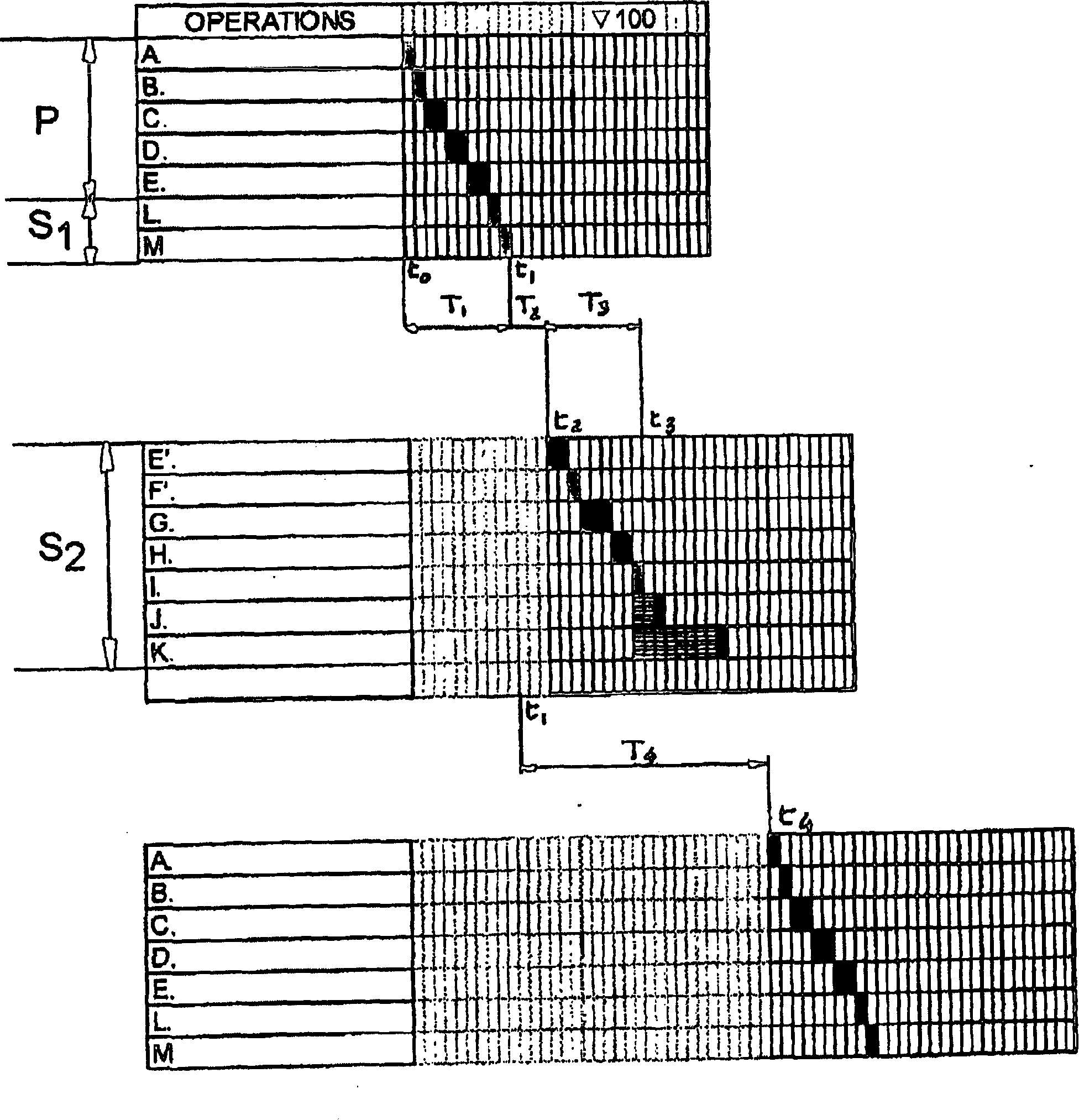

[0078] [78] As noted above, figure 1 The graph in represents the time taken for the different steps A to I in the overall connection process carried out in the usual way in the input section of the continuous in-line processing unit.

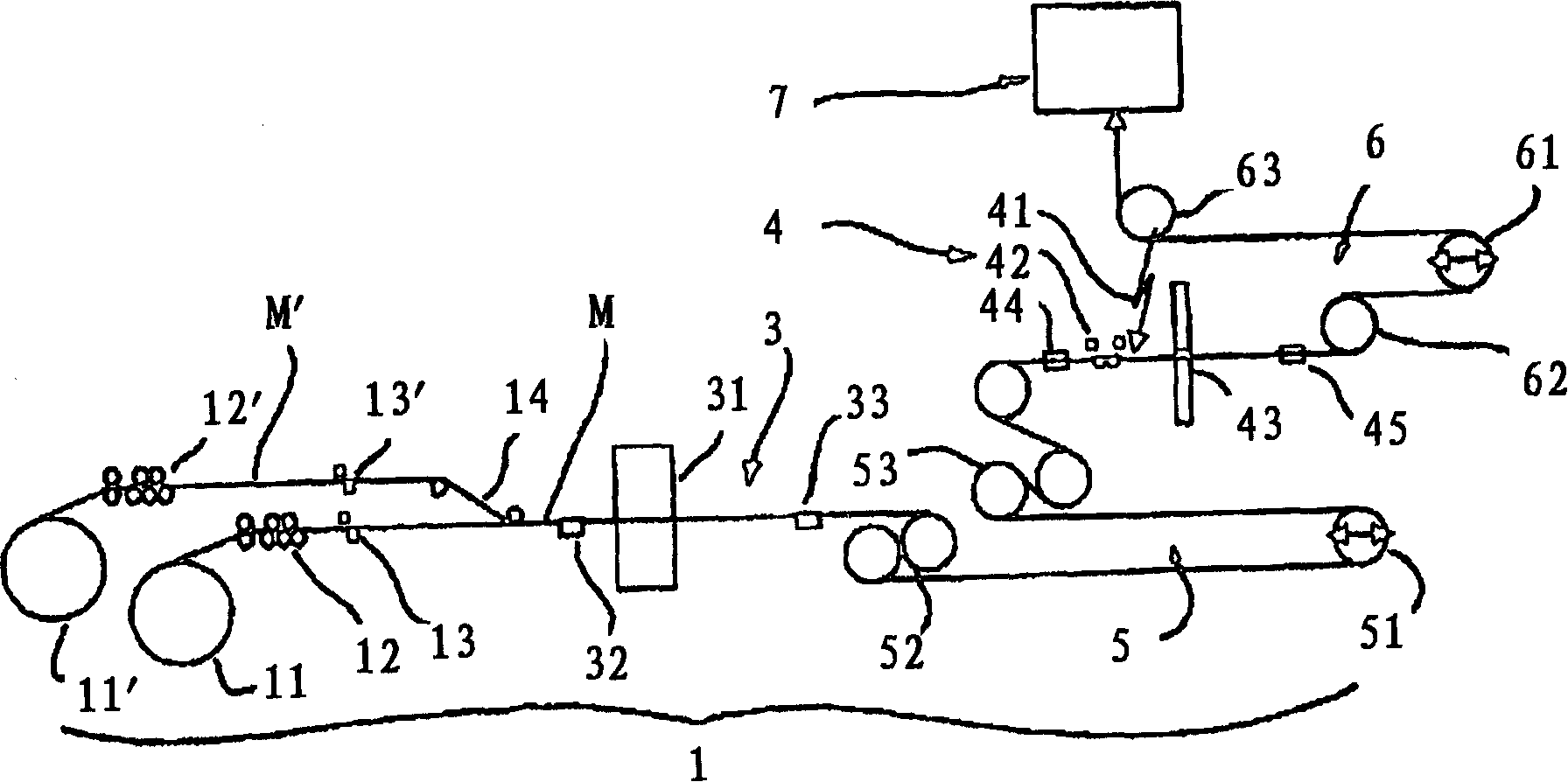

[0079] [79] figure 2 Schematically represents the structure of the input section in the advanced plant according to the first embodiment of the present invention.

[0080] [80] As usual, the strip to be processed can be unwound from either of the two uncoilers 11, 11', both of which are connected to the device 12 for unwinding and straightening the strip. , 12' are connected, and are connected with the cutting head machine 13, 13'. A switching device 14 is able to insert the strip M or M' from the unwinder 11, 11' respectively into the input section.

[0081] [81] According to the invention, the inlet section 1 is divided into two parts 3, 4, between which an intermediate accumulator 5 is arranged. As usual, after exiting the input section,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com