Plastic working method and plastic working system

一种加工系统、加工方法的技术,应用在金属加工设备、制造工具、薄料处理等方向,能够解决精度降低、重复精度低等问题,达到生产率提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

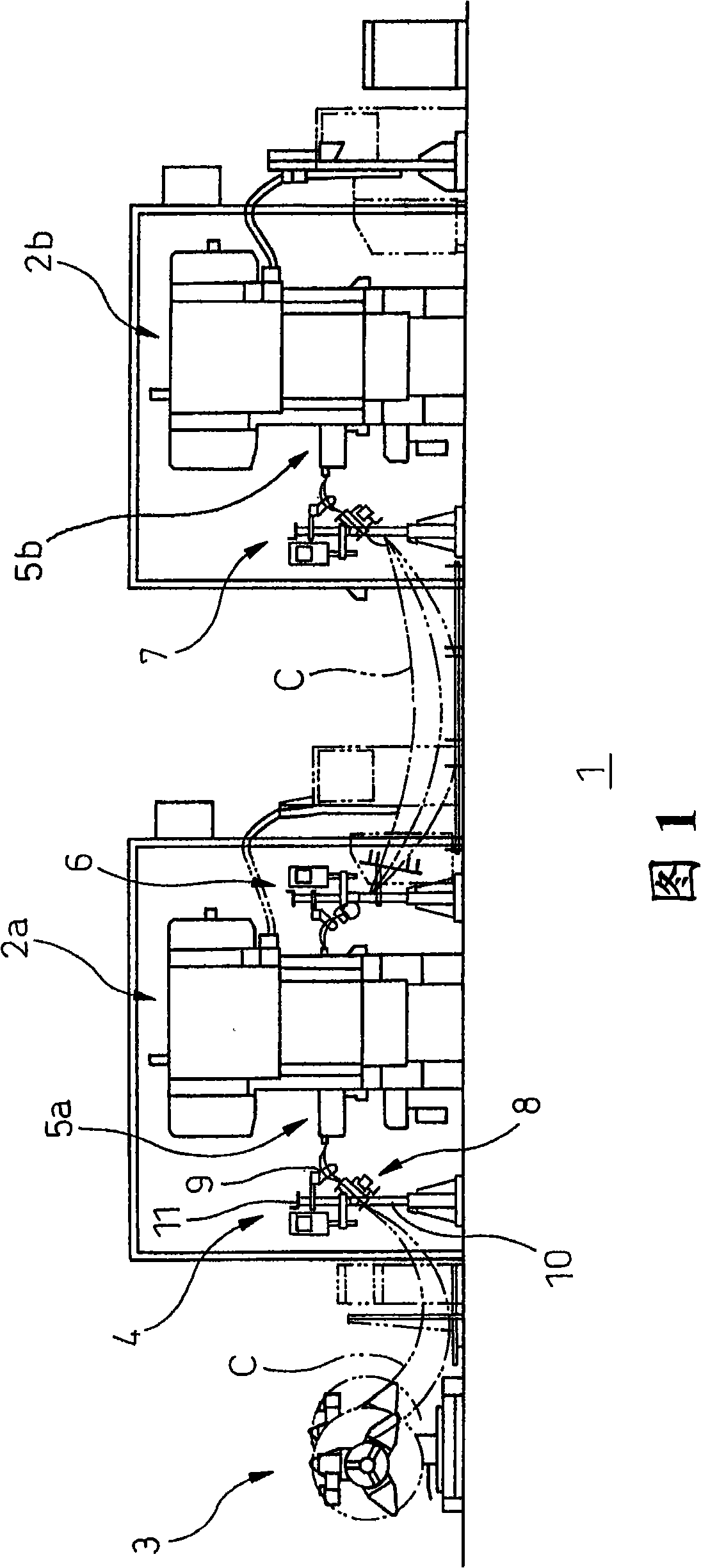

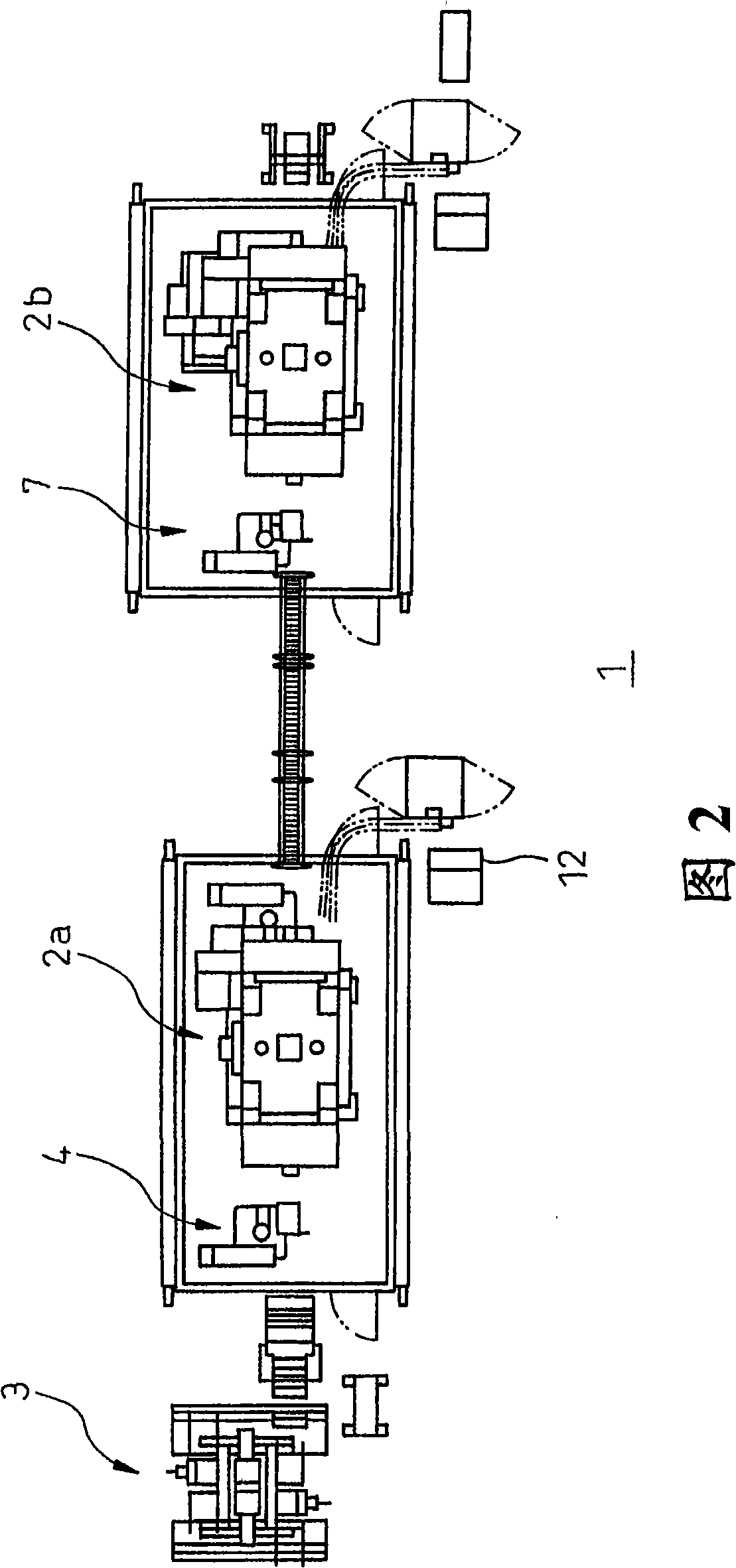

[0034] Fig. 1 is a view showing a compaction processing line 1, which is an example of the plastic processing system of the present invention.

[0035] The compaction processing line 1 includes two sets of compaction devices 2 for carrying out predetermined compaction processing on a coil C (ie, a workpiece). These two sets of compression devices 2 are referred to as the first compression device 2a and the second compression device 2b below.

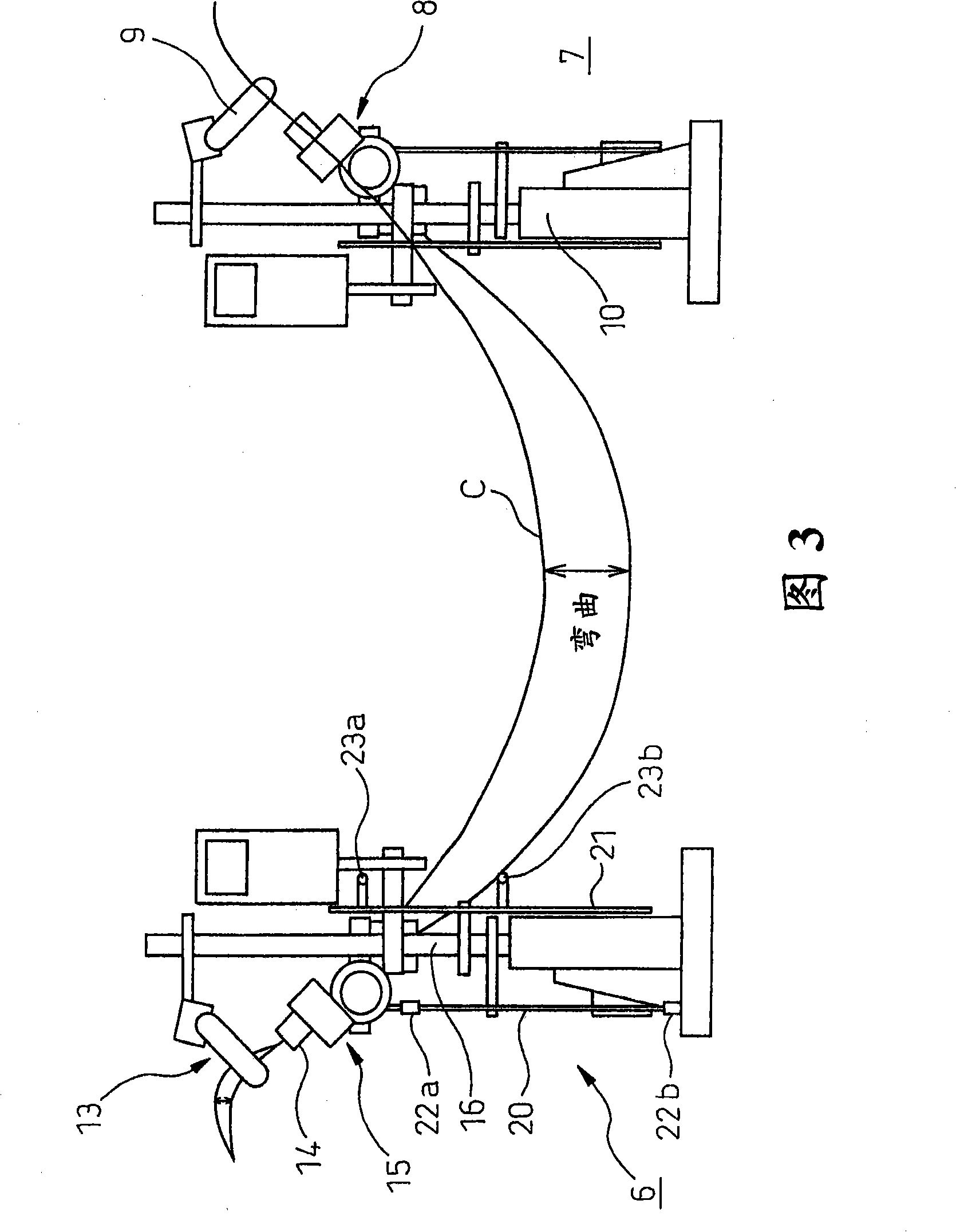

[0036] In other words, the compaction processing line 1 includes: an uncoiler 3, that is, a conveying device for conveying the coil C; a first feeding device 4; an intermittent feeding mechanism 5a; a first compacting device 2a, that is, the previous compacting device tightening device; feeding regulating device 6; second feeding device 7; intermittent feeding mechanism 5b;

[0037] The first and second pressing devices 2a, 2b each have a metallic mold for performing a predetermined pressing process. In this connection, the basic const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com