A connection node between low-damage self-resetting shear walls and horizontal members

A technology of horizontal components and connecting nodes, applied in building components, building structures, building types, etc., can solve the problems of affecting the seismic performance of the overall structure, floor cracks, affecting the floor, etc. The effect of assembly construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

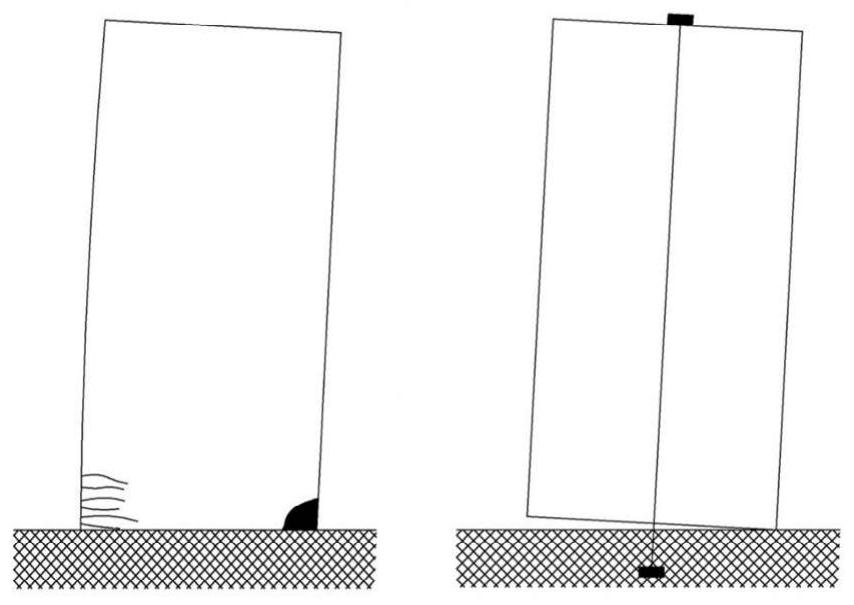

[0044] In this embodiment, the horizontal component is the floor 2. When the self-resetting shear wall adopts an embedded arrangement, the self-resetting shear wall is adjacent to the floor, and there is deformation inconsistency between them.

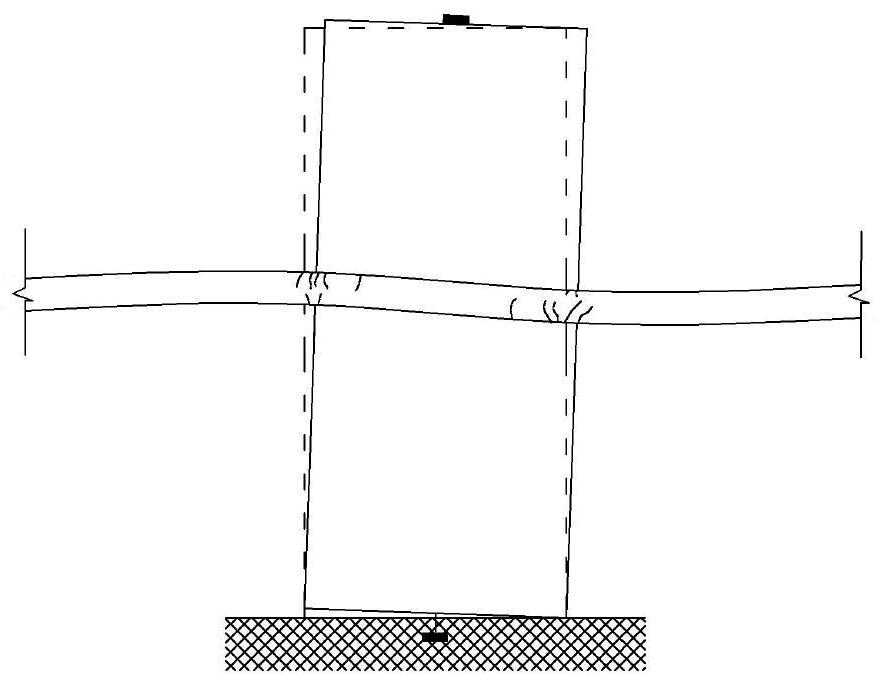

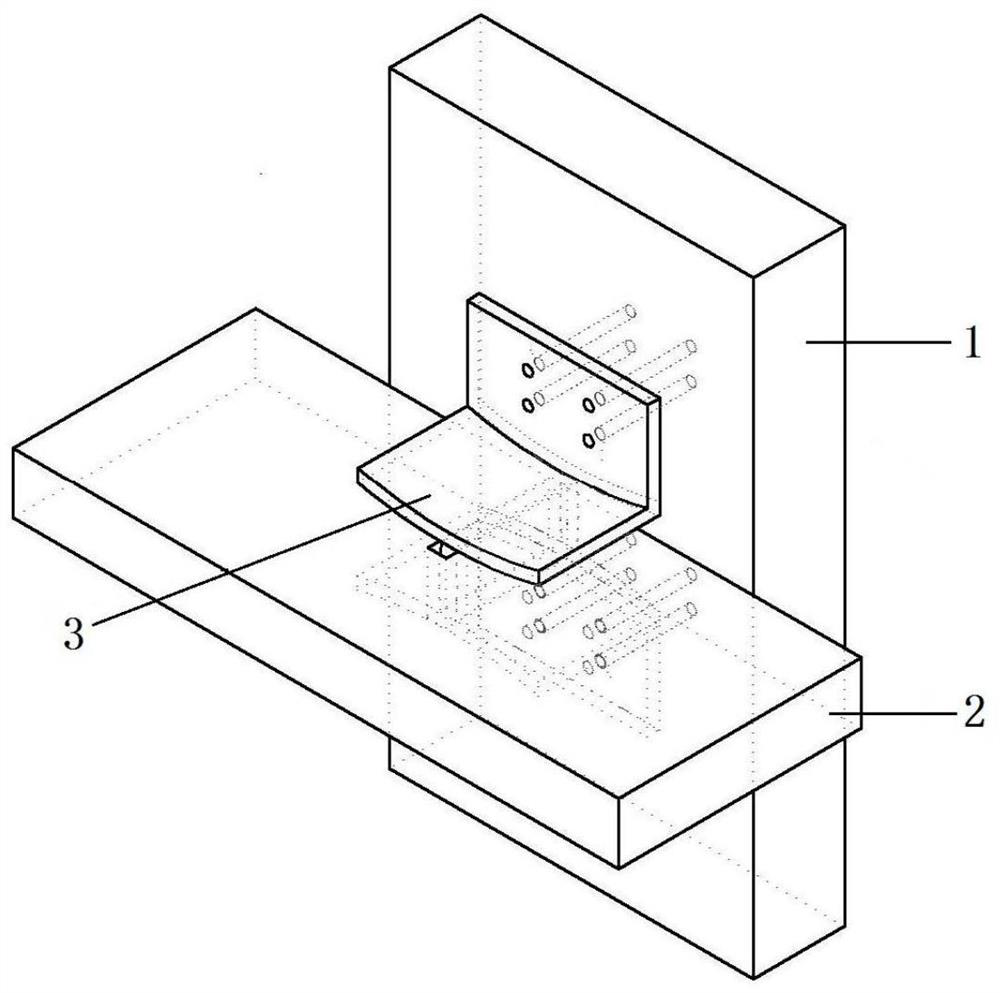

[0045] Such as Figure 1-5 Shown: a connection node between a low-damage self-resetting shear wall and a horizontal member, which includes a self-resetting shear wall 1, a floor 2, and a steel connector 3;

[0046] The floor 2 is rectangular, and a groove 2-1 is vertically provided on the outside of one of the long sides;

[0047] Such as Figure 3-2 As shown: the steel connector 3 includes an upper angle steel 3-1, a lower angle steel 3-2 and a connecting rod 3-3 connected between the fold lines of the upper and lower angle steels, and the two ends of the connecting rod 3-3 are respectively Shrink inward to form an arc;

[0048] First, fix the floor 2 and the steel connector 3; place the floor 2 horizontally between the plates of t...

Embodiment 2

[0066] Such as Image 6 As shown: in this embodiment, the horizontal member is a frame beam 9, and frame columns 8 are arranged on both sides of the frame beam 9; when the self-resetting shear wall 1 adopts an external hanging arrangement or is used to The shear wall is adjacent to the frame beam 9 at the corresponding floor position, and there is deformation inconsistency between them.

[0067] The middle part of the steel connector 3 is engaged with the frame beam 9 with a reserved groove, the distance between the upper and lower angle steels is slightly larger than the height of the frame beam 9, and the vertical and rotational degrees of freedom are loosened by corresponding radian design. Its mechanism of action and construction and installation method of present embodiment and embodiment 1 are all the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com