Device and method for winding sheared waste from steel band edges

An edge and waste technology, applied in the field of edge shearing waste devices, can solve problems such as hard work and achieve the effect of increasing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

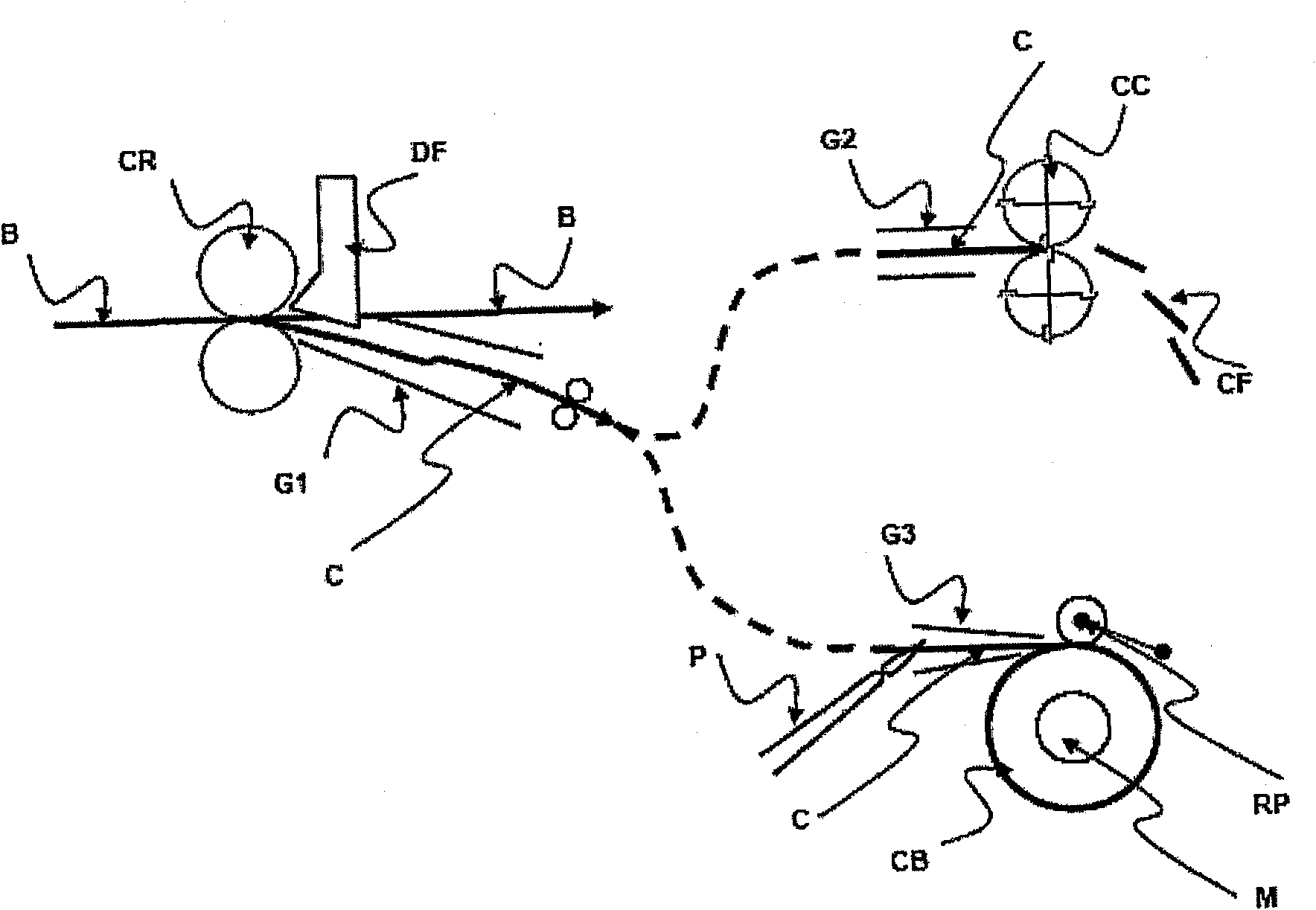

[0042] figure 1 Side view showing the principle of operation of the edge shear CR and removal of the scrap C, i.e. a view in the direction of travel of the strip B whose edges are sheared to form scrap to be removed to the strapping machine .

[0043] The strip B thus passes through the edge shears CR and the waste C output from the two circular blades (on the right and left inner sides of the strip) is deflected by the deflector DF in the direction of the shredder or strapping device. The trough G1 is deflected. The edge cutter consists of two symmetrical heads, each cutting one of the two edges of the strip.

[0044] In the case of shredding, the scrap C arrives through an additional chute G2 between the rotating drums of the scrap cutter CC, whose knives ensure that the strip is cut across its width in a sequential and periodic manner. Broken off on the CF. Thus, the size of the resulting tape piece allows for easier removal.

[0045] In the case of strapping, the scrap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com