A mixer with gas agitation for chemical and pharmaceutical use

A mixer and gas technology, which is applied to mixers, mixers, chemical instruments and methods with rotary stirring devices, etc., can solve the problems of increased twisting force of the stirring mechanism, deformation and aggravation of the stirring mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

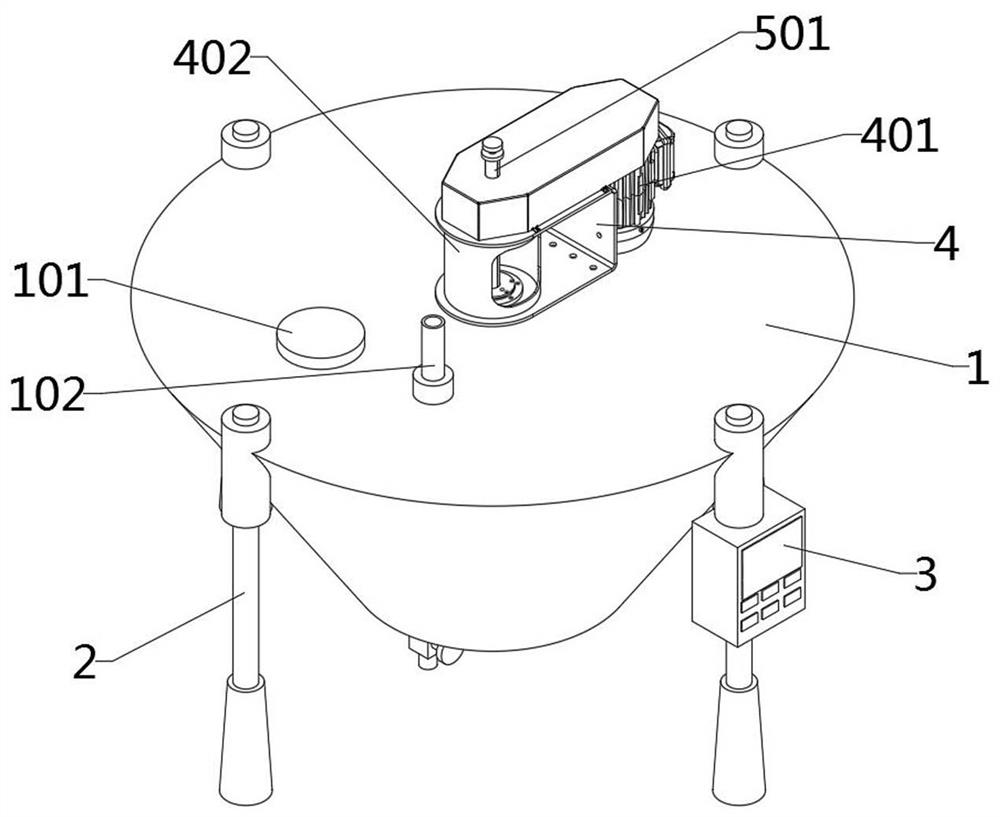

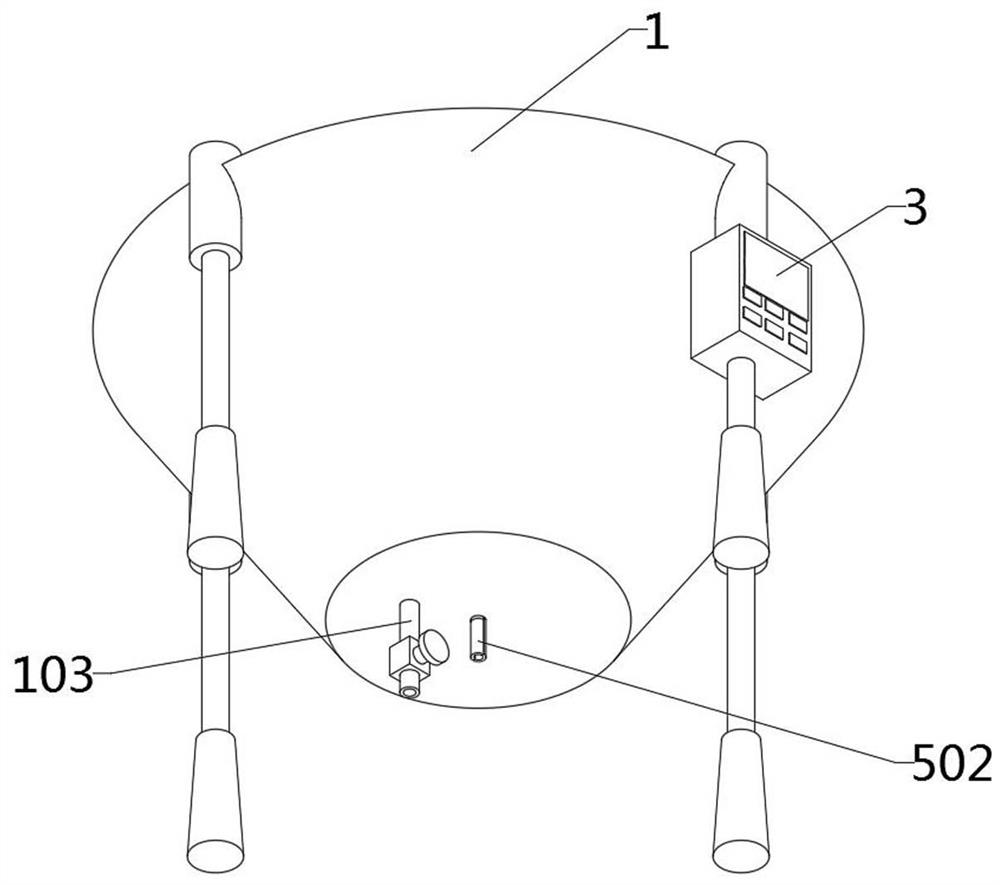

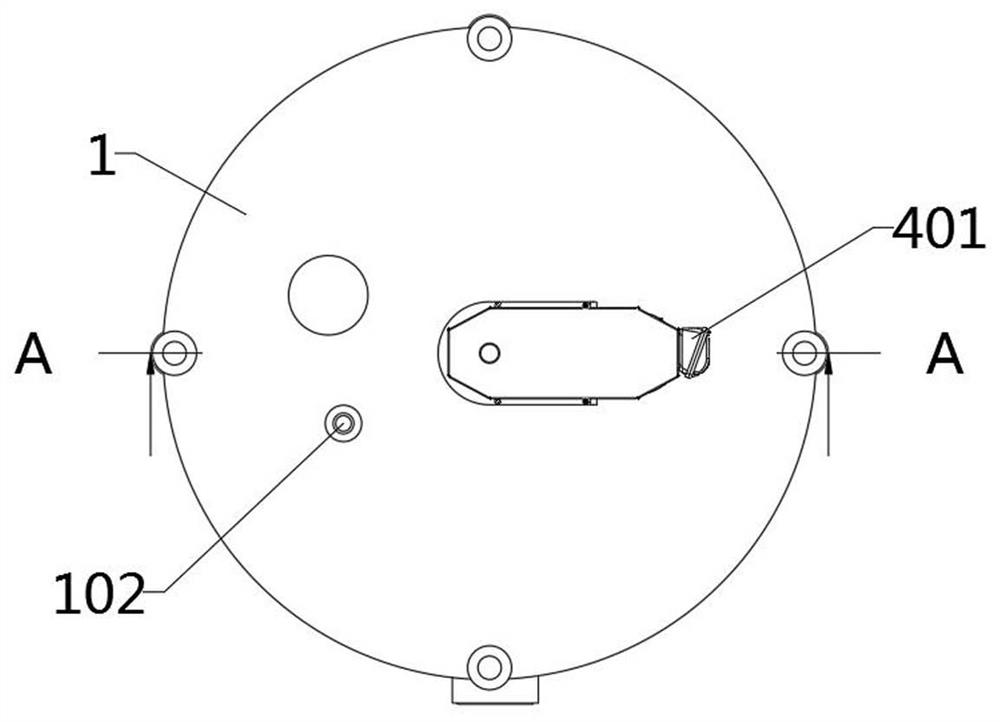

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The invention provides a mixer with gas agitation for chemical industry and pharmacy, which includes a mixing tank 1; the mixing tank 1 is a truncated cone-shaped structure with a wide top and a narrow bottom. Supporting feet 2, one of which is fixedly installed with a control box 3; the driving unit 4 is fixedly installed in the middle of the upper end of the mixing bucket 1; the pneumatic shaft 5 is installed in the mixing bucket 1 for vertical rotation; 1. At least six scrapers 7 are installed in the annular array at the lower part of the inner cavity; the six scrapers 7 are connected by a series ring 8; the upper end of the scraper 7 and the pneumatic shaft 5 are connected by turning The plate 9 is connected with the stationary phase; the air outlet pipe 10 is installed on the pneumatic shaft 5 between the liquid turning connecting plate 9 and the lower end of the scraper 7;

[0036] Such as Figure 4 , Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com