Equipment for rolling round thread into flat thread

A technology of equipment and round wire, which is applied in the direction of accumulating material equipment, metal processing equipment, metal rolling, etc., can solve the problems of long production cycle, high labor intensity, low production efficiency, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

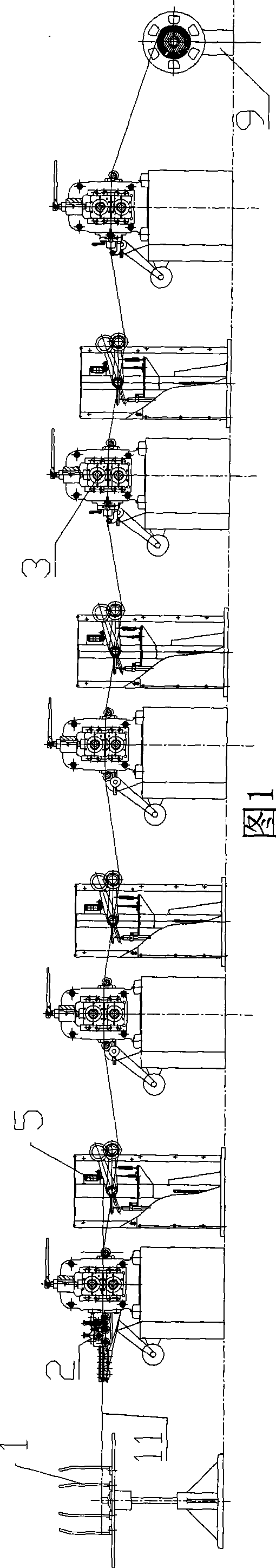

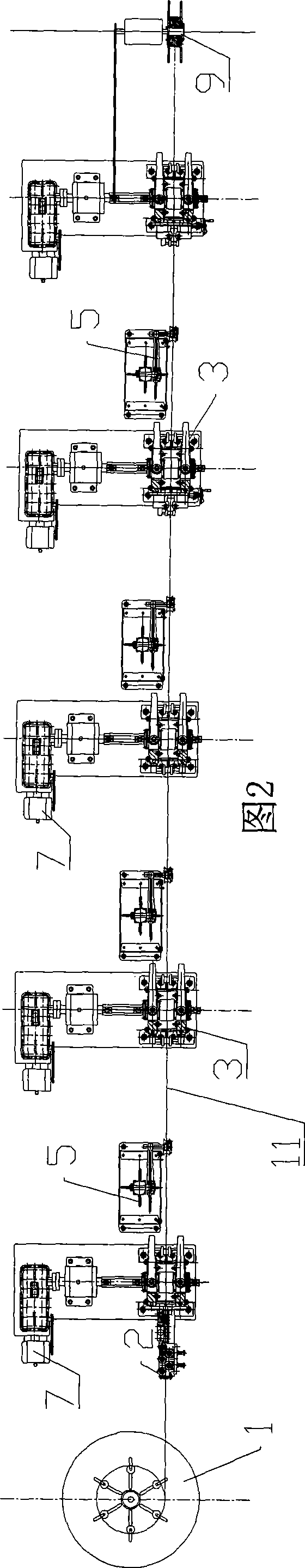

[0021] The equipment for rolling flat wire from round wire shown in Figure 1 - five-unit rolling mill, its function is to transform round wire into flat wire after five passes of cold rolling.

[0022] The round wire 11 drawn from the unwinding stand 1 is first straightened by the straightening device 2, and then rolled by the five series-connected active rolling mills 3 driven by the speed regulating motor 7, and then enters the receiving device 9. A flat wire storage quantity control device 5 mainly composed of a rocker and a displacement sensor is arranged between two adjacent rolling mills.

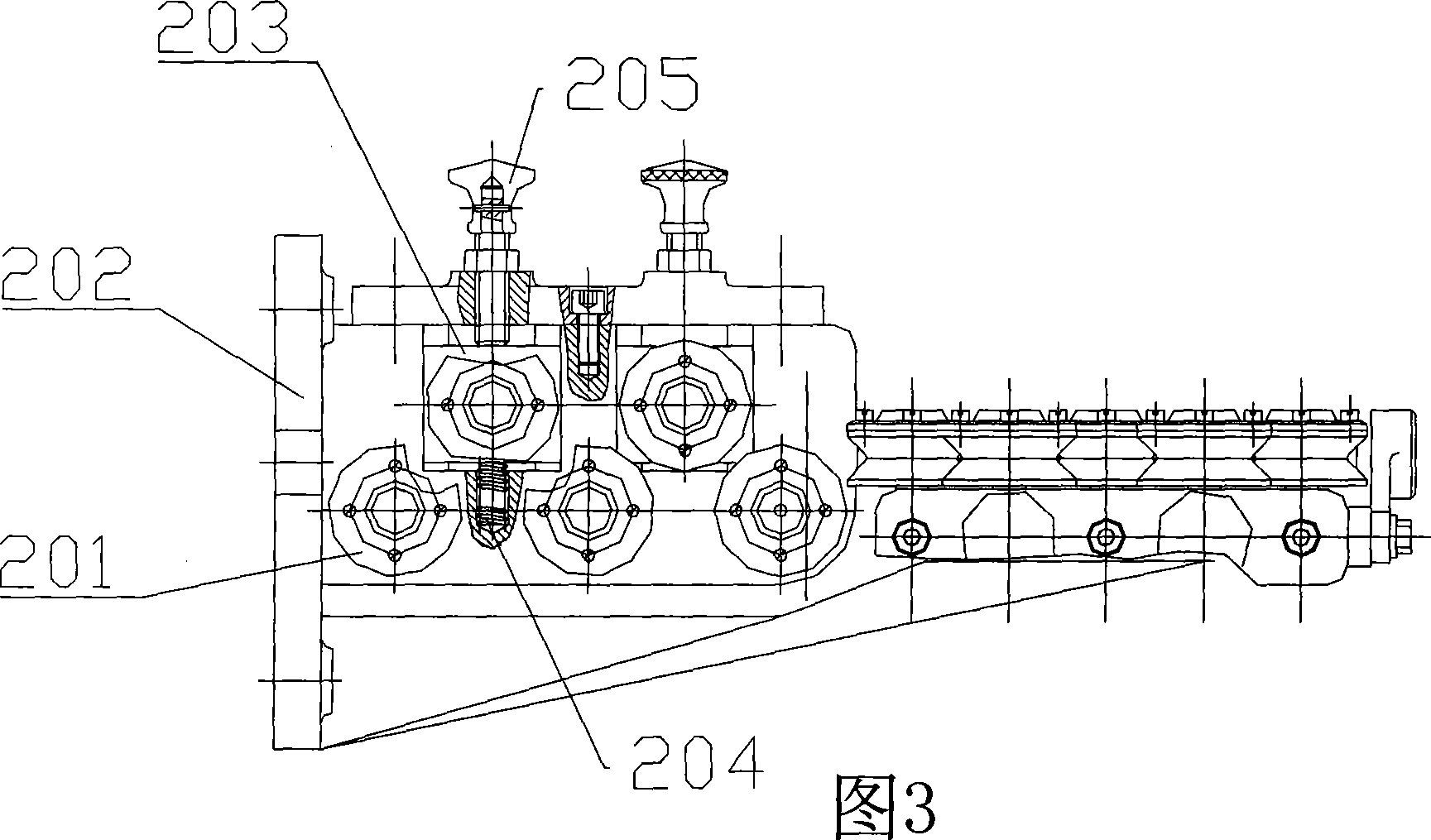

[0023] The flat wire storage quantity control device 5 includes a frame 501, a rocker 511, a travel switch 503, a displacement sensor 505, and the like. The rocker is rotatably connected to the frame, and the right end of the rocker is connected to the counterweight roller 517 by rolling through the shaft 516 . The displacement sensor arranged on the frame is in contact with the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com