Steel pipe collecting device

A technology for collecting devices and steel pipes, applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve problems such as surface quality impact, worker health damage, steel pipe surface scratches, etc., to improve surface quality, reduce damage, and reduce friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

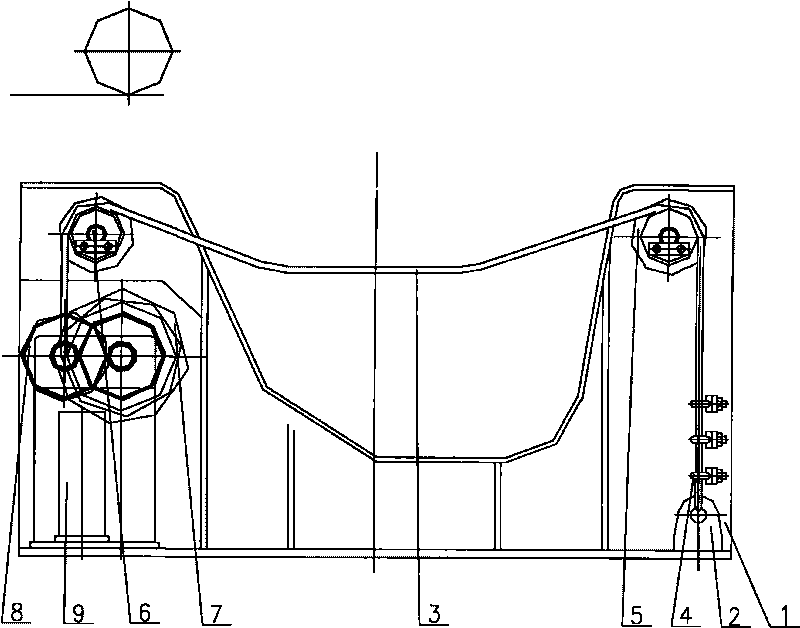

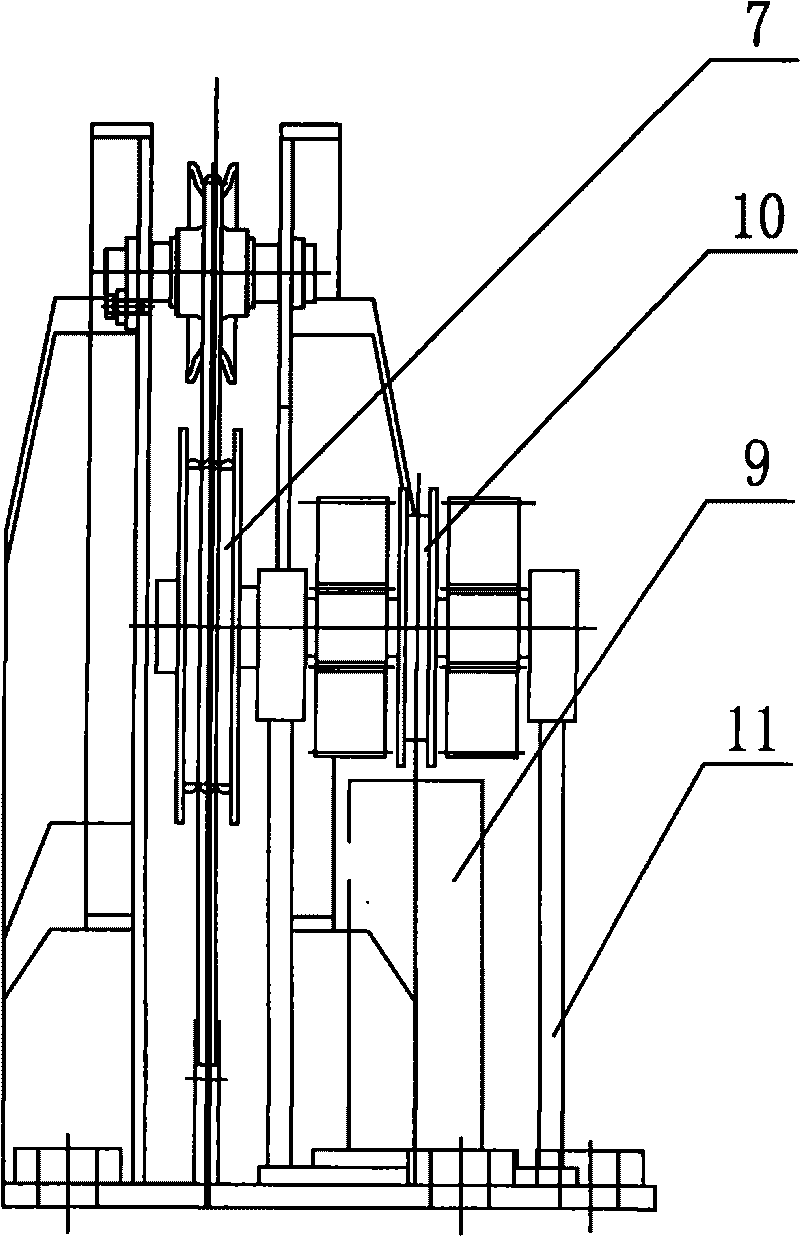

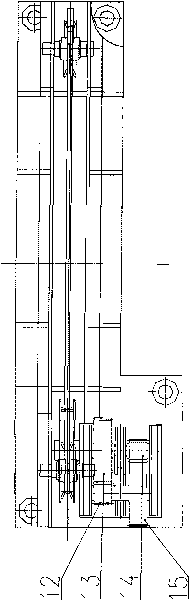

[0015] In order to meet the steel pipe surface quality requirements, reduce noise, and improve the working environment in the work area, the invention discloses a steel pipe collecting device.

[0016] See figure 1 , the device includes a material basket 1, a buffer device 3, a guide wheel 5, a retractable reel 7, a transmission mechanism 8 and a spring box 9, the material basket 1 is a steel structure, and the material basket 1 is fixed on the foundation through anchor bolts, The center of material basket 1 is a collection tank. In order to meet the requirements of steel pipe bundling, the side wall of the collection tank adopts a slope design. The reel support 11 is welded on the base plate of the material basket 1, the spring box 9 is installed on the base plate of the reel support 11, and the transmission mechanism 8 is installed on the side plate of the reel support 11. The two guide wheels 5 are respectively installed on the side plate of the material basket 1 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com